Installation, use and maintenance

2

1.

1.1.

1. INTRODUCTION

INTRODUCTIONINTRODUCTION

INTRODUCTION

1.1

1.1 1.1

1.1 PURPOSE OF THE MANUAL

PURPOSE OF THE MANUALPURPOSE OF THE MANUAL

PURPOSE OF THE MANUAL

Th s publ cat on conta ns all the nformat on

necessary for the nstallat on, use and ma ntenance

of the manual flywheel sl c ng mach nes to be used

for food, w th c rcular blade, models 330/83 and

370/81.

The purpose of th s manual s to allow the user,

above all the d rect user, to take every precaut on

and arrange all human and mater al means

necessary for a safe and lengthy use of these

mach nes.

1.2

1.2 1.2

1.2 KEEPI

KEEPIKEEPI

KEEPING THE MANUAL

NG THE MANUALNG THE MANUAL

NG THE MANUAL

Th s manual must be g ven to the person who w ll

use and ma nta n the mach nes and th s person w ll

keep the manual n a safe and dry place, ready to

be used.

We recommend that a copy be kept on f le.

For any correspondence w th the manufacturer or

author sed personnel, please refer to the

nformat on on the plate and the mach ne ser al

number.

The manual must be kept for the ent re l fe of the

mach ne and n case of need (ex. any damage to

even a part of the manual that makes consult ng t

d ff cult) the user must acqu re a new copy

exclus vely from the manufacturer.

The user must let the manufacturer know the

address of any new owner of the mach ne.

1.3

1.3 1.3

1.3 USE OF THE MACHINE

USE OF THE MACHINEUSE OF THE MACHINE

USE OF THE MACHINE

The use and conf gurat ons of the mach ne are the

only ones allowed by the manufacturer; do not try to

use the mach ne d fferently from the nd cat ons.

The mach nes are to be used for cutt ng only food

products of the type and s ze nd cated n the

follow ng paragraphs.

The manufacturer decl nes all respons b l ty der ved

from an mproper use or use by personnel who has

not read and fully understood the contents of th s

manual; changes and/or repa rs carr ed out on

one’s own; the use of spare parts that are not

or g nal or not spec f c for the type of mach ne..

For any explanat on or doubts on the contents of

For any explanat on or doubts on the contents of For any explanat on or doubts on the contents of

For any explanat on or doubts on the contents of

th s

th sth s

th s

manual, please contact mmed ately the

manual, please contact mmed ately the manual, please contact mmed ately the

manual, please contact mmed ately the

manufacturer

manufacturermanufacturer

manufacturer

or an author sed techn cal ass stance

or an author sed techn cal ass stance or an author sed techn cal ass stance

or an author sed techn cal ass stance

serv ce and

serv ce andserv ce and

serv ce and

quote the paragraph number of the

quote the paragraph number of the quote the paragraph number of the

quote the paragraph number of the

requ red subject

requ red subjectrequ red subject

requ red subject.

..

.

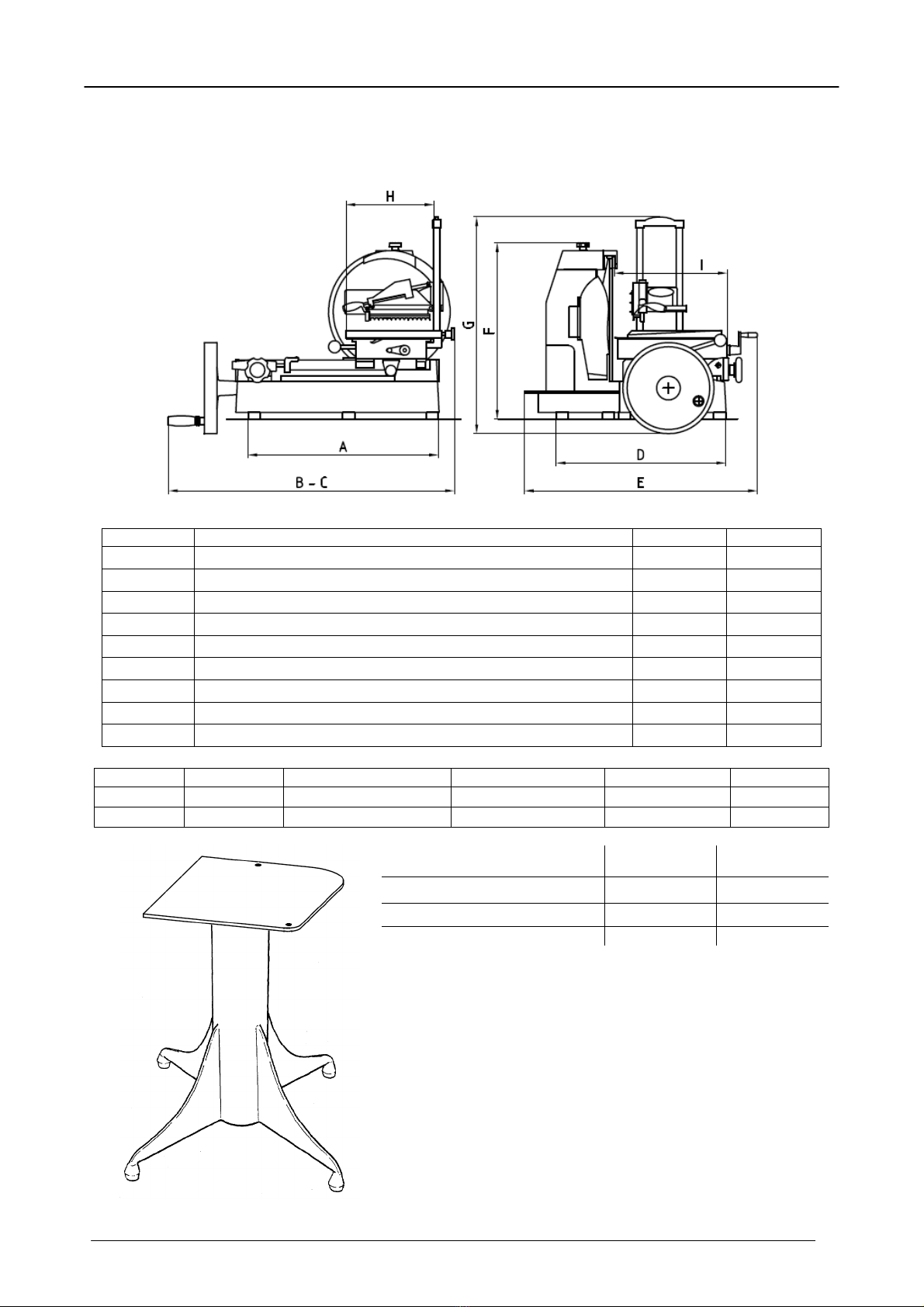

2. GENERAL

2. GENERAL2. GENERAL

2. GENERAL

INFORMATION

INFORMATIONINFORMATION

INFORMATION

2.1

2.1 2.1

2.1 MACHINE L

MACHINE LMACHINE L

MACHINE LIMITS, SAFETY REGULATIONS

IMITS, SAFETY REGULATIONSIMITS, SAFETY REGULATIONS

IMITS, SAFETY REGULATIONS

The mach ne has been des gned and made to sl ce

food products of the type and s ze as nd cated n

paragraphs 3.1, 3.2, and 3.3.

Env ronmental cond t ons for us ng the

Env ronmental cond t ons for us ng the Env ronmental cond t ons for us ng the

Env ronmental cond t ons for us ng the

mach ne

mach nemach ne

mach ne

The operat ng env ronment must have the follow ng

character st cs:

-Temperature.............................. …..da -5°C a +40 °C

-Relat ve hum d ty......................................... max. 95%

The mach ne cannot be used n open areas and/or

exposed to atmospher c agents and n places w th

fumes, smoke or corros ve and/or abras ve dust,

w th the r sk of f re or explos on and n any case

where the use of ant deflagrat ng components are

prescr bed.

General safety regulat ons

General safety regulat onsGeneral safety regulat ons

General safety regulat ons

The sl c ng mach ne must be used only by personnel

who has carefully read the contents of th s manual.

The operators must be over 18 years of age, n

perfect mental and phys cal cond t ons, have the

r ght att tude and capac ty (w th the necessary

knowledge for manoeuvr ng and normal

ma ntenance of s mple mechan cal and electr cal

components).

For a safe use of the mach ne follow the

nstruct ons below:

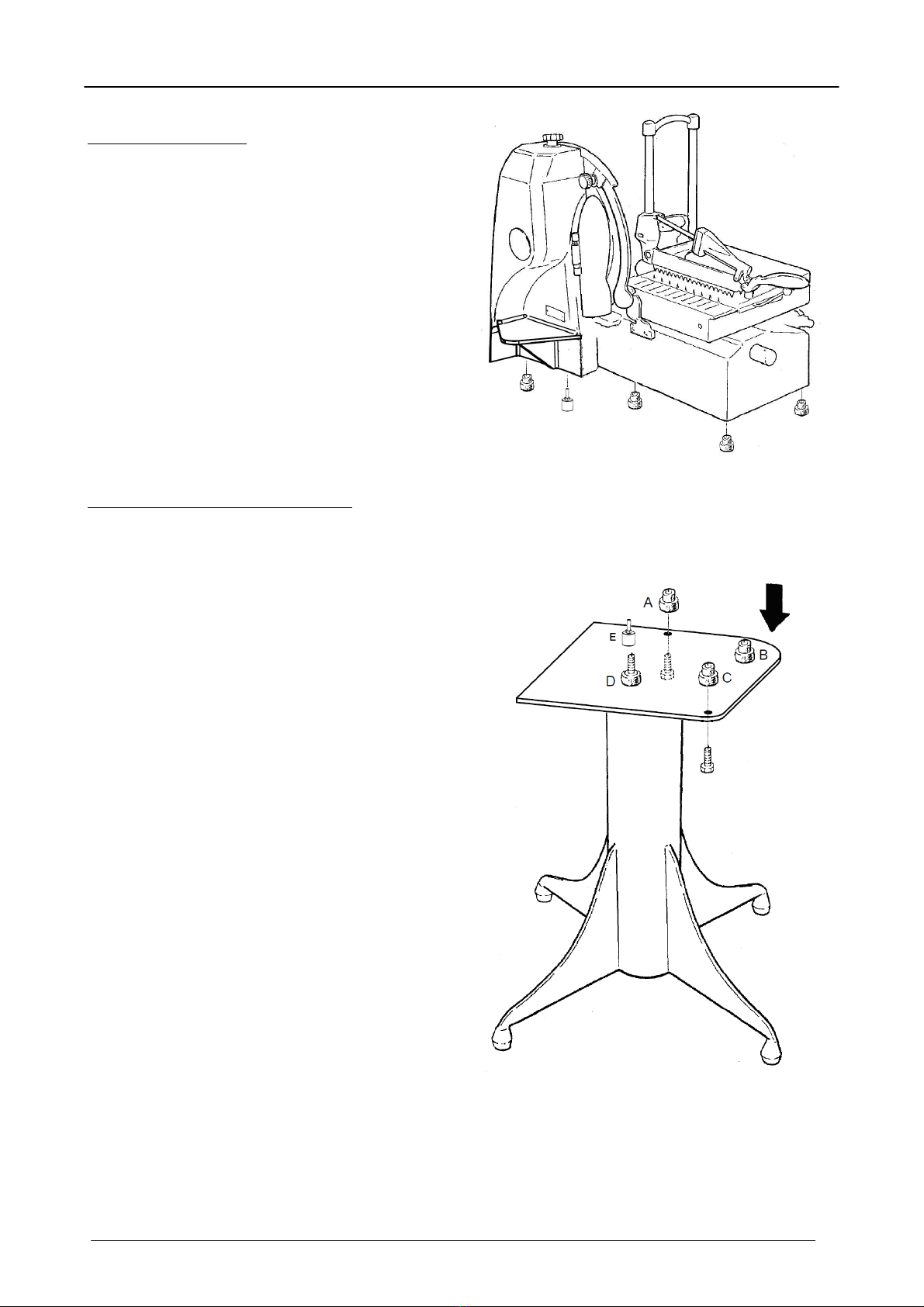

Install the mach ne accord ng to the

nstruct ons n the paragraph “Installat on”;