Metek DREXELBROOK Universal IV Lite User manual

Installation and

Operating Instructions

For Assistance Call + 215-674-1234

A Leader in Level and Analytical Measurement

Universal IV™ Lite and Universal UIV™ Pro

Model Transmitters

2- Wire RF Admittance / Capacitance Level

Measurement System with HART Protocol

AMETEK Drexelbrook makes no warranty of any kind with regard to the material contained in this

manual, including, but not limited to, implied warranties or tness for a particular purpose. Drexelbrook

shall not be liable for errors contained herein or for incidental or consequential damages in connection

with the performance or use of material.

© Copyright AMETEK Drexelbrook

EDO# 02-22-123

UIV-LM

Issue # 5

205 Keith Valley Road, Horsham, PA 19044

Telephone: +1 215-674-1234

Fax: +1 215-674-2731

Website: www.drexelbrook.com

An ISO 9001 Certied Company

Universal IV™Transmitter

with HART® Protocol

This page has no content

Table of Contents

Section 1: Introduction

1.1 System Description ............................................................................................... 1

1.2 Technology ............................................................................................................ 3

1.3 Models Available ................................................................................................... 4

1.4 Probe Selection Table ........................................................................................... 6

1.5 Area Classications ............................................................................................. 6

Section 2: Installation

2.1 Unpacking ............................................................................................................. 7

2.2 Hazardous Location Installations .......................................................................... 7

2.3 Mounting the Electronic Unit ................................................................................. 8

2.4 Wiring the Electronic Unit.................................................................................... 14

2.5 Wiring the Sensing Element................................................................................ 15

2.6 Spark (Static Electricity) Protection..................................................................... 17

2.7 Surge Voltage (Lightning) Protection................................................................... 18

2.8 RFI (Radio Frequency Interference) Filters......................................................... 18

2.9 Electrostatic Filters (Desalter Filter) .................................................................... 20

Section 3: Conguration and Calibration with Drexelbrook PC Software HRTWin

3.1 Installing The USB Modem.................................................................................. 21

3.2 Install the Windows Version HRTWin Software................................................... 22

3.3 Description of Function Keys............................................................................... 23

3.4 Conguration....................................................................................................... 24

3.5 HRTWin Status Messages .................................................................................. 28

3.6 Calibration ........................................................................................................... 29

3.7 Set D/A Trim ........................................................................................................ 33

3.8 Congure Meter................................................................................................... 34

3.9 Strapping Table ................................................................................................... 34

3.10 Save/Print Entries................................................................................................ 36

3.11 Validation............................................................................................................. 37

3.12 Calibration & Conguration via Display/Keypad.................................................. 41

3.13 Status Messages................................................................................................. 46

3.14 HART Multi-Drop ................................................................................................. 49

Section 4: Conguration and Calibration with HART®Calibrator

4.1 Start-up................................................................................................................ 51

4.2 Conguration....................................................................................................... 52

4.3 Calibration ........................................................................................................... 54

4.4 D/A Trim............................................................................................................... 58

4.5 Bench Calibration Information Sheet................................................................... 60

Section 5: Troubleshooting

5.1 Identifying a Problem/Symptom .......................................................................... 62

5.2 Troubleshooting Loop Connection ...................................................................... 62

5.3 Universal IV transmitter does not communicate with HRTWin Software............. 63

5.4 Transmitter Drift Test ........................................................................................... 64

5.5 Troubleshooting Sensing Element ...................................................................... 65

5.6 Troubleshooting Coaxial Cable ........................................................................... 67

5.7 Static Electricity................................................................................................... 68

5.8 Radio Frequency Interference............................................................................. 68

5.9 Factory Assistance .............................................................................................. 69

5.10 Field Service........................................................................................................ 69

5.11 Customer Training ............................................................................................... 70

5.12 Return Equipment ............................................................................................... 70

5.13 Universal IV Troubleshooting Guide.................................................................... 71

Section 6: Specications

6.1 Transmitter Specications ................................................................................... 73

Section 7: Hazardous Location Supplementary Installation Instructions

7.1 General safety information .................................................................................. 75

7.2 The Compartment Cover..................................................................................... 76

7.3 Standards and Approvals .................................................................................... 77

Section 8: Control Drawings

8.1 ATEX / IECEX .................................................................................................... 79

8.2 FM US / FMC ...................................................................................................... 87

Section 1: Introduction

1.1 System Description

The instructions in this manual are for the AMETEK

Drexelbrook Universal IV for level measurement in liquids,

slurries, interfaces, and granulars.

Each system consists of a Universal IV two-wire, 4-20 mA

HART® electronic unit and a 700 series sensing element. A 380

series connecting cable is also supplied for connection of the

sensing element to remote electronic units.

The Universal IV system is an admittance-to-current transducer.

A change in level produces a change in admittance which results

in a change of current. It is termed a two-wire transmitter

because the same two wires that are used to power the unit also

indicate the change in level (4-20 mA).

Universal IV - Installation and Operating Instructions

2

Figure 1-1 Capacitance

Sensing Element

k

air

A

d

Ckmedia

C=kA

d

C = k A

d

Ak

air

d

C

kmedia

C=kA

d

Tank Wall

Coating

High Resistance

Little to No Resistance

Probe Insulation

Probe Rod

(More Coating is

Easier to Ignore)

R

Xc

Xc

R

Oscillator circuitry through phase shift

cancels small amounts of RF current

flow (both Resistive and Capacitive)

caused by coating

Level

Figure 1-2

RF Admittance Sensing Element

with Cote-Shield

Introduction

3

1.2 Technology

Capacitance

In a simple capacitance measurement, the capacitance increases as the

process medium covers more of the sensing element. In an insulating medium,

this is due to the increase in dielectric constant (k) from air to that of the

medium. In a conductive medium, this is due to the decreased distance from

ground as the medium provides a conductive path from the ground reference,

typically the vessel wall, to the outer surface of the sensing element

insulation.

This change in capacitance causes an imbalance in a capacitance bridge which

is detected in the circuitry and converted to an output proportional to level.

Radio Frequency (RF) Admittance

RF Admittance is the next generation. Although similar to capacitance it

adds a valuable feature, the ability to compensate for conductive coatings.

The patented Cote-Shield™ circuitry of the Universal IV Pro Model measures

resistance and capacitance separately. The level component of the sensing

element capacitance has a negligible resistance however, a conductive coating

will have a much greater resistance. The design of the circuitry also produces

signals for the resistive and capacitive RF currents of a conductive coating

to be of identical magnitude but of opposite phase. This allows the Universal

IV to subtract the effect of the coating and produce an accurate level

measurement even in the most difficult applications.

This patented Cote-Shield™ circuitry is designed into the Universal IV Pro

Model and enables the instrument to ignore the effect of buildup or material

coating on the sensing element. The sensing element is mounted in the vessel

and provides a change in RF admittance indicating the level of material.

The Cote-Shield™ circuitry prevents the transmission of RF current through

the coating on the sensing element. The only path to ground available for the

RF current is through the material being measured.

The result is an accurate measurement regardless of the amount of coating on

the sensing element. By far the most versatile technology available, it works

with all types of materials in a vast array of conditions; from cryogenics to

high temperature, and from vacuum to 10,000psi pressure.

Lite Model

The Universal IV Lite Model is the entry level RF Capacitance measurement

system for use where Cote-Shield™is not required. Lite models can be used

in non-coating and insulating coating applications. Universal IV Lite is not

recommended for use in conductive coating applications. In addition, the

Lite model has a 20-7,000 pF range that may limit the measurement span on

conductive liquids.

Pro Model

The Universal IV Pro model has the most versatility with full capabilities

of Code-Shield and measurement span of 1-45,000 pF. The Pro can handle

shorter and longer measurement spans and is compatible with a vast array of

applications.

Universal IV - Installation and Operating Instructions

4

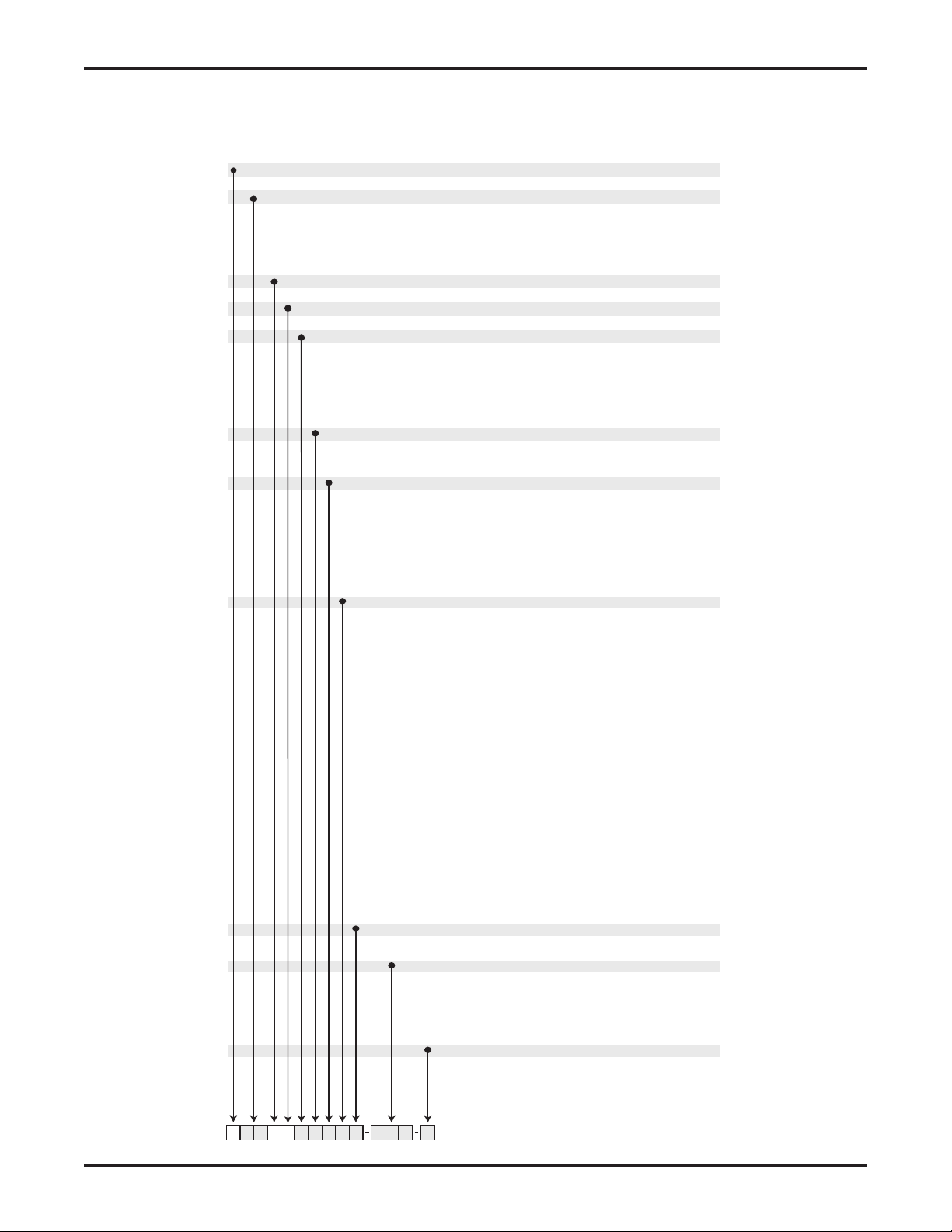

U 1 0

Future Use

0 Future Use

Technology

UUniversal IV

Digital Protocols

1HART®

Measurement Type / Frequency and Phasing

P0 Pro model: Admittance, 100 KHz, 0° Phase, 1 - 45,000 pF span

P1 Pro model: Admittance, 15 KHz, 0° Phase, 1 - 45,000 pF span

P2 Pro model: Admittance, 100 KHz, 45° Phase, 1 - 45,000 pF span

P3 Pro model: Admittance, 15 KHz, 45° Phase, 1 - 45,000 pF span

L0 Lite model: Capacitance, 100 KHz, 0 Phase, 20 - 7,000 pF span

L1 Lite model: Capacitance, 15 KHz, 0° Phase, 20 - 7,000 pF span

Approvals

0Unapproved

1FM/FMc IS

2FM/FMc XP

3ATEX ia

4ATEX d [ia]

5IECEx ia

6IECEx d [ia]

Electrical Connection

03/4" NPT without external ground lug

1M20 with external ground lug

23/4" NPT with external ground lug

Surge / Noise Suppression

0No additional filtering required

1Signal filtering RFI and Surge protection (Integral or Remote)

2Probe RFI (Remote only)

3Signal filtering and Probe RFI (Remote only)

4Probe HDSP (Heavy Duty Spark Protector) - Remote only

5Signal filtering and Probe HDSP (Remote only)

6Probe RFI and Probe HDSP (Remote only)

7Signal filtering and Probe RFI and Probe HDSP (Remote only)

DDesalter Filter (Remote only)

Integral / Remote options

0Integral configuration

1Remote configuration without cable

2Remote configuration with 10 ft General Purpose Cable

3Remote configuration with 25 ft. General Purpose Cable

4Remote configuration with 35 Ft. General Purpose Cable

5Remote configuration with 50 ft. General Purpose Cable

6Remote configuration with 75 ft. General Purpose Cable

7Remote configuration with 100 ft. General Purpose Cable

8Remote configuration with 10 ft. Triax Cable

9Remote configuration with 25 ft. Triax Cable

ARemote configuration with 35 ft. Triax Cable

BRemote configuration with 50 ft. Triax Cable

CRemote configuration with 75 ft. Triax Cable

DRemote configuration with 100 ft Triax Cable

ERemote configuration with 10 ft Hi Temp Cable

FRemote configuration with 25 ft. Hi Temp Cable

GRemote configuration with 35 ft. Hi Temp Cable

HRemote configuration with 50 ft. Hi Temp Cable

JRemote configuration with 75 ft. Hi Temp Cable

KRemote configuration with 100 ft Hi Temp Cable

LRemote configuration with 10 ft Hi Temp Composite Cable

MRemote configuration with 25 ft. Hi Temp Composite Cable

NRemote configuration with 35 ft. Hi Temp Composite Cable

ORemote configuration with 50 ft. Hi Temp Composite Cable

PRemote configuration with 75 ft. Hi Temp Composite Cable

QRemote configuration with 100 ft Hi Temp Composite Cable

ZRemote configuration with custom cable

Dual seal option

0Without Dual Seal option

1With Dual Seal option

Special Software

0None

ZSpecial Software

Sensing Element Code

### Sensing element 3-digit code (Refer to probe selection table)

000 Remote System without a probe

ZZZ Special sensing element

R00 Universal retrofit kit upgrade with all adapters for all probes

R## Retrofit kit upgrade with probe dependent adapters

R09 Remote only retrofit kit upgrade

Process gland wetted part (X)

ACarbon Steel

B316/316L SS

CHast C-276

PPFA

EMonel

UTitanium

X* Upon request

Sensing Element Selected From Table

Process connection (XX)

A0 3/4" NPT

B0 1" NPT

BA 1" 150# RF Carbon Steel

BB 1" 150# RF 316/316L Stainless Steel

CB 1" 300# RF 316/316L Stainless Steel

BD 1" 150# RF 316/316L SS TFE

C2 1 1/2" Tri-Clamp

E2 2" Tri-Clamp

FA 2" 150# RF Carbon Steel

FB 2" 150# RF 316/316L Stainless Steel

GB 2" 300# RF 316/316L Stainless Steel

FC 2" 150# RF CS TFE Face

FD 2" 150# RF 316/316L SS TFE

FE 2" 150# RF CS Inserted TFE

FH 2" 150# RF 316L SS Seal-Tyte

G0 1/2" NPT

IA 3" 150# RF Carbon Steel

IB 3" 150# RF 316/316L Stainless Steel

J2 3" Tri-Clamp

JB 3" 300# RF 316/316L Stainless Steel

KB 4" 150# RF 316/316L SS

KC 4" 150# RF CS TFE Face

KD 4" 150# RF 316/316L SS TFE

KG 4" 150# RF CS Seal-Tyte

LA 4" 300# RF Carbon Steel

LB 4" 300# RF 316/316L Stainless Steel

2B 8" 600# RF 316/316L Stainless Steel

XX* Many more options available upon request (ANSI, DIN, JIS)

Insertion Length in MM

XXXXXX Length of the probe in millimeters from process connection to the bottom of the probe

Cote-Shield™ Length in MM

XXXXXX Length of the Cote-Shield in millimeters for 3-terminal probes. Not applicable for 2-terminal probes

Inactive Length in MM

XXXXXX Length of the inactive part of the probe that is not measured.

This option is primarily used in Interface measurement and Desalters

Inactive Material

ACarbon Steel

B316/316L SS

CHast C-276

TTeflon Covered

NNot Applicable

X* Many more options are available upon request

Introduction

5

U 1 0

Future Use

0 Future Use

Technology

UUniversal IV

Digital Protocols

1HART®

Measurement Type / Frequency and Phasing

P0 Pro model: Admittance, 100 KHz, 0° Phase, 1 - 45,000 pF span

P1 Pro model: Admittance, 15 KHz, 0° Phase, 1 - 45,000 pF span

P2 Pro model: Admittance, 100 KHz, 45° Phase, 1 - 45,000 pF span

P3 Pro model: Admittance, 15 KHz, 45° Phase, 1 - 45,000 pF span

L0 Lite model: Capacitance, 100 KHz, 0 Phase, 20 - 7,000 pF span

L1 Lite model: Capacitance, 15 KHz, 0° Phase, 20 - 7,000 pF span

Approvals

0Unapproved

1FM/FMc IS

2FM/FMc XP

3ATEX ia

4ATEX d [ia]

5IECEx ia

6IECEx d [ia]

Electrical Connection

03/4" NPT without external ground lug

1M20 with external ground lug

23/4" NPT with external ground lug

Surge / Noise Suppression

0No additional filtering required

1Signal filtering RFI and Surge protection (Integral or Remote)

2Probe RFI (Remote only)

3Signal filtering and Probe RFI (Remote only)

4Probe HDSP (Heavy Duty Spark Protector) - Remote only

5Signal filtering and Probe HDSP (Remote only)

6Probe RFI and Probe HDSP (Remote only)

7Signal filtering and Probe RFI and Probe HDSP (Remote only)

DDesalter Filter (Remote only)

Integral / Remote options

0Integral configuration

1Remote configuration without cable

2Remote configuration with 10 ft General Purpose Cable

3Remote configuration with 25 ft. General Purpose Cable

4Remote configuration with 35 Ft. General Purpose Cable

5Remote configuration with 50 ft. General Purpose Cable

6Remote configuration with 75 ft. General Purpose Cable

7Remote configuration with 100 ft. General Purpose Cable

8Remote configuration with 10 ft. Triax Cable

9Remote configuration with 25 ft. Triax Cable

ARemote configuration with 35 ft. Triax Cable

BRemote configuration with 50 ft. Triax Cable

CRemote configuration with 75 ft. Triax Cable

DRemote configuration with 100 ft Triax Cable

ERemote configuration with 10 ft Hi Temp Cable

FRemote configuration with 25 ft. Hi Temp Cable

GRemote configuration with 35 ft. Hi Temp Cable

HRemote configuration with 50 ft. Hi Temp Cable

JRemote configuration with 75 ft. Hi Temp Cable

KRemote configuration with 100 ft Hi Temp Cable

LRemote configuration with 10 ft Hi Temp Composite Cable

MRemote configuration with 25 ft. Hi Temp Composite Cable

NRemote configuration with 35 ft. Hi Temp Composite Cable

ORemote configuration with 50 ft. Hi Temp Composite Cable

PRemote configuration with 75 ft. Hi Temp Composite Cable

QRemote configuration with 100 ft Hi Temp Composite Cable

ZRemote configuration with custom cable

Dual seal option

0Without Dual Seal option

1With Dual Seal option

Special Software

0None

ZSpecial Software

Sensing Element Code

### Sensing element 3-digit code (Refer to probe selection table)

000 Remote System without a probe

ZZZ Special sensing element

R00 Universal retrofit kit upgrade with all adapters for all probes

R## Retrofit kit upgrade with probe dependent adapters

R09 Remote only retrofit kit upgrade

Process gland wetted part (X)

ACarbon Steel

B316/316L SS

CHast C-276

PPFA

EMonel

UTitanium

X* Upon request

Sensing Element Selected From Table

Process connection (XX)

A0 3/4" NPT

B0 1" NPT

BA 1" 150# RF Carbon Steel

BB 1" 150# RF 316/316L Stainless Steel

CB 1" 300# RF 316/316L Stainless Steel

BD 1" 150# RF 316/316L SS TFE

C2 1 1/2" Tri-Clamp

E2 2" Tri-Clamp

FA 2" 150# RF Carbon Steel

FB 2" 150# RF 316/316L Stainless Steel

GB 2" 300# RF 316/316L Stainless Steel

FC 2" 150# RF CS TFE Face

FD 2" 150# RF 316/316L SS TFE

FE 2" 150# RF CS Inserted TFE

FH 2" 150# RF 316L SS Seal-Tyte

G0 1/2" NPT

IA 3" 150# RF Carbon Steel

IB 3" 150# RF 316/316L Stainless Steel

J2 3" Tri-Clamp

JB 3" 300# RF 316/316L Stainless Steel

KB 4" 150# RF 316/316L SS

KC 4" 150# RF CS TFE Face

KD 4" 150# RF 316/316L SS TFE

KG 4" 150# RF CS Seal-Tyte

LA 4" 300# RF Carbon Steel

LB 4" 300# RF 316/316L Stainless Steel

2B 8" 600# RF 316/316L Stainless Steel

XX* Many more options available upon request (ANSI, DIN, JIS)

Insertion Length in MM

XXXXXX Length of the probe in millimeters from process connection to the bottom of the probe

Cote-Shield™ Length in MM

XXXXXX Length of the Cote-Shield in millimeters for 3-terminal probes. Not applicable for 2-terminal probes

Inactive Length in MM

XXXXXX Length of the inactive part of the probe that is not measured.

This option is primarily used in Interface measurement and Desalters

Inactive Material

ACarbon Steel

B316/316L SS

CHast C-276

TTeflon Covered

NNot Applicable

X* Many more options are available upon request

Universal IV - Installation and Operating Instructions

6

301 Low Viscosity

conductive liquids

700-0001-022 TFE-covered rod Rod 3/8" OD

3/4" NPT

100oF @ 1000 PSI

300oF @ 500 PSI

303 Low Viscosity

insulating liquids

700-0001-026 TFE-covered

rod with 316

SS perforated

concentric shield

Concentric Shield

1.66" OD

1 1/2" NPT

100oF @ 1000 PSI

300oF @ 500 PSI

311 Low viscosity

conducting liquids

700-0002-024 TFE-covered rod Rod

3/4" OD

3/4" NPT

100oF @ 1000 PSI

450oF @ 500 PSI

312 Interface of liquids

containing ketones

and esters

700-0002-027 FEP-covered rod Rod

.56" OD

3/4" NPT

100oF @ 1000 PSI

300oF @ 500 PSI

603 Heavy Coating,

Highly Conductive

liquids

700-0002-037 “PVDF”-covered

rod

Rod

.54" OD

3/4" NPT

100oF @ 1000 PSI

250oF @ 500 PSI

606 Conducting liquids

and interfaces

700-0002-057 “PVDF”-covered

rod

Rod

.84" OD

1" NPT

100oF @ 1000 PSI

250oF @ 500 PSI

713 Agitated

conducting liquids

and granulars

700-0005-018 “PVDF”-covered

cable

Cable

5/16" OD

3/4" NPT

100oF @ 1000 PSI

250oF @ 500 PSI

716 Heavy-duty for

abrasive granulars

700-0005-019 Urethane-

covered

cable

Cable

3/4" OD

2" NPT

150oF @ 5 PSI

318 Long lengths of

conducting liquids

700-005-054 PFA-covered

cable

Cable

.093" OD

3/4" NPT

100oF @ 1000 PSI

300oF @ 500 PSI

747 Insulating liquids

and granulars

700-0205-078 PVDF covered

cable

Cable

5/16" OD

1" NPT

250oF @ 5 PSI

101 Insulating liquids 700-1202-001 316 SS PEEK Bare Rod

3/8" OD

3/4" NPT

450oF @ 200 PSI

1.4 Probe Selection Table

1.5 Area Classications

The standard electronic unit mounted in the durable housing is

dual-rated and meets the following conditions:

• Type NEMA 4X Waterproof / Corrosion

• IP 66

See Section 1.4 for detailed specifications of sensing elements

that are most often recommended with a Universal IV system.

Contact the factory or your local representative if additional

information is required.

The electronic unit and sensing element are connected by a

three-terminal coaxial cable. Drexelbrook cables are available in

• General Purpose

• Triax

• Composite (first 10 feet high temperature)

See Section 6.2 for Specifications

Installation

7

Section 2: Installation

2.1 Unpacking

Carefully remove the contents of the carton and check each item

against the packing list before destroying any packing material.

If there is any shortage or damage, report it immediately to the

factory.

2.2 Hazardous Location Installations

Installation in hazardous areas must comply with the control

drawings See Section 7.4. Always install to the NEC and/

or local requirements/ codes/ directives as mandated by the

authority having jurisdiction. Before using Intrinsic Safety

Barriers, read manufacturer's instruction for barrier operation.

The electronic unit is rated T4 and may not be used with

materials with an auto ignition temperature of less than 135Cº.

Substitution of components may impair intrinsic safety. To

prevent ignition of flammable or combustible atmospheres,

disconnect power before servicing.

Universal IV - Installation and Operating Instructions

8

2.3 Mounting the Electronic Unit

The Universal IV Series system was designed for field mounting,

but it should be mounted in a location as free as possible

from vibration, corrosive atmospheres, and any possibility

of mechanical damage. For convenience at start-up, mount

the instrument in a reasonably accessible location. Ambient

temperatures should be between -40°F and 167°F (-40°C and

75°C).

The mounting location for the sensing element is often

determined by whether there is a suitable location inside a

vessel. An external side arm or stilling well can be considered.

The following sensing element mounting and installation

instructions should be followed so that the equipment will

operate properly and accurately:

Figure 2-1

Recommended Conduit Installation

Installation

9

2.3 Mounting the Electronic Unit (Continued)

A. When Installing an insulated sensing element, use

caution during installation to avoid damaging the

insulation. Puncturing the insulation can render the

system inoperable.

B. Sensing elements should be mounted so they are not in

the direct stream of a filling nozzle / chute. If this is

not possible, a direct baffle should be installed.

C. Do not take the sensing element apart or loosen the

packing glands. Follow instructions in Figure 2-3.

D. Avoid installing the sensing element with any of the

common mistakes shown in Figure 2-4.

E. If a stilling well is used, ensure that "vent" holes

are large enough to allow free passage of both air and

process material. The holes should be 5/8" or larger,

120° apart, and every 2-3 feet along the length of the

stilling well.

F. Sensing elements that are mounted in agitated vessels

may require brackets and supports to protect the

sensing element from mechanical fatigue and ultimate

failure. See Figure 2-5.

G. For non-metallic vessels without Drexelbrook self-

grounding sensing elements, choose one of the grounding

recommendations shown in Figure 2-6.

Universal IV - Installation and Operating Instructions

10

SENSING

ELEMENT

DEPENDENT

2.3 Mounting the Electronic Unit (Continued)

Integral System Mounting

Figure 2-2

Integral Mounting Dimensions

Installation

11

2.3 Mounting the Electronic Unit (Continued)

Remote System Mounting

SENSING

ELEMENT

DEPENDENT

Figure 2-2-1

Remote Mounting Dimensions

Universal IV - Installation and Operating Instructions

12

Figure 2-4

Common Installation

Mistakes

PROBE

CONTACTS

SIDE OF STILLING

WELL

SLUDGE

SLUDGE

MAY CLOG

PIPE

LACK OF PROPER GROUND

(EARTH) CONNECTION

BETWEEN SENSOR MOUNTING

AND VESSEL WALL

NOZZLE DIAMETER

TOO SMALL

OR

LENGTH TOO LONG

DAMAGE

MAY

OCCUR

HERE

DAMAGE

MAY

OCCUR

HERE

PROBE

MAY

FLEX

INSIDE

PIPE

FILL LINE

AVOID

FILL

STREAM

WALL BUILD-UP

TOUCHES SENSOR

STILLING

WELL

LACKS

VENT

HOLES

Figure 2-3

Installing Sensing Element

Installation

13

FLEXIBLE

BOTTOM

ANCHOR

PART# 727-XX-X

CUSTOMER

SUPPLIED

SUPPORT

RECOMMENDED FLEXIBLE

SENSOR INSTALLATION

FLEXIBLE

CABLE TYPE

SENSOR

ROD

STYLE

SENSOR

CUSTOMER

SUPPLIED

SUPPORT

BRACKET

INSULATED

SUPPORT

BUSHINGS

PART # 713-XX-X

RECOMMENDED RIGID

SENSOR INSTALLATION

AVOID WEIGHTED

FLEXIBLE SENSORS IN

AGITATED VESSELS

Figure 2-5

Installing Sensing

Element

in Agitated Vessel

Figure 2-6

Providing Ground

Reference*

*This is a sensing

element ground

reference and possibly

different from an

electrical power

ground.

GROUND

CLAMP

PLASTIC

TANK

SENSOR

A B

C

CLAMP CLAMP

E

D

WEIGHT

PUMP

F

RUN 14 AWG. WIRE FROM FABRICATED

GROUND TO GREEN SENSOR GROUND

SCREW

METAL

C

MOUNT SENSOR IN METAL PIPE

Mounting the level sensor inside a metal

pipe provides an excellent ground

reference.

Use only if the process material is

greater than 1000 uMHOS/cm such as acids

and caustic.

A

GROUND ROD

A ground rod can be fabricated out of any

metal compatible with the process. Use

material that is at least 3/8inch dia. such as

pipe, All-Thread, or tubing. The ground rod

must be parallel and relatively close to the

sensor for insulating and low conductivity

materials.

B

GROUND WIRE

1/4 inch or larger dia. stainless steel rope

that is anchored or weighted can be used.

E

SUBMERGED METAL STRUCTURE

Use any constantly submerged metal

object such as: pumps, agitators, or

thermowells.

F

METAL FLANGE

A submerged metal flange or orifice plate

can be used.

Use only if the process material is greater

thatn 1000 uMHOS/Cm. such as acids and

caustic.

D

METAL PIPING

Metal piping that connects to the tank

bottom can be used as a ground

reference. Use only if the process material

is greter than 1000 uMHOS/cm such as

acids and caustic.

If the vessel is non metallic see grounding sketch below. sensors

with factory supplied concentric shield or ground rod do not need

additional grounding.

In metal vessels measure continuity from housing ground screw to

metal wall of vessel. A good ground will measure less than 5 ohms.

Ground element must be equal to or below the bottom of the

sensing element

2.3 Mounting the Electronic Unit (Continued)

Universal IV - Installation and Operating Instructions

14

CAUTION!

Before using Intrinsic Safety Barriers, read manufacturer's

instruction for barrier operation.

The Universal IV has a built-in current limiter which holds the

signal current to a maximum of 28 mA.

The signal connections are made to the three-terminal block on

the front of the chassis. Due to the low power consumption of the

instrument, the wiring need only be light gauge (e.g. 20 AWG).

Shielded twisted pair cables are recommended.

Integral units are pre-wired to the sensing element at the

factory. Figure 2-7 shows the wiring of the integral unit.

See Figure 2-8 for wiring connections of the remote unit. The

cable from the sensing element is connected to the terminal strip

below the instrument chassis. The cable connections are sensing

element (prb) or center wire (cw), ground (gnd), and shield (shd).

2.4 Wiring the Electronic Unit

Figure 2-6.1

Universal IV Wiring Connections

This manual suits for next models

1

Table of contents

Other Metek Transmitter manuals