metex PRO MILL E3 User manual

OPER

MILL E3

ATOR’S MANUAL

1

NOTE

The information contained in this handbook is intended as a guide to the operation of these machines and

does not form part of any contract. The data it contains has been obtained from the machine

manufacturer and from other sources. Whilst every effort has been made to ensure the accuracy of these

transcriptions it would be impracticable to verify each and every item. Furthermore, development of the

machine may mean that the equipment supplied may differ in detail from the descriptions herein. The

responsibility therefore lies with the user to satisfy himself that the equipment or process described is

suitable for the purpose intended.

LIMITED WARRANTY

We Makes every effort to assure that its products meet high quality and durability standards and

warrants to the original retail consumer/purchaser of our products that each product be free from defects

in materials and workmanship as follow: ONE YEAR LIMITED WARRANTY ON ALL PRODUCTS UNLESSSPEClFIED

OTHERWISE. This Warranty does not apply to defects due directly or indirectly to misuse, abuse,

negligence or accidents, normal wear-and tear, repair or alterations outside our facilities, or to a lack of

maintenance.

We shall in no event be liable for death, injuries to persons or property or for incidental, contingent,

special, or consequential damages arising from the use of our products.

The manufacturers reserve the right to change specifications at any time as they continually strive to

achieve better quality equipment.

To take advantage of this warranty, the product or part must be returned to us for examination, postage

prepaid. Proof of purchase date and an explanation of the complaint must accompany the merchandise. If

our inspection discloses a defect, we will either repair or replace the product, or refund the purchases

price if we cannot readily and quickly provide a repair or replacement, if you are willing to accept a refund.

We will return repaired product or replacement at our expense, but if it is determined there in no

defect, or that the defect resulted from causes not within the scope of our's warranty, then the user

must bear the cost of storing and returning the product.

Copyright. The copyright of this instruction book is the property of us and may not be reproduced or

copied without prior consent of us.

2

WARNING!

Read and understand the entire instruction

manual before attempting set-up or

operation of this mill/drill

1. This machine is designed and intended for use

by properly trained and experienced personnel

only. If you are not familiar with the proper safe use

of mill/drills, do not use this machine until proper

Training and knowledge has been obtained.

2. Keep guards in place. Safety guards must

be kept in place and in working order.

3. Remover adjusting keys and wrenches. Before

turning on machine, check to see that any adjusting

wrenches are removed from the tool.

4. Reduce the risk of unintentional starting.

Make sure switch is in the OFF position before

plugging in the tool.

5. Do not force tools. Always use a tool at the rate

for which it was designed.

6. Use the right tool. Do not force a tool or

attachment do a job for which it was not designed.

7. Maintain tools with care. Keep tools sharp and

clean for best and safest performance. Follow

instructions for lubrication and changing accessories.

8. Always disconnect the tools from the power

Source before adjusting or servicing.

9. Check for damaged parts. Check for alignment of

moving pads, breakage of parts, mounting, and any

Other condition that may affect the tools operation.

10. Turn power off, Never leave a tool unattended,

Do not leave a tool until it comes to a complete stop.

11. Keep work area clean, Cluttered areas and bench

Invite accidents.

12. Do not use in a dangerous environment, Do not

Use power tools in damp or wet locations, or expose

Them to rain. Keep work area well lighted.

13. Keep children and visitors away. All visitors

should be kept a safe distance from the work area

14. Make the workshop child proof. Use padlocks,

. master switches and remove starter keys.

15. Wear proper apparel. Loose clothing, gloves,

neckties, rings, bracelets, or other jewelry may

get caught in moving parts. Non-slip footwear

is recommended. Wear protective hair covering

to contain long hair. Do not wear any glove.

16. Always use safety glasses. Also use face or

dust mask if cutting operation is dusty.

Everyday eyeglasses only have impact

resistant lenses, they are not safety glasses.

accessories may be hazardous.

17 Do not overreach. Keep proper footing and

balance at all times.

18. Do not place hands near the cutterhead

while the machine is operating.

19. Do not perform any set-up work while

machine is operating.

20. Read and understand all warnings posted

on the machine.

21 This manual is intended to familiarize you with

the technical aspects of this mill/drill. It is not,

nor was it intended to be, a training manual.

22. Failure to comply with all of theses warnings

may result in serious injury.

23. Some dust created by power sanding, sawing,

grinding, drilling and other construction act/rites

contains chemicals known to cause cancer, birth

defects or other reproductive harm.

24. Your risk from those exposures varies,

depending on how often you do this type of work.

To reduce your exposure to these chemicals,

work in a well ventilated are, and work with

approved safety equipment

3

MATN TECHNZCAL SPECZFTCATTON

SPECCIFICATION

The specifications in this manual are given as general information and are not binding. We reserves

the right to effect, at any time and without prior notice, changes or alterations to parts, fitting and

accessory equipment deemed necessary for any reason whatsoever.

Drilling Capacity ................................................................................................ 32mm

End Mill Capacity .............................................................................................. 20mm

Face Mill Capacity ............................................................................................. 76mm

Spindle Taper ................................................................................................... ISO30

Spindle Stroke ................................................................................................. 95mm

Head Tilt ............................................................................................................ ±90°

Number of Spindle Speeds ............................................................................ Variable

Ranger of Spindle Speeds .......................................................................... 100-2500 RPM

Working Surface of Table ............................................................................... 700X210 mm

Max. Table longitudinal Travel ........................................................................ 500mm

Max. Table Cross Travel ................................................................................. 200mm

Max. vertical travel ......................................................................................... 310mm

Number of T-Slots .............................................................................................. 3

T-Slot Size ..................................................................................................... 14 mm

Brushless Motor ......................................................................................... 1.5KW, IPh, 240V

Overall Dimensions ................................................................................. 900x740x1150 mm

Net Weight(approx.) ......................................................................................... 220KGS

Shipping Weight (approx.) ................................................................................. 240KGS

4

WARRANTY ................................................................................................................. 1

WARNINGS .................................................................................................................. 2

SPECIFICATIONS ........................................................................................................ 3

TABLE OF CONTENTS ................................................................................................ 4

CONTENTS OF SHIPPING CONTAINER .................................................................... 5

UNPACKING AND CLEAN-UP ..................................................................................... 5

ASSEMBLY ................................................................................................................... 6

INSTALLATION ............................................................................................................. 6

CONTROLS ................................................................................................................ 7 - 8

ELECTRICAL CONNECTIONS .................................................................................... 9

ARBOR REPLACE ....................................................................................................... 10

GIB ADJUSTMENT ...................................................................................................... 11

MAINTENANCE ........................................................................................................... 12

TROUBLE SOLUTION ................................................................................................. 12

TABLE OF CONTENTS

Read and understand the entire contents of this

Manual before attempting set-up or operation!

Failure to comply may cause serious injure!

WARNING

1 MILL E3

1 Drawbar (installed on machine)

1 Digital scale & Speed Readout

1 Test Flow Chart

1 Operator Manual

1 Toolbox & Tools

CONTENTS OF SHIPPING CONTAINER

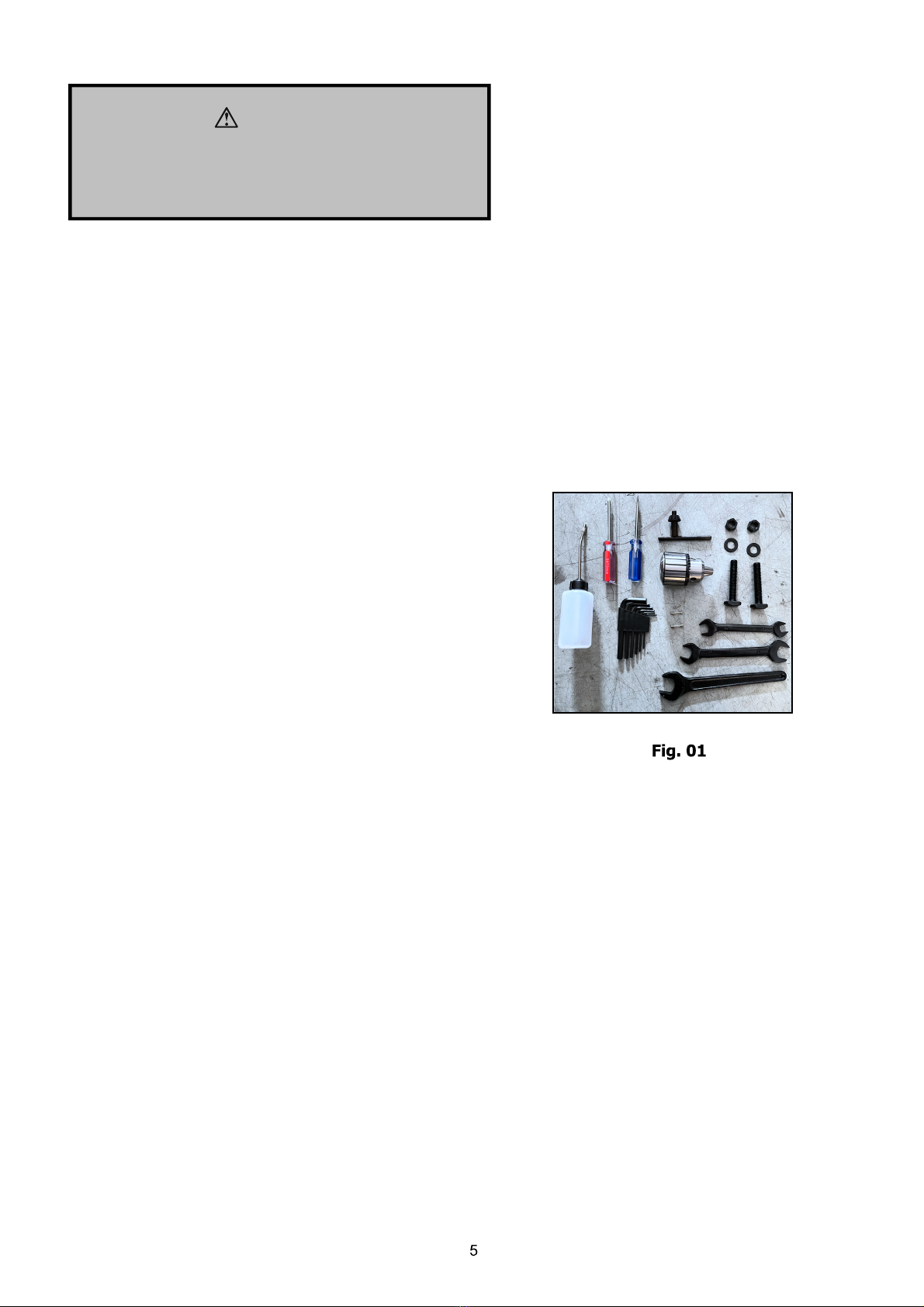

Toolbox Contents (Fig.01)

1 Oil Gun

2 Fuse (15A)

1 Single End Spanner (24mm)

2 Double End Spanner (12-14mm,17-19mm)

6 Hex Socket Wrench (2.5,3,4,5,6,8mm)

1 Drill Chuck with Key

1 Flat Blade Screwdriver

1 Cross Blade Screwdriver

2 M12 “T” Screw

2 M12 Washer

2 M12 Nut

Unpacking and Clean-up

1. Finish removing the wooden crate from around

the mill/drill.

2. Unbolt the machine from the crate bottom.

3. Sling mill/drill with the proper equipment.

4. Clean all rust protected surfaces using a mild

commercial solvent, kerosene or diesel fuel. Do not

use paint thinne , gasoline, or lacquer thinner.

These will damage painted surfaces. Cover all

cleaned surfaces with a light film of machine oil.

1 Drill Chuck Arbor ISO3 (installed on machine))0-JT6

66

Assembly

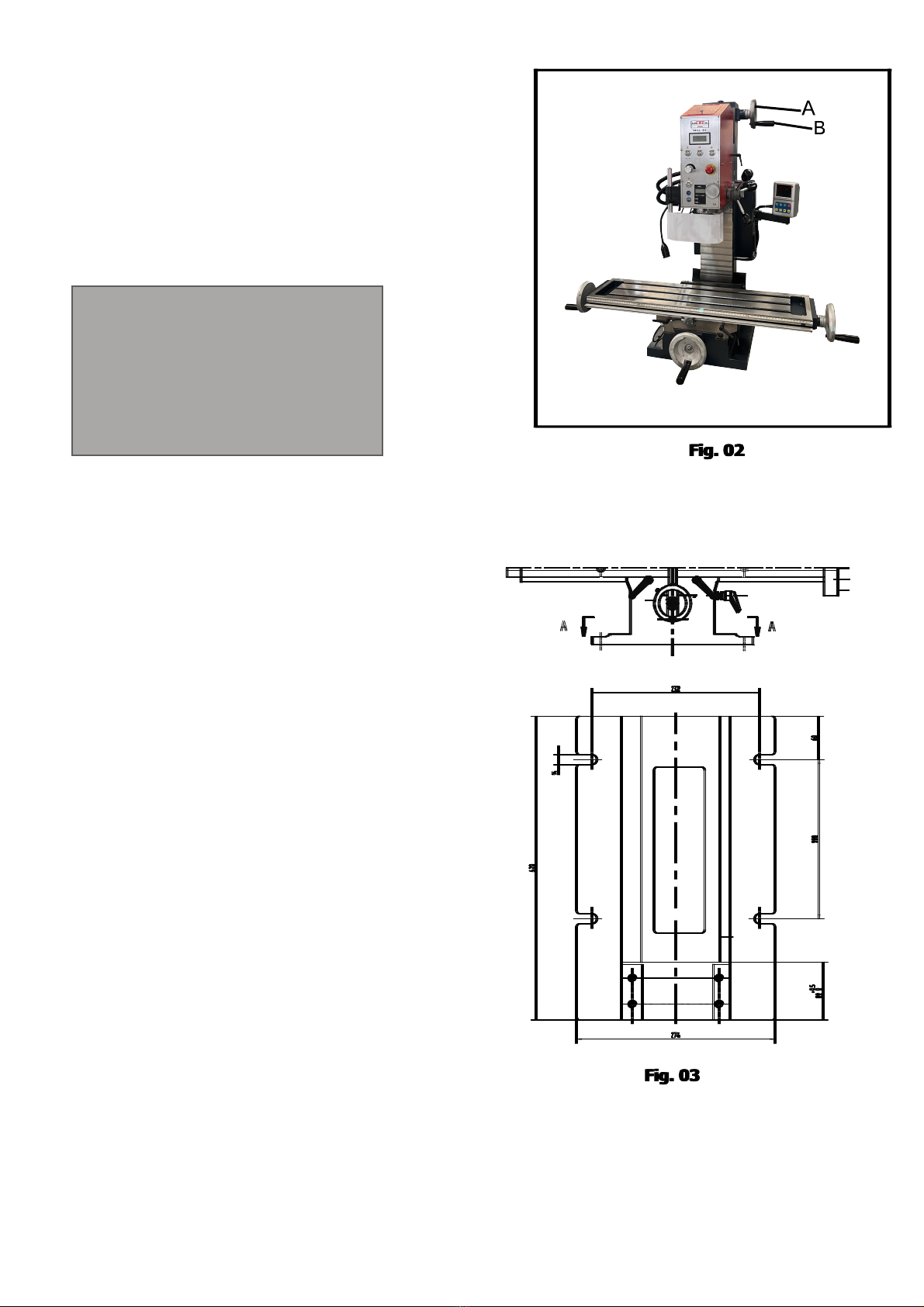

1. Screw handles (A, Fig.02) onto handwheel (B,

Fig.3) and tighten.

2. Repeat for remaining handles of table.

Installation

Machine is heavy! Use an appropriate lifting

device and use extreme caution when moving the

machine to its final location.

Failure to comply may cause serious injury!

WARNING!

1. The location for the mill/drill should be well lit, dry,

and have room enough to allow the head to

rotate 360°.

2. Carefully lift the mill/drill with properly rated

equipment to a sturdy stand or working bench.

For best performance, through bolt the mill/drill to

a stand.

We do not recommend that unattached machines be

operated, as the machine will move during

operation!

3. Before bolting the mill/drill to a bench or stand,

the unit must be level in both directions. Place a

level on the table in both directions.

4. If the table of mill is not to level, shim under the

Iow corner(s) until level. Tighten the fastening

bolts. Check for level again. Adjust as necessary

until the mill/drill is level. Check again when

securing bolts are tightened.

Installation Drawing (Fig. 03)

The installation drawing described below may differ

from the real dimensions. The tolerances are in the

range of the general tolerances according to DIN

7168.

7

CONTROL

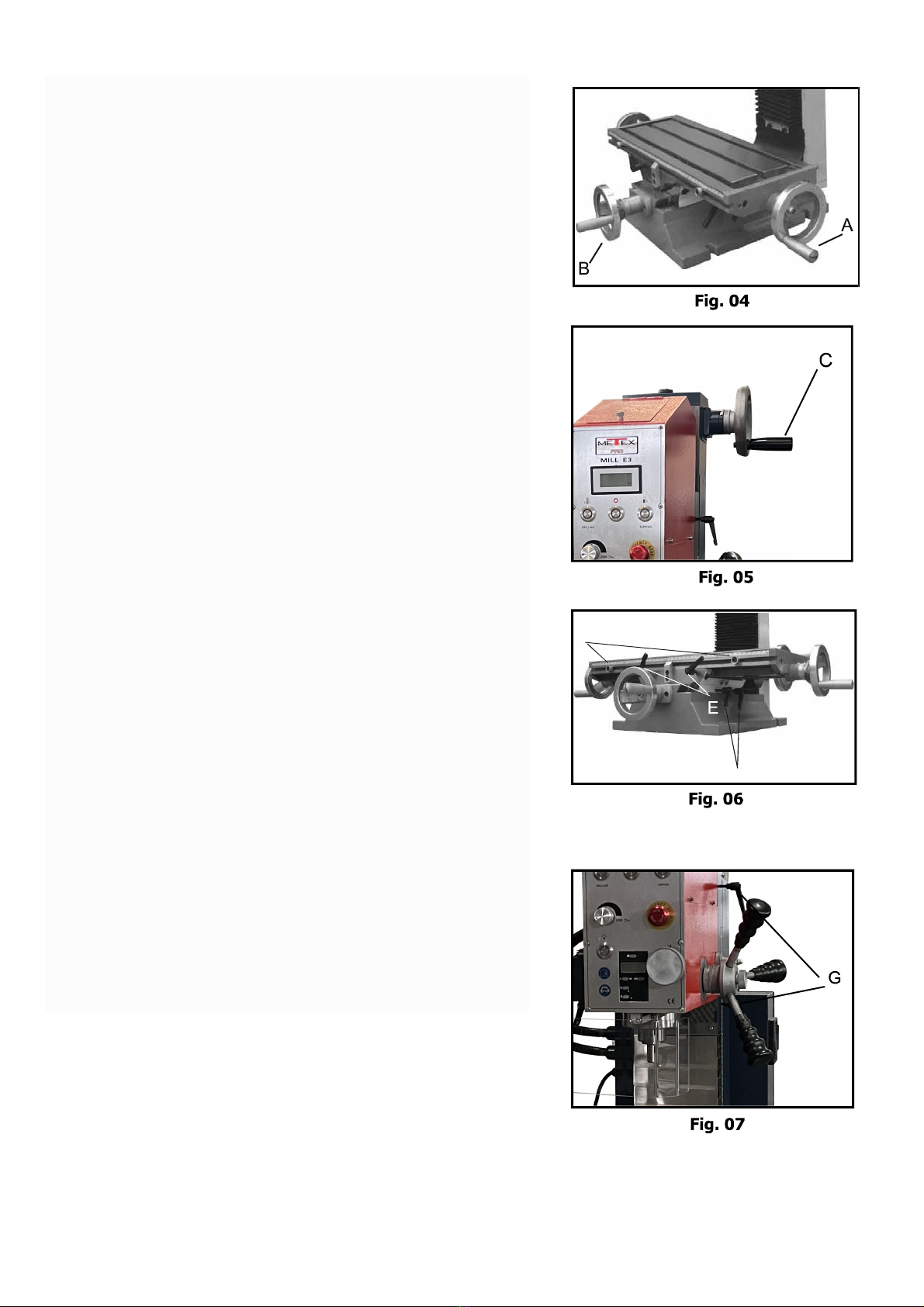

Longitudinal Handwheel (A, Fig. 04)

Located on two side of the table. Moves table side to

side.

Cross Feed Handwheel (B, Fig. 04)

Located on the front of the base. Moves table toward,

or away from the column.

Head Elevating handwheel (C, Fig.05),

Locate on the right of column. The head can be

adjusted up or down to suit height requirements for

different workpieces. Turn it clockwise to up head on

the column and counter-clockwise to down. When the

head is at the desired height, lock in place with the

locks

.

Caution: Have to loosen the locks for the slideways

before above operation!

Adjustable Table Stops (D, Fig.06)

Located on table front. Adjust to stop table at any

setting along the longitudinal axis.

Table locks

Longitudinal table locks (E, Fig. 06) are located on

front of the table. Cross-feed table locks (F, Fig.05)

are located on the right side under the table. Turn

clockwise to lock the slideways.

Mill Head locks (G, Fig.07)

Located on the right of column. Turn clockwise to lock

the mill head.

Quill Lock Lever (H, Fig. 07)

Located on the left of the mill head. The height of the

spindle can be locked with the quill lock lever. Set the

desired height with the quill lever and turn the lever

down. Turn clockwise to lock the quill, reverse to

loosen.

Caution: For best results. All milling operations

should be done with the quill/spindle as close to

the head assembly as possible. Lock spindle, table

and mill head in place before starting milling

operations!

8

MJ

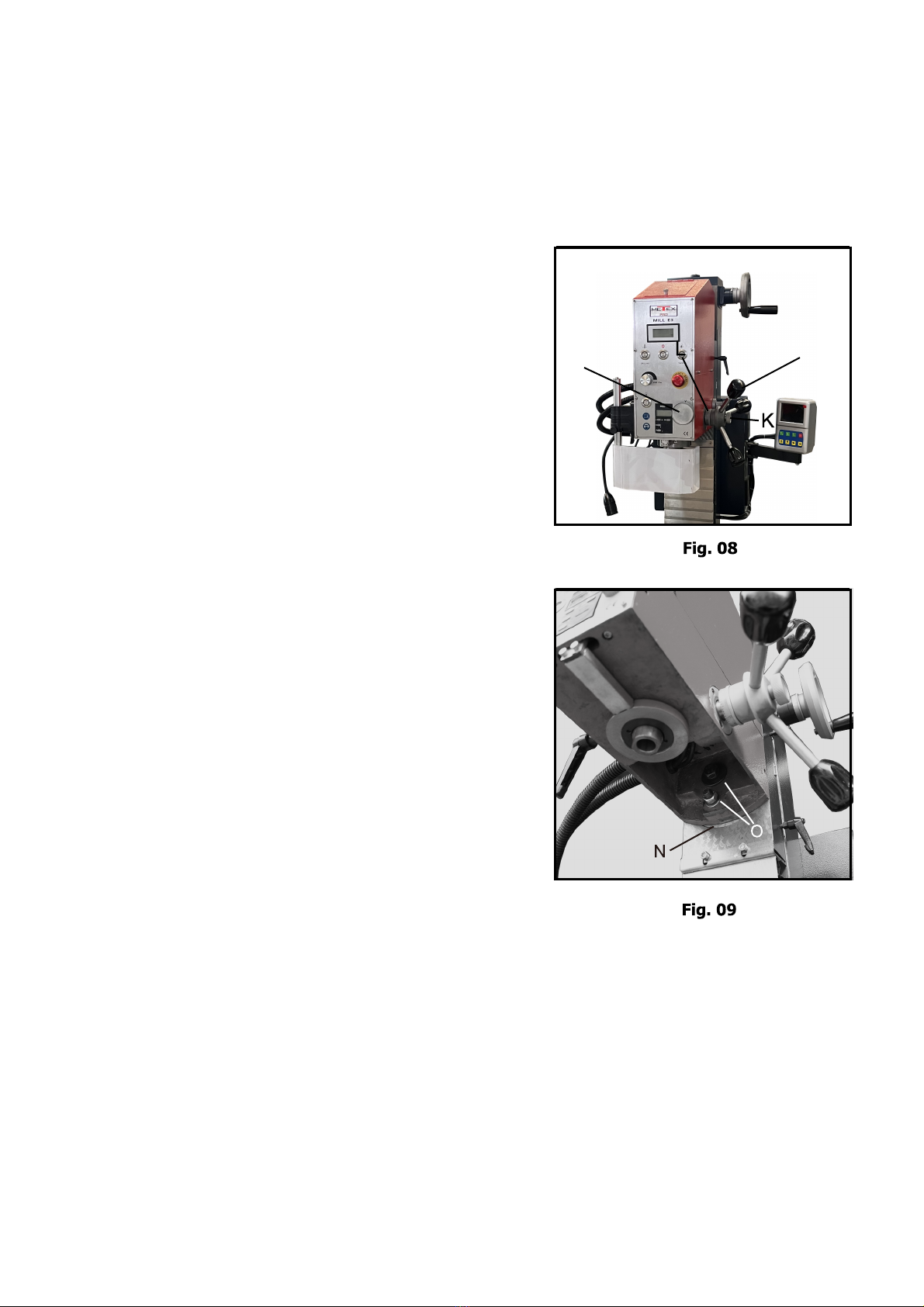

Down feed Handles: (J, Fig. 08):

Located on the right side of the head casting.

Counter-clockwise movement advances the quill

toward the table. Return spring retracts the handles.

The knob (K, Fig. 08) must be loose before the

operating the handles. The graduated dials (L, Fig.

08) on the handle base can be indexed or "zeroed" to

help make accurate and convenient movements.

Fine Down Feed

Turn counter-clockwise the knob (K, Fig. 08) to

engage the fine down feed knob (M, Fig. 08) what

located on the front of the head. Turn it according to

you want to move downward, Clockwise turn the

hand wheel to down feed the spindle, reverse to

retract it.

Mill Head Rotation

The head is designed to tilt 90° either left or right,

enabling it to perform task such as angle drilling or

horizontal slotting. Loosen the lock nuts (N, Fig. 09)

under the head. Rotate the head to its desired

position, using the reference guide (O, Fig.09). Once

in place, re-tighten the lock nuts.

Note: make sure to provide support for the head

so it doesn't unexpectedly rotate on its own.

Always maintain control of the head.

Caution: Even at Iow spindle speeds, metal

fragments from the cutting process can be expelled

by the mill/drill. Always wear eyewear and

protective clothing when operating the machine!

9

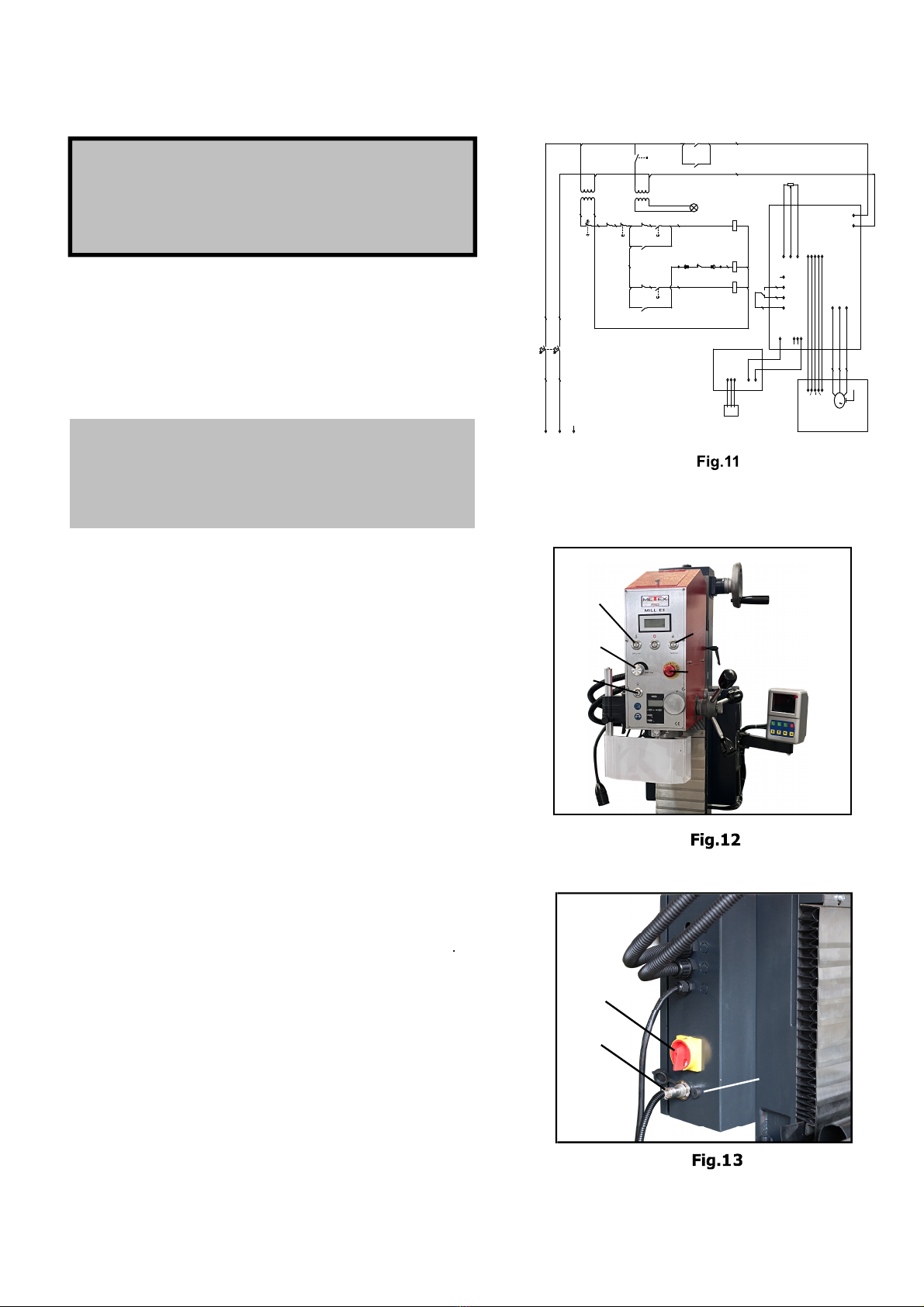

94BL-7550 1.1KW

Brushless Motor

3 25 5.2

E

R

A

B

L

( E,

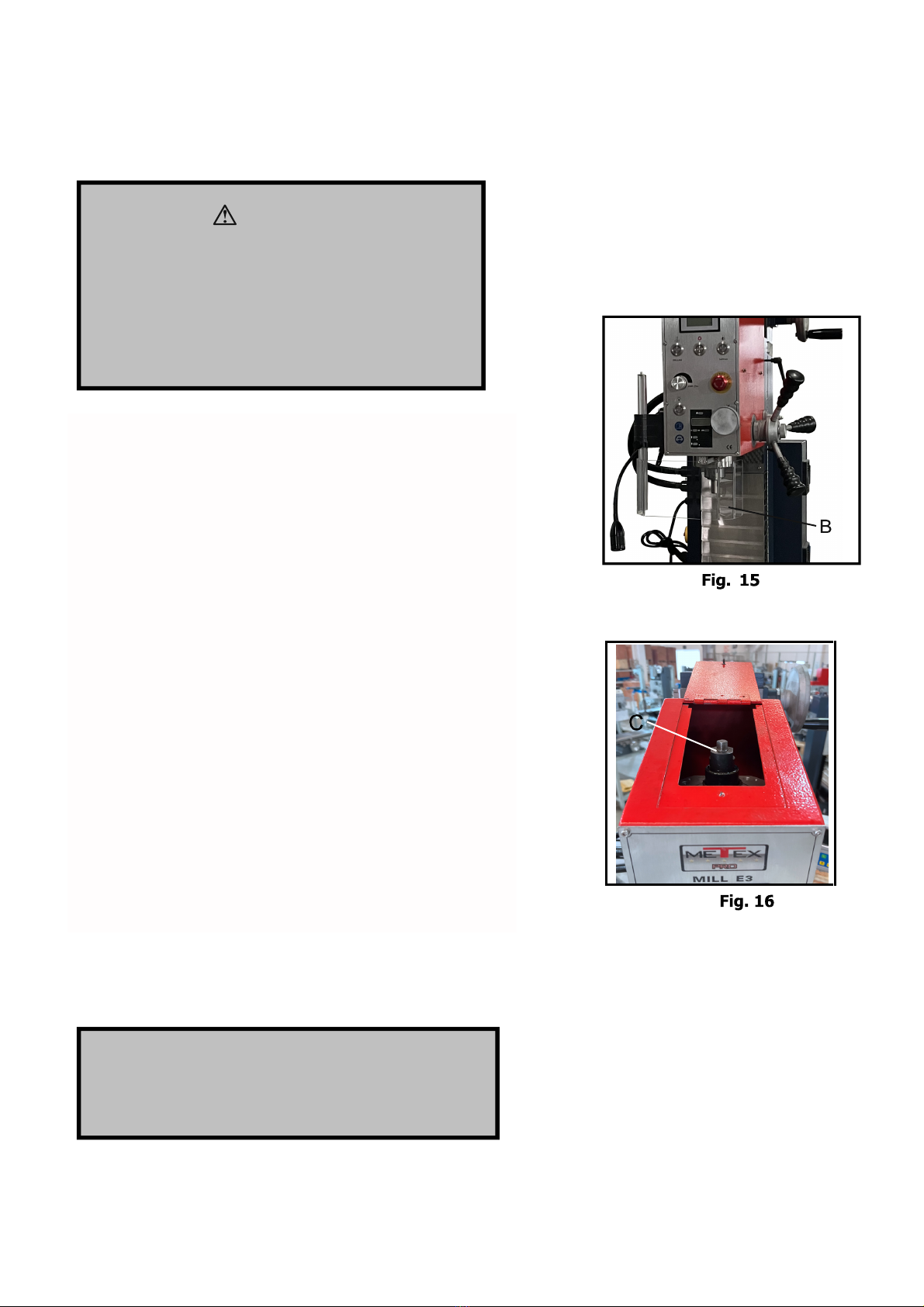

Emergency Stop Switch (A, Fig.12) Depress to stop

all machine functions. Twist to re-rest.

Work light switch ( L, Fig.12 ) Press once to turn on

the work light, press again to turn off the work light.

Power switch ( R, Fig.12 )

3

M

1

TC1 TC2

AC24V/10A

3

24

1 1 3 8 1

0V

KA2 FWD FWD

REV

COM

2

3

1 1 2 2 2 83

Working lamp

36

Speedometer

0V

0V

W

1V 1U1W

W1 U1 PE

M1

bla

blu gre yel

red

750W / 1.1KW

Spindle

Sensor

V1

blue yellow green

U V

5V

5V

34

1

6

6 5

NL

L

1AC230V

N PE

N1L1

1

2

3

4

QS1

7 3 4

KA3

KA2X1X1 SQ1 XT1XT1

KA1

KA3

SB4

8

1

1

4

COM

REV

0V A B C 5V

IVA V5

46 7

6

28

5

22 25

26 30 32

6 7

4

SB1 SQ1 SB3 KA3 KA1 A1

R1

L

N

KA1

SB2

KA1 L2

N1

KA3

0

2

3 4

3 4

1

AC24V/10A

3 4

2

SB5

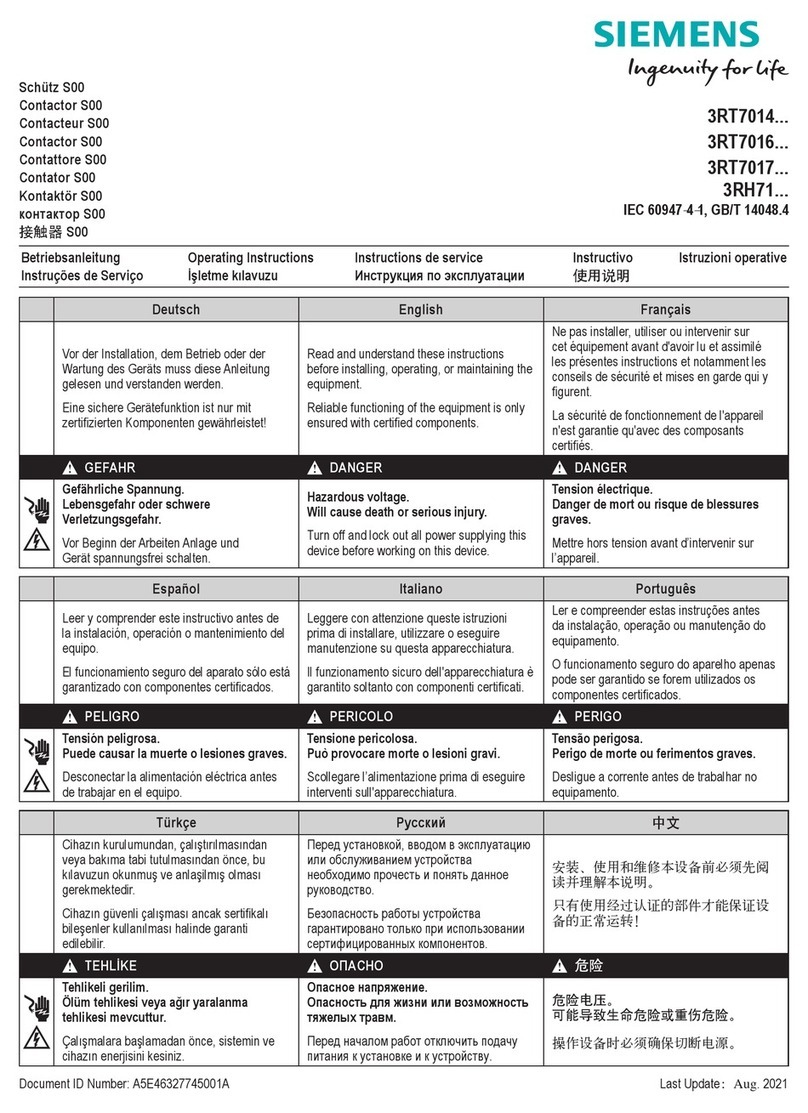

ELECTRICAL CONNECTIONS

WARNING!

Make sure the machine is properly ground!

Failure to do so may cause serious injury and

damage to user!

WARNING!

A qualified electrician must make all electrical

connections!

Failure to do so may cause serious injury!

Before connecting the machine to the mains, make sure

that the electrical values of the mains supply are the

same as those for the machine's electrical components.

Use the wiring diagram (Fig. 11) for connecting the lathe

to the mains supply.

Work light switch ( F, Fig.12 ) Press once to turn on

the work light, press again to turn off the work light.

Brushless Motor

its type is 94BL-7550, 230V, 2500rpm, 5.2A, 1.1 KW

Work light switch ( F, Fig.12 ) Press once to turn on

the work light, press again to turn off the work light

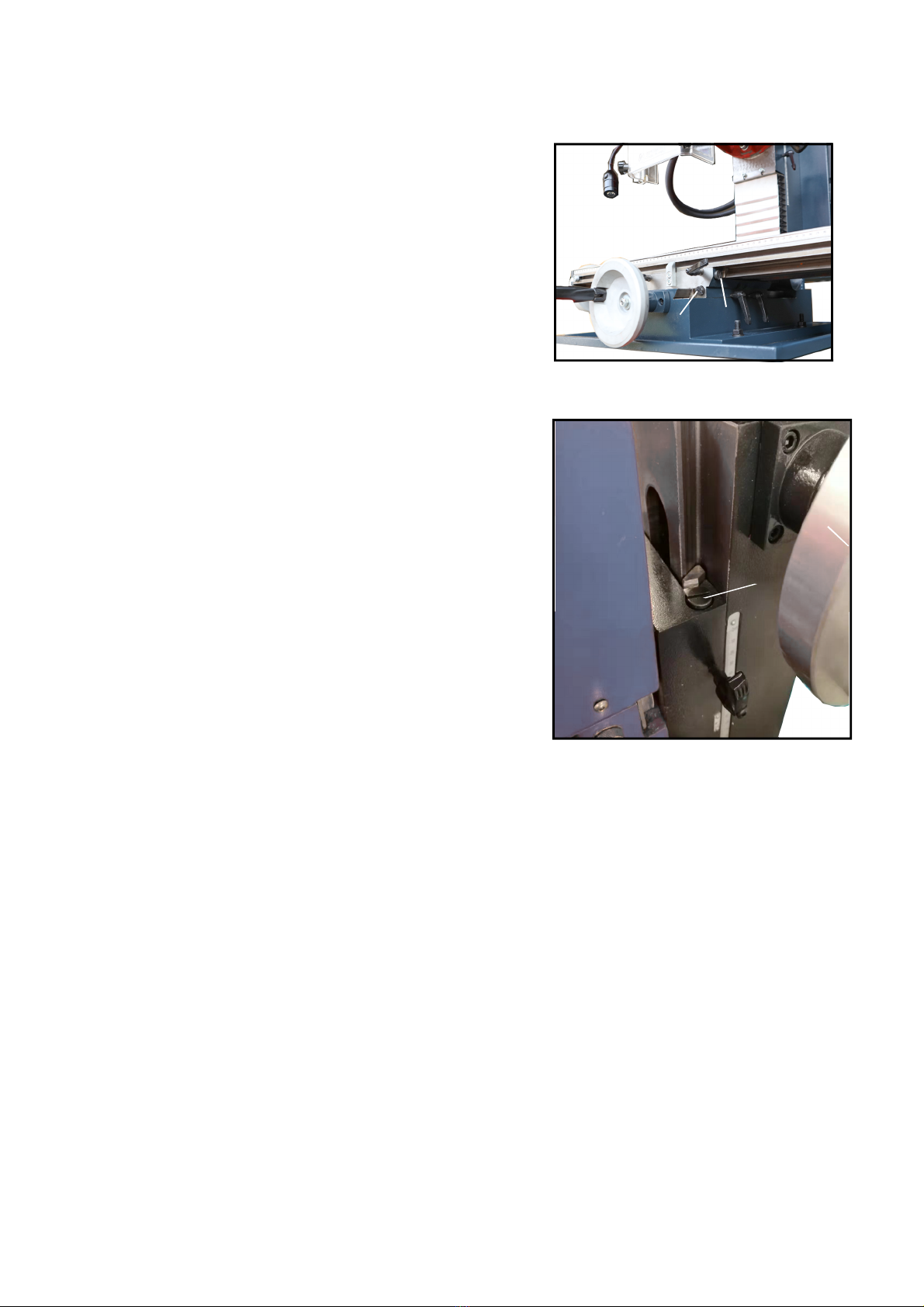

Foot Switch (H, Fig.13) (Optional for tapping function)

Remove the parts from the aviation socket, plug the foot

switch(optional). Depress the reverse switch, the spindle

will rotate in reverse direction, then step on the foot switch

for tapping and release for return.

Main power switch (P, Fig.13)

Make sure that all 2 phase (L&N) are connected

Forward Switch (B, Fig. 12) Depress to start the spindle

rotate in forward direction.

Reverse Switch (C, Fig. 12) Depress to start the spindle

rotate in reverse direction.

Emergency Stop Switch (D, Fig.12) Depress to stop

all machine functions. Twist to re-rest.

Potentiometer (E, Fig. 12) Turn clockwise to increase the

spindle speed and count-clockwise to decrease. Always

start the machine with the potentiometer knob set at Zero.

Fuse holder (G, Fig. 13) Located on the of electric box

Left side. Fuse rated at 10A. Open to change the fuse if

necessary.

Spindle on/off switch (A, Figure 12). Depress to connect

the power supply to the machine. When the spindle is

working, press the switch again to stop the rotation.

G

H

P

2.

1.

3.

4.

5.

6.

10

This machine is designed and intended for use by

properly trained and experienced personnel only! Zf

you are not familiar with the proper and safe use of

mill/drills, don't use the machine until proper

training and knowledge have been obtained!

Failure to comply may cause serious injury!

WARNING!

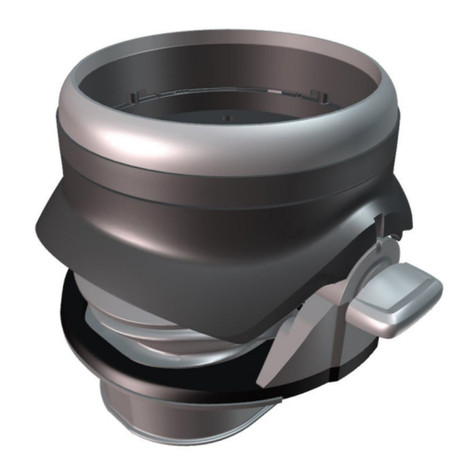

Arbor Replacement

1. Disconnect machine from the power source,

unplug.

2. Hold the flat of spindle (B, Fig.15) to keep it from

moving while loosening the drawbar (C, Fig 16)

with the 22-25 spanner in toolbox.

3. Loosen the drawbar approximately three to four

full turns.

4. Tap the drawbar head with a rubber mallet to

dislodge the arbor.

5. Grasp the arbor with on hand while loosening the

drawbar with the other. Continue to loosen the

drawbar until the arbor can be withdrawn from

the spindle. Wipe out the spindle with a clean dry

rag.

6. Wipe down the new arbor with a clean dry rag

and place the arbor into the spindle. Thread the

drawbar into the arbor. Tighten the drawbar with

a spanner while holding the spindle.

WARNING!

Do not loosen the drawbar more than three or

four turns before hitting with a rubber mallet.

Damage to the drawbar threads may occur!

11

A

B

Fig. 17

C

Fig. 18

GIBS ADJUSTMENT

After a period of time, movement of the table over the

ways will cause normal wear. Adjust the gibs to

compensate for this wear.

1. The horizontal gib adjustment screw (A, Fig.17) is

found to the rear right on table. The traverse gib

adjustment screw (B, Fig.17) is found on the right

side of saddle under the table. The vertical gib

adjustment screw (C, Fig.18) is found onto the

column.

2. Loose the screw from small taper end of gib. Turn

the screw from large taper end of gib slightly

clockwise to tighten. Turn the table handwheel and

check the tension.

3. Re-adjust as required.

12

Solution

Readjust gibs

Lock all axes but the one moving

Lock mill head

Tighten quill lock

Center tool

reshape, sharpen, or replace tool

Lock quill

Make sure setup is parallel to table

Use sharp bits

Remount tool

Remount chuck on arbor

Tighten drawbar

Tighten or replace bearings

Reduce speed

Reduce feed rate

Apply lubricant

Clean chuck

Clean arbor and remount

Clean spindle and replace drawbar

Plug in machine

Tighten wiring connections

Maintenance

Keep the maintenance of the machine tool during the operation to guarantee the accuracy and

service life of the machine.

1. In order to retain the machine's precision and functionality, it is essential to treat it with care, keep

it clean and grease and lubricate it regularly. Only through good care, you can be sure that the

working quality of the machine will remain constant. Disconnect the machine plug from the

mains supply whenever you carry out cleaning, maintenance or repair work!

2. Lubrication all slideways lightly before every use. The leadscrew must also be lightly lubricated

with lithium base grease.

3. During the operation, the chips what falls onto the sliding surface should be cleaned timely, and

the inspection should be often made to prevent chips falling into sliding ways. Asphalt felt should

be cleaned at certain time. Do not remove the chips with your bare hands. There is a risk of

cuts due to sharp-edged chips.

4. After the operation every day, eliminate all the chips and clean different part of the machine and

apply machine oil to prevent rusting.

5. In order to maintain the machining accuracy, take care of the arbor, drawbar, the surface of the

worktable and the guide way and avoid mechanical damage and the wear due to improper guide.

6. If the damage is found, the maintenance should be done immediately.

Trouble Solution

Problem

Too chatters

Possible Cause

Gibs too loose on table, column

Unused feeds not locked

Mill head not locked

Quill too loose

Tool not on center

Improper tool shape, tool dull

Quill moving

Setup wrong

Bit dull

Bit not mounted correctly in chuck

Chuck loose in spindle

Drawbar not secured

Bearing loosen or worn

Cutting too fast

Bit fed into work too fast

Chuck sticking

Debris in chuck

Chuck loose on arbor

Drawbar not tight

Machine unplugged

Loose electrical connections

Depth of cut is not consistent

Hole is off center or bit wanders

Bit turns erratically or stops

Chuck is difficult to tighten or loosen

Chuck wobbles

Turn on machine and nothing happer

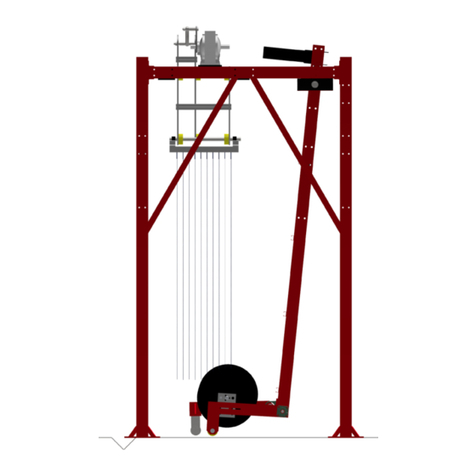

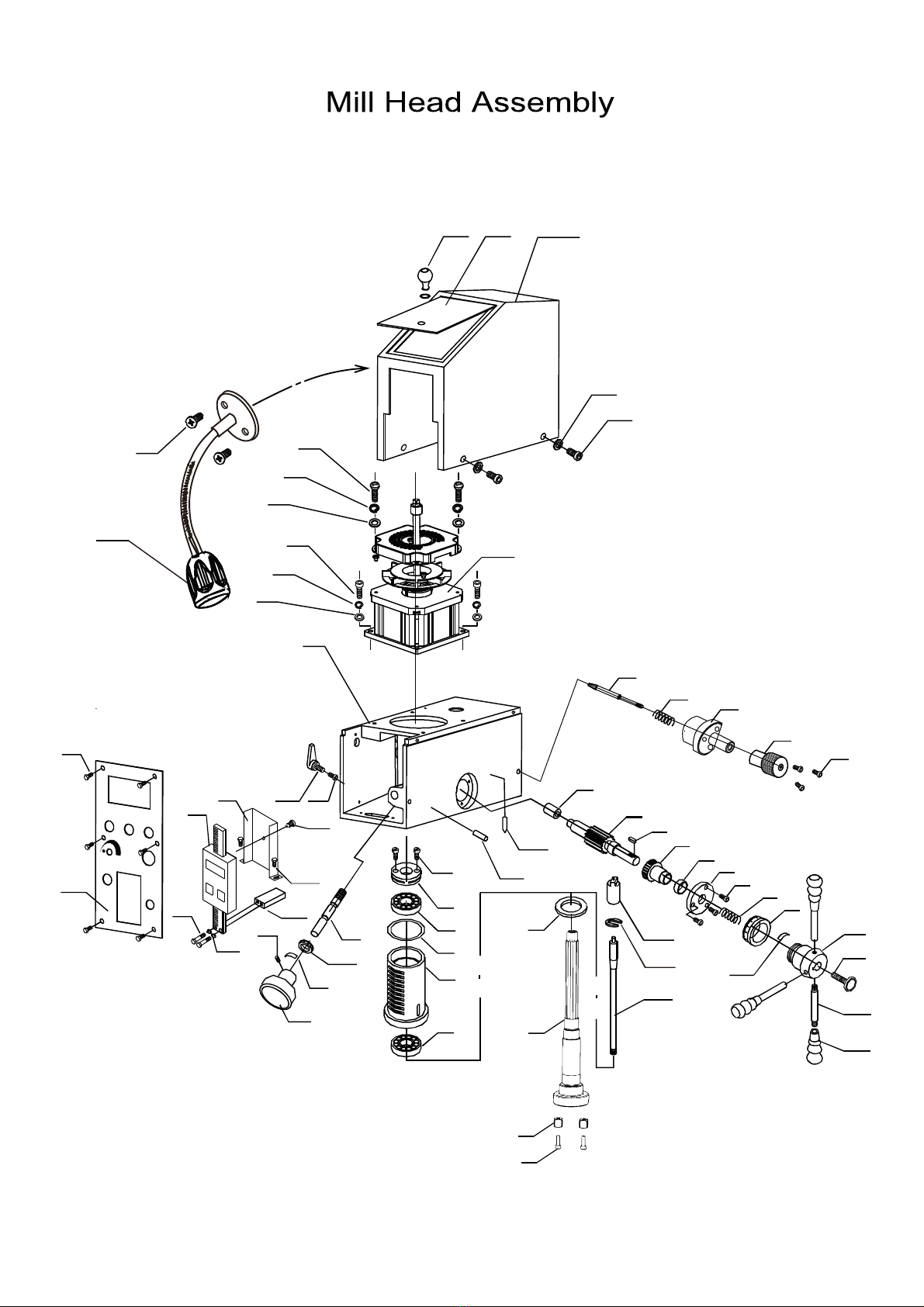

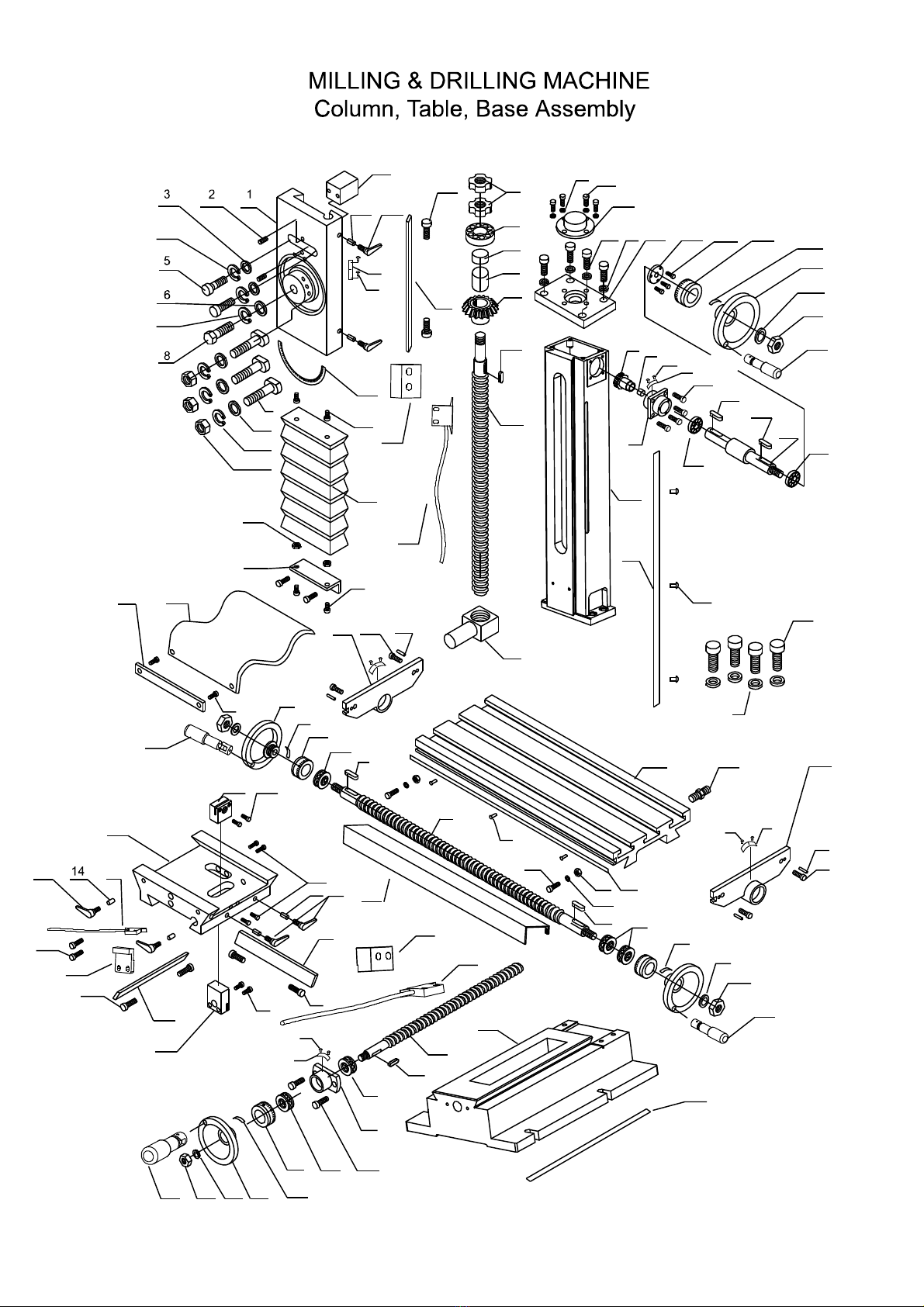

PART LIST

MILL E3

214 215

205

205

216

217

218

219

220

201 202 203

204

221

222

223

224

225

226

227

228

229

230

231

232

233 234

235

237

236

259

260

238

239

240

241

242

243

244

245

246

247

248

249

250

251

252

253

225

210

211

212

213

206

255

207

208

209

1

205

123

254

258 257

247

256

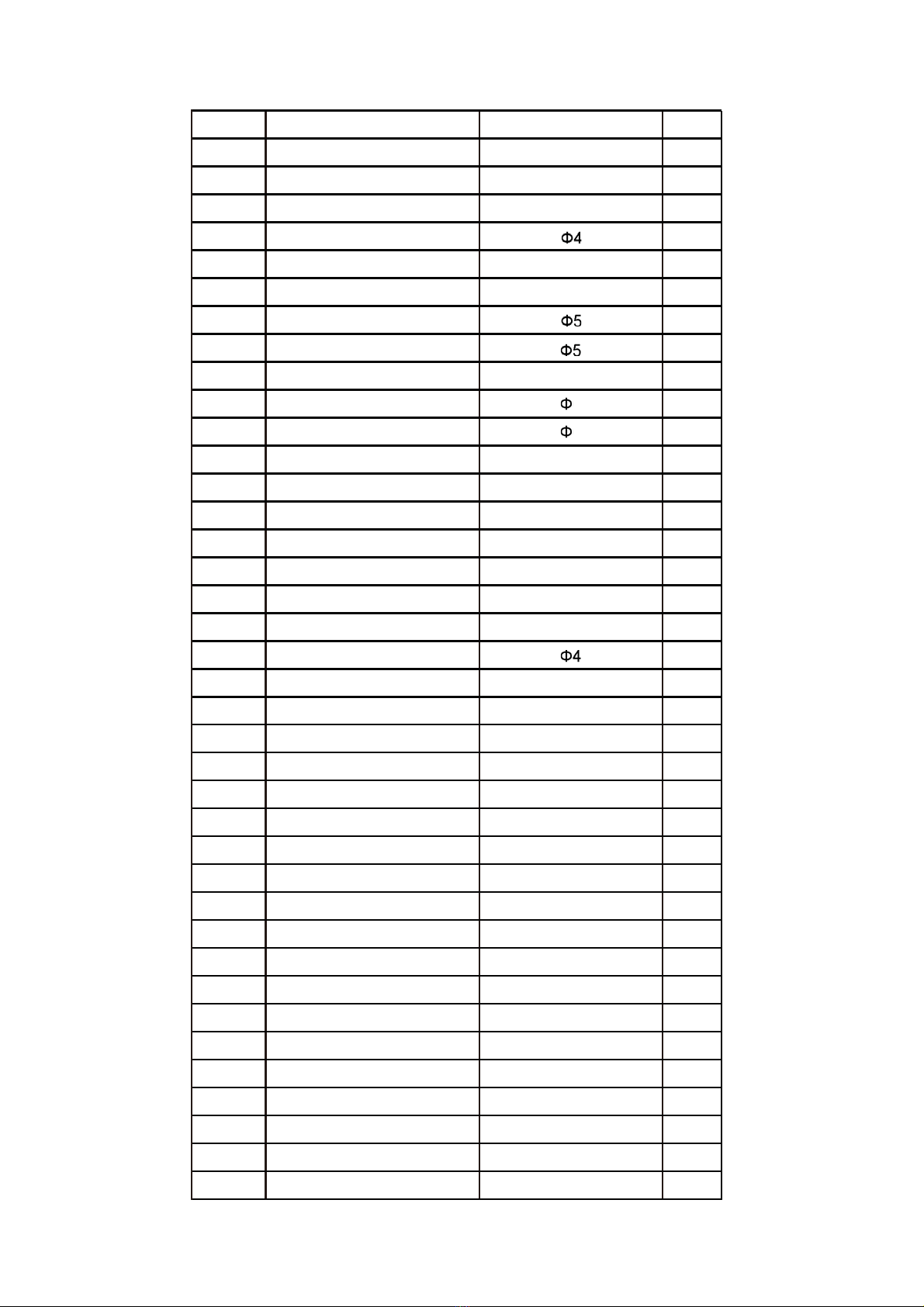

Parts No. Descrip tion Specific ation Qty

201

202

203

204

205

206

207

208

209

210

211

212

213

214

215

216

217

218

219

220

221

222

223

224

225

226

227

228

229

230

231

232

233

234

235

236

237

238

1

1

1

7

4

4

4

4

4

4

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

5

1

1

1

1

1

1

1

2

1

8

2

”8/3gulP

Drawbar Cover

Motor Cover

Washer4

Hex Head Cap Screw M4×8

Round head Phillips screw M5×16

Spring washer

Washer

Hex Head Cap Screw M8×2

8

8

0

Spring washer

Washer

Washer

MBrushless otor 1.5KW

Mill Head

Locking Lever M8×20

Brass Pin

Bracket

Digital Scale

Hex Head Cap Screw M4×60

Base

Hex Head Cap Screw M3×8

Label

Knob

Set Screw M5×10

Spring Piece

Dial

Worm Shaft

Bearing 7007

7006

Sleeve

Rubber Ring

Bearing

Adjusted Nut

Hex Head Cap Screw M5×12

03×6niP

Pin 5×12

Spindle

Ring

Retainer cup

MILL HEAD ASSEMBLY

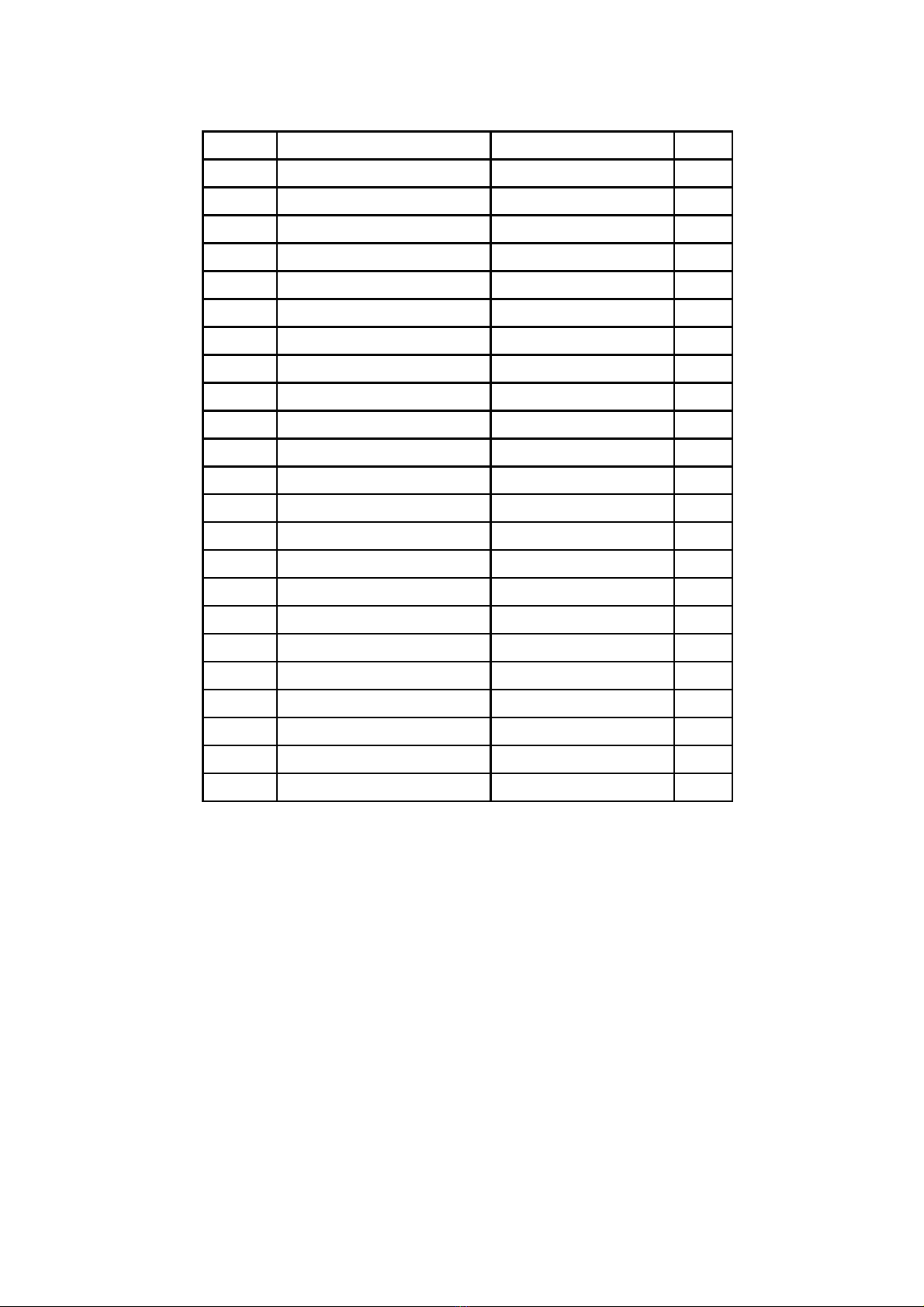

Position Washer239

1042

1

1

3142

3242

243

1442

1

1

1

1

1

1

1

1

1

1

2

1

1

245

246

247

248

249

250

251

252

253

254

255

256

257

25

259

260

Stopper 2

2

8

3

Drawbar

Handle

Handle Lever

Locking Knob

Base

Dial

Spring

Hex Head Cap Screw M4×12 3

Flange

Washer

Worm Gear

Gear shaft

Key 6×16

Block

Screw

MILL HEAD ASSEMBLY

Work Lamp

Compression spring

Locking pin seat

Locking pin sleeve

He M6×16x Head Cap Screw

21

72

7315

62

63

42

64 48

75

74

42

64

48

67

68

66

65

58

54

59

17

53

52

46 46

47

48

45

44

3

43

42

41403938

32

40

50

12

21

17

16

14 15

29

30

31

32

33

34

21

35

36

437

17

13

18

4

7

27

28

11

20

84

21

22

23

24

26 25

10

19

9

16

17

56

55

57

575860

7170

71 18

76 84

73

85

7714

78

66

83

18

7

61

7963

4262

44

45 3

82

81

80

57

79

49

51

69

3

44

48

17 16

17

16

45

73

45

4

Table of contents

Popular Industrial Equipment manuals by other brands

GFA

GFA ELEKTROMAT KE 40.24-40,00 installation instructions

Clarke

Clarke CPT250 Operating and maintenance instructions

Siemens

Siemens 3RT7014 Series operating instructions

Ultraflex

Ultraflex X72 installation manual

SMC Networks

SMC Networks MHZ2-6 Series operating manual

Tescom

Tescom 44-3200 Instructions for use