Mounting instructions (Original: de)

8031363

1411NH

†‡

Swivel flange

DAMS-K-V1-...-V-R3

Festo AG & Co. KG

Postfach

73726 Esslingen

Germany

+49 711 347-0

www.festo.com

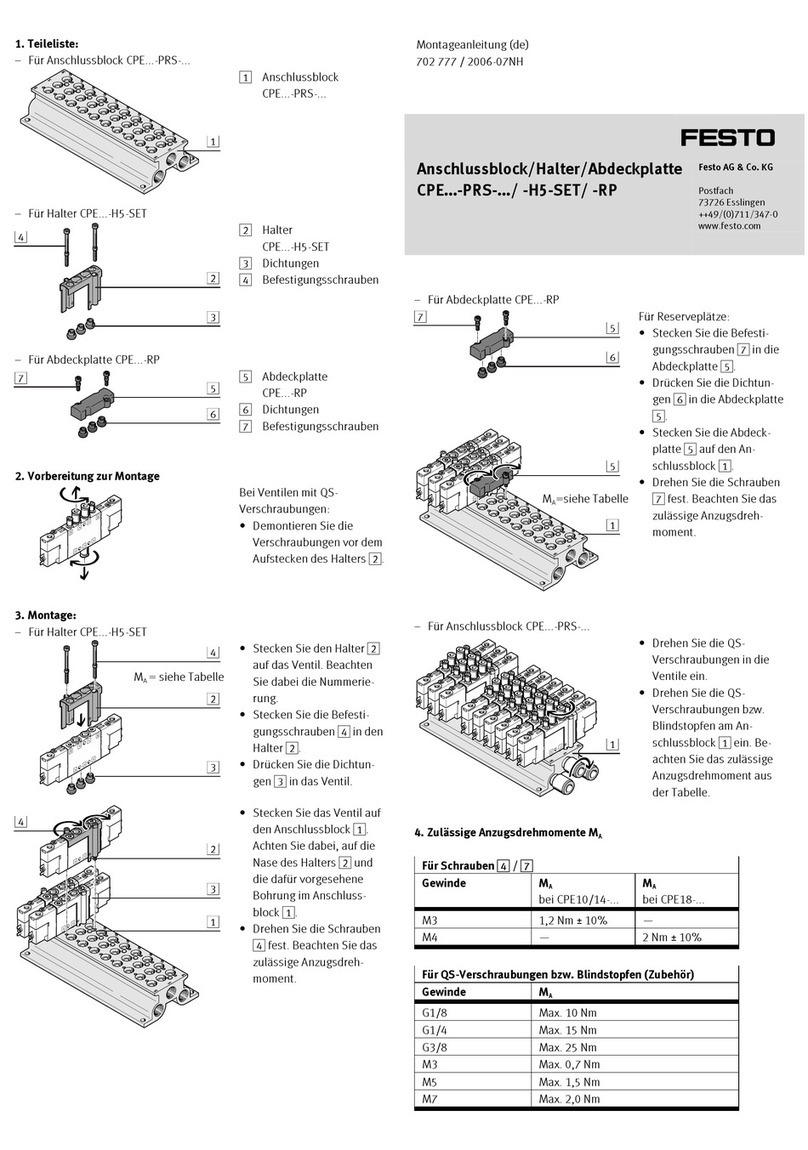

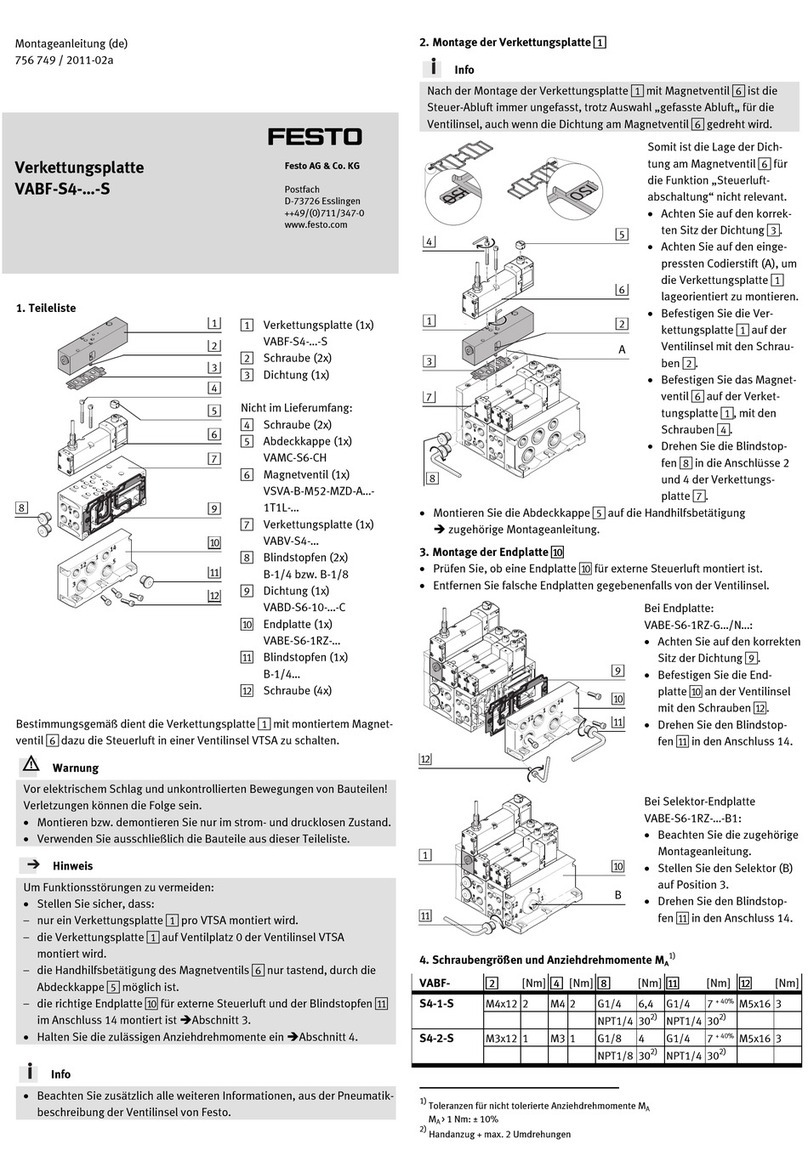

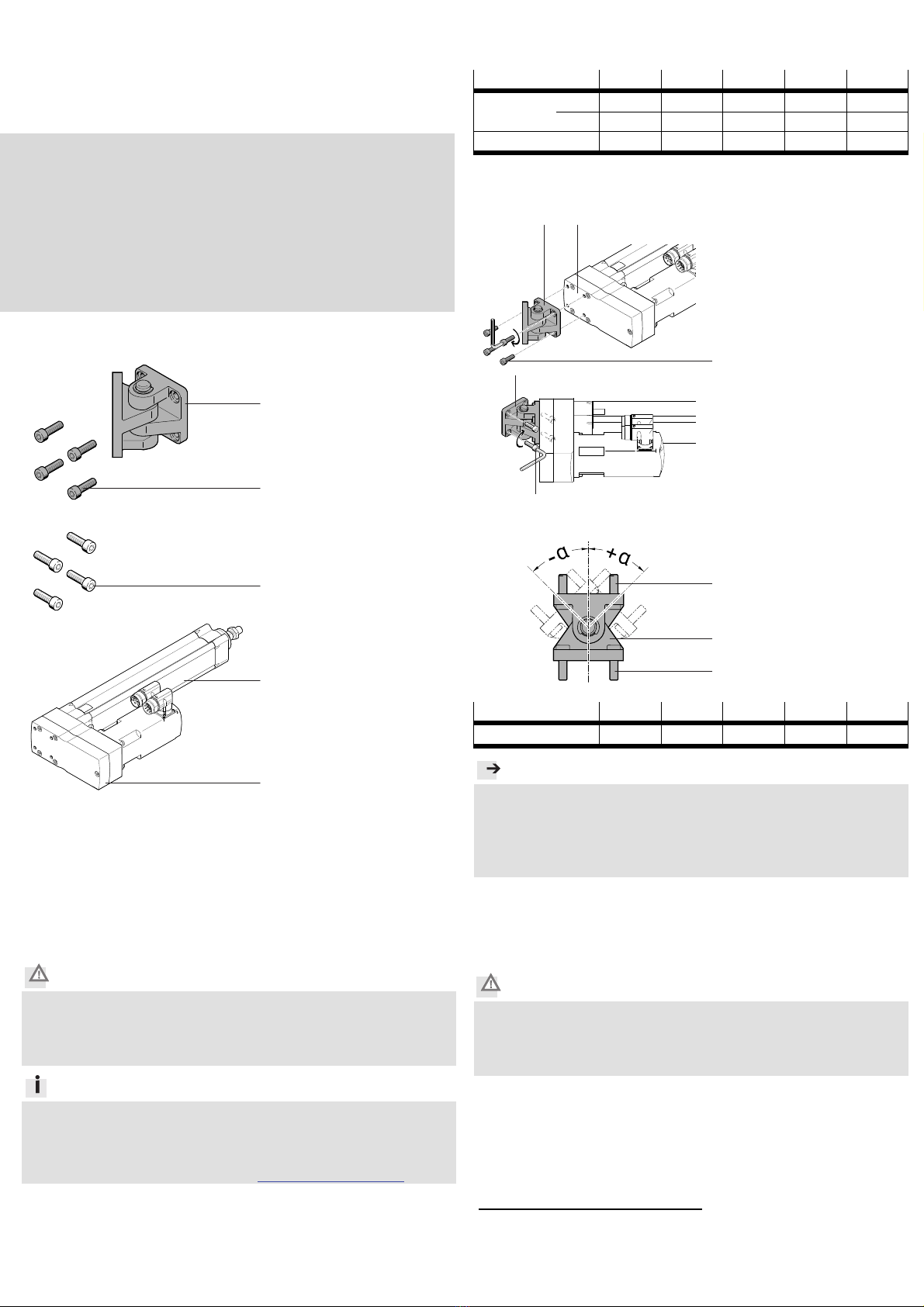

1. Parts list

21107d_1

1Swivel flange

2Screw

(1x)

(4x)

Not included in delivery:

21107d_3

3Screw (4x)

21107d_2

4Electric cylinder

ESBF

5Parallel kit

EAMM-U

(1x)

(1x)

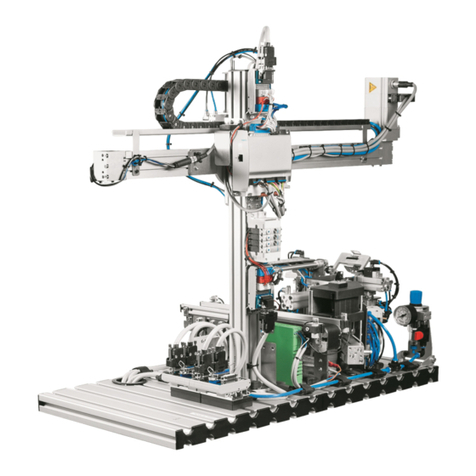

2. Intended use

Swivel flange DAMS-K-V1-...-V-R3:

Swivel mounting of the electric cylinder 4on parallel kit 5.

The swivel flange is designed for the higher loading forces of the electric

cylinder 4.

3. Safety instructions and notes on mounting

Caution

Unexpected movement of components.

Injury due to impacts or pinching.

Switch off power supply before mounting work.

Observe the safety instructions (applicable documents).

Information

Applicable documents

operating instructions for the electric cylinder 4

mounting instructions for the parallel kit 5

Accessories for the electric cylinder 4www.festo.com/catalogue

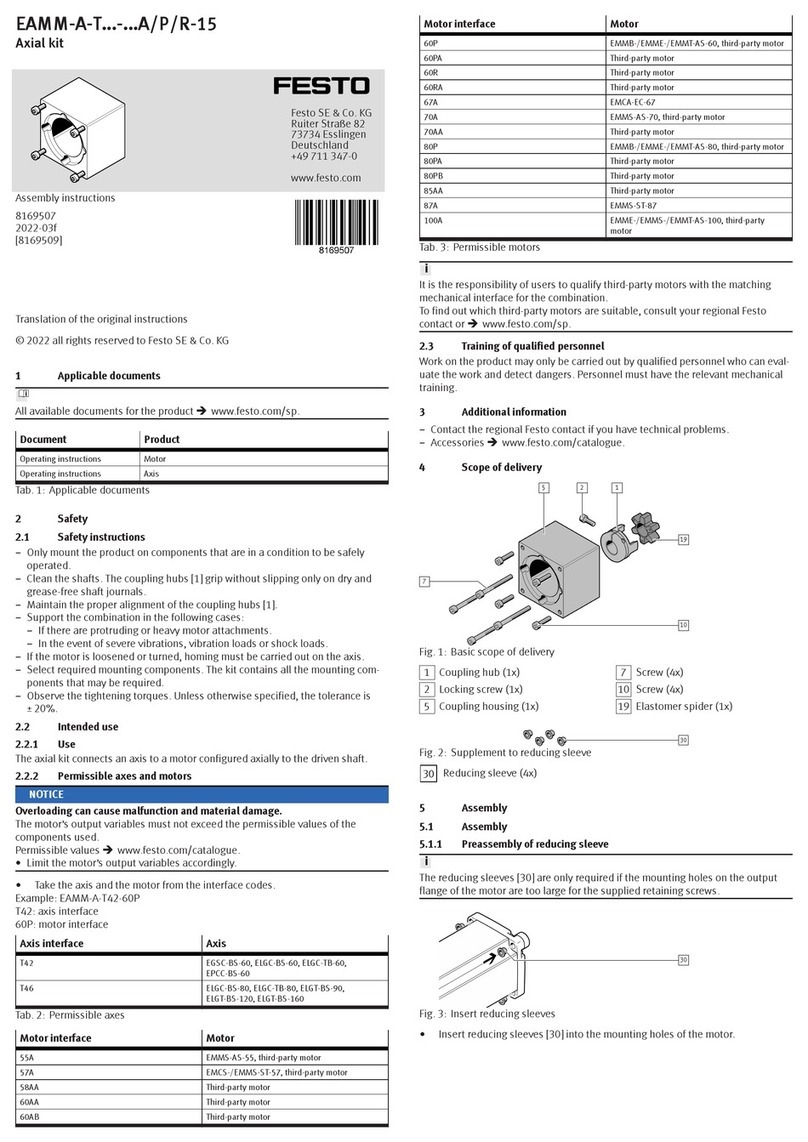

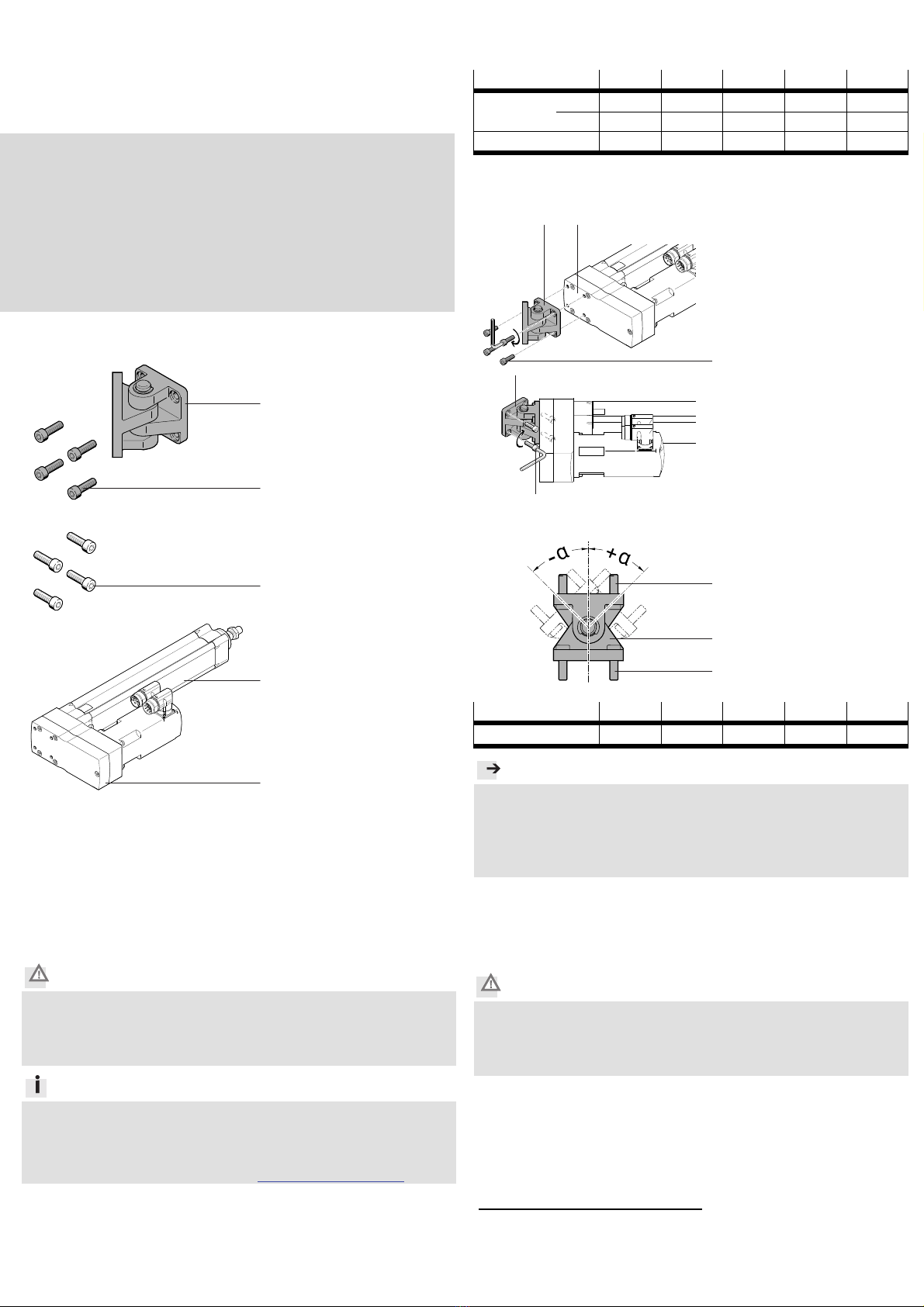

4. Screw sizes and tightening torques MA

1)

DAMS-K-V1-...-V-R3 40 50 63 80 100

2

Screw M6x20 M8x25 M8x25 M10x30 M10x30

[Nm] 6 14 14 27 27

3

Screw M6 M8 M8 M10 M10

Select screws 3suitable for the installation situation.

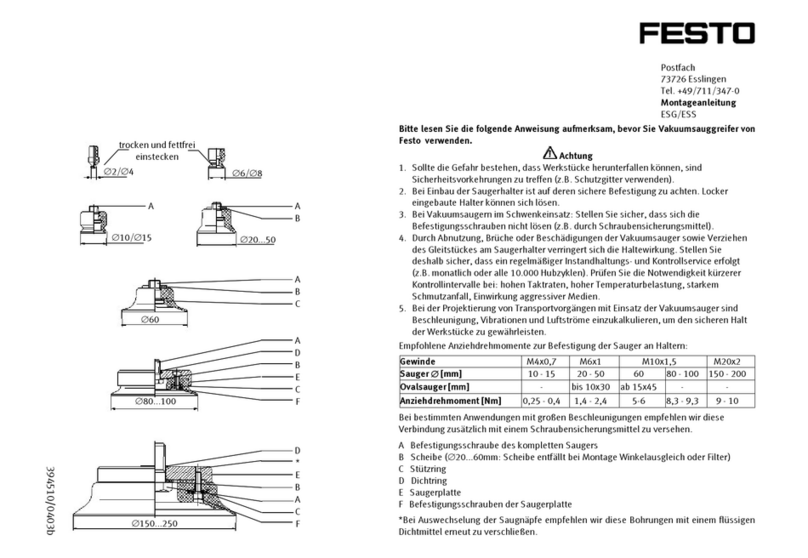

5. Mounting

21107d_4

Place the swivel flange 1

on the parallel kit 5

depending on the required

swivel direction.

Tighten screws 2. Comply

with the tightening torque

(section 4).

21107d_5

Secure the swivel flange 1

to the mounting surface by

using the screws 3.

6. Maximum swivel angle á2)

21107d_6

DAMS-K-V1-...-V-R3 40 50 63 80 100

Swivel angle á3

±32° ±45° ±42° ±31° ±36°

Note

Limitations of the swivel angle are caused by the overall structure of the

system.

Collision of components, e.g. parallel kit 5with the mounting surface.

Prior to commissioning:

Check the possible swivel angle of all moving components.

7. Maintenance

The swivel flange DAMS-...-40/-50/-63/-80 is maintenance-free.

When using swivel flange DAMS-...-100:

Caution

Breaking of the swivel flange 1. Unexpected movement of components.

Injury due to electric shock, impact, squeezing.

Replace electric cylinder 4and swivel flange 1at the same time.

The service life of the components is comparable with one another.

1) Tolerance for tightening torques MAwithout indication of tolerance ± 10 %

2) Maximum swivel angle applies for screws 2/3according to DIN EN ISO 4762:2004-06

and DIN 912:1983-12.

3) Tolerance for á± 1°