1

Governors America Corp. © 2021 Copyright All Rights Reserved

EEG7500 Enhanced Electric Governor 8-2021-A8 PIB5115

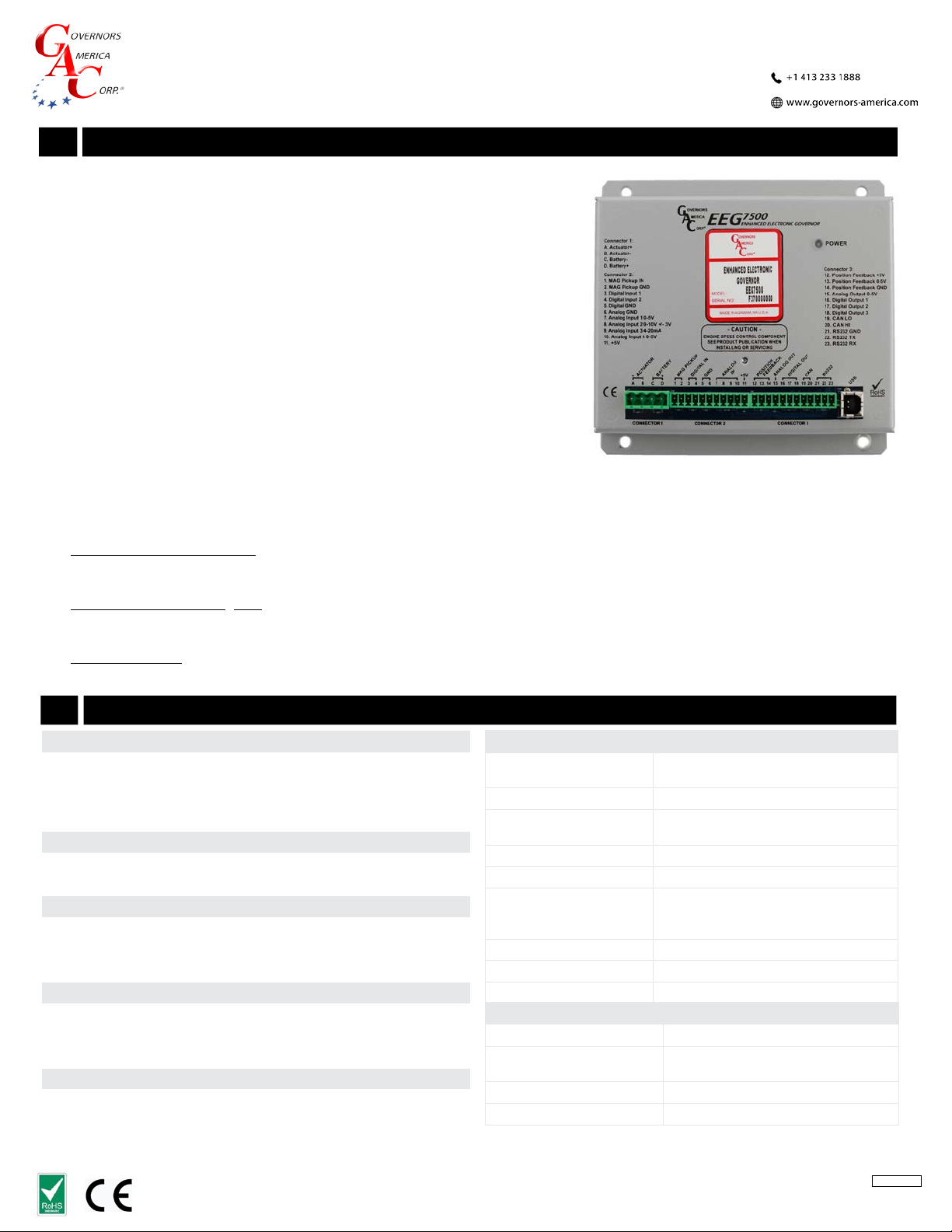

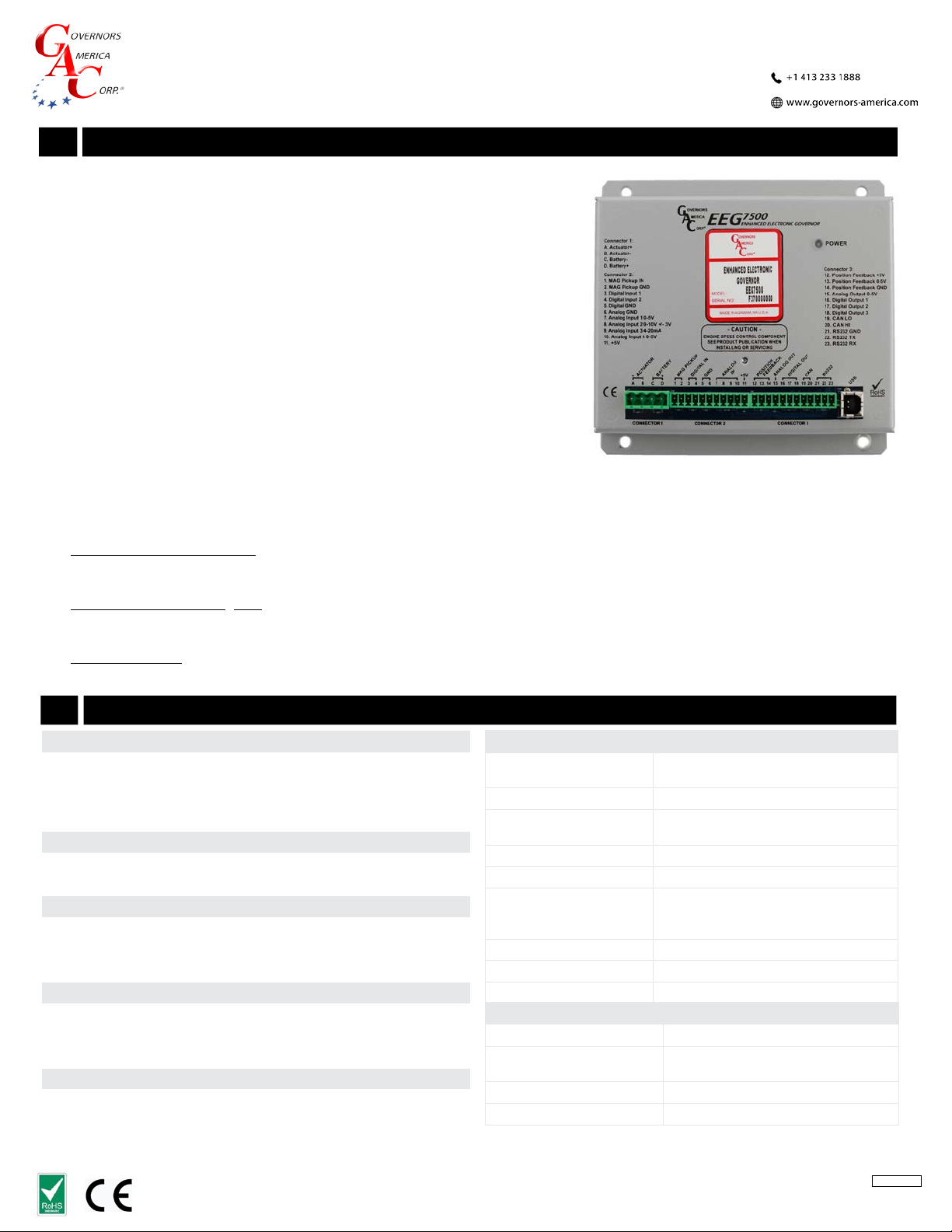

EEG7500

Enhanced Electronic Governor

1INTRODUCTION

GAC’s EEG7500 enhanced electronic governor is designed to regulate engine speed

on diesel and gaseous fueled engines. When paired with a GAC actuator the EEG is

a suitable upgrade for any mechanical governor system that needs exibility, preci-

sion, or accurate control of governed speed. The EEG7500 is designed for industrial

engine applications from generator sets, mechanical drives, pumps, and compressors

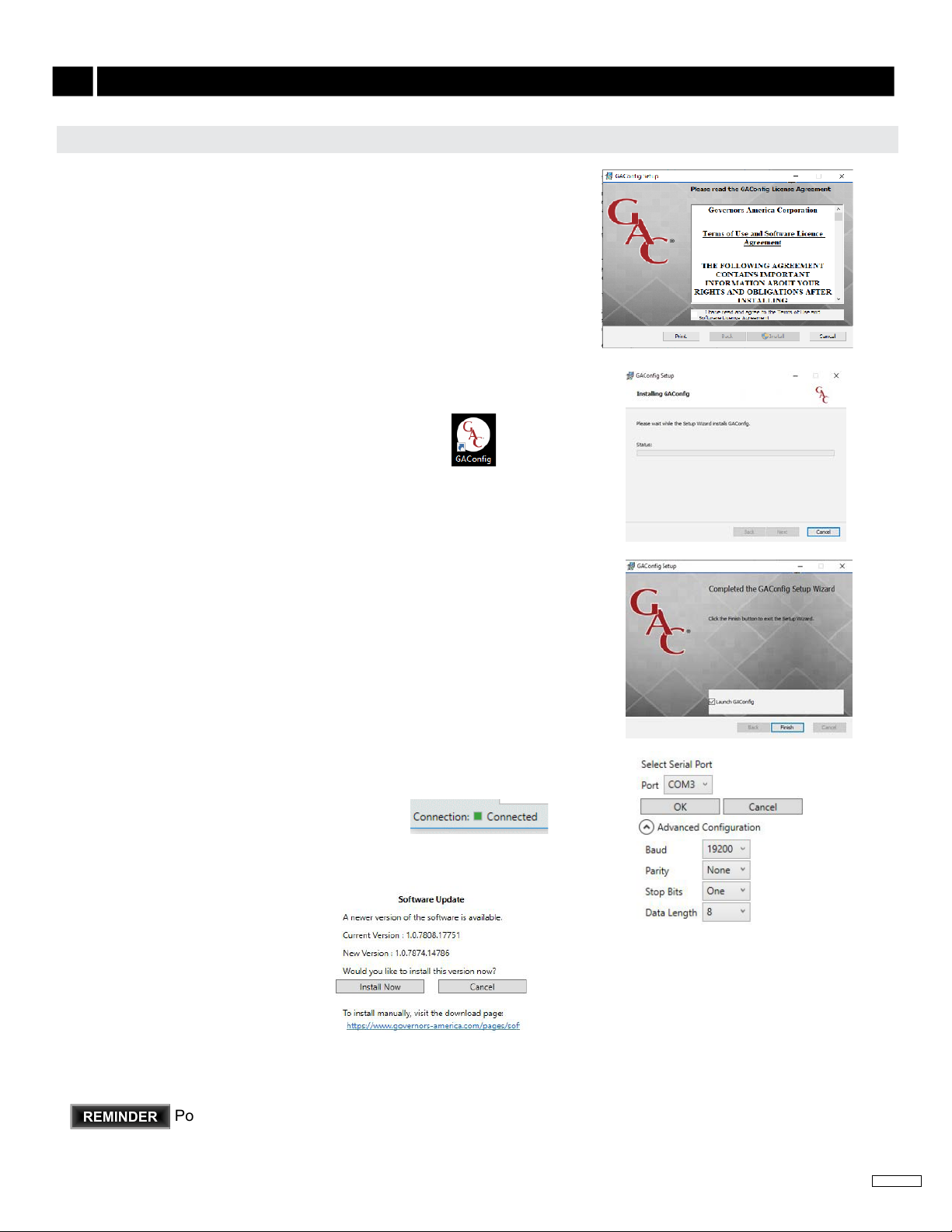

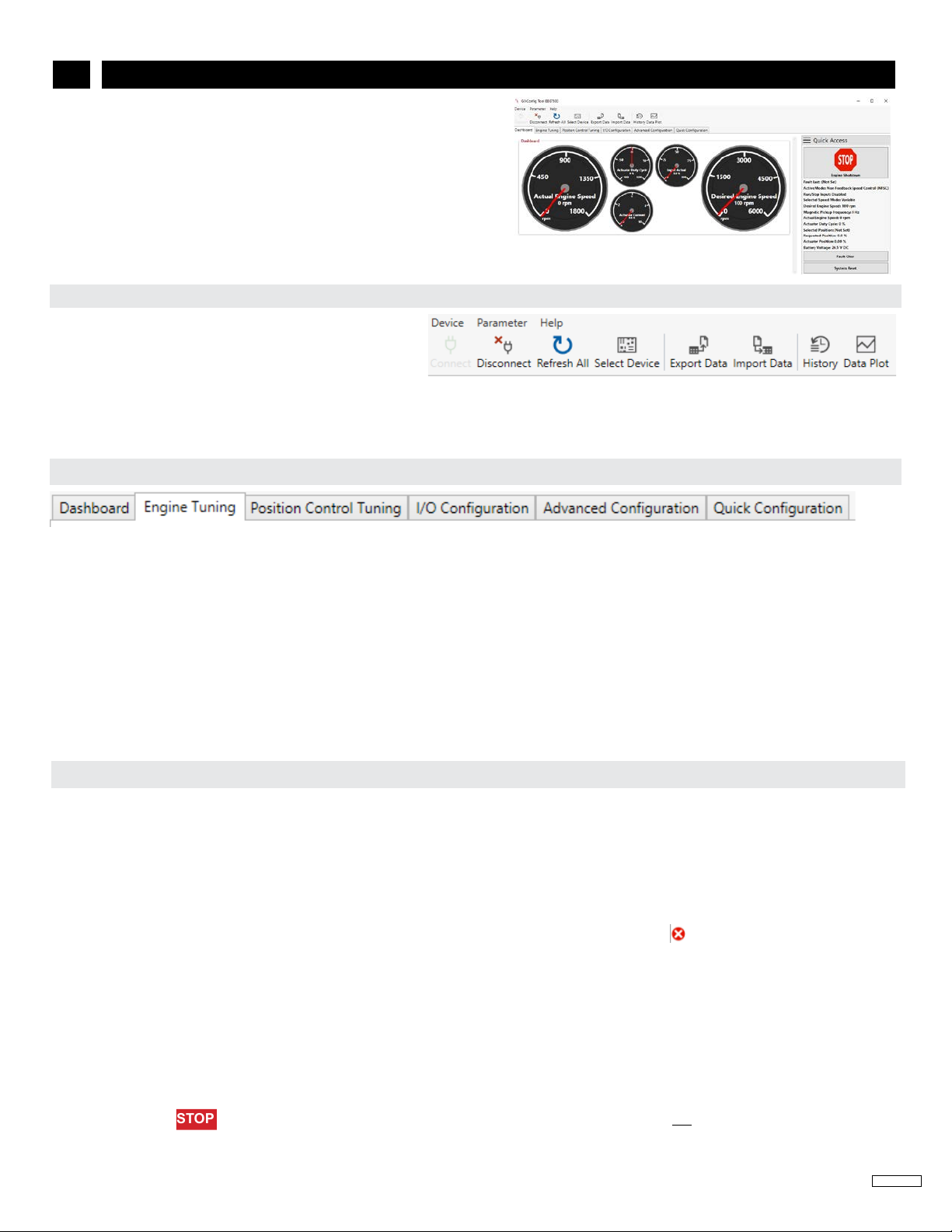

to o-road mobile equipment. Conguring is easy with GAC’s free GACong Tool

software. The EEG7500 supports:

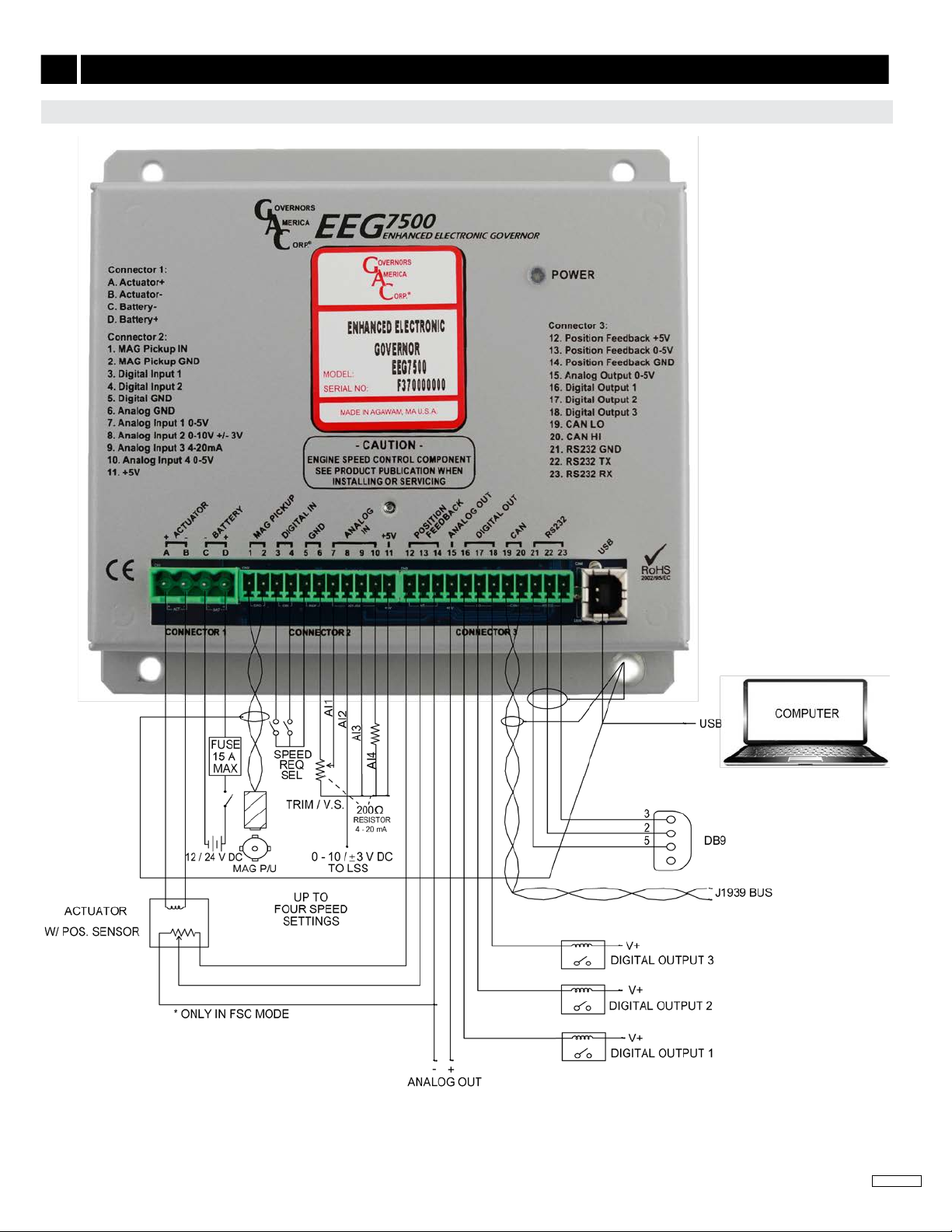

Flexible actuator compatibility including bidirectional actuators with or without

actuator position feedback signal, bi-directional torque motors, and Bosch-style

throttle bodies.

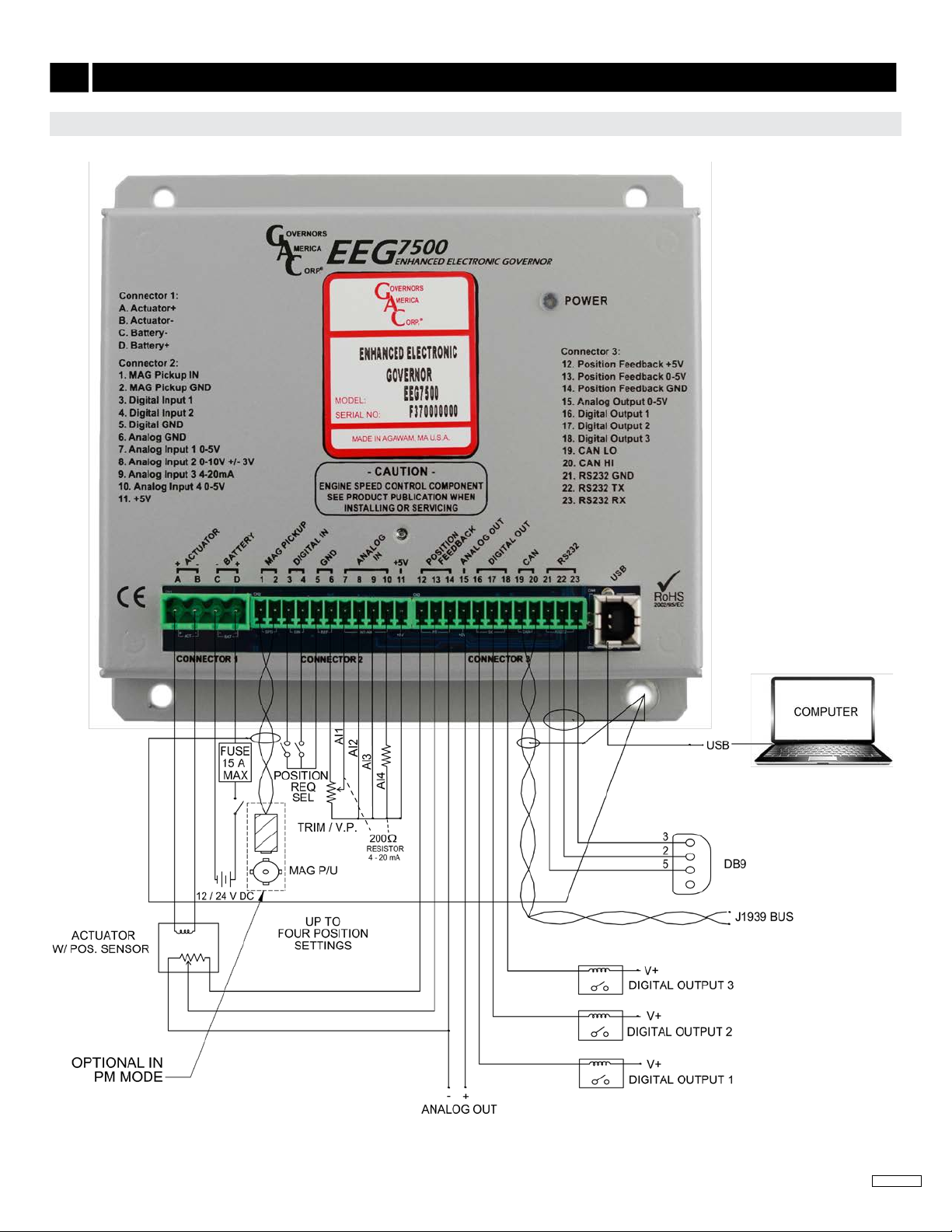

Fully congurable digital and analog inputs and outputs

Inputs: 5 analog, 2 digital

Outputs: 1 analog, 3 digital

0 - 5 V DC, 4 - 20 mA, 0 - 10 V DC, or ±3 V DC input ranges

Speed Sync using CAN bus

Virtual Input/Output Routing

Feedback Speed Control Mode

Variable Speed Capability

Fuel Curve Shaping

EEG7500 supports three operating modes:

Non-Feedback Speed Control (NFSC) provides standard PID governing function for use with proportional actuators. No position

feedback sensor is required. PID (Proportional, Integral, Derivative) governor functions are optimized for best response and control

of the requested engine revolutions per minute (rpm).

Feedback Speed Control (FSC) combines NFSC and PM modes for use with proportional or bidirectional (torque motor) actuators. A

position feedback sensor is required. The Speed PID position request is the input to the Positioner loop, the Position PID optimizes

response and control of the requested actuator position.

Positioner Control (PC) (uncommon) provides actuator positioning control and is used with proportional actuators or bidirectional

(torque motor) actuators with a feedback sensor (required).

2

PERFORMANCE

Isochronous Operation ± 0.25 %

Governed Speed /

Sensor Frequency Range 100 Hz - 12 kHz

Droop Range Up to 25 % regulation

COMPLIANCE / STANDARDS

Agency CE and RoHS Requirements

Communications USB, RS-232-C, SAE J1939

PHYSICAL

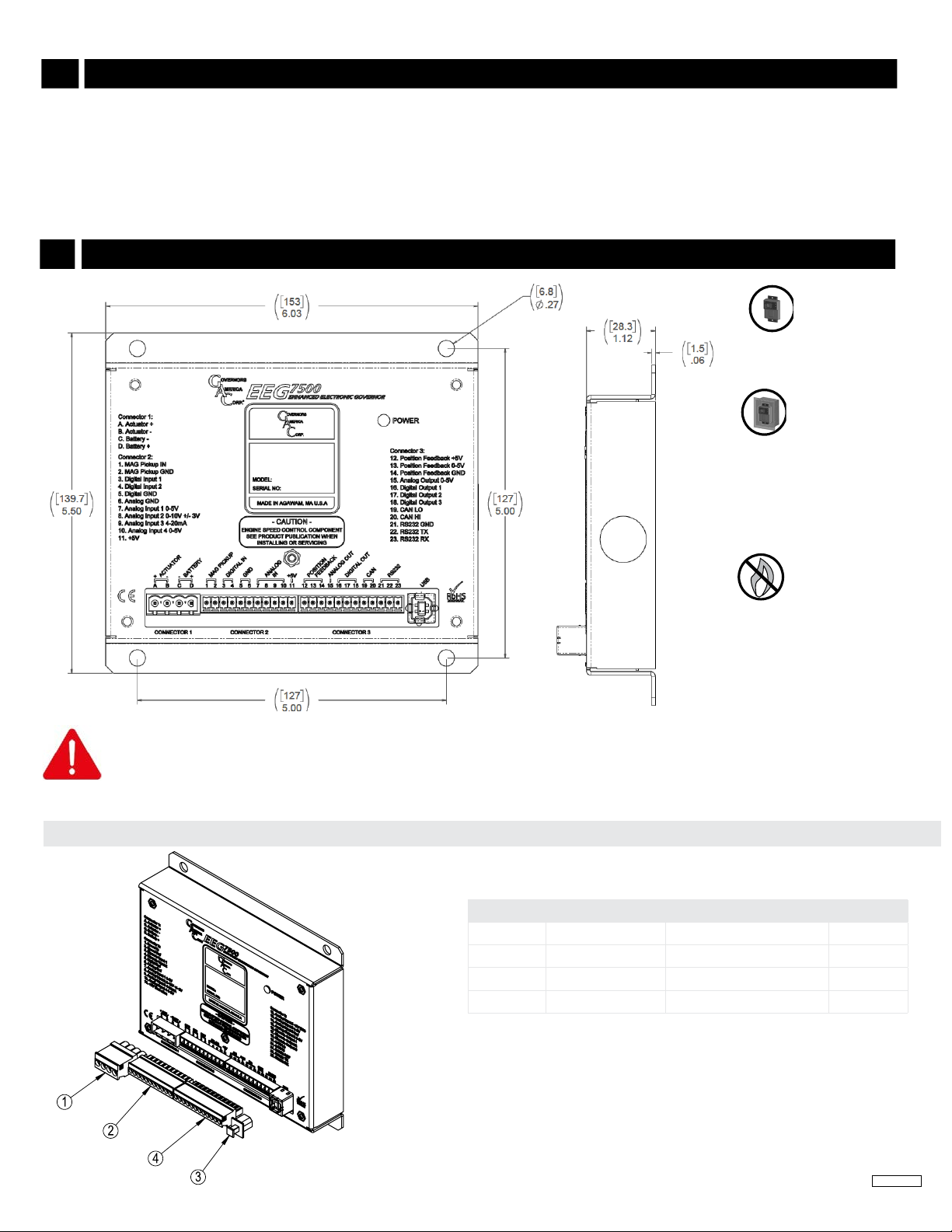

Dimension See Section 3, Controller Installation

Weight 18.4 oz [0.52 kgf]

Mounting Any position, vertical preferred

RELIABILITY

Vibration 10 - 2000 Hz @ 7 g, per SAE J1455

Shock 20 g, 11 ms per SAE J1455

Testing 100 % Functional Testing

LED

Solid Green Ready. Controller is powered on.

Blinking Green Warning. Engine service due, or other. Dis-

played in GACong Tool System Status.

Unlit No power.

INPUT / OUTPUT

Supply 12 - 24 V DC Battery systems

(6.5 to 32 V DC)

Polarity Negative Ground (Case Isolated)

Power Consumption 200 mA continuous plus actuator current

400 mA with excitation at MAX load current

Speed Sensor Signal Input 1.0 - 60.0 V RMS

Actuator Output 10 A Continuous

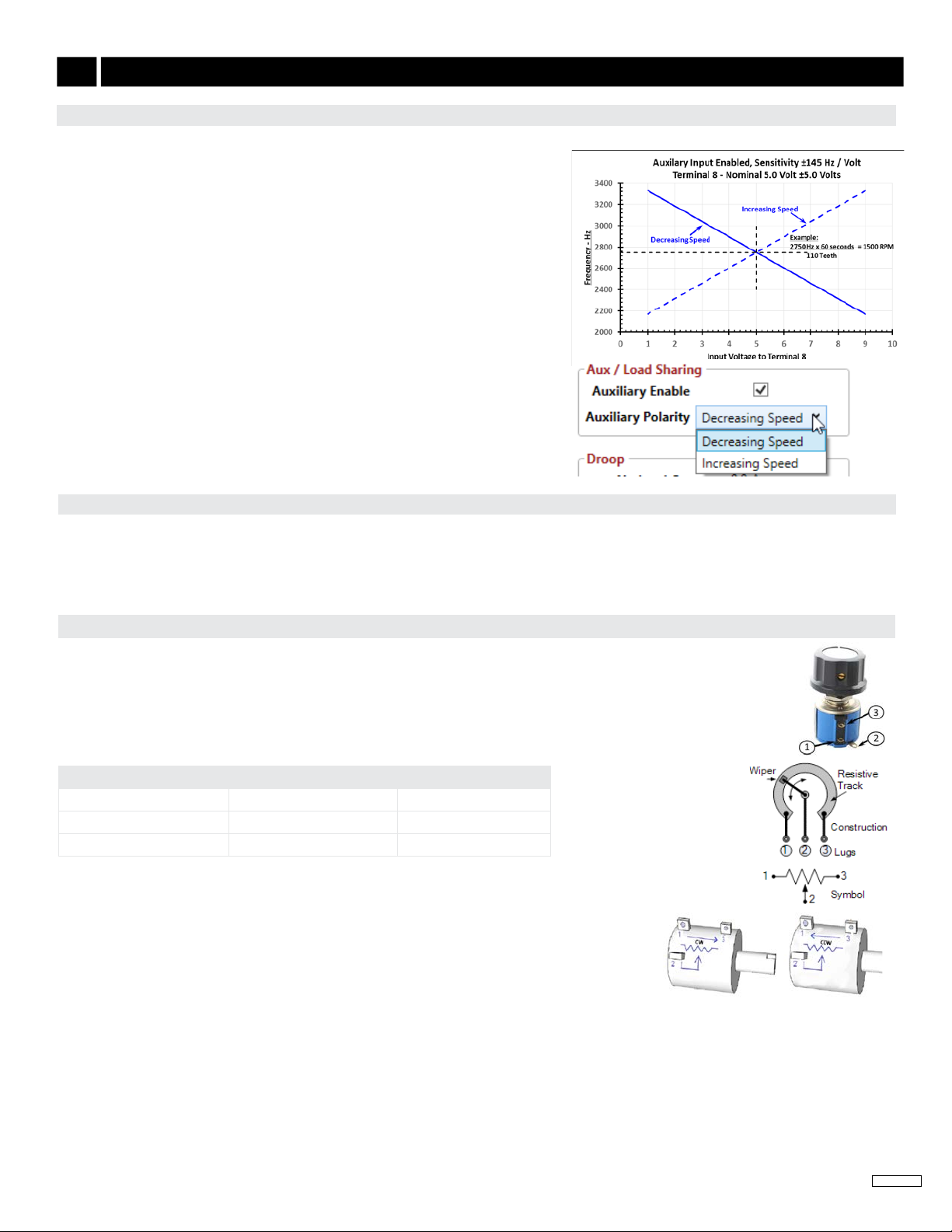

Load Share /

Synchronizer Input

0 - 10 V DC (5 V Nominal, Selectable

Polarity, 145 Hz / V Sensitivity)

or 0 V ± 3 V DC

Reverse Power Protection Protected to -40 V DC

Transient Voltage Protection 60 V DC

Digital Switch Output(s) Rated to 2 A DC

ENVIRONMENTAL

Ambient Temperature -40 to 180 °F [-40 to 85 °C]

Relative Humidity up to 90 % Non-Condensing

at 38 °C [100 °F] (per SAE J1455)

Salt Spray ASTM B117

All Surface Finishes Fungus Proof and Corrosion Resistant

EEG7500 SPECIFICATIONS