nozzle holder are replaced;

• Do not remove or short-circuit the safety devices.

• Use only original spare parts.

• Always replace any damaged parts of the machine

with original materials.

• Do not run the machine without its housings. This

would be dangerous to the operator and anyone else

in the work area, and would prevent the machine from

being cooled properly.

2.4 EXPLANATION OF TECHNICAL SPECIFICATIONS

This machine is manufactured according to the following

international standards: IEC 60974.1 - IEC 60974.3 - IEC

60974.7 - IEC 60974.10 CL. A - IEC 61000-3-11 - IEC

61000-3-12 (61000-3-12 (see note 2).

N°. Serial number.

Must be indicated on any type of request

regarding the device.

Three-phase static transformer-rectifier fre-

quency converter.

Downslope.

Suitable for plasma cutting.

TORCH TYPE Type of torch that may be used with this

machine to form a safe system.

U0. Secondary open-circuit voltage.

X. Duty cycle percentage.

The duty cycle expresses the percentage of

10 minutes during which the welding machine

may run at a certain current I2and voltage

U2without overheating.

I2. Cutting current.

Art. 359: 60A @ 208/220/230/400/440V

Art. 361: a) 100A @ 400/440V

b) 80A @ 208/220/230V

U2Secondary conventional voltage with welding

current I2This voltage depends on the

distance between the contact tip and the

workpiece.

If this distance increases, the cutting vol

tage also increases and the duty cycle

X% may decrease.

U1. Rated supply voltage for 208/220/230V -

400/440V with automatic voltage change.

3~ 50/60Hz 50- or 60-Hz three-phase power supply

I1Max Max. absorbed current at the corresponding

current I2and voltage U2.

I1eff This is the maximum value of the actual cur-

rent absorbed, considering the duty cycle.

This value usually corresponds to the capa-

city of the fuse (delayed type) to be used as

a protection for the equipment.

IP23 S. Protection rating for the housing.

Grade 3as the second digit means that this

equipment may be stored, but it is not

suitable for use outdoors in the rain, unless

it is protected.

. Suitable for use in high-risk environments.

NOTE:

1- The machine has also been designed for use in envi-

ronments with a pollution rating of 1. (See IEC 60664).

2- This equipment complies with IEC 61000-3-12 provided

S

that the maximum permissible system impedance Zmax

is less than or equal to 0,146 (Art. 359)-0,088 (Art. 361)

at the interface point between the user's supply and the

public system. It is the responsibility of the installer or

user of the equipment to ensure, by consultation with the

distribution network operator if necessary, that the equip-

ment is connected only to a supply with maximum per-

missible system impedance Zmax less than or equal to

0,146 (Art. 359)-0,088 (Art. 361).

2.5 START-UP

The machine must be installed by qualified personnel.

All connections must be made in compliance with

current safety standards and full observance of safety

regulations (see CEI 26-23 - IEC TS 62081).

Connect the air supply to the fitting B.

If the air supply comes from a pressure regulator of a

compressor or centralized system, the regulator must be

set to an output pressure of no more than 8 bar (0.8 Mpa).

If the air supply comes from a compressed air cylinder,

the cylinder must be equipped with a pressure regulator.

Never connect a compressed air cylinder directly to the

regulator on the machine! The pressure could exceed

the capacity of the regulator, which might explode!

Connect the power cord A: the yellow-green cable wire

must be connected to an efficient grounding socket on

the system. The remaining wires must be connected to

the power supply line by means of a switch placed as

close as possible to the cutting area, to allow it to be shut

off quickly in case of emergency.

The capacity of the cut-out switch or fuses installed in

series with the switch must be equal to the current I1eff.

absorbed by the machine.

The absorbed current I1eff. may be determined by rea-

ding the technical specifications shown on the machine

under the available supply voltage U1.

Any extension cords must be sized appropriately for the

absorbed current I1max.

3 USE

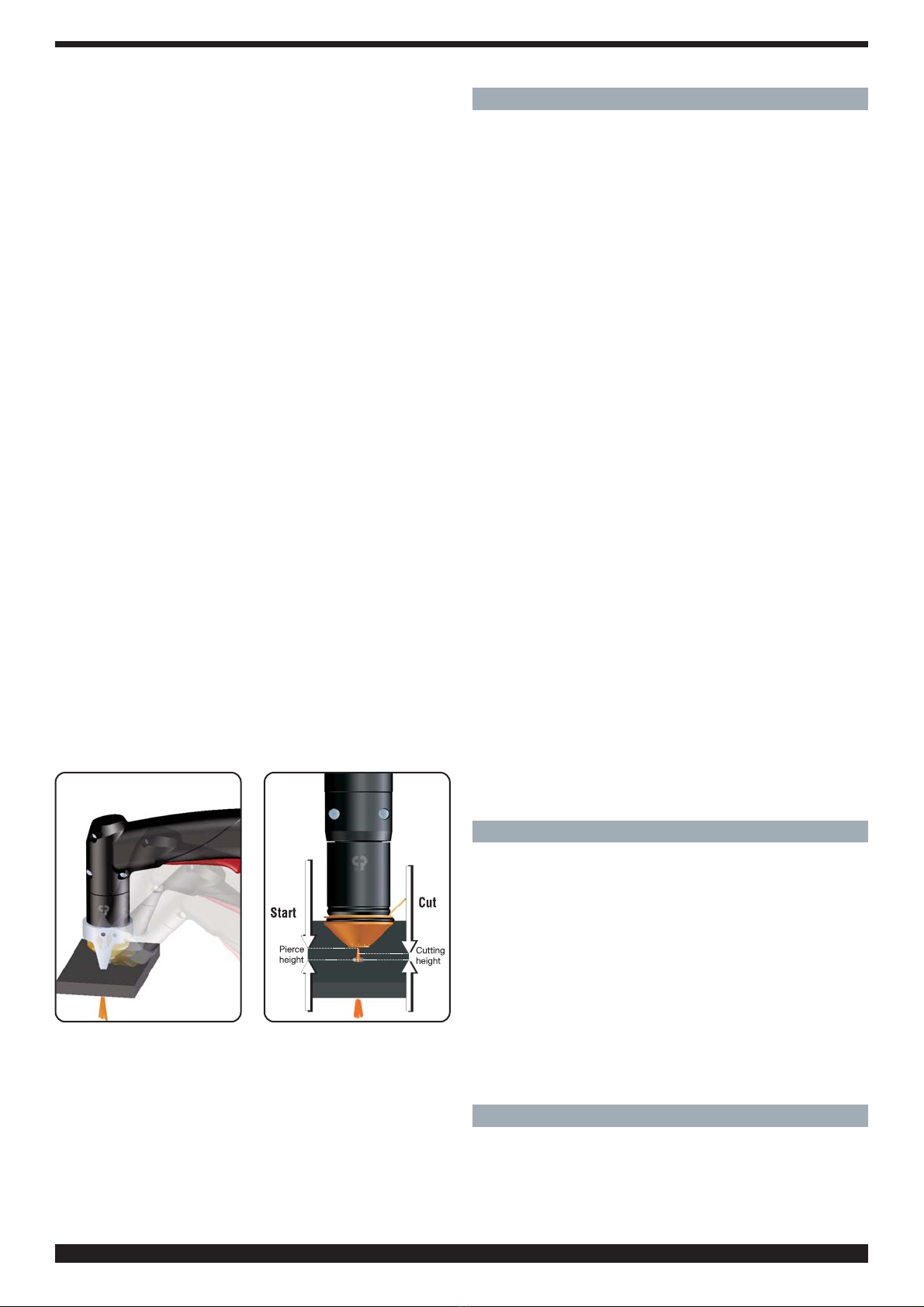

Make sure the trigger has not been pressed.

Turn the machine on using the switch C. The warning

lamp Vwill light to indicate that the machine is on.

By pressing for an instant the welding torch button com-

pressed air flow is opened. Under this condition set the

pressure shown by the pressure gauge F, at 5 bar (0.5

MPa) for 6 m long torches and 0.55 bar (0.55 MPa) for 12

m long torches by means of the reducer knob E, and

then lock the knob by pushing it down.

Connect the grounding clamp to the workpiece.

The cutting circuit must not be deliberately placed in

direct or indirect contact with the protective wire except

in the workpiece.

If the workpiece is deliberately grounded using the pro-

tective conductor, the connection must be as direct as

possible and use a wire of at least the same size as the

cutting current return wire, and connected to the work-

piece at the same point as the return wire using the return

wire clamp or a second grounding clamp placed in the

immediate vicinity. Every precaution must be taken to

avoid stray currents.

9