1.7.2008 Rev.

1. General .......................................................................................................... 1

1.1 Symbols used in the manual .......................................................................................... 1

1.2 Symbols used on the appliance ...................................................................................... 1

1.3 Checking the relationship of the appliance and the manual .......................................... 1

2. Safety .............................................................................................................. 2

2.1 How to operate the oven safely ..................................................................................... 2

2.2 Disposal of the oven ...................................................................................................... 2

3. Functional description .................................................................................. 3

3.1 Intended use of the appliance ........................................................................................ 3

3.1.1 Restrictions governing the oven use ...................................................................... 3

3.2 Operating principle ........................................................................................................ 3

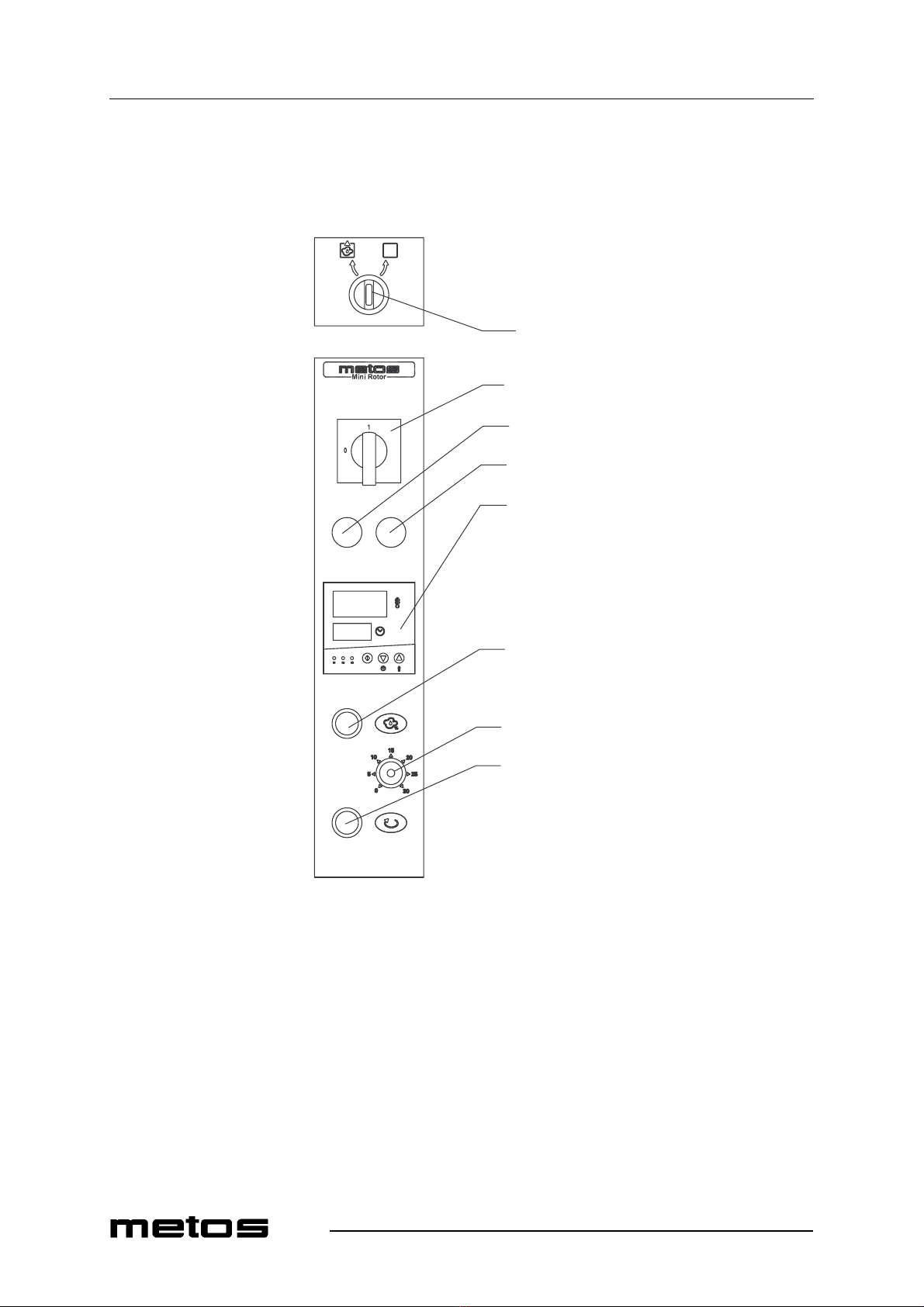

3.3 Control panel ................................................................................................................ 4

3.4 Time and temperature adjuster ...................................................................................... 5

3.4.1 Temperature setting ............................................................................................... 5

3.4.2 Cooking time setting .............................................................................................. 5

4. Operation instructions ................................................................................. 6

4.1 Before using the oven .................................................................................................... 6

4.1.1 Before baking ......................................................................................................... 6

4.2 Baking ............................................................................................................................ 6

4.2.1 Moistening ............................................................................................................. 7

4.2.2 Tips for the baking and proving of frozen foods ................................................... 7

4.3 After use ........................................................................................................................ 8

4.3.1 Cleaning ................................................................................................................. 8

4.3.2 Service ................................................................................................................... 9

5. Installation ................................................................................................... 10

5.1 General ........................................................................................................................ 10

5.2 Moving the oven to the installation place and unpacking ........................................... 10

5.3 Positioning the oven .................................................................................................... 10

5.4 Electricity connection .................................................................................................. 11

5.5 Water connection ......................................................................................................... 11

5.6 Drain connection ......................................................................................................... 11

5.7 Steam exhaust from inside the baking chamber .......................................................... 11

5.8 Exhaust ventilation ...................................................................................................... 11

5.9 Starting up ................................................................................................................... 11

5.10 Factory settings ...................................................................................................... 12