Table of contents

1. Safety precautions ........................................................................................................................1

Explanation of symbols....................................................................................................................1

List of symbols.................................................................................................................................2

Warning・Cautions .........................................................................................................................3

2. Before operating the unit..............................................................................................................4

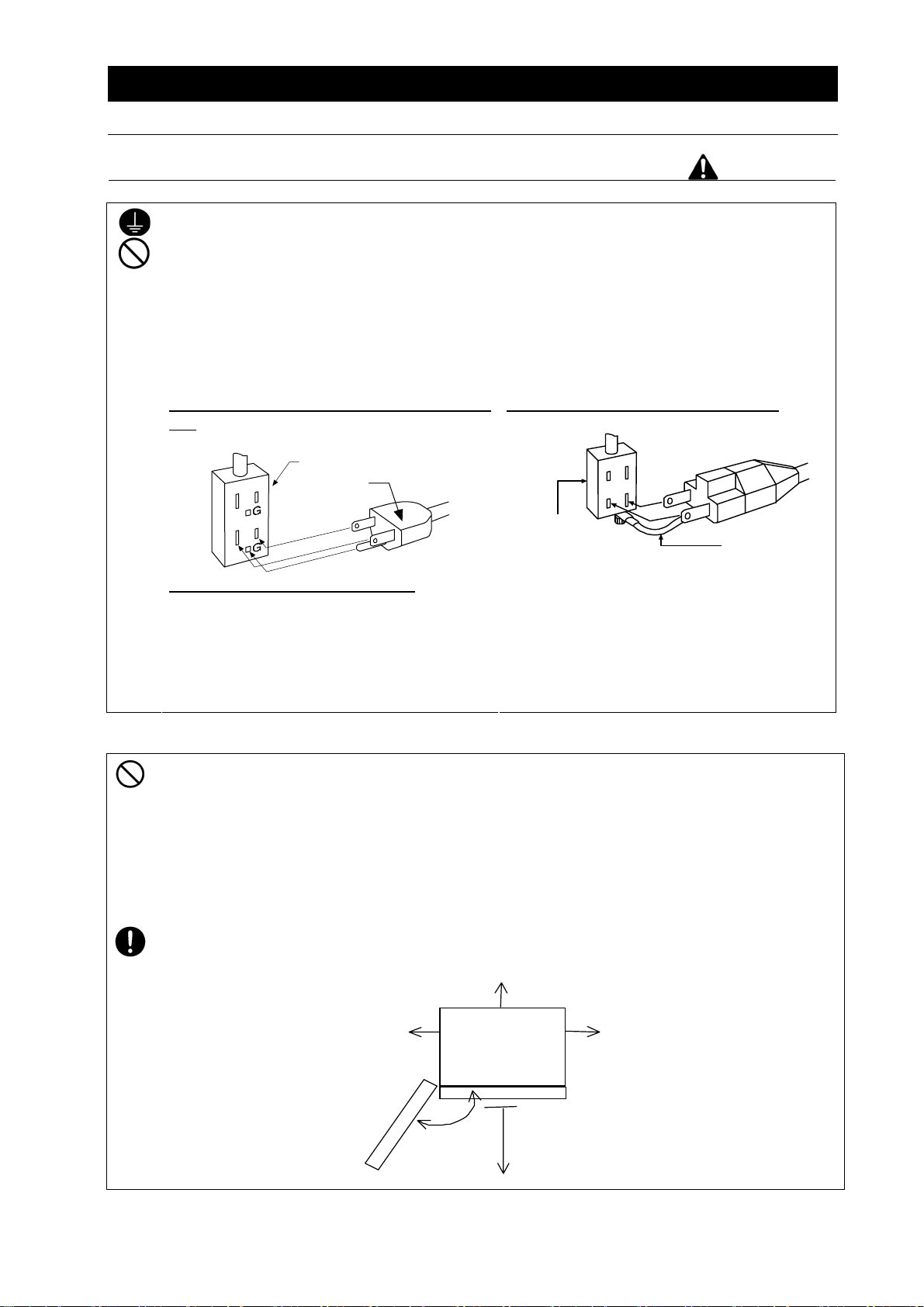

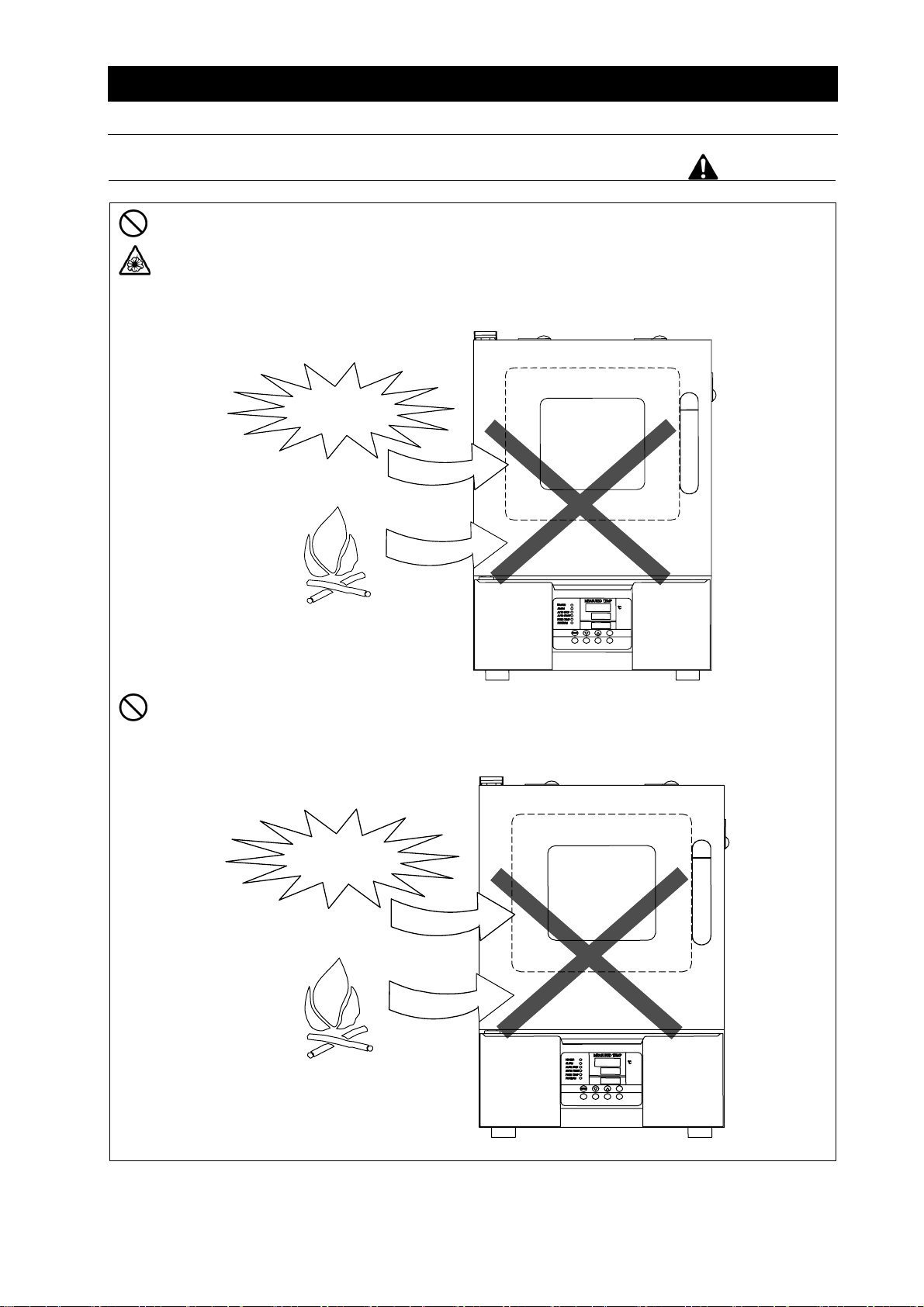

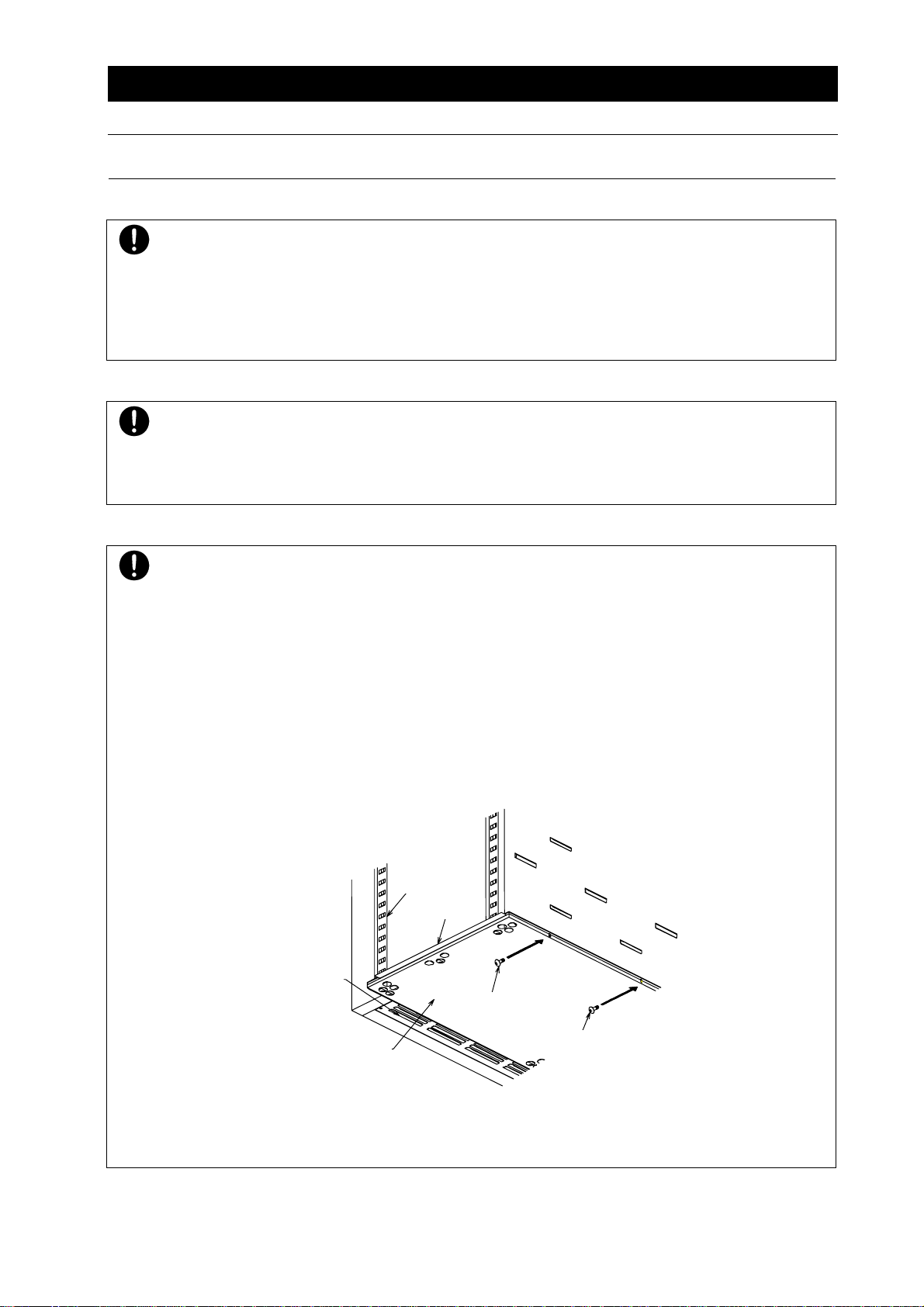

Precautions when installing the unit ................................................................................................4

3. Names and functions of parts ......................................................................................................9

Main body........................................................................................................................................9

Operation panel.............................................................................................................................10

Explanation of characters ..............................................................................................................11

4. Operating procedures.................................................................................................................13

List of operation modes and functions...........................................................................................13

Operation mode・function setting keys and characters ................................................................15

Settings for overheat prevention device ........................................................................................16

Operating procedures (fixed temperature operation).....................................................................17

Operating procedures (quick auto stop operation) ........................................................................18

Operating procedures (auto stop operation)..................................................................................19

Operating procedures (auto start operation)..................................................................................21

Preparing a program......................................................................................................................23

Program repeat operation..............................................................................................................28

Programming sheet .......................................................................................................................29

Useful functions (calibration offset function) ..................................................................................31

Useful function (lock function) .......................................................................................................32

5. Cautions on handling..................................................................................................................33

6. Maintenance procedures ............................................................................................................35

Daily inspection/maintenance........................................................................................................35

7. When the unit is not used for a long time or when disposing.................................................36

When the unit is not used for a long time or when disposing.........................................................36

Notes about disposition .................................................................................................................36

8. Troubleshooting ..........................................................................................................................37

Safety device and error codes.......................................................................................................37

When a malfunction is suspected..................................................................................................38

9. After sales service and warranty................................................................................................39

When requesting a repair ..............................................................................................................39

10. Specifications ............................................................................................................................40

11. Wiring diagram...........................................................................................................................41

12. List of replacement parts..........................................................................................................42

13. List of dangerous materials......................................................................................................43

14. Standard installation manual....................................................................................................44