Locker Controller ELS ASSIGN Touch Technical Manual

Locker Controller ELS ASSIGN Touch Technical Manual ......................................................................... 3

Product description............................................................................................................................. 3

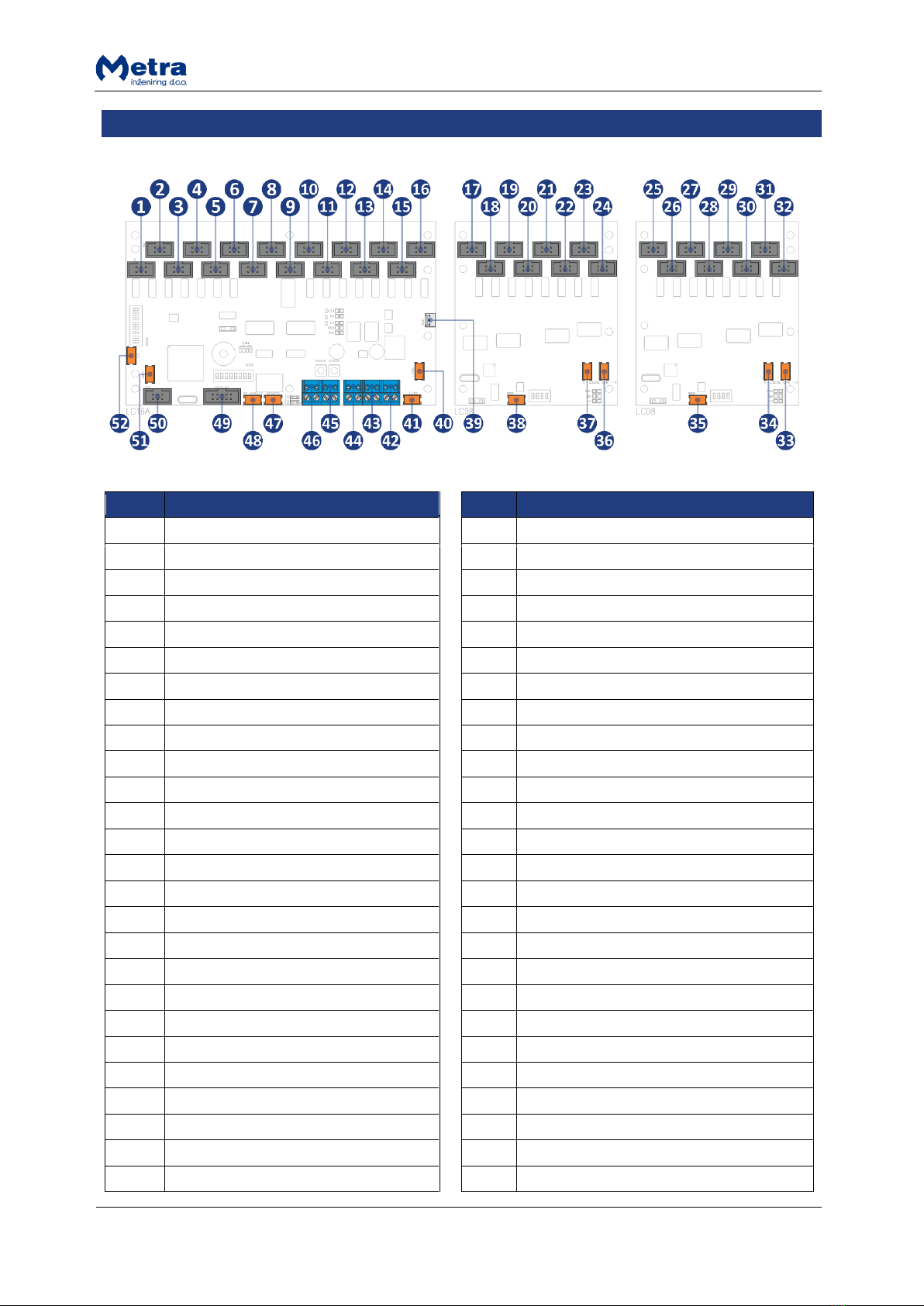

Basic Parts ........................................................................................................................................... 4

Locker Controller PCB with two extension modules and connecting PCB ..................................... 4

Emergency Open Push-button (optional)....................................................................................... 4

Installation .......................................................................................................................................... 4

Standalone configuration ............................................................................................................... 4

Full network configuration ............................................................................................................. 5

Connections ........................................................................................................................................ 6

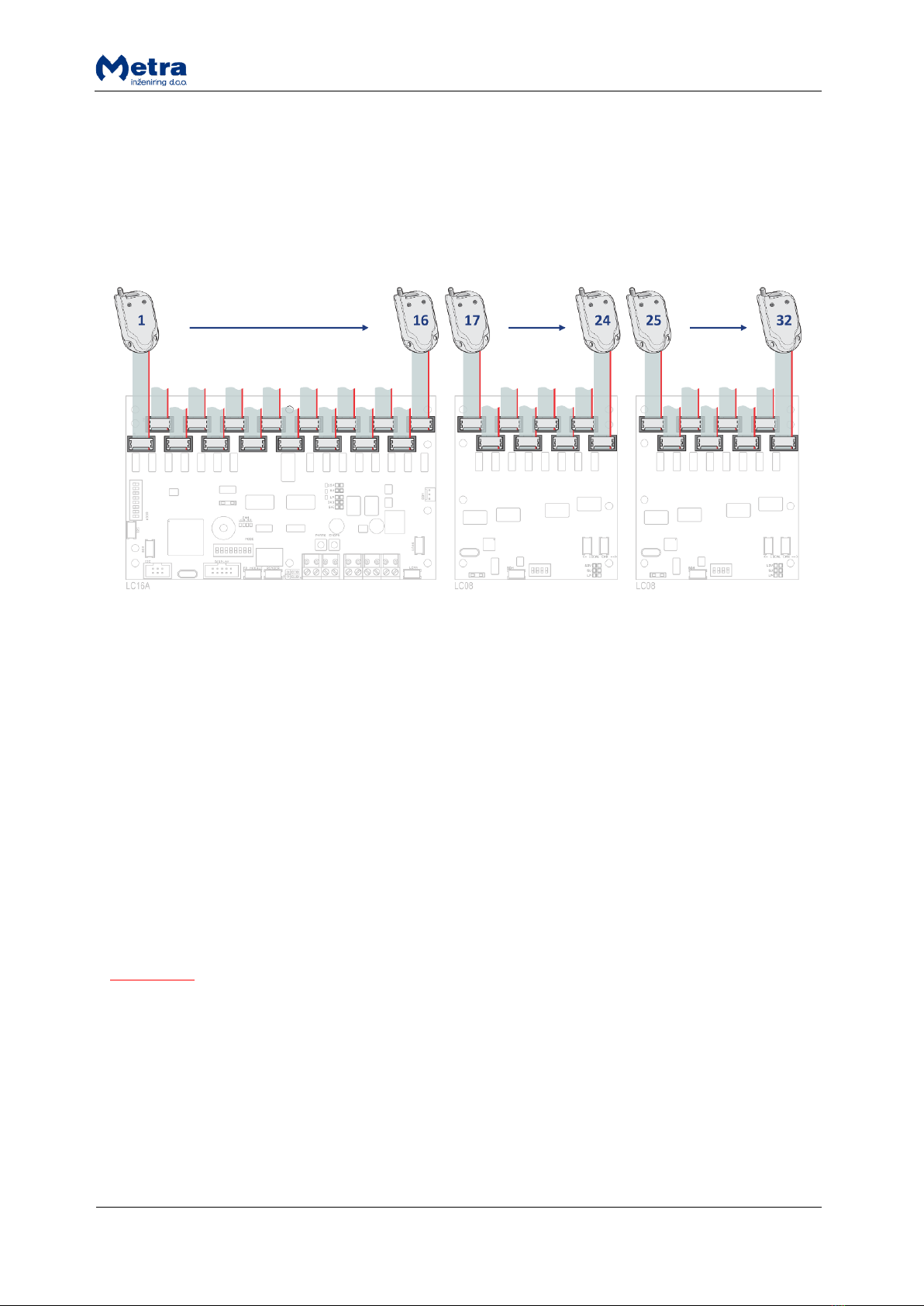

Connecting Locker Extension Modules........................................................................................... 7

Locker Extension Module setting ................................................................................................... 7

Connecting Electronic Locks ........................................................................................................... 8

Power supply connection (Locker Controller without distribution board) .................................... 8

Power supply connection (Locker Controller with distribution board).......................................... 9

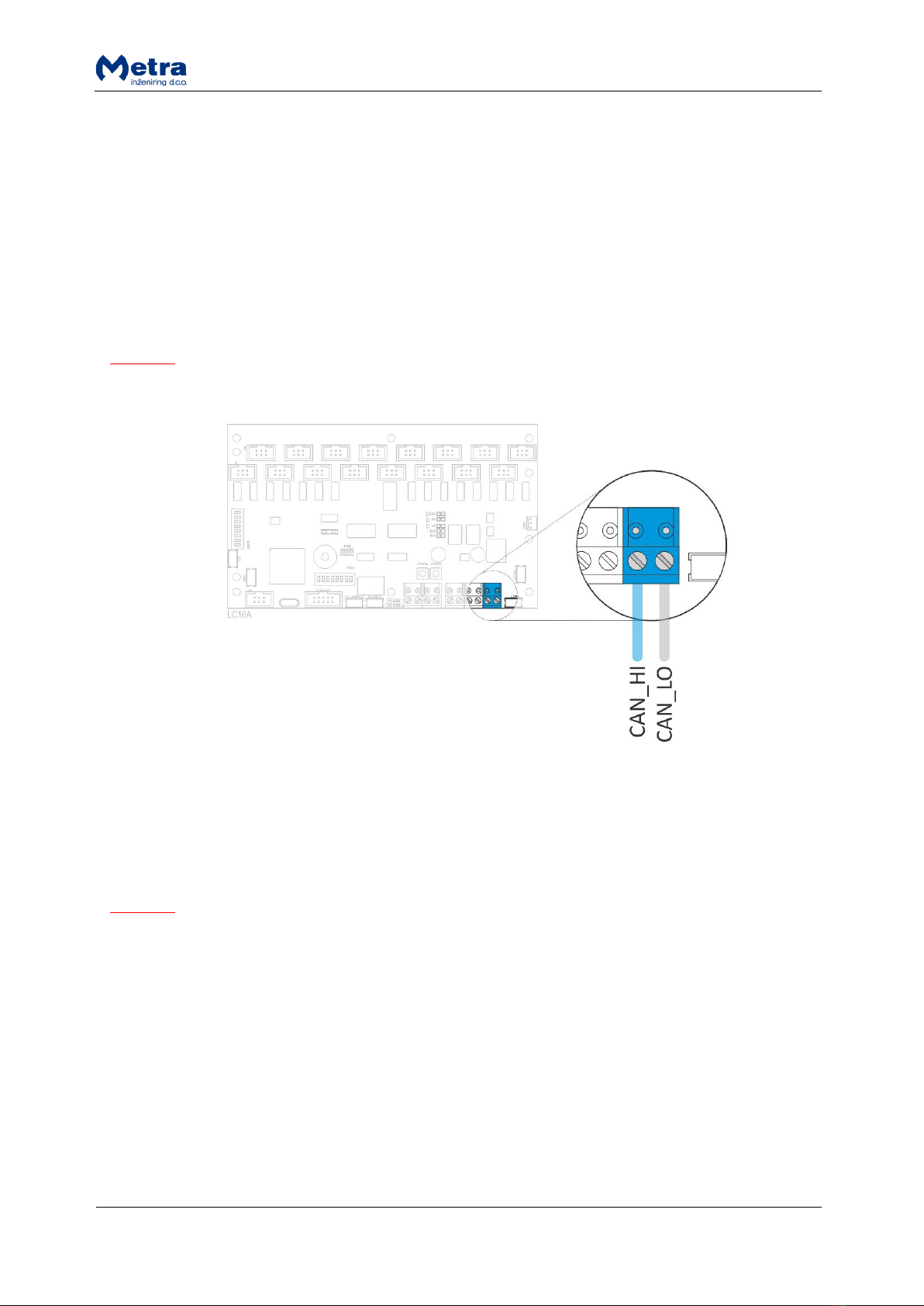

Metra NET Network connection (Locker Controller without distribution board)........................ 10

Metra NET Network connection (Locker Controller with distribution board) ............................. 10

External emergency open pushbutton connection (optional) ..................................................... 11

DIP switch settings ............................................................................................................................ 12

Network address........................................................................................................................... 12

Operating modes .......................................................................................................................... 14

Signalization ...................................................................................................................................... 14

Power-on ...................................................................................................................................... 14

Operation...................................................................................................................................... 15

Network Communication ............................................................................................................. 15

Setting Operational parameters –via Display Touch........................................................................ 16

Setting Operational parameters –via Metra NET Network.............................................................. 16

Emergency Open procedure ............................................................................................................. 16

Internal Emergency open pushbutton.......................................................................................... 17

External Emergency open pushbutton ......................................................................................... 17

Device replacement .......................................................................................................................... 17

Maintenance ..................................................................................................................................... 18

Troubleshooting Guide ..................................................................................................................... 18

Technical data ................................................................................................................................... 18

Appendix ........................................................................................................................................... 18