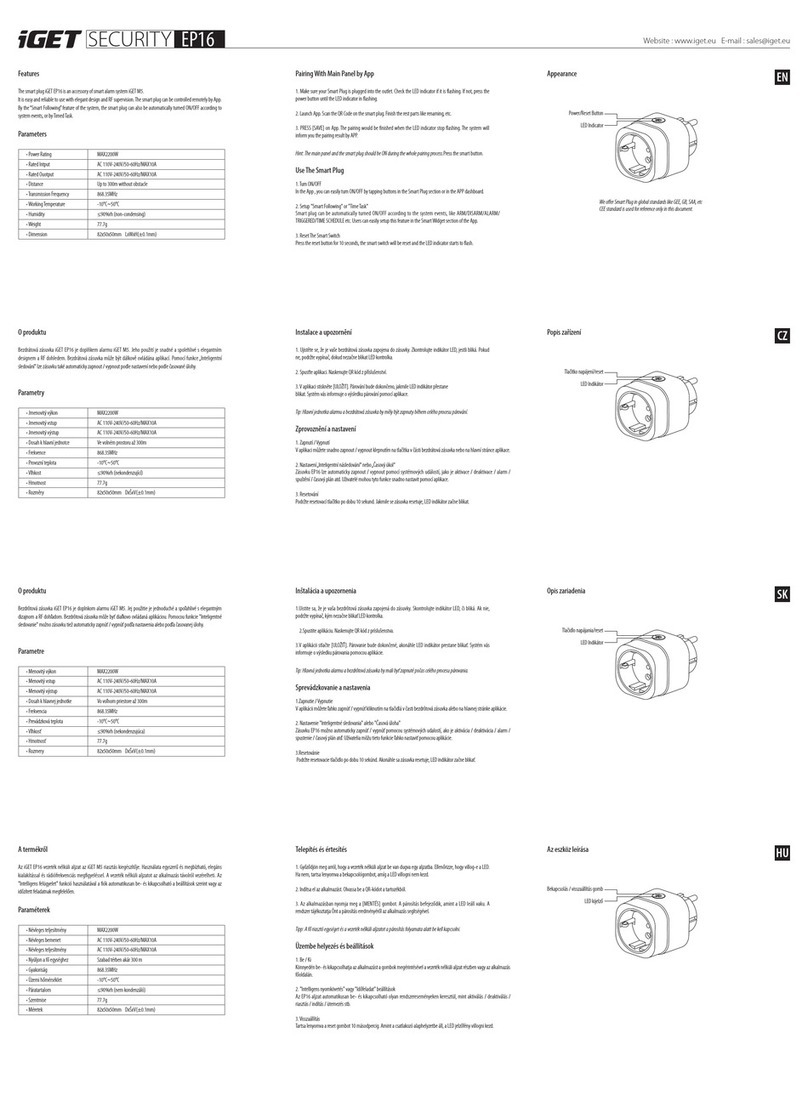

Metrix 5534 User manual

5534/5535/5544/5545 SIGNAL CONDITIONER SENSORS

Installaon Manual

OVERVIEW

These Accelerometer Signal Condioners ac-

cept signals from machine casing mounted

Metrix Seismic Accelerometer or most

competve accelerometers and produce a

4-20 mA current source output proporonal

to the measured variable. The detecon

circuit is responsive to true RMS vibraon

but the output may be scaled either to peak

or RMS units. A green LED indicates sensor

and cable integrity. In the event of sensor

failure, the LED exnguishes and the output

current is driven below 3.6 mA, thereby

signaling a malfuncon. A BNC connector

gives access to the buered input signal for

local analysis. Oponal features for either

model include lters and galvanic isolaon

between input, output and power supply.

INSTALLATION

Each signal condioner is supplied with

either a at mounng base or a DIN rail

adapter. When mounng in the Metrix

Part #7595 explosionproof housing, the

DIN rail adapter version must be used. The

Metrix Part #7876 and Metrix Part #8172

weatherproof housings may be specied

for at base or DIN rail mounted signal

condioners. For the best results, the signal

condioner should be installed within 1000

feet (300 m) of the transducer.

WIRING

SENSOR (Signal Input): Connect the trans-

ducer or charge amp output cable leads

to these terminals. If the transducer is a

self-generang velocity pickup, polarity is

arbitrary unless the signal polarity at the SIG

Doc# M8687 • REV E July 2017

Doc# M8687 • REV E July 2017 Page 2 of 8

OUT BNC connector is important for analysis purposes. If an accelerometer, piezoelectric ve-

locity transducer or charge amp is used, correct polarity must be observed. The cable shield

should be wired to the terminal as follows:

4-20 mA (Current Source Output): Wire the receiving device to

these terminals, observing correct polarity. The total resistance of

the receiver input and wiring must be between 25 and 600 ohms.

SIG OUT (Signal Output): This signal is idencal to the input signal

and is buered for driving remote vibraon analysis instruments. The

terminal block terminals and the BNC connector are wired in parallel.

24 VDC (Power Input): For best results, the sum of the DC power

voltage, plus or minus AC ripple and noise, should be within 20 to 30

volts.

In Class I, Div. 2, Groups A, B, C & D locaons, the signal condioner

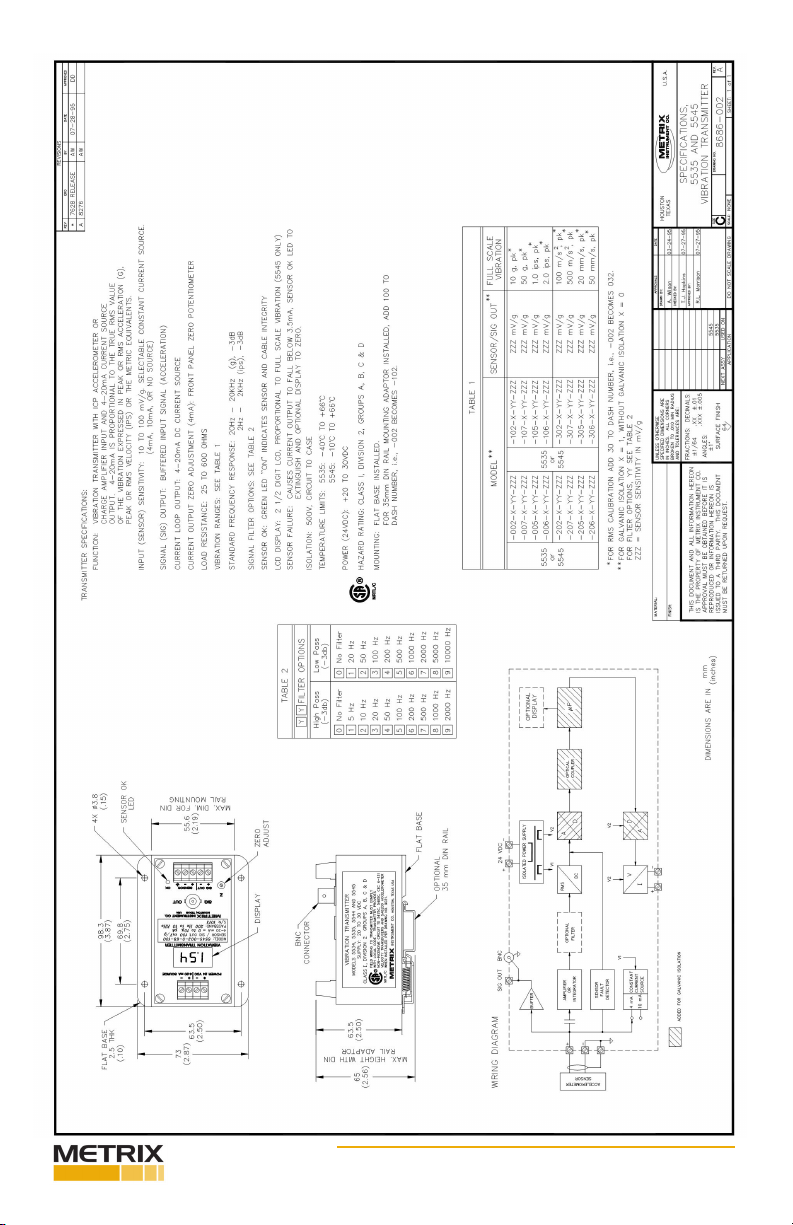

may be wired in accordance with page 4 or drawing 9031. Pages

6 and 7 show wiring diagrams for the 5534/5544 and 5535/5545,

respecvely.

INSTALLATION CONSIDERATIONS

Many variables exist in transmier installaons such as locaon, type of enclosure, proximity

and type of other devices, type and length of wiring, etc.

In general, the transmier should be located in a separate enclosure from electrical systems,

which switch electrical power at large voltages or currents, such as motor controls. Grounded

metal enclosures are muchpreferred to nonmetallic ones in areas where strong AC power or

radio frequency (RF) elds are present, even on an intermient basis. Possible sources of

electrical interference are electrical motors and generators, SCR drives, motor contactors, RF

heaters, engine ignion systems, handheld transceivers (walkie-talkies), cell phones, etc.

Handheld transceivers and cell phones are capable of interfering with the proper opera-

on of the transmier, especially with the enclosure door open and the device held in close

proximity to wiring. The RF ltering components in the transmier protect against normally

expected RF levels, but excessive levels can cause interference. It is good pracce to keep

operang RF sources as far away from electronic devices as possible. In severe cases a fer-

rite core (Metrix Part# 97007-006) may be required to be added on power or signal wiring.

These commonly available devices are either snapped over the wiring or the wiring is looped

several mes through the device.

In some installaons, the 24VDC power source can have signicant electrical noise present.

Common sources of noise are baery chargers, unregulated power supplies and switch-

ing type power supplies. 24VDC relays and solenoids that are not protected with snubbing

diodes or transient protectors will generate voltage transients that may interfere with the

proper operaon of the transmier. Ensure that the 24VDC power source is a regulated type

and free from electrical noise under all condions.

None of the wiring connected to the transmier or other devices within the enclosure

should be run in conduits or cable trays with plant power wiring or control relay and sole-

noid wiring. All inputs and outputs should be wired with shielded cables. Totally shielded

(100% foil) cables are preferred to 90% braided type shielded cables. The shield should be

Doc# M8687 • REV E July 2017 Page 3 of 8

connued to within 1 to 2 inches (25 to 50mm) of the transmier terminals. The shield itself

should be connected to the provided shield terminal. The shield connecon should be as

short as possible. Ensure that all shields are connected only at one end, preferably at the

transmier. Alternate shield connecons are possible such as to instrumentaon grounds,

etc. In general, connecon of shields to earth grounds should be avoided except at one cen-

tral earth grounding point for a complete system as “ground loops” may be created, which

can introduce unwanted power frequency pickup.

SENSOR MALFUNCTION

The signal condioners are provided with a sensor malfuncon detector, which causes the

output current to drop below 3.5 mA, the SENSOR OK LED to exnguish and the Display

(5544 & 5545 only) to read zero, in the event of an open circuit. The 5535 and 5545 also

detect incorrect polarity or shorted cable condions.

CALIBRATION

NULL OFFSET

The oset calibraon can be checked as follows:

Disconnect the transducer cable leads from the signal condioner and connect the following

in its place:

• Model 5534, 5544: Short circuit transducer connecons, except for -40X, -50X,

-60X and -70X (piezovelocity) units which require a resistor as specied for Models

5535 & 5545.

• Model 5535, 5545: Tie the transducer connecons together as follows:

4mA sensor current source condioners — 2.49K ohm resistor

10mA sensor current source condioners — 1K ohm resistor

No sensor current source condioners — short circuit

To adjust, remove the plasc plug from the Z (Zero) control and adjust the laer to obtain

exactly 4 mA output. Remove the short (or the resistor) and reconnect the transducer cable.

SPAN

The 20 mA output (SPAN) is factory set to the full scale value indicated on the nameplate

and is not eld adjustable. The most reliable way to check the calibraon of the sensor and

signal condioner as a system is to compare the indicated vibraon with an independent,

accurate vibraon measurement at the same locaon.

FORMULA: Measured mA - 4 mA

20 mA - 4 mA

EXAMPLE:

Measured mA Full Scale Vib Actual Vib

<3.5 1.0 ips, pk Sensor fault

4.0 1 .0 i p s , p k 0.0 ips, pk

12.0 1.0 ips, pk 0.5 ips, pk

20.0 1.0 ips, pk 1.0 ips, pk

STARTUP CURRENT

The signal condioners employ a DC-DC converter. As with all converters of this nature, a

large current spike occurs at startup. The current spike has a peak of 100 mA and lasts for

40 ms. Care should be exercised when wiring several units onto one supply. Power supplies

without adequate capacity will not allow the units to start properly. The internal power sup-

ply fuse may open as a result of this condion.

Doc# M8687 • REV E July 2017 Page 4 of 8

Doc# M8687 • REV E July 2017 Page 5 of 8

Doc# M8687 • REV E July 2017 Page 6 of 8

Doc# M8687 • REV E July 2017 Page 7 of 8

Doc# M8687 • REV E July 2017 Page 8 of 8

info@metrixvibraon.com

www.metrixvibraon.com

8824 Fallbrook Dr. Houston, TX 77064, USA

Tel: 1.281.940.1802 • Fax: 1.713.559.9421

Aer Hours (CST) Technical Assistance: 1.713.452.9703

This electronic equipment was manufactured according to high quality stan-

dards to ensure safe and reliable operaon when used as intended. Due to

its nature, this equipment may contain small quanes of substances known

to be hazardous to the environment or to human health if released into the

environment. For this reason, Waste Electrical and Electronic Equipment

(commonly known as WEEE) should never be disposed of in the public waste

stream. The “Crossed-Out Waste Bin” label axed to this product is a reminder

to dispose of this product in accordance with local WEEE regulaons. If you

have quesons about the disposal process, please contact Metrix Customer

Services.

ENVIRONMENTAL INFORMATION

This manual suits for next models

3

Table of contents