Metrix MX2033 User manual

Digital Proximity System

Installaon Manual

1180

Doc# 100545 • REV C (May 2016)

The DPS (Digital Proximity System) family

consists of two devices, the MX2033 and

MX2034. The MX2033 is a convenonal

3-wire driver while the MX2034 is a two-

wire current loop transmier. Users can con-

gure either unit to measure peak-to-peak

vibraon, gap distance, or rotaonal speed.

These products are used in conjuncon with

a proximity probe and extension cable to

measure the vibraon levels, gap distances,

or rotaonal speed of machinery shas.

Users can also congure the units via a USB

cable and conguraon soware.

Doc# 100545 • REV C (May 2016) Page 2 of 16

HIGH VOLTAGE

PRESENT

PROTECTIVE

EARTH NOTE

DANGER or

CAUTION

FUNCTIONAL

GROUND

SAFETY TERMS AND SYMBOLS

Terms that appear in this manual requiring special aenon include:

• WARNING: Warning statements idenfy condions or pracces that could result in injury

or loss of life.

• CAUTION: Cauon statements idenfy condions or pracces that could result in dam-

age to the product, loss or corrupon of data, or damage to the environment or other

property.

• NOTE: Notes idenfy material of special interest or importance to the user, not including

cauons or warnings.

Symbols that may appear on the product and/or in this manual include:

GENERAL SAFETY SUMMARY

Review the following safety precauons to avoid injury and prevent damage to this product

or any products connected to it.

• USE ONLY AS SPECIFIED

To avoid potenal hazards, use this product only as specied. Only qualied personnel

should perform installaon and uninstallaon procedures.

• OBSERVE ALL TERMINAL RATINGS

To avoid re or shock hazard, observe all rangs and markings on the product. Consult

the individual secons of this manual for further rangs informaon before making con-

necons to the product.

• AVOID EXPOSURE TO CIRCUITRY

Do not touch exposed electrical connecons and components when power is present.

• DO NOT OPERATE WITH SUSPECT FAILURES

If you suspect there is damage to this product, have it inspected by qualied personnel.

Doc# 100545 • REV C (May 2016) Page 3 of 16

RECEIVING, INSPECTING AND HANDLING THE SYSTEM

Metrix ships the probe, extension cable, and driver as separate units that the user intercon-

nects at the installaon site. Carefully remove all equipment from the shipping containers

and inspect it for shipping damage. If you see shipping damage, le a claim with the carrier

and submit a copy to Metrix Instrument Co. Include part numbers and serial numbers on all

correspondence. If no damage is apparent and the equipment is not going to be used imme-

diately, return the equipment to the shipping containers and reseal unl ready for use. Store

the equipment in an environment that is free from potenally damaging condions such as

extreme temperature, excessive humidity, or a corrosive atmosphere.

OVERVIEW

The Metrix Digital Proximity System comes in two versions:

• MX2033 – 3-wire proximity driver

• MX2034 – 2-wire, loop-powered proximity transmier

The followings secons cover each of these in more detail.

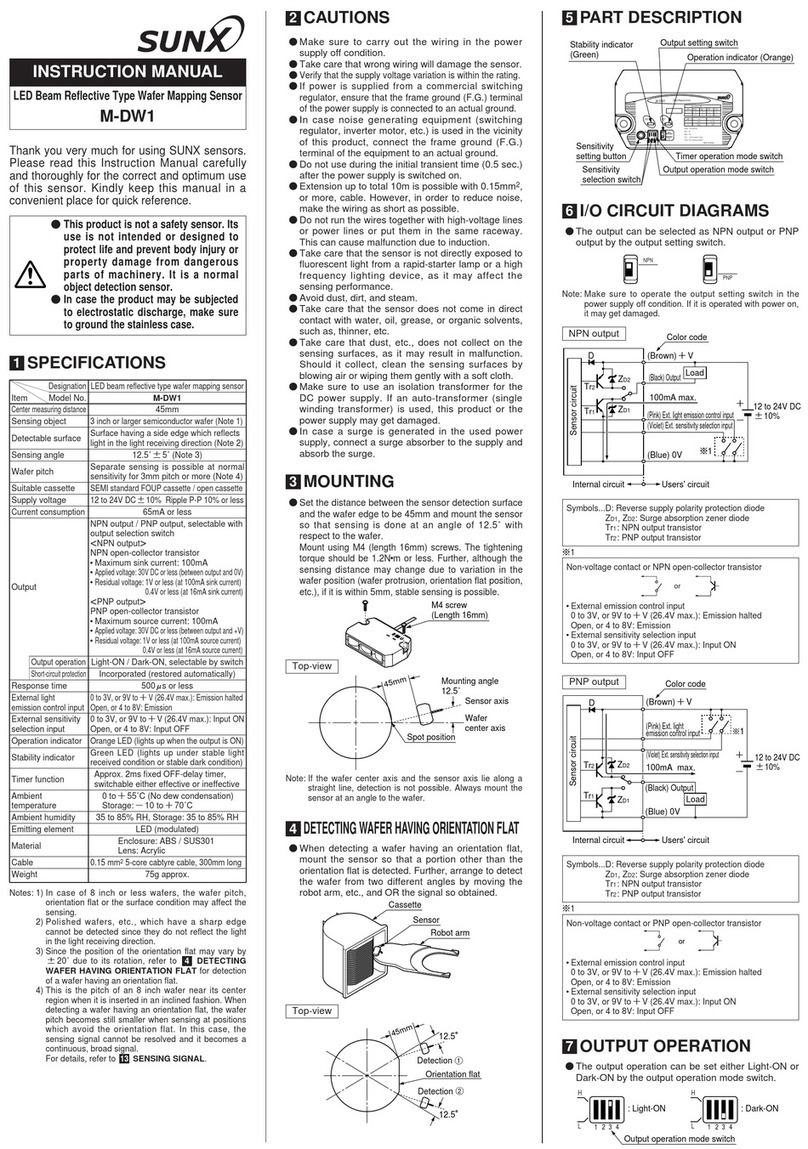

MX2033 Three-Wire Proximity Driver

The MX2033 signal output is compable with industry-standard connuous-vibraon moni-

toring systems and is the format specied in API Standard 670. It uses -24VDC excitaon

and provides the output signal in mV/mm, typically 7.87 mV/mm (200mV/mil) for 5 mm and

8mm probes and 3.94 mV/mm (100 mV/mil) for 11 mm probes.

MX2034 Two-Wire Vibraon / Posion / Speed Transmier

The MX2034 signal format is for use when vibraon, axial posion, or rotaonal speed

measurements will be directly connected to a PLC, DCS, SCADA system, or other instrumen-

taon that accepts an ISA standard 4-20 mA signal, without the use of a separate monitor

system. It is powered by +24 VDC, supplied within the current loop. The device is user-pro-

grammable to funcon as either a radial vibraon transmier (where the 4-20 mA signal is

proporonal to peak-peak vibraon amplitude), as an axial posion transmier (where the

4-20 mA signal is proporonal to average probe gap) or as a rotaonal speed transmier

(where the 4-20mA signal is proporonal to sha speed). For convenience when connecng

to signal analyzers, portable data collectors, and test instrumentaon, the raw vibraon /

speed signal is available at a short-circuit protected BNC connector.

INSTALLATION

Probe Installaon

Mount the probe in a simple bracket, such as the Metrix Model 7646, in a tapped hole in

the bearing cap or by means of a Metrix Model 5499 Probe Housing. The laer arrangement

provides an easy means to adjust the probe air gap, especially where the target is some

distance from the outside surface of the machine.

When inserng the probe through the machine case or bearing cap, the signal voltage may

vary widely before the proper gap is obtained. Therefore, be sure the gap is within 0.07” (1.8

mm) of the target before aempng to set the gap electrically. If possible, set the probe gap

while the machine is shutdown, to avoid the danger of damaging the probe in the event that

it touches the sha.

Doc# 100545 • REV C (May 2016) Page 4 of 16

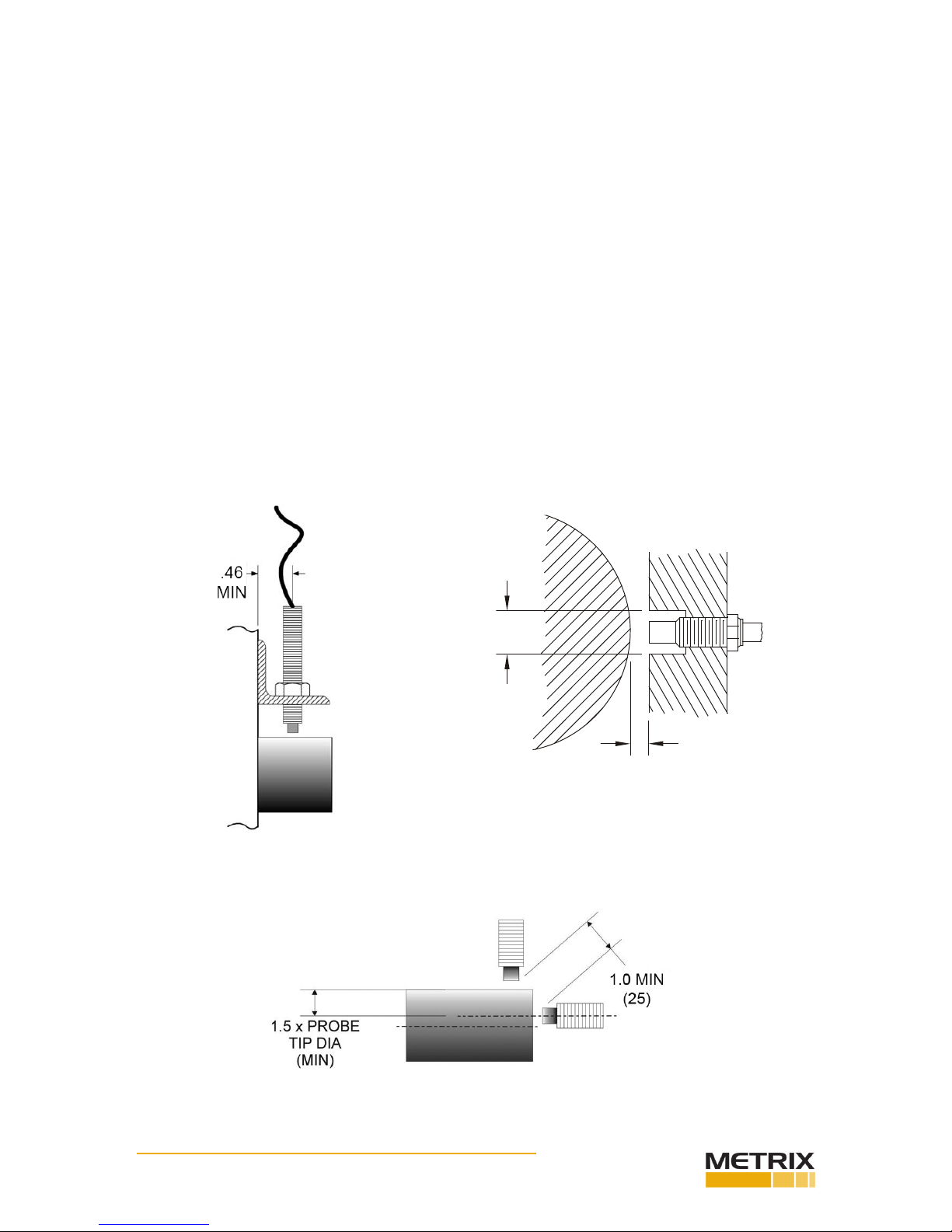

Figure 1: Clearance dimensions for standard 5mm and 8mm radial vibraon measurements.

(Tight View can be closer)

Figure 2: Minimum distance between probe ps.

(Tight View can be closer)

Connect the probe to the driver/transmier using the proper coax extension cable. If a con-

nector must be replaced, the overall length of the probe or extension cable can be reduced

by 2” total without adversely aecng the calibraon and linearity. Insulate the probe con-

nector/extension cable connector juncon with the Metrix 8973 connector insulator.

Radial vibraon measurements

For radial vibraon measurements, mount the probe perpendicular to the sha with the

probe p approximately 0.050” (1.25 mm) from the sha surface. Provide the probe p with

sucient clearance from surrounding metal to prevent an erroneous output. As a minimum,

the clearance diameter should be 0.75” (19 mm) for the full length of the probe p. See

Figure 1. You can set the probe gap “electrically” to the center of its measurement range by

observing the DC output voltage at the BNC connector on the MX2034 or the terminal block

connecon on the MX2032 / MX2033 with an isolated meter. Adjust the probe gap to obtain

-10 VDC, which corresponds to a gap of approximately 0.050” (1.25 mm). The preferred

stac gap range is 0.035” to 0.050”. This gap corresponds to a voltage of -7.0 VDC to -10

VDC. To prevent cross-feed between two probes mounted in the same vicinity, maintain a

minimum 1.0” (25 mm) spacing between the probe ps. See Figure 2.

0.75” (19 mm)

MIN

GAP

Doc# 100545 • REV C (May 2016) Page 5 of 16

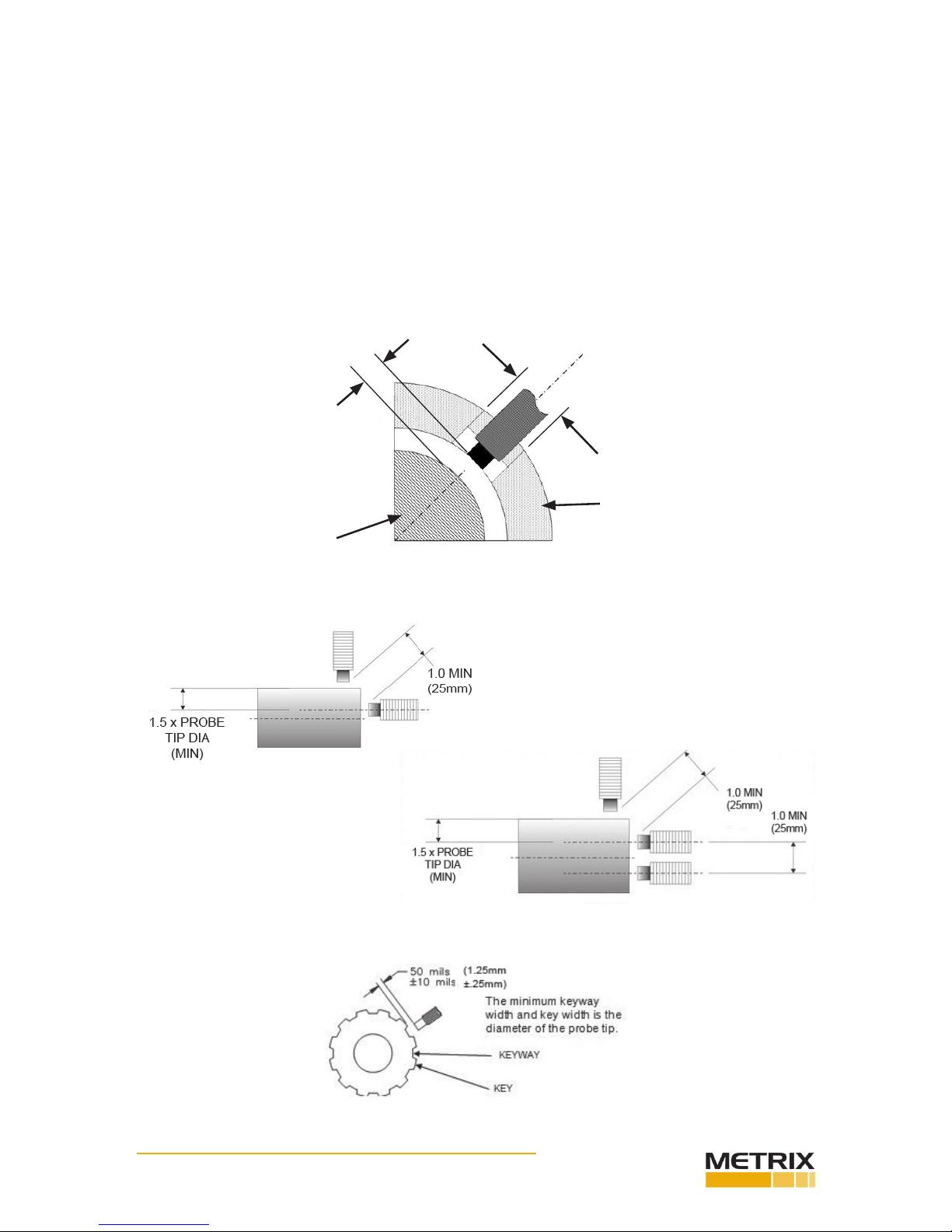

Figure 3: Key dimensions for thrust measurements

Thrust measurements

For thrust measurements ensure the thrust range is within the probe range. Move the ma-

chine to ensure the thrust range is set properly within the probe linear range.

For posion (thrust) measurements, mount the probe with the probe axis parallel to the

sha and with the probe p approximately 0.050” (1.25 mm) from the end of the sha. For

11 mm diameter probes, this distance is approximately 0.088”(22mm). Provide the probe p

with sucient clearance from surrounding metal to prevent an erroneous output. As a mini-

mum, the clearance diameter should be 0.75” (19 mm) for the full length of the probe p.

For an 11mm probe, the minimum clearance should be 0.88” (22 mm). See Figure 1. You

can set the probe gap “electrically” to the center of its measurement range by observing the

DC output voltage at the BNC connector with an isolated meter. Adjust the probe gap to ob-

tain -10 VDC, which corresponds to a gap of approximately 0.050” (1.25 mm). The preferred

stac gap range is 0.035” to 0.050”(0.8 to 1.25 mm). This corresponds to a gap voltage of

-7.0 VDC to -10 VDC. Note that for 11 mm probes, the voltage is -9 VDC. To prevent cross-

feed between two probes mounted in the same vicinity, maintain a minimum of 1.0” (25

mm) spacing between the probe ps. For 11 mm probes, this distance is approximately 1.5”

(38mm). See Figure 3.

Speed measurements

For RPM measurements, mount the probe with its axis radial to the sha with its p approxi-

mately 0.050” (1.25 mm) from the outermost surface of the sha. The probe p must be

provided with sucient clearance from surrounding metal to prevent an erroneous output.

As a minimum, the clearance diameter should be 0.75” (19 mm) for the full length of the

probe p. See Figure 4. For the exact gapping procedure, see the secon concerning calibra-

on. To prevent cross-feed between two probes mounted in the same vicinity, at least 1.0”

(25 mm) spacing between the probe ps should be maintained. See Figures 5, 6.

The minimum keyway depth is 0.060” (1.5 mm). The minimum keyway width and key width

is the diameter of the probe p (Figure 7). These minimums will ensure that the transmit-

ter or driver responds properly to the keyway at all RPMs. Some experimentaon may be

required such as adjusng the probe gap or modifying the keyway dimensions.

The probe can be mounted in a simple bracket, such as the Metrix Model 7646, in a tapped

hole in the bearing cap or by means of a Metrix Model 5497PM or 5499 Probe Housing. The

laer arrangement provides an easy way to adjust the probe air gap, especially where the

target is some distance from the outside surface of the machine.

Doc# 100545 • REV C (May 2016) Page 6 of 16

Figure 4

Figure 5

Figure 6

When inserng the probe through the machine case or bearing cap, the signal voltage may

vary widely before the proper gap is obtained. Therefore, be sure the gap is within 0.07” (1.8

mm) of the target before aempng to set the gap electrically. If possible, set the probe gap

while the machine is shutdown, to avoid the danger of damaging the probe in the event that

it touches the sha.

Connect the probe to the transmier using the proper extension cable such that the com-

bined system length of probe + cable matches the transmier conguraon (refer to Metrix

datasheet 1028003, ordering opon B). Do not change the length of the extension cable

from the system, as such acon will adversely aect the calibraon and linearity. If a con-

nector must be replaced, the overall length of the cable can be reduced by 2” without harm.

Insulate the probe connector / extension cable connector juncon with the Metrix Model

8973 connector insulator.

Figure 7

HOUSING

0.75” (19mm)

Min Clearance

SHAFT

GAP

Doc# 100545 • REV C (May 2016) Page 7 of 16

Extension Cable Installaon

Route the extension cable using the following guidelines:

• Check that the Driver/Transmier, extension cable, and probe belong to the same system

(e.g. Metrix 10000 Series or Metrix 3300 series) and that the total system length is cor-

rect (5m or 9m).

• Secure the extension cable to supporng surfaces or places in conduit. Make certain the

cable is not kinked, scraped, nor bent beyond the minimum recommended radius of 1”.

• Secure coaxial connectors between the extension cable and the proximity probe. Con-

necon should be “nger ght” with an addional quarter turn using an open ended

9/32” wrench or equivalent.

• Insulate the connecon between the probe lead and the extension cable by wrapping the

connector with Teon tape and the Metrix 8973 connector insulator. Avoid electrical tape

for insulaon because of its tendency to melt and detach over me.

Driver / Transmier Installaon

Mount the driver or transmier in a suitable enclosure in a locaon that is compable with

its environmental specicaons. Refer to the datasheet for the environmental specicaons.

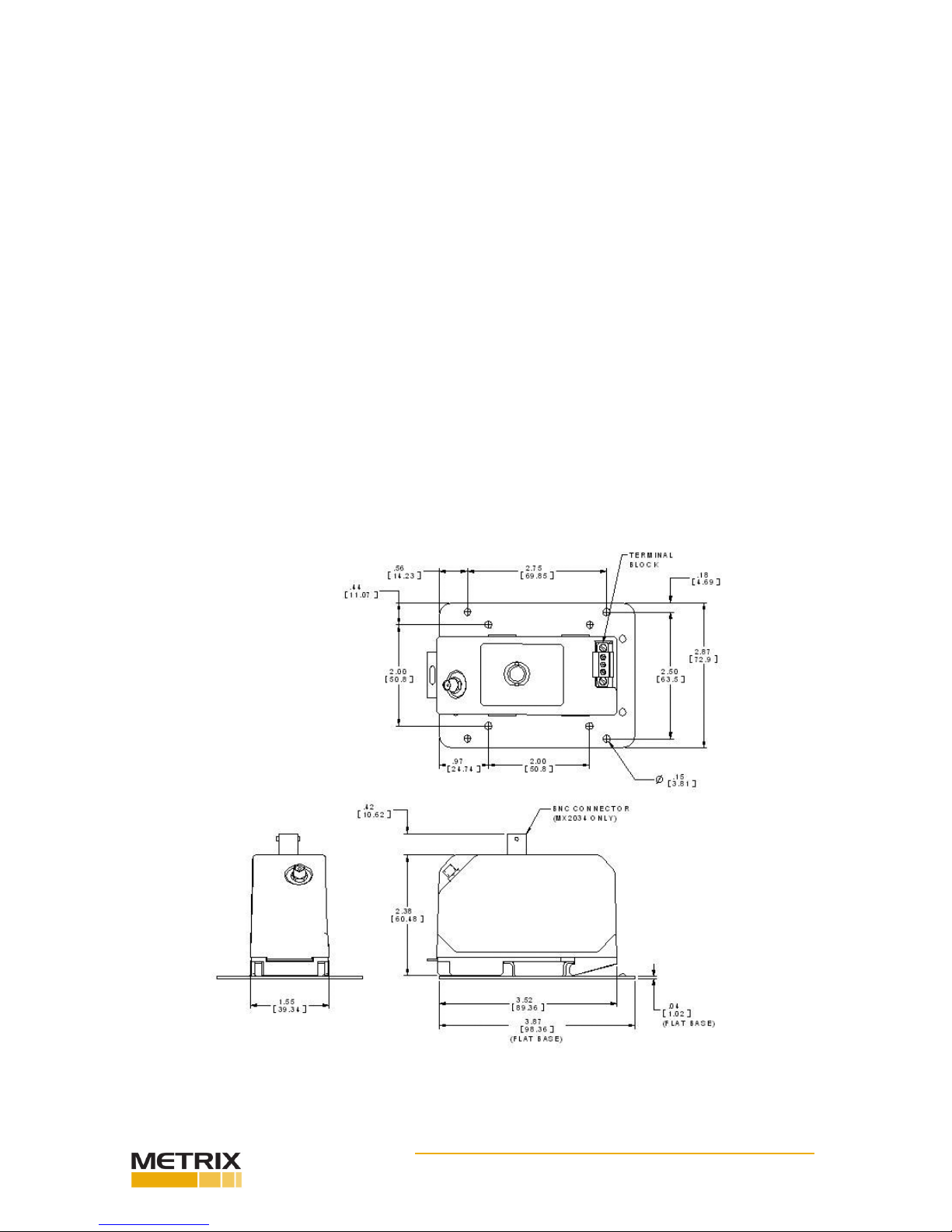

The driver or transmier comes as a DIN rail mount. The below gure shows the unit with

the oponal at base mounng plate, Metrix part number 9647. The 9647 mounng plate

has two dierent hole paerns. One is for Metrix 5465/5488 transmiers and the other pat-

tern is for Metrix 5533, MX3300 and most other manufacturers’ probe drivers.

Figure 8: Key dimensions for at base installaon.

Doc# 100545 • REV C (May 2016) Page 8 of 16

MX2033 Field Wiring Installaon

The driver circuit is insulated from ground by its plasc housing. If grounding of the driver

is required, a jumper wire can be used to connect the COM terminal to one of the mount-

ing screws. Proper aenon must be given to other connecons in the circuit to prevent

unwanted ground loops which can cause improper operaon.

MX2034 Field Wiring Installaon

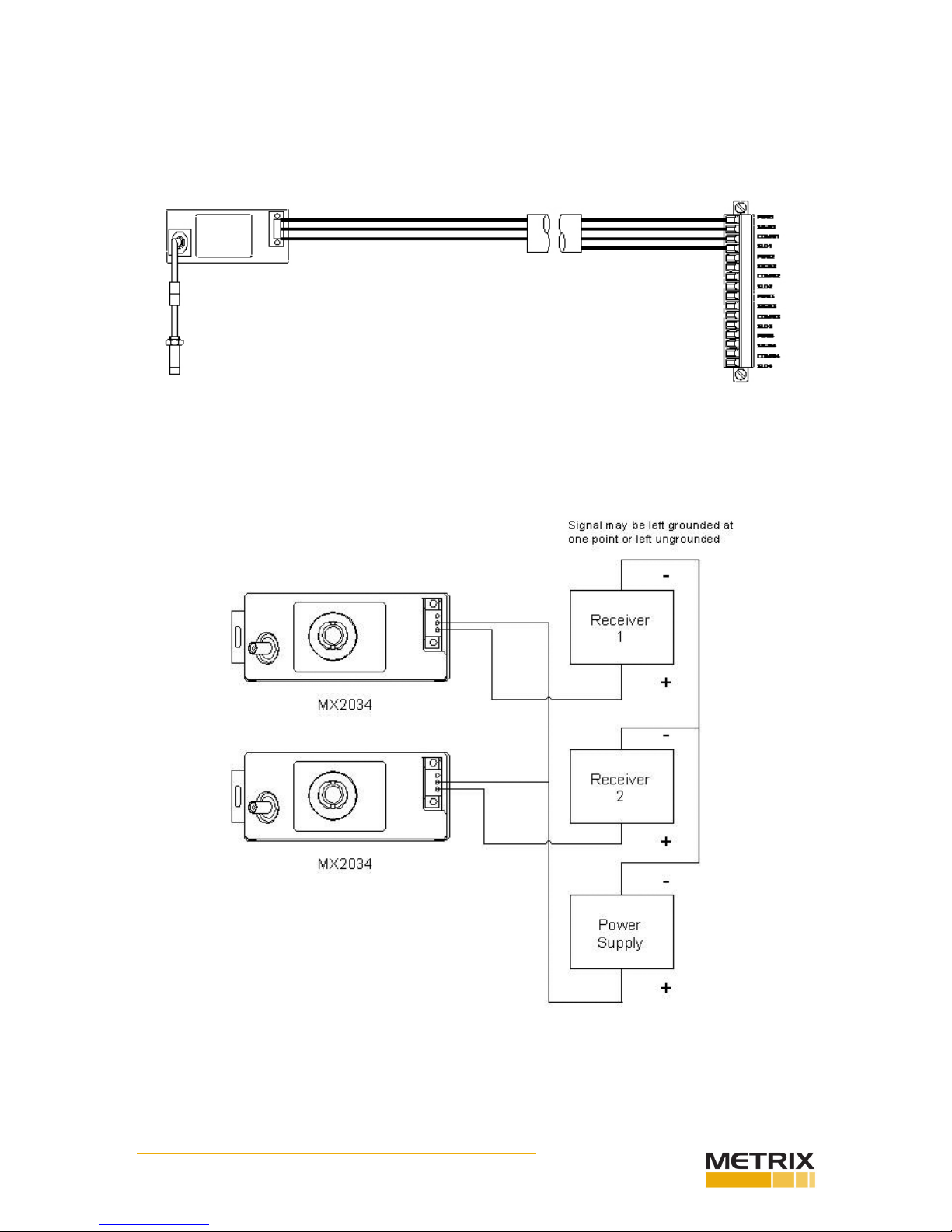

You can wire the MX2034 transmier with one or mulple receivers as shown in Figure 9 or

Figure 10.

Figure 9: MX2034 wiring with individual receivers

Doc# 100545 • REV C (May 2016) Page 9 of 16

Figure 10: MX2034 wiring with mulple receivers

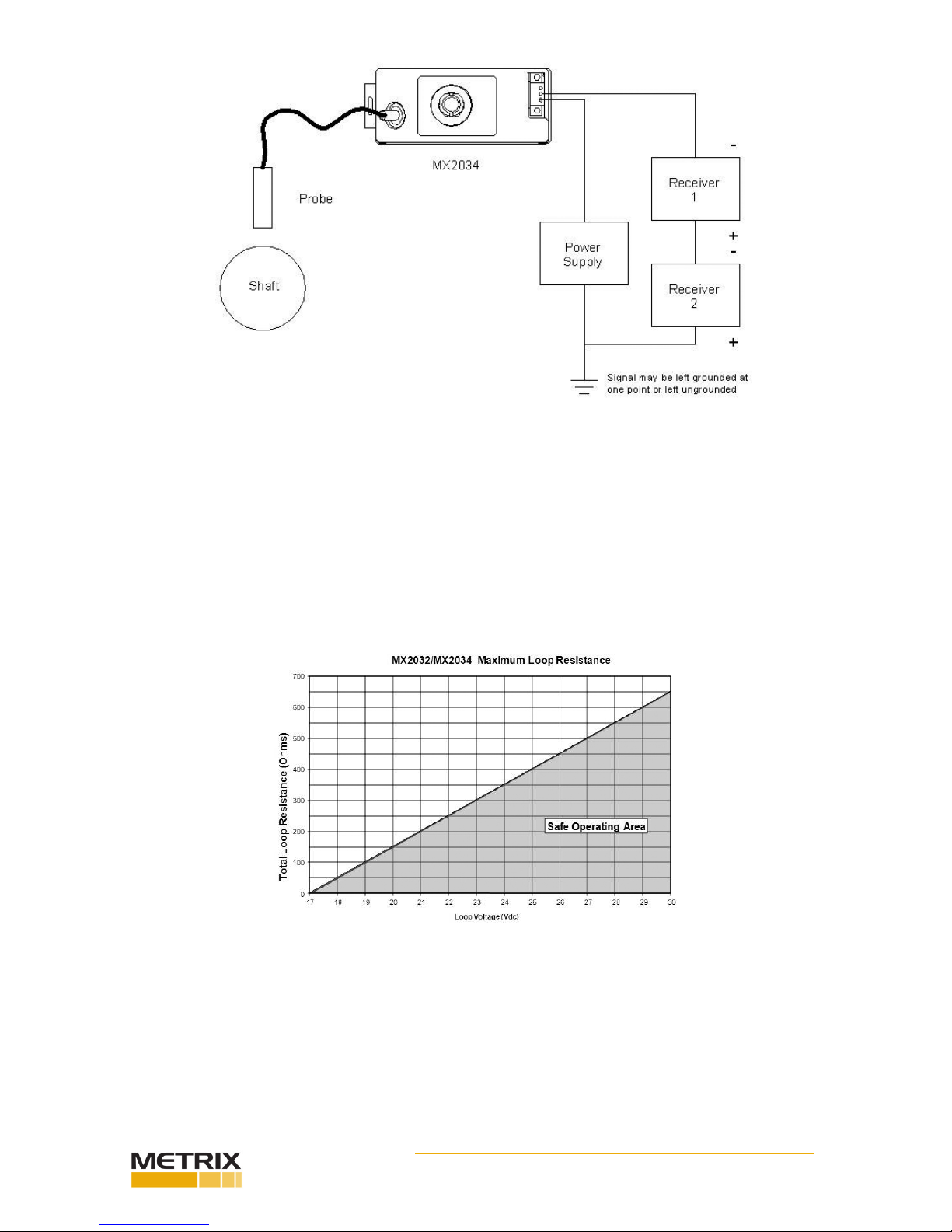

Connect the eld wiring (16 to 22AWG) in accordance with the appropriate diagrams. For

the MX2034, the minimum power supply voltage is 17 V plus 1 volt for each 50 Ω of loop

resistance. See Graph 1.

Doc# 100545 • REV C (May 2016) Page 10 of 16

HAZARDOUS AREA INSTALLATIONS

MX2034 (DPS) General Requirements

Connect the eld wiring in accordance with Metrix drawing 100508 for ATEX installaons and

100506 for North American installaons.

Baseefa 05ATEX0195X Exia; Intrinsically Safe

II 1G Ex ia IIC T4 Class I, Div. 1, Groups A, B, C,D

(-40°C < Tamb < 85°C) Temp Code T4 (–40°C ≤ Ta ≤ +85°C)

SPECIAL CONDITIONS OF SAFE USE

Mount the DPS in a separate enclosure capable of withstanding a 7 joule impact and provid-

ing a minimum ingress protecon of IP54.

Consider that the DPS is not capable of withstanding the insulator test required by Clause

6.4.12 of EN50020:2002 when installing the DPS.

The DPS cannot be repaired in the eld. Replace a failed DPS with an equivalent unit.

Do not expose the DPS to dust condions.

Do not install the DPS where it may be subjected to mechanical and excessive thermal

stresses or where it may be aacked by exisng or foreseeable aggressive substances.

Install the DPS such that its terminals are protected to at least IP20.

Protect the plasc DPS enclosure from impact and fricon.

Perform a risk assessment in accordance with Clause 10 of EN60079-25 and install lightning

protecon arresters as deemed necessary.

WARNING – SUBSTITUTION OF COMPONENTS MAY IMPAIR INTRINSIC SAFETY. AVERTISSEMENT:

LA SUBSTITUTION DE COMPOSANTS PEUT COMPROMETTRE LA SECURITE INTRINSEQUE.

WARNING – TO PREVENT IGNITION OF FLAMMABLE OR COMBUSTIBLE ATMOSPHERES, DIS-

CONNECT POWER BEFORE SERVICING.

WARNING – TO PREVENT IGNITION OF FLAMMABLE OR COMBUSTIBLEATMOSPHERES, READ,

UNDERSTAND, AND ADHERE TO THE MANUFACTURER’S LIVE MAINTENANCE PROCEDURES.

Doc# 100545 • REV C (May 2016) Page 11 of 16

Intrinsically Safe Installaon in Hazardous Environments

The driver requires a minimum of 17 VDC for proper operaon. The voltage drop across the

specied zener barriers on the installaon drawings with a 20 mA loop current is 8.1 VDC. The

minimum loop power supply voltage required is 25.1 VDC plus 1 volt for each 50 Ω of loop

resistance. The maximum loop power supply voltage that may be applied to the safety barrier

is 26 VDC. Therefore, the maximum loop resistance with a 26 VDC supply is 45 Ω.

Example: Single wire resistance = 5 Ω

Resistance of receiver = 50 Ω

Total loop resistance = 55 Ω

Minimum supply voltage = 55 Ω (1VDC/50 Ω) + 25.1 VDC = 26.2 VDC

Permanent wiring connecon to the Dynamic Signal terminal or BNC connectoris not allowed

under the intrinsic safety cercaon requirements. Table 1 lists recommended zener barri-

ers. Other barrier manufacturers can be used as long as they meet the required parameters

noted on the installaon drawings.

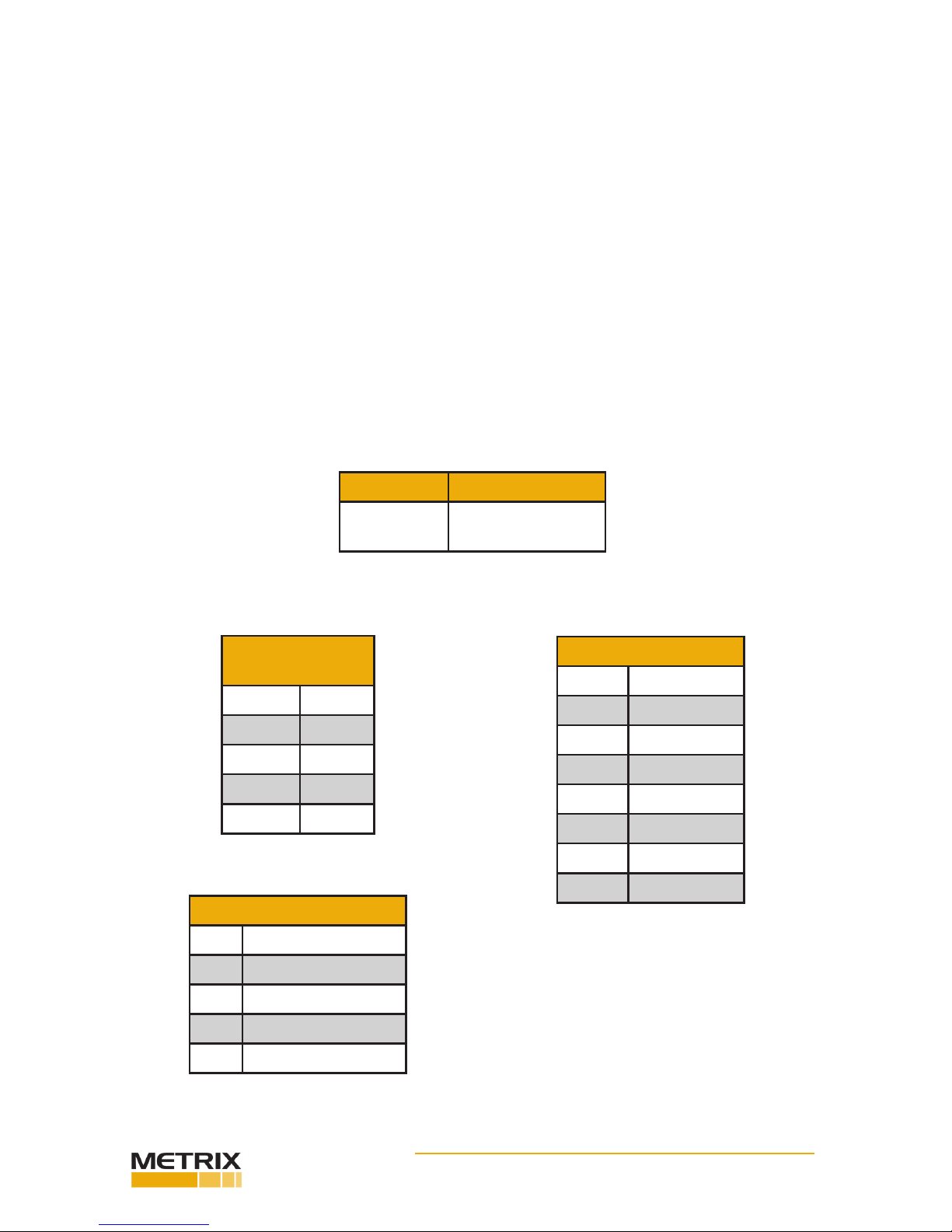

DPS Model MTL Barrier Model

MX2034 MTL 787(+) or

equivalent

Table 1: Recommended Barriers

INPUT/OUTPUT PARAMETERS

Power Terminal

Enty Parameters

Ui28V

Ii93mA

Pi0.66W

Ci18nF

Li0

Table 2: Power Terminal Enty Parameters

UL/CSA Parameters

Voc = 5.36V

Ioc = 93mA

Ca= 62uF

La= 8.5mH

Po= 0.5W

Table 4: Probe Connector

UL/CSA Enty Parameters

ATEX Parameters

Uo5.36V

Io3.64mA

Po20mW

Ci24nF

Li110μH

Co32μF

Lo500μH

Lo/Ro> 1000μ/H/Ω

Table 3: Probe Connector

ATEX Enty Parameters

Doc# 100545 • REV C (May 2016) Page 12 of 16

Installaon in Zone 2 and Div. 2 Areas

Zone 2 Area

Baseefa 06ATEX0113X Ex nA IIC T4 (–40°C ≤ Ta ≤ +85°C)

SPECIAL CONDITIONS OF SAFE USE:

Connect the eld wiring in accordance with Metrix drawing 100515.

When the DPS is being used in accordance with the type of protecon: Ex nA IIC T4 (–40°C ≤

Ta ≤ +85°C), the apparatus must be mounted in an enclosure capable of withstanding a 7 joule

impact (at -40°C if non-metallic) and provide a degree of ingress protecon of at least IP54.

The DPS is cered as a component only and must be installed in a suitable enclosure ac-

ceptable to local authories.

Field wiring from the safe area to the transmier must conform with the local electrical

code. The transmier provides a non-incendive circuit to probe and extension cable, which

therefore require no further electrical protecon.

Do not use Dynamic Signal BNC connector or terminal unless area is known to be non-haz-

ardous.

Transmier is cered as a component only and must be installed in a suitable enclosure ac-

ceptable to local authories.

The driver is not capable of withstanding the insulator test required by Clause 6.4.12 of

EN50020:2002. This must be taken into account when installing the driver.

Div. 2 Area

Class I Division 2 Hazardous Locaons (Non-Incendive), when installed per drawing 100512.

THIS EQUIPMENT IS SUITABLE FOR USE IN CLASS I, DIVISION 2, GROUPS A, B, C, D OR NON-

HAZARDOUS LOCATIONS ONLY.

WARNING - EXPLOSION HAZARD – SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY

FOR CLASS I, DIViSION 2.

AVERTISSEMENT - RISQUE D’EXPLOSION – LA SUBSTITUTIOND E COMPOSANTSP EUTR ENDRE

CE MATERIEL INACCEPTABLE POUR LES EMPLACEMENTS DE CLASSE I, DIVISION 2.

MX2033 Intrinsically Safe Installaon in Hazardous Environments

Baseefa 05ATEX0195X Exia; Intrinsically Safe

II 1G Ex ia IIC T4 Class I, Div. 1, Groups A, B, C,D

(-40°C < Tamb < 85°C) Temp Code T4 (–40°C ≤ Ta ≤ +85°C)

Connect the eld wiring in accordance with Metrix drawing 100509 for ATEX installaons and

100506 for UL/CSA installaons. The driver requires a minimum of 17 VDC for proper opera-

on. The voltage drop across the specied zener barriers on the installaon drawings with a

10 mA supply current is 4.1 VDC. The minimum loop power supply voltage required is 25.1

VDC plus 1 volt for each 50 Ω of loop resistance. The maximum loop power supply voltage

that may be applied to the safety barrier is 26 VDC. Therefore, the maximum loop resistance

with a 26 VDC supply is 45 Ω.

Doc# 100545 • REV C (May 2016) Page 13 of 16

Example: Single wire resistance = 5 Ω

Resistance of receiver = 50 Ω

Total loop resistance = 55 Ω

Minimum supply voltage = 55 Ω (1 VDC/50 Ω) + 25.1 VDC = 26.2 VDC

SPECIAL CONDITIONS OF SAFE USE:

The apparatus must be mounted within a separate enclosure capable of withstanding a 7

joule impact and providing a minimum ingress protecon of IP54.

The transmier is not capable of withstanding the insulator test required by Clause 6.4.12 of

EN50020:2002. This must be taken into account when installing the driver.

The driver cannot be repaired in the eld and must be replaced by an equivalent unit. The

driver is not to be exposed to dust condions.

The driver should not be installed where it may be subjected to mechanical and excessive ther-

mal stresses or where it may be aacked by exisng or foreseeable aggressive substances.

The apparatus enclosure is made from plasc which must be protected from impact and fricon.

Installer must perform a risk assessment in accordance with Clause 10 of EN60079-25 and

install lightning protecon arresters as deemed necessary.

WARNING – SUBSTITUTION OF COMPONENTS MAY IMPAIR INTRINSIC SAFETY.

AVERTISSEMENT: LA SUBSTITUTION DE COMPOSANTS PEUT COMPROMETTRE LA SECURITE

INTRINSEQCJE.

WARNING – TO PREVENT IGNITION OF FLAMMABLE OR COMBUSTIBLE

ATMOSPHERES, DISCONNECT POWER BEFORE SERVICING.

WARNING – TO PREVENT IGNITION OF FLAMMABLE OR COMBUSTIBLE ATMOSPHERES, READ,

UNDERSTAND, AND ADHERE TO THE MANUFACTURER’S LIVE MAINTENANCE PROCEDURES.

INPUT/OUTPUT PARAMETERS

Power Terminal

Enty Parameters

Ui30V

Ii101mA

Pi0.915W

Ci17.6nF

Li110μH

Table 5: Power Terminal

Enty Parameters.

ATEX Parameters

Uo5.36V

Io3.64mA

Po20mW

Ci24nF

Li110μH

Co32μF

Lo500μH

Lo/Ro> 1000μ/H/Ω

Table 6: Probe Connector

ATEX Enty Parameters.

UL/CSA Parameters

Voc = 5.36V

Ioc = 93mA

Ca= 62μF

La= 8.5mH

Po= 0.5W

Table 7: Probe Connector

Intertek Enty Parameters.

Doc# 100545 • REV C (May 2016) Page 14 of 16

Table 8 lists recommended zener barriers. Other barrier manufacturers can be used as long

as they meet the required parameters noted on the installaon drawings.

Installaon in Zone 2 and Div. 2 Areas

Zone 2 Area

Baseefa 06ATEX0113X Ex nA IIC T4 (–40°C ≤ Ta ≤ +85°C)

SPECIAL CONDITIONS OF SAFE USE:

Connect the eld wiring in accordance with Metrix drawing 1113106.

When the apparatus is being used in accordance with the type of protecon: Ex nA IIC T4

(–40°C ≤ Ta ≤ +85°C), the apparatus must be mounted in an enclosure capable of withstand-

ing a 7 joule impact (at -40°C if non-metallic) and provide a degree of ingress protecon of at

least IP54.

Driver is cered as a component only and must be installed in a suitable enclosure accept-

able to local authories.

Field wiring from the safe area to the transmier must conform with the local electrical code.

The transmier provides a non-incendive circuit to probe and extension cable, which there-

fore require no further electrical protecon.

The driver is not capable of withstanding the insulator test required by Clause 6.4.12 of

EN50020:2002. This must be taken into account when installing the driver.

Div. 2 Area

Class I Division 2 Hazardous Locaons (Non-Incendive), when installed per drawing 100512,

sheet 2.

THIS EQUIPMENT IS SUITABLE FOR USE IN CLASS I, DIVISION 2, GROUPS A,B, C, D OR NON-

HAZARDOUS LOCATIONS ONLY.

WARNING - EXPLOSION HAZARD – SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY

FOR CLASS I, DIViSION 2.

AVERTISSEMENT - RISQUE D’EXPLOSION – LA SUBSTITUTIOND ECOMPOSANTSP EUTR ENDRE

CE MATERIEL INACCEPTABLE POUR LES EMPLACEMENTS DE CLASSE I, DIVISION 2.

DPS Model MTL Barrier Model

MX2033 MTL 796(-) or

equivalent

Table 8: Recommended Barriers.

Doc# 100545 • REV C (May 2016) Page 15 of 16

CAUTION: Do not connect test equipment

or cables to the driver unless the area has

been determined to be non-hazardous.

This electronic equipment was manufactured according to high quality stan-

dards to ensure safe and reliable operaon when used as intended. Due to

its nature, this equipment may contain small quanes of substances known

to be hazardous to the environment or to human health if released into the

environment. For this reason, Waste Electrical and Electronic Equipment

(commonly known as WEEE) should never be disposed of in the public waste

stream. The “Crossed-Out Waste Bin” label axed to this product is a reminder

to dispose of this product in accordance with local WEEE regulaons. If you

have quesons about the disposal process, please contact Metrix Customer

Services.

ENVIRONMENTAL INFORMATION

CALIBRATION AND SIGNAL ANALYSIS

General

Factory calibrated units are for use with the specied probe, extension cable and target part

numbers. Use the User conguraon soware (see secon 0) to congure un-congured

units before pung into service. For maximum accuracy, calibrate the driver with the probe

and cable to be used.

Doc# 100545 • REV C (May 2016) Page 16 of 16

All trademarks, service marks, and/or registered trademarks used in this

document belong to Metrix Instrument Company, L.P. except as noted below:

Teon® is a mark of DuPont in the United States and other countries.

© 2014, Metrix Instrument Company, L.P. All rights reserved.

info@metrixvibraon.com

www.metrixvibraon.com

8824 Fallbrook Dr. Houston, TX 77064, USA

Tel: 1.281.940.1802 • Fax: 1.713.559.9421

Aer Hours (CST) Technical Assistance: 1.713.452.9703

Other manuals for MX2033

2

This manual suits for next models

1

Table of contents

Other Metrix Transmitter manuals