Metrix ST5484E User manual

ST5484E 2-WIRE SEISMIC VIBRATION TRANSMITTER

Installaon Manual

DOC# M9162 • REV AB (April 2019)

1. OVERVIEW

The ST5484E Seismic Vibraon Transmit-

ter combines a vibraon sensor and signal

condioner in a single package for sensing

machinery vibraon level and transming a

proporonal 4-20 mA signal directly to PLCs,

DCSs, monitors, and computers. Versions

with 2 wires, 4 wires, terminal blocks, or

MIL-type connector are available.

The transmier has no moving parts and is

encapsulated in a stainless steel housing.

Each transmier is factory calibrated to the

sensivity marked on the label. An oponal

dynamic signal output can be specied.

Refer to Metrix Datasheet 1004457 for

specicaons, ordering informaon, and

outline dimensions.

2. MOUNTING

It is important to solidly mount the transmit-

ter body to the machine surface. Refer to

secon 6 on transducer placement. Dier-

ent machine preparaons are required for

the two basic transmier mounng styles;

NPT (Naonal Pipe Thread) and machine

thread (UNF and Metric). Transmiers with

the NPT type mounng stud are secured by

the thread engagement and the base of the

transmier does not contact the machine

surface. Transmiers with the machine

thread studs must contact the machine

surface. The base of the transmier must

make square and direct contact. This re-

quires preparing the surface of the machine

with a 1 1/2 inch counter bore (surfacing

tool). This tool can be used with a portable

1180

Flying Leads

2-Pin Terminal Block

4-Pin Terminal Block

2-Pin MIL Connector

Doc# M9162• REV AB (April 2019) Page 2 of 12

drill equipped with a magnec base but care must be taken so that the tapped and threaded

hole is perpendicular to the machined surface. The transmier must make contact all the way

around its base surface. Contact Metrix for more detailed counter bore instrucons.

If installing a transmier with a standard 1/4 inch NPT stud, drill a hole using a 7/16 inch bit, 5/8-

7/8 inch deep. Then tap using a 1/4 - 18 NPT (tapered pipe tap). Hand-ghten the transmier

and then turn an addional 1 to 2 turns using a wrench on the wrench ats. Do not use a pipe

wrench. A pipe wrench can apply extreme forces to the body and potenally damage electronic

components. A minimum of ve (5) threads of engagement should be made. A 1/4 inch to 1/2

inch NPT bushing is available for mounng the transmier in exisng 1/2 inch NPT holes. Also,

a Metrix model 7084 Flange Adapter can be used between the transmier and the machine

surface when there is not enough surface thickness to drill and tap a hole. The ange adaptor

mounts with three small screws.

If installing a transmier with one of the straight machined thread sizes, follow standard drill and

tap procedures. Do not drill a hole larger that the counter bore pilot diameter before using the

counter bore to prepare the machine surface. Drill out the hole with the correct tap drill size

aer preparing the surface.

The sensive axis of the transmier is in line with the mounng stud. The transmier can be

oriented in any (0 to 360 degree) posion.

3. WIRING

3.1 General

The ST5484E is connected like other loop powered transmiers. The following is a summary

based on area designaons.

Connect the eld wiring in accordance with the appropriate poron of Figure 1.

The ST5484E terminal block opon must be used with the following conductors specicaon:

• 14-24 AWG solid copper conductors OR

• 20-26 AWG stranded copper conductors

The ST5484E transmier requires a minimum of 11 VDC for proper operaon. This is the mini-

mum voltage required at the transmier (not the power supply), aer all other voltage drops

across eld wiring and receiver input impedance have been accounted for with the maximum

20mA of loop current owing. The minimum loop power supply voltage required is therefore 11

VDC plus 1 volt for each 50 W of total loop resistance.

Figure 1: Single-transmier loops Mulple-transmier loops

CAUTION: Use of a high-speed torque screw-

driver may damage the terminal blocks.

Doc# M9162• REV AB (April 2019) Page 3 of 12

Example:

Component Resistance

Signal wiring 10 W

DC Input Impedance of receiver 250 W

TOTAL LOOP RESISTANCE 260 W

Minimum supply voltage = 260 W (1 V/50 W) + 11 V = 16.2 VDC

The maximum loop power supply voltage that may be applied is 29.6 VDC (intrinsically safe)

or 30VDC (explosion proof and non-incendive). The maximum loop resistance (RL) is calcu-

lated by the equaon: RL = 50 (VS - 11) W

Example: RL = 50 (24 - 11) = 650 W for a 24 VDC loop supply.

3.2 Intrinsically Safe Installaon In Hazardous Locaons

Connect the eld wiring in accordance with Metrix drawing 9426 for CSA Class I, (A,B,C &

D) and Metrix drawing 9278 for IECEx / ATEX (Ex ia IIC T4 Ga) approvals. The leads must be

terminated inside an enclosure with a degree of protecon of at least IP20. A Metrix elbow

from the 8200 series may be used for these purposes. Refer to Metrix Datasheet 1004457

for addional details on accessories. The ambient temperature range is -40°C to 100°C.

The transmier requires a minimum of 11 VDC for proper operaon. The voltage drop

across the specied non-isolated barriers with a 20 mA loop current is 8.1 VDC. As such, The

minimum loop power supply voltage required is 19.1 VDC plus 1 volt for each 50 W of loop

resistance. The maximum loop power supply voltage that may be applied to the safety bar-

rier is 26 VDC. Therefore, the maximum loop resistance with a 26 VDC supply is 345 W.

Example:

Component Resistance

Signal wiring 5 W

DC Input Impedance of receiver 100 W

TOTAL LOOP RESISTANCE 105 W

Minimum supply voltage = 105 (1 V/50 W) + 19.1 V = 21.2 VDC

3.3 Explosion-Proof Installaon In Hazardous Locaons (CSA)

Some models of ST5484E transmiers are CSA cered explosion-proof, CSA US/C, Class I,

Div 1, Grps B-D and Class II, Div 1, Grps E-G (explosion proof). Connect the eld wiring in ac-

cordance with the appropriate poron of Figure 1. Refer to secon 3.1 for loop voltage and

resistance requirements. All conduit and juncon boxes used must be cered explosion-

proof for the class, division, and group required by the applicaon. Installaon of the trans-

mier must meet all of the explosion-proof installaon requirements of the local governing

agency and facility safety procedures.

3.4 Flame-Proof Installaon In Hazardous Locaons (ATEX, IECEX)

Some models of ST5484E transmiers are ATEX/IECEx cered ame-proof, Ex d IIC T4 Gb. Con-

nect the eld wiring in accordance with the appropriate poron of Figure 1. Refer to secon

3.1 for loop voltage and resistance requirements. All conduit and juncon boxes used must be

cered ame-proof for the area required by the applicaon. Installaon of the transmier

must meet all of the ame-proof requirements of the local governing agency and facility safety

procedures. The Metrix part 8200-001-IEC elbow is required to meet this approval.

Doc# M9162• REV AB (April 2019) Page 4 of 12

Doc# M9162• REV AB (April 2019) Page 5 of 12

Doc# M9162• REV AB (April 2019) Page 6 of 12

WARNING:

CSA Equipment Installaon Requirement per ordinary locaons standards,

C22.2/UL 61010-1:

Applicable for permanently connected equipment:

a) A switch or circuit-breaker must be included in the installaon;

b) It must be suitably located and easily reached;

c) It must be marked as the disconnecng device for the equipment.

Equipment environmental Rangs:

a) Polluon degree 3

b) Installaon category I

c) Altude 2000m

d) Outdoor: Type 4x

e) Temperature -40°C to 100°C

4. ELECTROMAGNETIC COMPATIBILITY

In order to meet the requirements of electromagnec compability in areas of high electro-

magnec interference, the eld wiring must be:

• Shielded twisted pair cable enclosed in grounded metallic conduit, or

• Double shielded twisted pair cable with a metallic body cable gland ng and with the

outer shield grounded.

Use standard two-conductor, twisted pair, shielded wiring for the long run to the instrumen-

taon enclosure. The transmier is connected like other loop-powered end devices.

WARNING:

ATEX Condions for Safe Use (Ex d)

For temperature classicaon and safety:

• Use conduit elbow, Metrix reference 8200-001-IEC, which is a Killark product with

reference: Y-3-EX.

• Ambient Operang Temperature: -40°C to +100°C

NOTE: Metrix also strongly recommends the use of our ferrite bead kit (Metrix

p/n 100458) as an extra precauon against electromagnec interference that may

be induced in eld wiring from subsequently bleeding into the transmier.

WARNING:

ATEX Condions for Safe Use (Ex ia)

The ST5484E is intrinsically safe and can be used in potenally explosive atmo-

spheres. This transmier must only be associated to intrinsically safe cered appara-

tus, and this combinaon must be compable as regards intrinsic safety.

The electrical parameters of cered equipment connected to the transmier must

meet the following criteria:

Uo ≤ 29.6 VDC, Io ≤ 100mA; Po ≤ 0.75W

Ambient operang temperature -40oC to +100oC

Doc# M9162• REV AB (April 2019) Page 7 of 12

5. CONNECTION TO PLC OR OTHER INDICATING INSTRUMENT

The rst step in conguring the PLC, DCS, or other recording instrument is to determine the source

of power. The ST5484E requires loop power. Some analog input channels on a PLC or DCS, for

example, provide this power from within. If they do not provide power, an external power supply

must be provided. Connect the transmier eld wiring using standard instrumentaon pracces.

Scaling of the display is on the basis of the range of the transmier. The measurement parameter

name is “vibraon” and the units are “in/s” (inches per second) or “mm/s” (millimeters per sec-

ond). The example below is based on a standard 1.0 in/s transmier.

6. TYPICAL TRANSMITTER PLACEMENT

The ST5484E measures seismic vibraon (i.e., vibraon velocity) at the aachment point on the

machine, using engineering units of in/s (inches per second) or mm/s (millimeters per second)

depending on the selected ordering opon. The transmier’s sensive direcon is through the long

axis of its cylindrical body. It will not measure side-to-side moon.

Typical transmier mounng for casing vibraon measure-

ments is in the horizontal direcon at the bearing housings

as depicted in Figure 2. The horizontal direcon usually

incurs more vibraon because most machines’ foundaon

constrains vercal vibraon more than horizontal vibraon.

A horizontal mounng arrangement is also depicted in Figure

3, but with addional detail showing typical accessories.

When ying leads are ordered, a 24- or 72-inch length may

be specied using ordering opon D on the Metrix product

datasheet 1004457. These leads may be cut to length and

then spliced to eld wiring as shown in Figure 3. Figure 2

Typical transmier

mounng

When vibraon level

at transmier is…

Transmier output

will be…

PLC (or other) should read…

0.0 in/s (i.e. no vibraon) 4.0 mA (± 0.1 mA) 0.00 in/sec

1.0 in/s (i.e. full scale vibraon) 20.0 mA (± 0.5 mA) 1.00 in/sec

Momentary “jolts” that can occur at start-up, or during some operang condion changes, do not

reect a machine’s steady-state operang condion. To prevent such occurrences from generang

nuisance alarms, program a me delay into the alarm such that the indicated vibraon level must

persist above the alarm setpoint for a preset period of me before an alarm is generated. The

indicated vibraon level must cross the threshold level and stay above it for a preset me before

any alarm acon is taken. A 2- to 3-second delay is normally applied to most machinery. Consult

Metrix if you have a queson about your machine’s operang characteriscs.

Some rough starng machinery may also need a start-up me lockout for alarms. A start-up

lockout is dierent than a me delay. A start-up lockout funcons the same as a me delay, but is

usually set to a much longer me. Both may be needed.

Doc# M9162• REV AB (April 2019) Page 8 of 12

Figure 3

When aaching conduit to the transmier, observe the following:

• Because the transmier is sensive to vibraon, avoid unsupported lengths of conduit and

excessive mass (such as large hubs or juncons) hanging directly o the end of the transmier.

These can introduce unwanted vibraons that do not reect actual machinery vibraon and

cause mechanical stresses that can lead to premature transducer failure.

• A “Y” type conduit elbow, such as the Metrix 8200 series, is preferred because it prevents the

conduit from extending too far away from the transmier, thus liming the likelihood of break-

age. It also precludes long unsupported lengths of conduit directly aligned with the transmit-

ter’s bore (longitudinal axis) as noted in the bullet above.

• Avoid aachment of rigid conduit directly to the transmier; instead, use a small length of

exible conduit to mechanically isolate the transmier from vibraon that might occur in rigid

conduit.

• If a 1-inch to 3/4-inch reducer is used at the elbow, a smaller diameter exible conduit can be

used.

NOTE: Hazardous area locaons do not allow a splice at the locaon shown

in Figure 3. Instead, the splice must be made in a second conduit hub

(meeng splicing requirements) located at the end of exible conduit.

Doc# M9162• REV AB (April 2019) Page 9 of 12

7. INSTALLATION BEST PRACTICES FOR RFI IMMUNITY

The ST5484E is case isolated from the loop power connecon to the

PLC, DCS, SCADA, or other +24 VDC alarm system. With the correct

grounding scheme, this type of isolaon avoids ground loops and re-

sults in good RF immunity. However, in situaons which involve inter-

ference from high-powered transmiers and especially spread-spec-

trum type radios, the ST5484E may become vulnerable to RF noise.

Since it is oen dicult to idenfy these situaons in advance, Metrix

strongly recommends ulizing the following Best Pracces when install-

ing all ST5484E transmiers in the eld:

1. Twist the sensor leads together (at least 10 twists per foot).

2. Slide the twisted leads through the included ferrite core and posi-

on as close to the sensor as praccal. Refer to Figures 4 and 5.

3. If possible, cut the leads short and use a shielded twisted pair. Fol-

low step 2 in this applicaon as well.

As shown in Figure 5, “chokes” that aenuate dierent frequencies can

be created by looping a dierent number of turns through the ferrite

core. More wire turns adds more inductance, aenuang progressively

lower frequencies. Mulple “chokes” can be created in this manner

and placed in series on the wire leads to cover a broad frequency band.

Always locate the choke covering the higher frequency band closest to

the sensor.

8. CALIBRATION

The ST5484E transmier has been factory calibrated for the full-scale vibraon level marked

on the label. If the calibraon is in doubt, the unit can be veried in the eld by following

the procedures outlined below. Note that there are no Zero and Span adjustments on the

transmier. Addionally, the transmier uses a true RMS amplitude detecon circuit; units

supplied with a full scale range in peak units scale the underlying RMS measurement by a

Figure 5: Leads may also be

looped through the ferrite

core to aenuate dierent

frequencies. The opmal

number of loops will vary

by applicaon and the

interfering frequency(ies).

Figure 4: Leads may be

simply fed straight through

the ferrite core.

factor of 1.414 to provide a “derived peak” rather than true peak measurement.

7.1 Zero Vericaon

In the absence of vibraon the output current should be 4 mA ± 0.1 mA. If the ambient

vibraon exceeds 2% of full scale, the transmier should be removed from the machine and

placed on a vibraon free surface for this measurement. Oen a piece of foam can be used

to isolate the transmier from external moon.

7.2 Span Vericaon

Subject the transmier to a known vibraon within the full scale range marked on the label.

If you are using a portable vibraon shaker where it can be tested at full scale, the output

should be 20 mA ± 0.5 mA.

9. OPTIONAL DYNAMIC OUTPUT

The transmier can be ordered with an oponal dynamic output. Transmiers supplied with

this opon can be idened by the presence of four ying leads instead of two (Figure 6), or

four terminal connecons instead of two (Figure 7).

The dynamic output is an acceleraon signal with a sensivity of 100 mV/g, ltered to the

Doc# M9162• REV AB (April 2019) Page 10 of 12

same frequency band as used for the 4-20mA velocity measurement (refer to opons E and

F on the Metrix Datasheet 1004457).

Observe the following when using this output:

• Only an electrically-isolated or baery-

powered portable vibraon analyzer

should be used when connecng to this

output. Since this is a loop-powered

device, an external ground will aect the

loop output and could cause a false alarm.

• When using a portable vibraon analyzer

or data collector, be sure to turn the

instrument sensor power o.

• Most portable vibraon analyzers have a

low input impedance and they will load

this signal, resulng in aenuaon of as

much as 20% to 30%. Refer to Table 1

which shows the nominal aenuaon

expected for a given input impedance.

• In all cases for all locaons, the use

of this signal is for temporary connec-

on only. Permanent connecon could

violate hazardous locaon installaon

requirements.

• Avoid impacng the transmier or

introducing other mechanical vibraons

when connecng to this output. Such

vibraon could result in spurious alarms

or machinery trips.

• When output is not in use, be sure leads

cannot touch conduit or each other

as this will aect the 4-20 mA current

output.

• Avoid introducing electrical noise when using

this output. Do not use this output with leads

longer than 5m (16 feet). Use of longer leads can

introduce electrical noise and aenuate high-

frequency signal content that may be present in

the raw acceleraon signal.

7

6

Table 1

Input Impedance

of Analyzer

dB

Aenuaon

10 MEG 0.01

5 MEG 0.02

2 MEG 0.04

1 MEG 0.09

500 K 0.18

200 K 0.43

100 K 0.84

50 K 1.61

20 K 3.57

10 K 6.10

Doc# M9162• REV AB (April 2019) Page 11 of 12

10. SPECIFICATIONS, ORDERING INFORMATION AND OUTLINE

DIMENSIONAL DIAGRAMS

Refer to Metrix product datasheet 1004457 for addional informaon.

Figure 1: Outline dimensions of the ST5484E (all

versions except MIL-Style Connector). Dimen-

sions in mm [inches]. Oponal* 8200-001 conduit

elbow shown installed.

* NOTE: 8200-AAA-IEC elbow is mandatory for

ATEX/IECEx/INMETRO Ex d (ameproof) ap-

proved installaons.

Figure 2: Outline dimensions of the

ST5484E-XXX-XX4-XX (MIL-Style Connector).

Dimensions in mm [inches].

Doc# M9162• REV AB (April 2019) Page 12 of 12

11. ENVIRONMENTAL INFORMATION

This electronic equipment was manufactured according to high quality stan-

dards to ensure safe and reliable operaon when used as intended. Due to its

nature, this equipment may contain small quanes of substances known to be

hazardous to the environment or to human health if released into the environ-

ment. For this reason, Waste Electrical and Electronic Equipment (commonly

known as WEEE) should never be disposed of in the public waste stream. The

“Crossed-Out Waste Bin” label axed to this product is a reminder to dispose of this product

in accordance with local WEEE regulaons. If you have quesons about the disposal pro-

cess, please contact Metrix Customer Service.

info@metrixvibraon.com

www.metrixvibraon.com

8824 Fallbrook Dr. Houston, TX 77064, USA

Tel: 1.281.940.1802 • Fax: 1.713.559.9421

Aer Hours (CST) Technical Assistance: 1.713.452.9703

Other manuals for ST5484E

1

Table of contents

Other Metrix Transmitter manuals

Popular Transmitter manuals by other brands

TC FLUID CONTROL

TC FLUID CONTROL KMS-2 Installation and operating manual

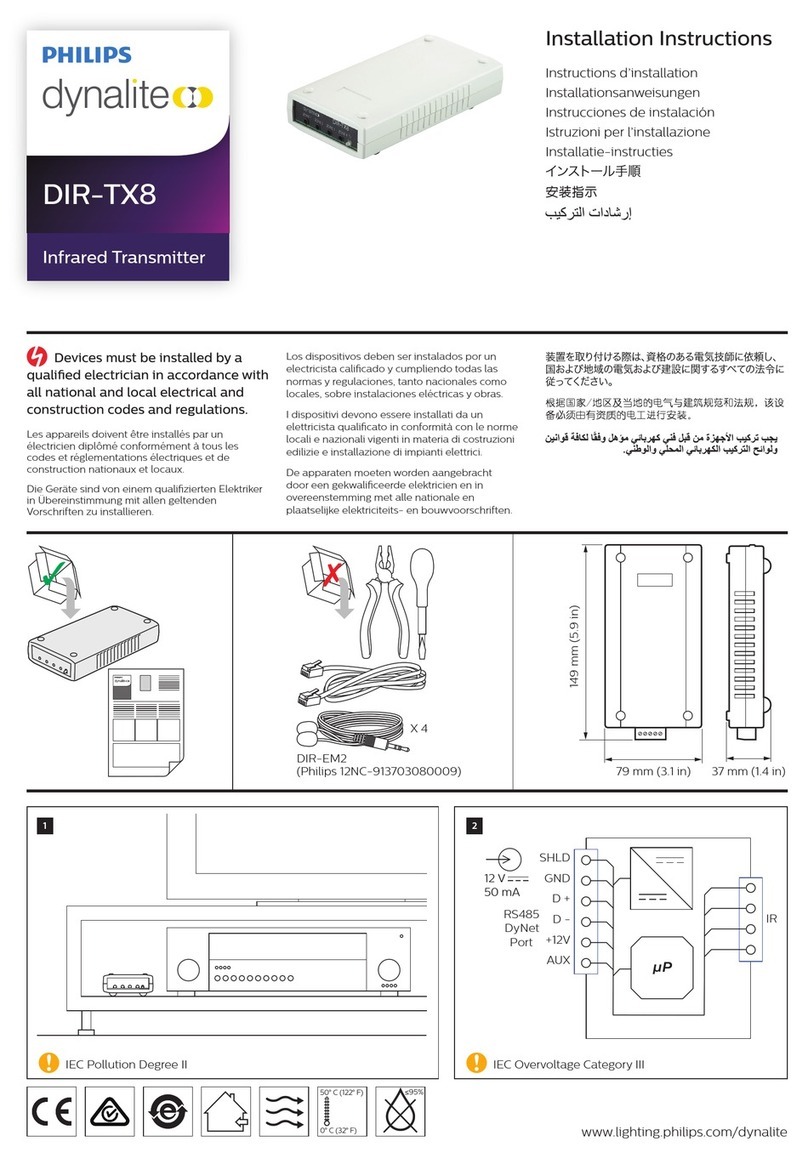

Philips

Philips Dynalite DIR-TX8 installation instructions

Security Brands

Security Brands 14-R300 instructions

DRAKE

DRAKE T-4XC instruction manual

ARJAY ENGINEERING

ARJAY ENGINEERING 2880-FCM user manual

Campbell

Campbell ST21 user manual