Indicates critical areas of installation

Metro Roman Tile Installation 7

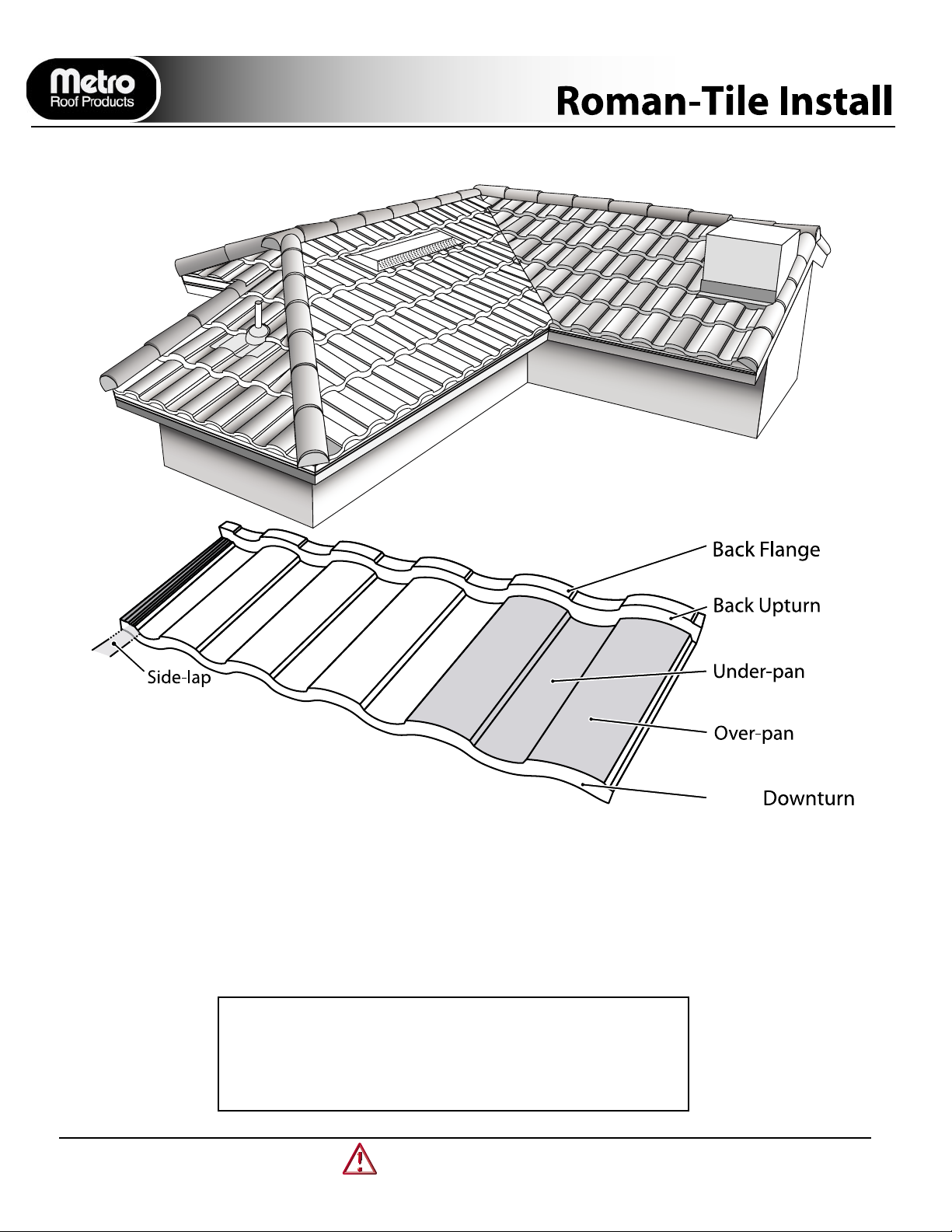

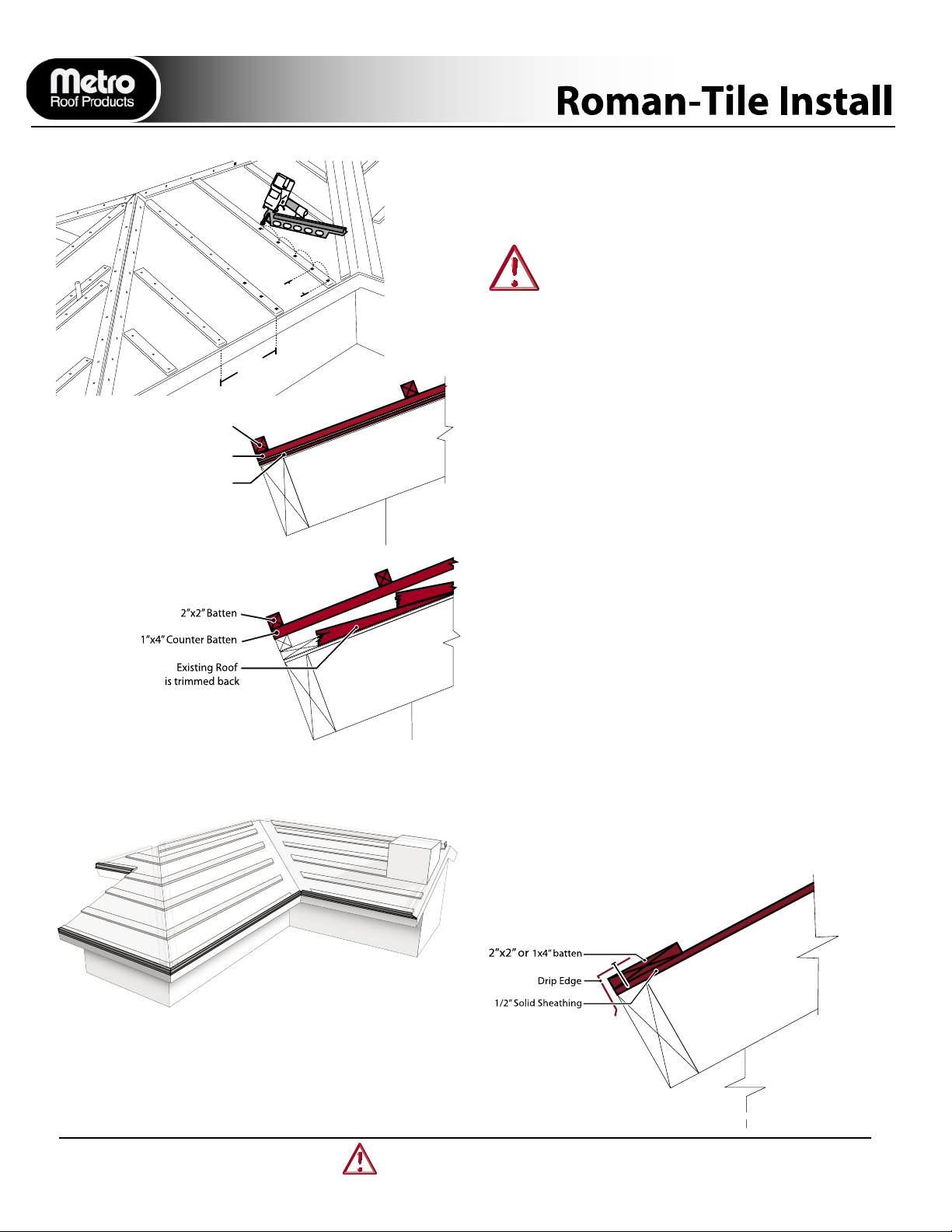

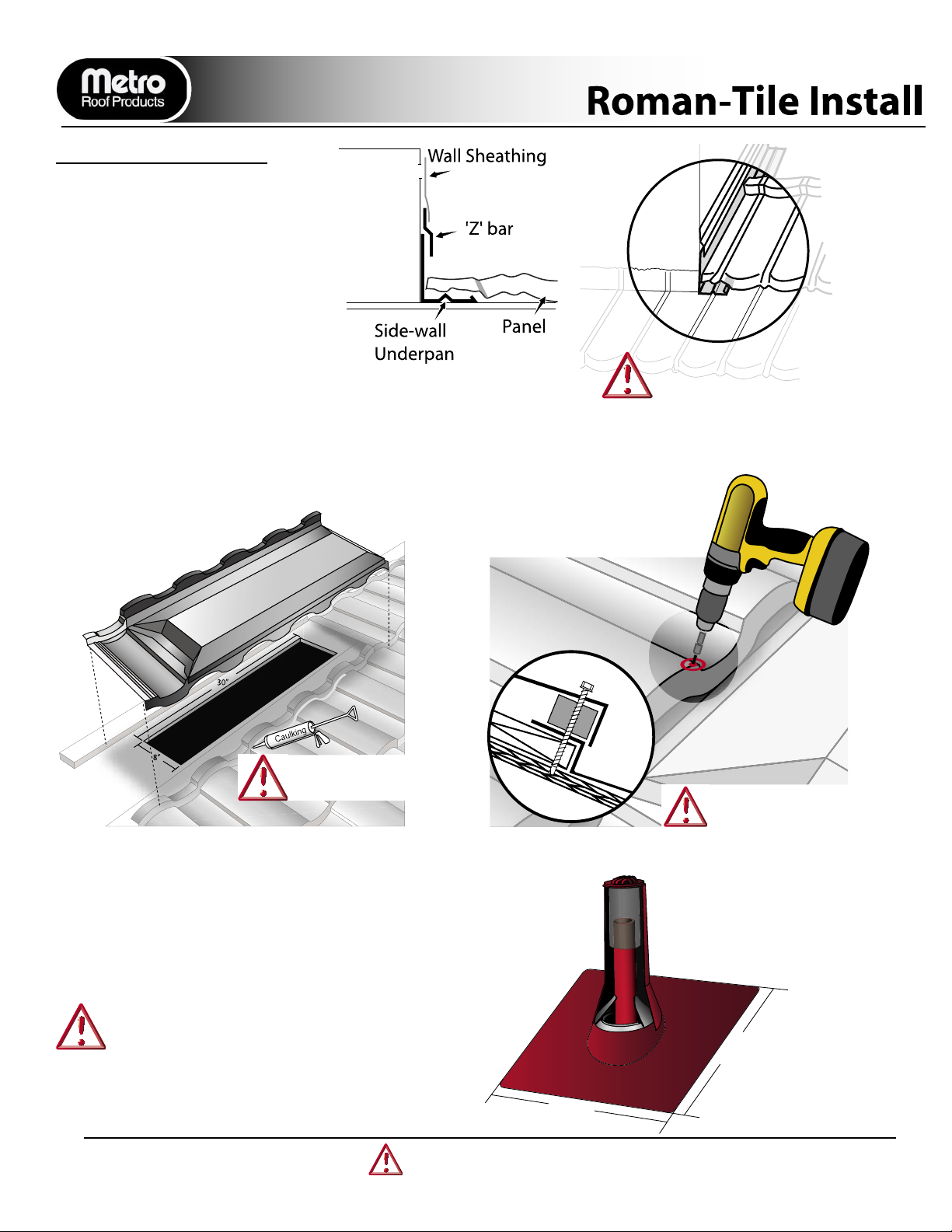

SIDE-HEAD WALL/CHIMNEY/SKYLIGHT

The following details apply to any square cornered protrusion through a roof.

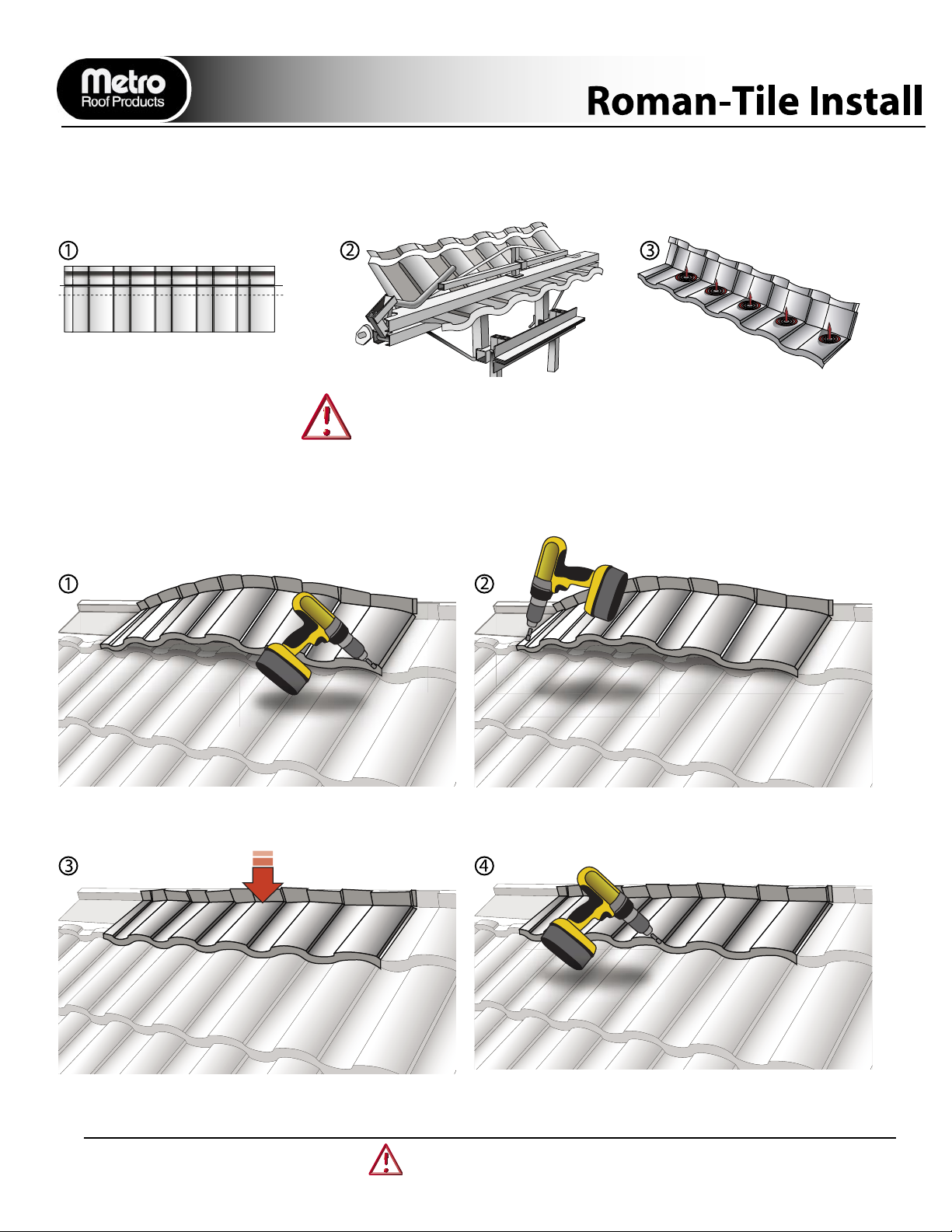

At front of chimney, measure, cut, and fold

up panel 2”. Cut panels on a 45 degree

angle as shown and fold tabs around

chimney.

On sides of chimney, cut and fold up

panels 2” as shown.

At back of chimney, seal each top corner

section. Keep panel battens away from

saddle as shown.

At back of chimney, install chimney saddle

as shown. Extend saddle a minimum of 6”

past each side of chimney. Hem ends 1” to

keep water on saddle flashing.

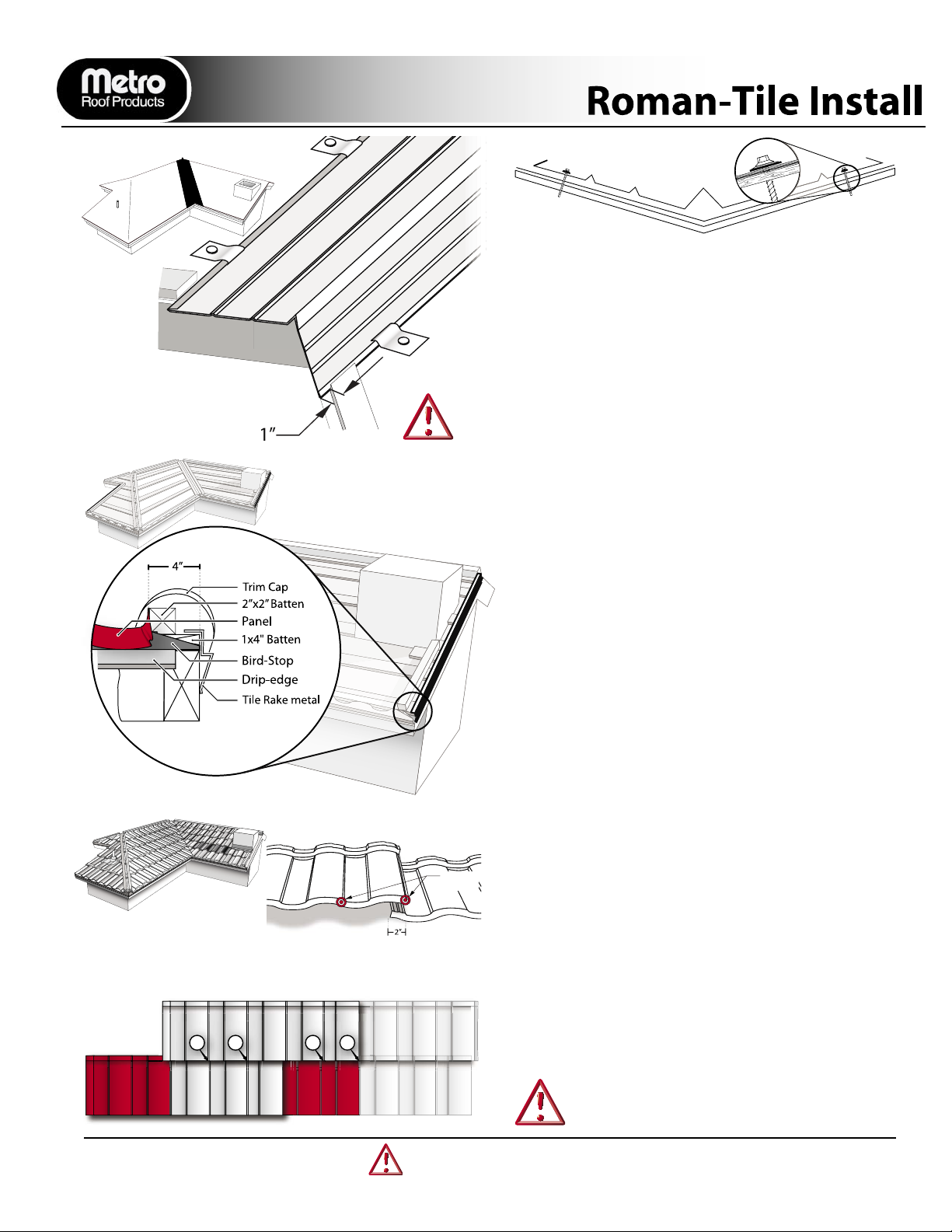

Install a section of Metro Roman Foam

Closure across the chimney saddle as

shown (align with Roman profile).

Roman Foam

Closure

6”

1” Hem

4.

1. 2. 3.

Fold flap down to

fit tight against

saddle bend

2”

Panel

Batten

Saddle

5. 6.

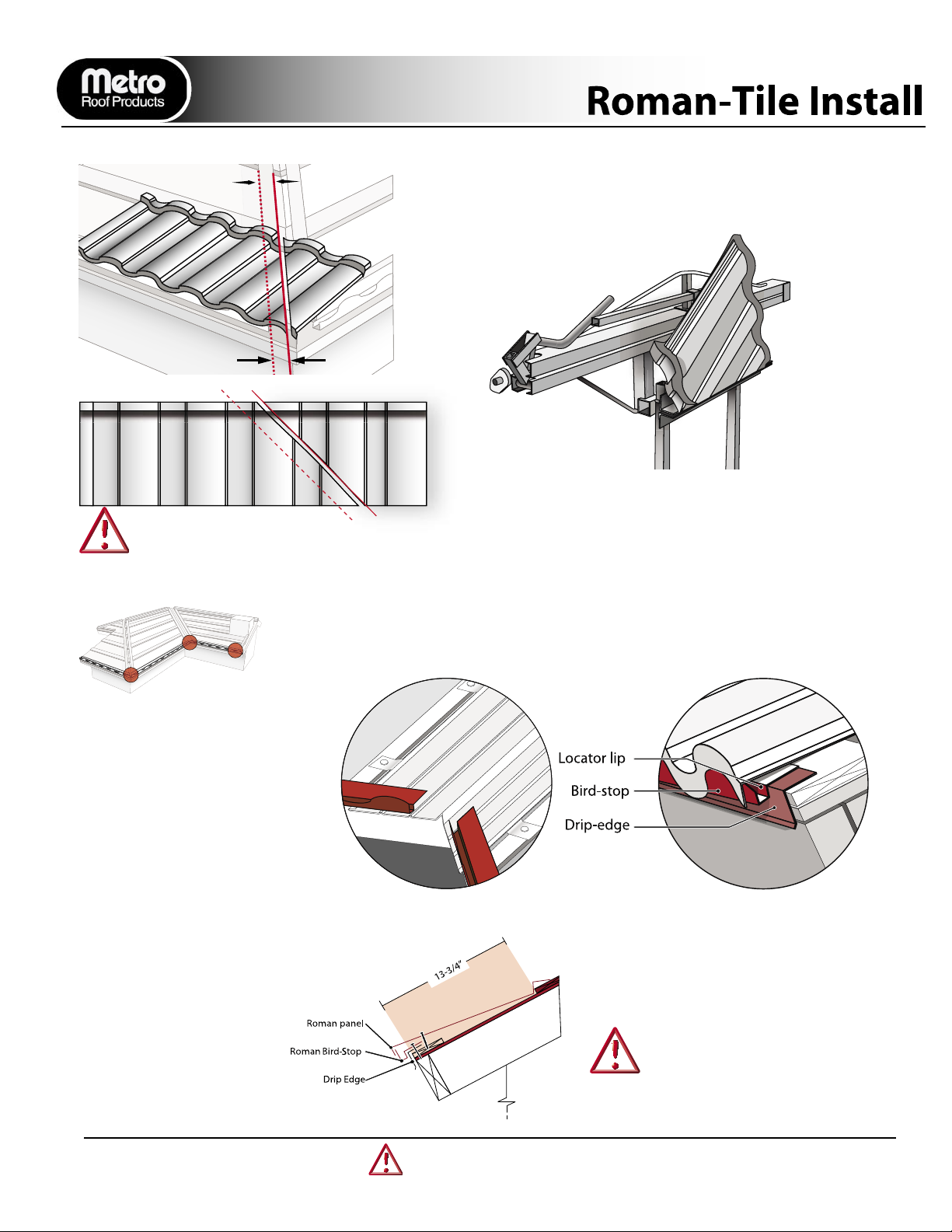

Always start from the bottom of the item

being flashed to ensure correct weather

protection.

Counter Flashing metal or Z-bar covers

bent up edges of panels.

Apply a bead of sealant across Foam

Closure and ‘Seat’ back cut-section panel

onto Foam Closure. Panels are fastened

through the front downturn of the panels,

the Foam Closure and saddle into deck-

ing.

Where applicable, cut and fold panels to

overlap the hand fabricated hem on the

sides of the chimney saddle.

©Copyright, all rights reserved