Metrohm 789 User manual

CH-9101 Herisau/Switzerland

E-Mail [email protected]

www.metrohm.com

789 Robotic Sample Processor XL

778 Sample Processor

Program version 5.789.0020+

and 5.778.0020+

Instructions for Use

8.789.1063 03.2007 / dm

II Metrohm Sample Processor

Teachware

Metrohm AG

Oberdorfstr. 68

CH-9100 Herisau

These instructions are protected by copyright. All rights reserved.

Although all the information given in these instructions has been checked with great

care, errors cannot be entirely excluded. Should you notice any mistakes please in-

form the author at the address given above.

© Metrohm AG 2007

Printed in Switzerland

Metrohm Sample Processor III

Table of Contents

1Introduction 1

1.1 Instrument description ....................................................................1

1.1.1 Field of application of the Metrohm Sample Processors........................1

1.1.2 Instrument versions..................................................................................3

1.2 Sample Processors as part of a system ........................................5

1.3 Information about these Instructions for Use................................6

1.3.1 Please note ..............................................................................................6

1.3.2 Additional documents..............................................................................6

1.3.3 Notation and pictograms.........................................................................6

1.4 Parts and controls ...........................................................................7

1.4.1 Overall view..............................................................................................7

1.4.2 Rear view..................................................................................................8

1.5 Connections.....................................................................................9

1.5.1 Sensors of the Sample Processor...........................................................9

1.6 Accessories .................................................................................. 11

1.7 The keypad.................................................................................... 13

1.7.1 The display.............................................................................................14

1.7.2 The keys.................................................................................................15

1.8 Safety information ........................................................................ 23

1.8.1 General: .................................................................................................23

1.8.2 Electrical safety ......................................................................................23

1.8.3 Personal protection................................................................................24

2Installation 25

2.1 Installation flow chart................................................................... 25

2.2 Instrument setup........................................................................... 26

2.2.1 Setup......................................................................................................26

2.2.2 Mains connection...................................................................................26

2.2.3 Connecting the keypad .........................................................................27

2.2.4 Mounting a 786 Swing Head .................................................................27

2.2.5 Mounting the robotic arm ......................................................................28

2.2.6 Connecting pumps ................................................................................29

2.2.7 Connecting dosing devices and stirrers................................................30

2.3 Data transmission connections ................................................... 31

2.3.1 Remote connections..............................................................................31

2.3.2 Serial connections (RS232) ...................................................................37

2.3.3 Connecting a printer ..............................................................................38

2.4 Connecting up accessories ......................................................... 40

IV Metrohm Sample Processor

2.4.1 Connecting rinsing and aspiration equipment......................................40

2.4.2 Attaching the tubing ..............................................................................41

2.4.3 Installing the titration accessories .........................................................42

2.4.4 Assembling pipetting accessories ........................................................44

2.4.5 Installing a double-hollow needle..........................................................45

2.4.6 Spray nozzles ........................................................................................45

2.4.7 Magnetic stirrer......................................................................................46

2.4.8 Mounting the stand support ..................................................................46

2.4.9 Installing the collection trough...............................................................47

2.4.10 Sample racks.........................................................................................47

2.4.11 Mounting the safety shield ....................................................................48

2.5 Start-up.......................................................................................... 49

3Operation 51

3.1 Operating principles..................................................................... 51

3.1.1 Display ...................................................................................................51

3.1.2 Instrument dialog...................................................................................52

3.1.3 Data input ..............................................................................................54

3.1.4 Text input ...............................................................................................55

3.2 Configuration ................................................................................ 57

3.2.1 Miscellaneous........................................................................................57

3.2.2 Tower settings .......................................................................................59

3.2.3 Rack definitions .....................................................................................61

3.2.4 Dosing units...........................................................................................64

3.2.5 RS232 settings.......................................................................................65

3.3 Composition of a method............................................................. 66

3.3.1 Run sequences and method parameters .............................................66

3.3.2 Sample Processor settings ...................................................................68

3.3.3 Stirrer settings........................................................................................69

3.3.4 Dosing device settings ..........................................................................70

3.3.5 Behavior during timeout ........................................................................71

3.3.6 Manual stop settings .............................................................................72

3.4 Commands.................................................................................... 74

3.4.1 Sample Processor commands..............................................................74

3.4.2 Switching components..........................................................................77

3.4.3 Dosing device control............................................................................78

3.4.4 Communication commands..................................................................80

3.4.5 Auxiliary commands ..............................................................................84

3.5 Managing methods....................................................................... 87

3.5.1 User-defined methods...........................................................................87

3.5.2 POWERUP method................................................................................88

3.6 Run control ................................................................................... 89

3.7 Sample racks ................................................................................ 90

Metrohm Sample Processor V

3.7.1 Metrohm standard sample racks ..........................................................90

3.7.2 Magnet codes........................................................................................91

3.7.3 Rack data...............................................................................................92

3.8 Dosing and liquid handling.......................................................... 95

3.8.1 Dosimats and Dosinos ..........................................................................95

3.8.2 Liquid handling functions ................................................................... 100

3.8.3 The DOS command............................................................................ 101

3.8.4 Pictograms.......................................................................................... 101

3.8.5 Liquid handling functions in detail...................................................... 102

3.8.6 Pipetting equipment............................................................................ 105

3.8.7 Pipetting procedure ............................................................................ 105

3.8.8 Preparing the Dosing unit ................................................................... 106

3.8.9 Pipetting .............................................................................................. 106

3.9 The Remote interface ................................................................. 109

3.9.1 Output lines......................................................................................... 109

3.9.2 Input lines............................................................................................ 109

3.9.3 SCN command ................................................................................... 110

3.9.4 CTL command .................................................................................... 110

3.9.5 Manual stop options ........................................................................... 111

3.10 LEARN mode............................................................................... 112

3.10.1 Setting lift and robotic arm positions.................................................. 112

3.10.2 Rack adjustment................................................................................. 113

3.10.3 Parametrizing sequence commands ................................................. 113

3.11 TRACE function .......................................................................... 114

3.12 Disabling keypad functions ....................................................... 114

3.12.1 Disable whole keypad......................................................................... 114

3.12.2 Disable configuration.......................................................................... 115

3.12.3 Disable parameter .............................................................................. 115

3.12.4 Disable method storage functions ..................................................... 115

3.12.5 Disable display.................................................................................... 115

3.13 786 Swing Head settings ........................................................... 116

4Service, maintenance, errors 119

4.1 Service......................................................................................... 119

4.1.1 Running time meter............................................................................. 119

4.2 Care and maintenance ............................................................... 119

4.3 Error messages .......................................................................... 120

5GLP validation – diagnosis 122

5.1 Validation / GLP .......................................................................... 122

5.2 Initializing the working memory ................................................ 123

VI Metrohm Sample Processor

6Annex 125

6.1 Technical data............................................................................. 125

6.1.1 Keypad.................................................................................................125

6.1.2 Interfaces .............................................................................................125

6.1.3 MSB connections ................................................................................125

6.1.4 Pumps and pump connections...........................................................125

6.1.5 Swing Head connection ......................................................................126

6.1.6 Lift ........................................................................................................126

6.1.7 Turntable..............................................................................................126

6.1.8 Stirrer connection (DIN socket) ...........................................................126

6.1.9 Mains connection ................................................................................126

6.1.10 Safety specifications............................................................................126

6.1.11 Electromagnetic compatibility (EMC)..................................................126

6.1.12 Ambient temperature...........................................................................127

6.1.13 Dimensions and materials...................................................................127

6.2 Standard methods ...................................................................... 128

6.2.1 Titrino ...................................................................................................129

6.2.2 PIP ext ..................................................................................................130

6.2.3 KF_ext. .................................................................................................132

6.2.4 pH_cal..................................................................................................134

6.2.5 Std_add ...............................................................................................135

6.3 Standard equipment ................................................................... 137

6.3.1 Metrohm Sample Processor:...............................................................137

6.3.2 Sample racks and sample beakers ....................................................149

6.3.3 786 Swing Head ..................................................................................153

6.3.4 Connection cables...............................................................................157

6.3.5 Optional accessories and additional devices.....................................158

6.3.6 Electrodes for automation ...................................................................161

6.4 Warranty and conformity.......................................................... 1621

6.4.1 Warranty.............................................................................................1621

6.4.2 Declaration of Conformity (778 Sample Processor) .........................1632

6.4.3 Declaration of Conformity (789 Robotic Sample Processor XL) ......1643

6.4.4 Quality Management Principles ........................................................1654

7Index 1665

Metrohm Sample Processor VII

List of Illustrations

Fig. 1 System components........................................................................................................5

Fig. 2 Overall view......................................................................................................................7

Fig. 3 Rear view .........................................................................................................................8

Fig. 4 Connection strip...............................................................................................................9

Fig. 5 Magnet sensor for rack code...........................................................................................9

Fig. 6 Beaker sensor on the tower...........................................................................................10

Fig. 7 Sensor on a robotic arm ................................................................................................10

Fig. 8 Accessories ...................................................................................................................11

Fig. 9 Keypad...........................................................................................................................13

Fig. 10 Safety Shield (example shown: 6.2751.0xx for transfer robotic arm) ...........................24

Fig. 11 Mounting the Swing Head .............................................................................................27

Fig. 12 Robotic arm with limiting screw .....................................................................................28

Fig. 13 Mounting the robotic arm ..............................................................................................29

Fig. 13 MSB connections...........................................................................................................30

Fig. 14 Remote cable.................................................................................................................31

Fig. 15 RS232 connections........................................................................................................37

Fig. 16 Distributor piece.............................................................................................................40

Fig. 17 Attaching the tubing.......................................................................................................41

Fig. 18 Macro titration head.......................................................................................................42

Fig. 19 Micro titration head ........................................................................................................42

Fig. 20 Robotic arm with titration accessories ...........................................................................43

Fig. 22 Transfer robotic arm with pipetting accessories............................................................44

Fig. 23 Transfe r robotic arm with double-hollow needle...........................................................45

Fig. 24 Spray nozzles.................................................................................................................45

Fig. 25 741 Magnetic stirrer .......................................................................................................46

Fig. 24 Stand support ................................................................................................................46

Fig. 25 Collection trough............................................................................................................47

Fig. 26 Attaching a sample rack ................................................................................................47

Fig. 27 Sample rack for XL models............................................................................................48

Fig. 28 Mounting the safety shield.............................................................................................48

Fig. 29 Safety shield for Swing Heads.......................................................................................48

Fig. 30 Dialog arrangement .......................................................................................................53

Fig. 31 Text input .......................................................................................................................56

Fig. 32 800 Dosino with Dosing units ........................................................................................95

Fig. 33 Dosing unit from below..................................................................................................96

Fig. 34 Dosing unit - ports .......................................................................................................100

Fig. 35 Remote interface..........................................................................................................125

Tables

Table 1 Model versions (1 tower) .................................................................................................3

Table 2 Model versions (2 towers)................................................................................................4

VIII Metrohm Sample Processor

1.1 Instrument description

Metrohm Sample Processor,Introduction 1

1 Introduction

This section offers you a first overview of the Metrohm Sample Proces-

sors. All the information applies to both the 789 Robotic Sample Proces-

sor XL and the 778 Sample Processor. You are informed about how you

can use these versatile instruments and are introduced to the most im-

portant parts and controls.

1.1 Instrument description

1.1.1 Field of application of the Metrohm Sample Processors

The Metrohm Sample Processors are very versatile instruments in-

tended exclusively for use in factories and laboratories, where they

cover a wide range of applications. In this way they provide an indis-

pensable service wherever large series of samples have to be proc-

essed, no matter whether in the titration, measurement or liquid

handling sectors.

As a result of the extensive communication possibilities you can work

via the parallel Remote and serial RS232 interface not just with the wide

range of Metrohm titrators, measuring instruments and dosing devices,

but you can also work with any other instruments that have a suitable

communications interface; these can be controlled by or control the

Sample Processor. These abilities mean that they are predestined for all

imaginable automation tasks in a modern laboratory, even within highly

integrated laboratory data systems.

Despite their comprehensive range of commands and the numerous

possible configurations, the Metrohm Sample Processors offer an un-

complicated type of operation that is also suitable for routine work as a

result of the possibility of managing user-defined methods.

The standard methods supplied with the instruments can be used for

routine tasks without any further fuss. After a short familiarization period

the user can alter them to meet any particular requirements and store

them in the instrument. This means that, apart from routine work,

Metrohm Sample Processors can also be used for demanding special

applications.

The run sequences for processing the individual samples are freely de-

finable within wide limits. The same applies to the start sequence and

1.1 Instrument description

2 Metrohm Sample Processor,Introduction

final sequence, which have to be carried out once before the start of a

sample series or once after it has been completed. This offers many

advantages, particularly for titrations. The electrode can be conditioned

before the first titration or subjected to a special rinsing process.

A learn mode is available for creating run sequences and, with its help,

command parameters can be set in manual operation.

Exchangeable standard sample racks are available for many sizes of

beakers and test tubes. Freely selectable "special beaker" positions can

be defined for each rack. These are then used for including rinsing or

conditioning beakers, which can be addressed in any part sequence,

on the rack.

By extending the system with a 786 Swing Head the number of samples

to be processed on a rack can be considerably increased. The robotic

arm of the 786 Swing Head allows any point on a sample rack to be

addressed. This means that the number (max. 999 rack positions) and

arrangement of the samples is virtually unlimited. On request we can

supply customer-specific special racks for individual requirements.

Freely definable position tables can be loaded via the RS232 interface

and suitable PC software for the configuration of special racks.

1.1 Instrument description

Metrohm Sample Processor,Introduction 3

1.1.2 Instrument versions

Variously equipped Metrohm Sample Processors models are available:

• All versions of the 789 Robotic Sample Processor XL are suitable

for sample racks of up to 48 cm diameter.

• All versions of the 778 Sample Processor are suitable for sample

racks of up to 42 cm diameter.

Model 2.789.0010

Model 2.778.0010

1 tower with 1 pump

+ 1 ext. pump connection

+ 1 stirrer connection

+ 1 Swing Head connection

Chassis with 3 MSB sockets

for dosing devices and/or

stirrers

+ Remote connection

(25-pin)

+ RS232 connection (9-pin)

+ keyboard connection

Model 2.789.0020

Model 2.778.0020

1 tower with 2 pumps

+ 1 stirrer connection

+ 1 Swing Head connection

Chassis with 3 MSB sockets

for dosing devices and/or

stirrers

+ Remote connection

(25-pin)

+ RS232 connection (9-pin)

+ keyboard connection

Model 2.789.0030

Model 2.778.0030

1 tower without pumps

+ 2 ext. pump connections

+ 1 stirrer connection

+ 1 Swing Head connection

Chassis with 3 MSB sockets

for dosing devices and/or

stirrers

+ Remote connection

(25-pin)

+ RS232 connection (9-pin)

+ keyboard connection

Table 1 Model versions (1 tower)

1.1 Instrument description

4 Metrohm Sample Processor,Introduction

Model 2.789.0110

Model 2.778.0110

2 towers with 2 pumps

+ 2 ext. pump connections

+ 2 stirrer connections

+ 2 Swing Head connec-

tions

Chassis with 3 MSB sockets

for dosing devices and/or

stirrers

+ Remote connection

(25-pin)

+ RS232 connection (9-pin)

+ keyboard connection

Model 2.789.0120

Model 2.778.0120

2 towers with 4 pumps

+ 2 stirrer connections

+ 2 Swing Head connections

Chassis with 3 MSB sockets

for dosing devices and/or

stirrers

+ Remote connection

(25-pin)

+ RS232 connection (9-pin)

+ keyboard connection

Model 2.789.0130

Model 2.778.0130

2 towers without pumps

+ 4 ext. pump connections

+ 2 stirrer connections

+ 2 Swing Head connec-

tions

Chassis with 3 MSB sockets

for dosing devices and/or

stirrers

+ Remote connection

(25-pin)

+ RS232 connection (9-pin)

+ keyboard connection

Table 2 Model versions (2 towers)

1.2 Sample Processors as part of a system

Metrohm Sample Processor,Introduction 5

1.2 Sample Processors as part of a system

772 Pump

685 Dosimat

COM 2

TiNet

2.x

PC

COM 2

LPT 1

PC

COM 1

COMx

USB

RS 232

Remote MSB

711 Liquino

731

Relay Box

DC

AC

MSB

756 KF

RS 232

805 Dosimat805 Dosimat

800

Dosino

800

Dosino

800

Dosino

800

Dosino

700

Dosino

700

Dosino

700

Dosino

700

Dosino

809 Titrando809 Titrando808 Titrando808 Titrando

823823

781pH/Ion Meter Metrohm781pH/Ion Meter Metrohm

Fig. 1 System components

741 Magnetic

Stirrer

772 Pump Unit

Titrinos

pH Meter / Ion Meter

756/831

Coulometer

731 Relay Box

711 Liquino

Titrandos

(6.2148.010 Remote Box

required)

Keypad

Printer

Personal

Computer

802 Rod Stirrer

823 Membrane

Pump Unit

801 Stirrer

804 Titation Stand 800 Dosino

805 Dosimat

700 Dosino

685 Dosimat

• Titrinos

• pH Meter

• Coulometer

• other

Metrohm in-

struments

• other manu-

facturers in-

struments

• Titrinos

• pH Meter

• Coulometer

• other Metrohm instruments

• balance

• instruments from

other manufacturers

• other Metrohm

instruments

786 Swing Head* 786 Swing Head**

786 Swing Head

* with titration-robotic arm

** with transfer-robotic arm

1.3 Information about these Instructions for Use

6 Metrohm Sample Processor,Introduction

1.3 Information about these Instructions for Use

1.3.1 Please note

Please read through these Instructions for Use carefully before you

start to use the Sample Processor. The instructions contain information

and warnings that must be observed by the user in order to guarantee

the safe use of the instrument.

1.3.2 Additional documents

• Quick Reference 8.789.1013 for the Metrohm Sample Processors

• Operating Tutorial 8.789.1023 for the Metrohm Sample Processors

• Technical Reference 8.789.1033 for the Metrohm Sample Proces-

sors

1.3.3 Notation and pictograms

The following notation and pictograms are used in these Instructions for

Use:

Location Menu item, parameter or input value

<OK> button, key

Danger

This symbol indicates a possible risk of death or injury to

the user if the instructions are not followed correctly.

Warning

This symbol indicates a possible risk of damage to the in-

struments or their components if the instructions are not fol-

lowed correctly.

Attention

This symbol indicates important information. Read the in-

formation provided before you continue.

Remarks

This symbol indicates additional information and tips.

1.4 Parts and controls

Metrohm Sample Processor,Introduction 7

1.4 Parts and controls

1.4.1 Overall view

Fig. 2 Overall view

1 Guide chain 6 Splash protection guide

2 Safety shield/Splash protection 7 Titration head

3 Sample rack 8 Lift

4 Stirrer rail 9 Tower

5 Splash protection fixing 10

Beaker sensor

11

Chassis

1

2

3

4

5

6

7

8

9

10

11

Safety information

Safety shield 2must always be in po-

sition before the Metrohm Sample

Processor is used.

1.4 Parts and controls

8 Metrohm Sample Processor,Introduction

1.4.2 Rear view

This illustration shows the rear view of the standard model 2.778.0010 with

one tower, one membrane pump and one connection for an external pump.

WARNING-FireHazard-

withthesametypeandratingoffuse

Forcontinuedprotectionreplaceonly

Made by Metrohm

Herisau Switzerland

S: 115 VA U : 100 - 240 V f: 50 - 6 0 H z

RS 232

MSB1

MSB3

MSB2

Power Keyboard

Remote

Ext.

Pump 2

Swing

Head

Pump 1

Fig. 3 Rear view

12 Distributor block 16 Stirrer connection (Tower 1)

For 802 Rod Stirrer or

741 Magnetic Stirrer

13 Membrane pump 17

Connection strip

14 PTFE tubing 18

Pump connection M8 (external)

15 Solenoid valve 19

Connection socket for the

786 Swing Head

a Warning: Biohazard

See Section 1.8.3 Personal protection

b

Warning: Resistance to chemicals

See section 2.4.1 Connecting rinsing

and aspiration equipment

12

13

14

15

16

17

18

19

1.5 Connections

Metrohm Sample Processor,Introduction 9

1.5 Connections

The electrical connections are the same for all models of the Metrohm

778/789 Sample Processor series.

WARNING-FireHazard-

withthesametypeandratingoffuse

Forcontinuedprotectionreplaceonly

Made by Metrohm

Herisau Switzerland

S: 115 VA U: 100 - 240 V f: 50 - 60 H z

RS 232

MSB1

MSB3

MSB2

Power Keyboard

Remote

Fig. 4 Connection strip

20 Mains switch 24 Serial RS232 connection (9-pin)

21 Keyboard connection 25

Mains connection

22 MSB connections MSB1 … MSB3

Metrohm Serial Bus

Connection of dosing devices and stir-

rers

26

Type plate

23 Remote connection (25-pin)

1.5.1 Sensors of the Sample Processor

Fig. 5 Magnet sensor for rack code

Rack sensor

The magnet sensor for recognizing

the individual rack code is located be-

neath the turntable of the Sample

Processor. The magnet code of a

rack can only be read in when the

rack is in the initial position. The mag-

net holder must be positioned directly

above the sensor.

For this reason the Sample Processor

should be initialized each time that a

rack is changed with the <RACK>

key.

20

21 22

23 24

25 26

Magnet

sensor

Magnet holder

1.5 Connections

10 Metrohm Sample Processor,Introduction

Fig. 6 Beaker sensor on the

tower

Optical beaker sensor

Each tower of a Metrohm Sample

Processor is equipped with a beaker

sensor that detects the presence of

a beaker in front of the tower. With

this infrared sensor beakers made

from different materials can be de-

tected, provided that they are lo-

cated in the correct position in front

of the tower and the beaker sensor

'Tower' has been selected in the

rack definition. This "Beaker test" is

carried out after each MOVE com-

mand (i.e. each rotation of the rack).

The beaker sensor on the tower can

only be used with single-row sample

racks.

Fig. 7 Sensor on a robotic arm

Tactile robotic arm sensor

Robotic arms with piezo sensors

may be used with multi-row racks.

The sensor is activated, when the lift

is run to work position and makes

physical contact with a sample

beaker.

Splash protection

/

Safety shield

Beaker sensor

Sample rac

k

Piezo sensor

1.6 Accessories

Metrohm Sample Processor,Introduction 11

1.6 Accessories

Fig. 8 Accessories

With suitable accessories a Sample Processor can be extended to form

a comprehensive automated system. Depending on the tasks to be

carried out, various standard components or even custom-made spe-

cial parts can be used. Please consult the list of accessories on page

137ff.

Sample racks

Custom-made racks for various vessel sizes with any arrangement of

rack positions can also be supplied in addition to the standard racks.

786 Swing Head with robotic arm

The use of multi-row sample racks or external titration cells requires the

use of a 786 Swing Head. This motor drive, which is mounted on the lift

of one of the Sample Processor towers, can move different types of ro-

botic arm. Various types of standard robotic arms with accessories for

titrating on the sample rack or for sample transfer to an external titration

cell are available.

Stand support

If an external titration cell is to be used then we recommend the use of

a stand support. The stand support can accommodate a magnetic stir-

rer (e.g. model 801) and, with a support rod, enables you to attach a ti-

tration cell or other accessories.

786 Swing Heads

Stand su

pp

ort

Robotic arm with

titration head

Sample rac

k

Robotic arm for

sample transfer

1.6 Accessories

12 Metrohm Sample Processor,Introduction

Swing head with tactile piezo sensor

When using a multi-row rack and a 786 Swing Head, a robotic arm with

a touch-sensitive piezo sensor may be used. With that kind of sensor

the presence of a sample beaker can be detected reliably.

Robotic arm for removing covers

Whenever covered sample containers are required (e. g. with volatile

samples) the lids can be removed by a special robotic arm (so called

Dis-Cover) with magnetic contact before the sample treatment. Special

lids are available for this purpose.

Accessory set for sample transfer

For pipetting samples into external titration cells an accessory set

(6.5619.000) is available, comprising all necessary parts.

Other manuals for 789

1

This manual suits for next models

1

Table of contents

Other Metrohm Computer Hardware manuals

Popular Computer Hardware manuals by other brands

ekwb

ekwb EK-FB ASRock X299 RGB Monoblock installation manual

Quanmax

Quanmax QBOX-2090 Series user guide

Runco

Runco DHD Series Owner's operating manual

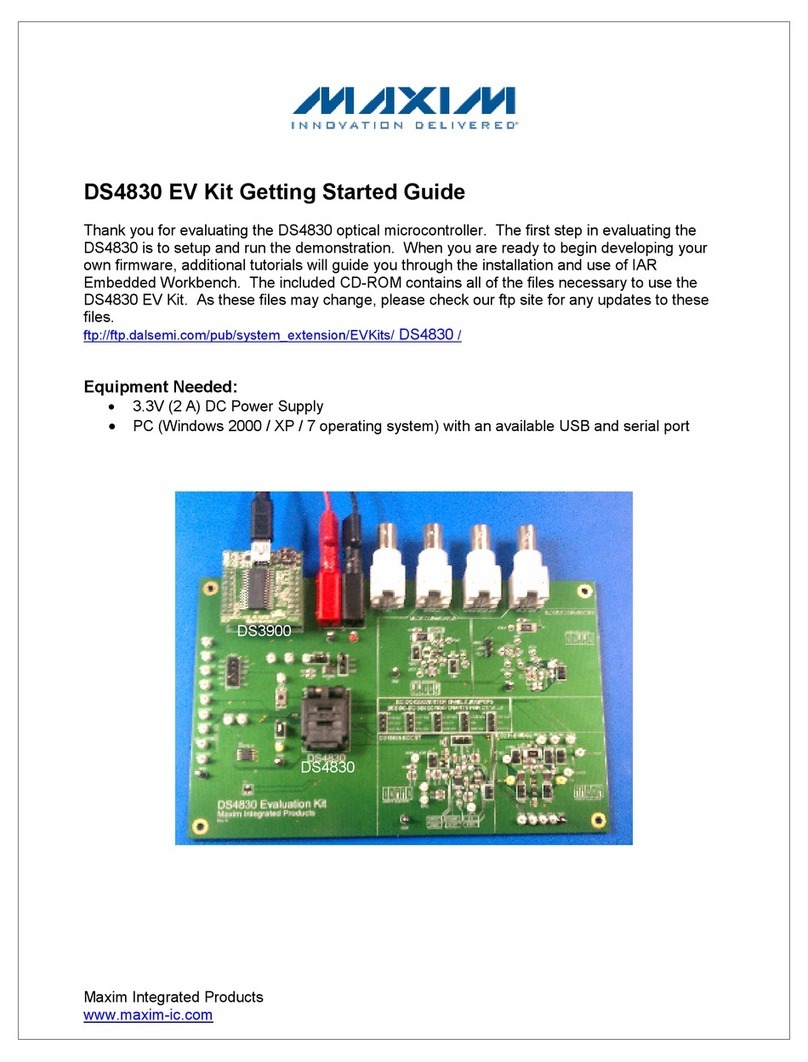

Maxim

Maxim DS4830 Getting started guide

National Semiconductor

National Semiconductor COP400-E02 user manual

Siemens

Siemens SIMATIC NET CP 243-1 Technical manual