■■■■■■■■■■■■■■■■■■■■■■ Table of contents

772 Pump Unit ■■■■■■■■ III

Table of contents

1 Introduction 1

1.1 Instrument description ......................................................... 1

1.1.1 Model versions ........................................................................ 1

1.1.2 Connectors .............................................................................. 1

1.1.3 Intended use ........................................................................... 1

1.2 About the documentation ................................................... 2

1.2.1 Symbols and conventions ........................................................ 2

1.3 Safety instructions ................................................................ 3

1.3.1 General notes on safety ........................................................... 3

1.3.2 Electrical safety ........................................................................ 3

1.3.3 Tubing and capillary connections ............................................. 4

1.3.4 Flammable solvents and chemicals ........................................... 4

1.3.5 Recycling and disposal ............................................................. 4

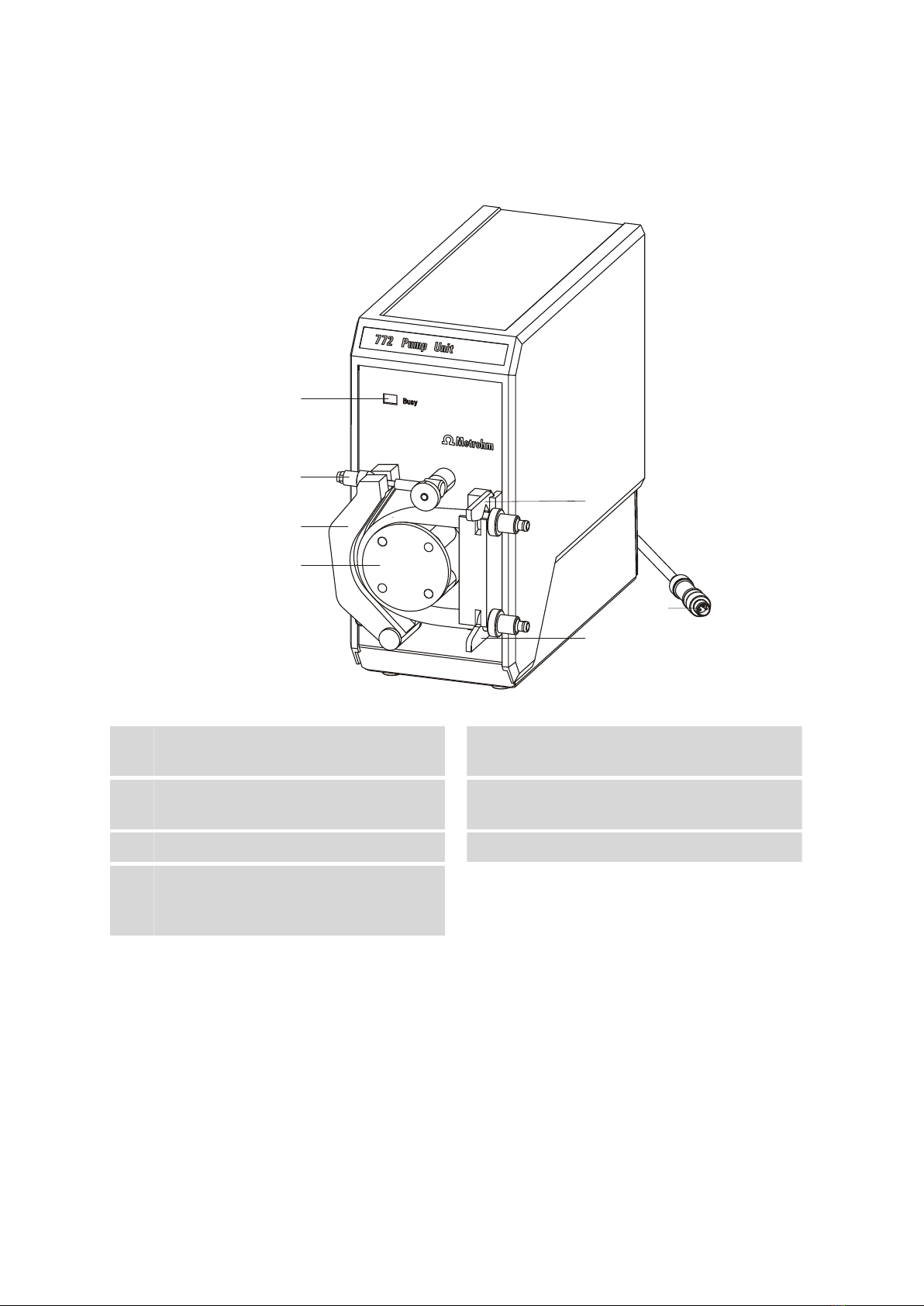

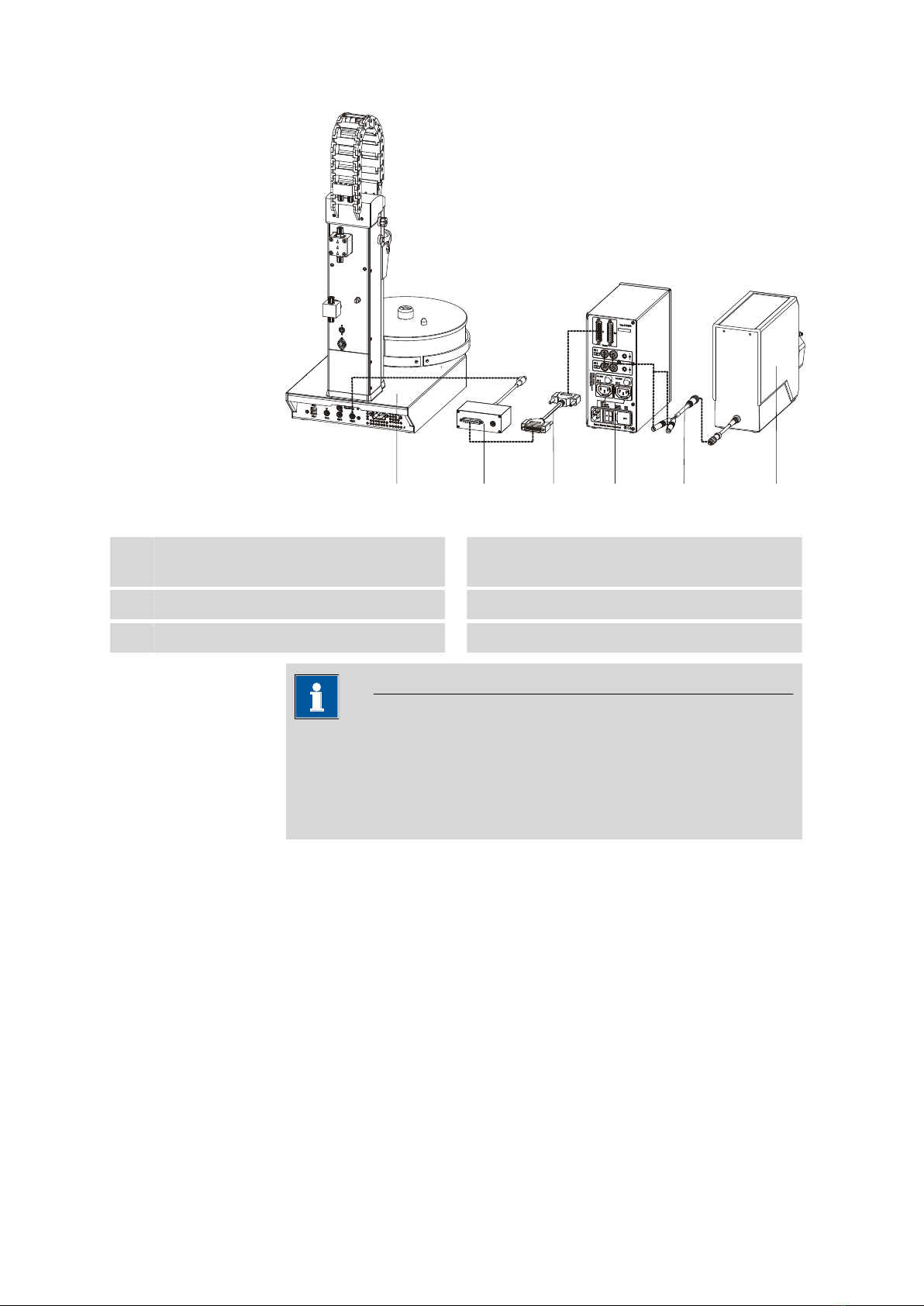

2 Overview of the instrument 6

3 Installation 7

3.1 Setting up the instrument .................................................... 7

3.1.1 Packaging ................................................................................ 7

3.1.2 Checks .................................................................................... 7

3.1.3 Location .................................................................................. 7

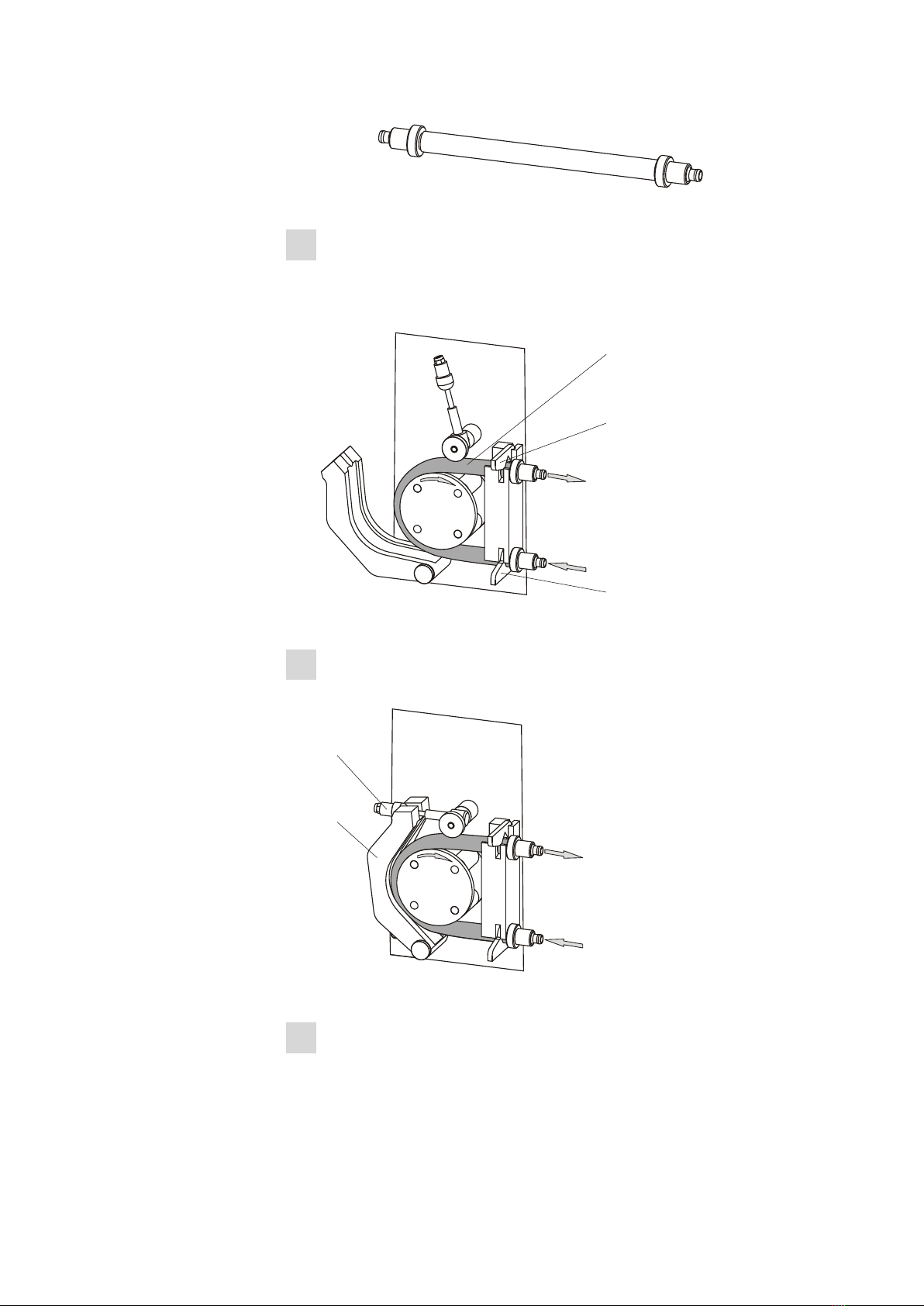

3.2 Mounting the tubings .......................................................... 7

3.2.1 Mounting the pump tubing ..................................................... 7

3.2.2 Installing the inlet tubing and outlet tubing .............................. 9

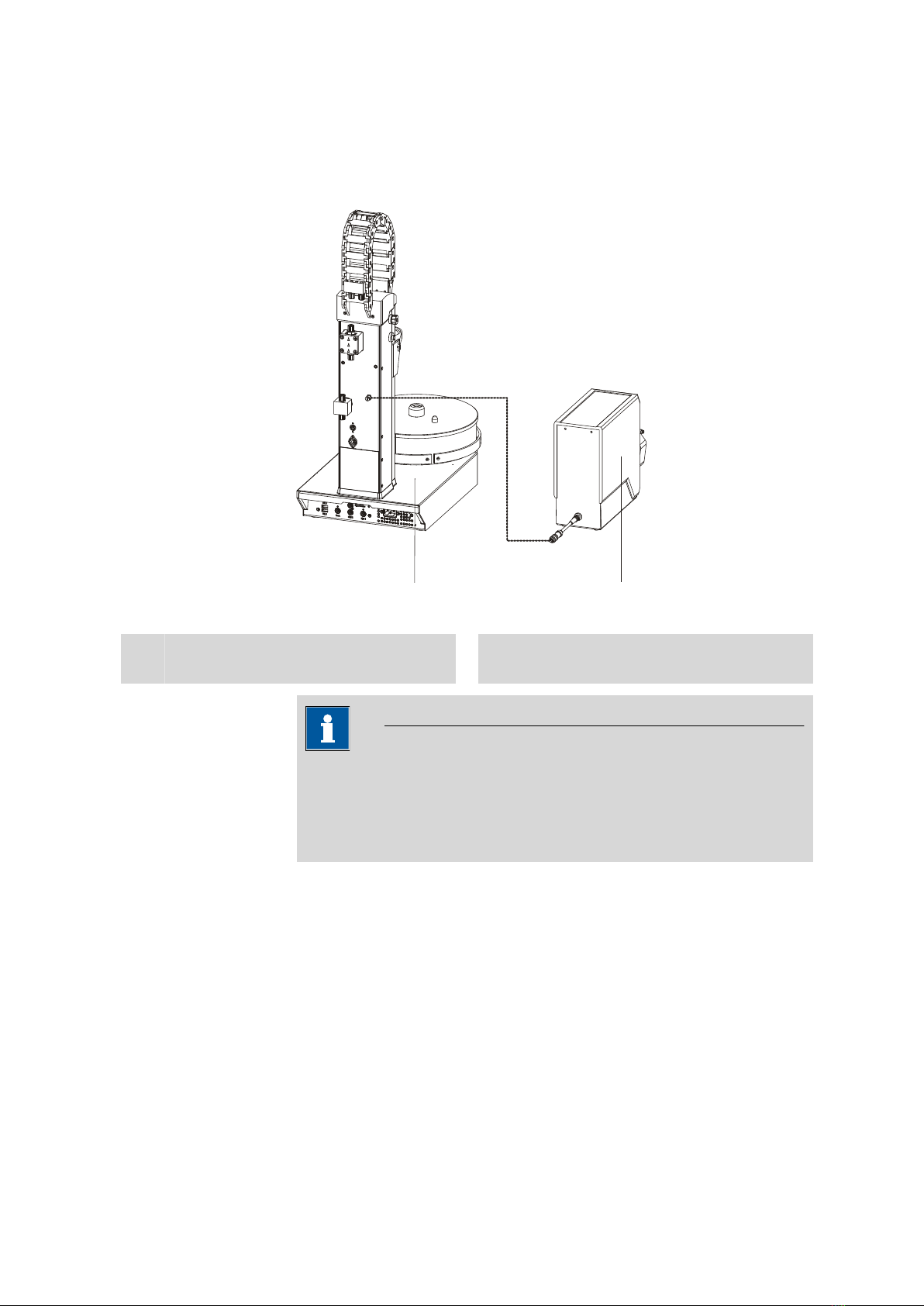

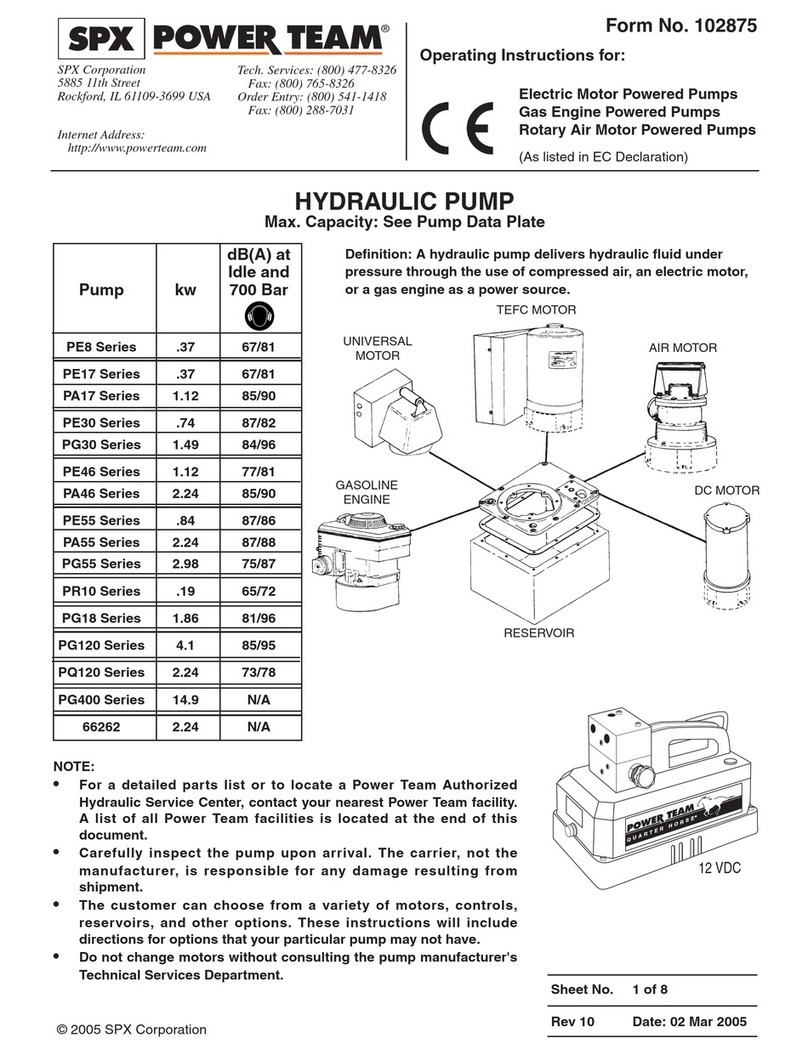

3.3 Connecting the peristaltic pump ....................................... 10

3.3.1 Connection to a Sample Processor ......................................... 11

3.3.2 Connection to the 731 Relay Box .......................................... 11

4 Operation 14

5 Operation and maintenance 15

5.1 General notes ...................................................................... 15

5.1.1 Care ...................................................................................... 15

5.1.2 Maintenance by Metrohm Service .......................................... 15

5.2 Pump tubings ...................................................................... 16

5.2.1 Selecting the pump tubing ..................................................... 16

5.2.2 Suitability test for tubing materials ......................................... 17

5.2.3 Tubing dimensions ................................................................. 17

5.2.4 Tubing lifetime ....................................................................... 17

5.2.5 PharMed® pump tubing data sheet ....................................... 18

5.2.6 Viton® pump tubing data sheet ............................................ 19

5.3 Tubings ................................................................................ 20