9. Carefully remove the bottom seat (5) out of the body

taking caution that the body seat face is not scratched

while doing so.

3.2 Assembly

Apply a good lubricant compatible with the flow medium

lightly to seats, seals, ball, and stem to facilitate assembly

and for ease of initial operation.

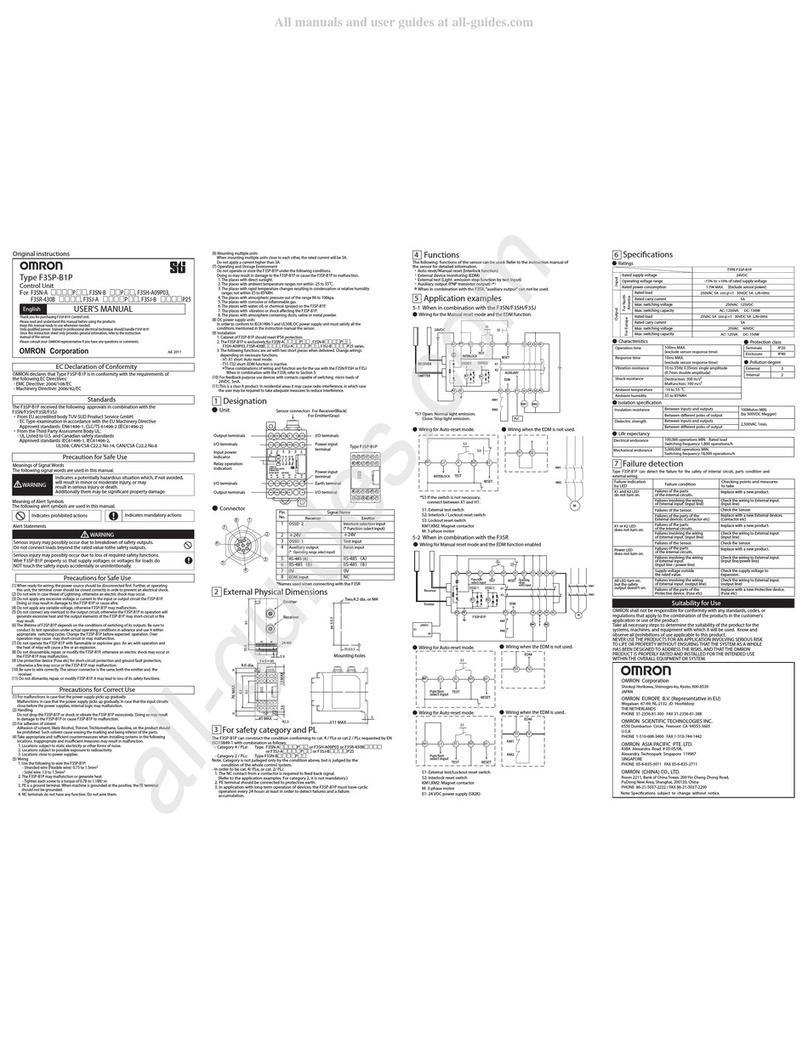

1. Slide one valve seat (5) sidewise into the body cavity

(1) to just below the stem hole and tilt it into place so

that the proper face will come in contact with the ball

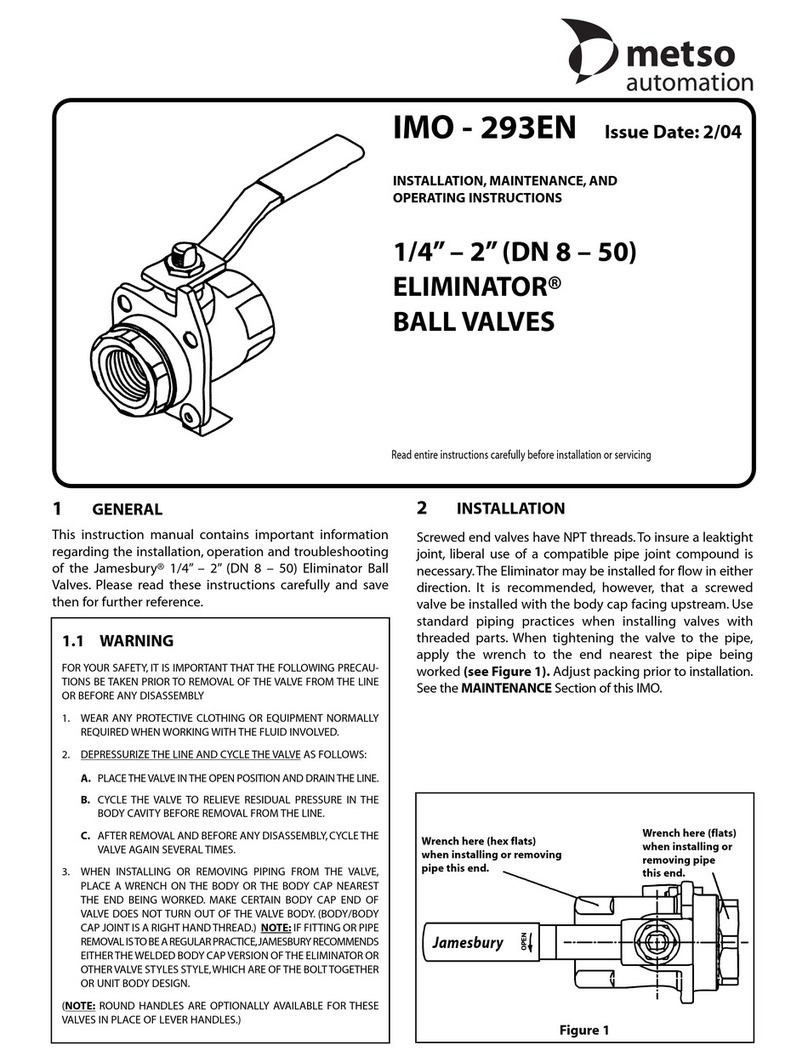

(3) (see Figure 3). Do not scratch or cut the seat face.

2. From inside of the body cavity, insert one stem bearing

(24), then one stem seal (7), then the second stem

bearing (24) up into the lower stem counterbore.

3. From the outside of the body, insert the two upper

stem seals (8) into the upper stem counterbore.

4. Insert the stem (4) into the body cavity (threaded end

first) and press it gently up into the stem bore until

resistance is felt from the lower stem bearing. Be careful

not to scratch the seals.

5. Holding the stem in place from inside the body, drop

the compression ring (21) over the threaded end of

the stem protruding out of the body stem bore. Follow

the same procedure with the slotted stem washer (50)

and then screw on one stem nut (16).

6. Tighten down the nut until stem is snugly into place.

Rotate the stem gently to assure proper seating.

Tighten the nut until the stem seals are fully seated,

then tighten the nut to the torque specified in (Table 1)

(Stem Nut Torque).

7. Using a spanner wrench, screw the insert (2) into the

body until it is fully seated. Mark the position as shown

in (Figure 4). Counting the number of turns, remove

the insert.

8. Insert the ball (3) rotating it onto the stem (4) in the

closed position. If necessary, turn the stem blade to

align with the ball slot.

2

3.1 Disassembly

1. Read the instructions in the WARNING Section.

2. Place the valve in the open position.

3. Remove the stem nut (16), lock washer (19), handle

(17), the second stem nut (16), stem washer (50), and

compression ring (21).

4. Place the valve in a vertical position with the insert

end up.

5. Unscrew and remove the insert (2) and body seal (6).

6. Place the ball into the closed position and remove the

top seat (5) and the ball (3).If these parts do not lift out

easily, take a piece of wood or some other soft material

object and gently tap the ball from the end opposite

the insert.This will unseat these parts without damaging

them.

7. Press the stem (4) into the valve body cavity. It may be

necessary to tap it with a piece of wood or some other

soft material.

8. Remove the stem, then pry out and discard the old

stem seals (8), the stem bearings (24), and secondary

stem seal (7).

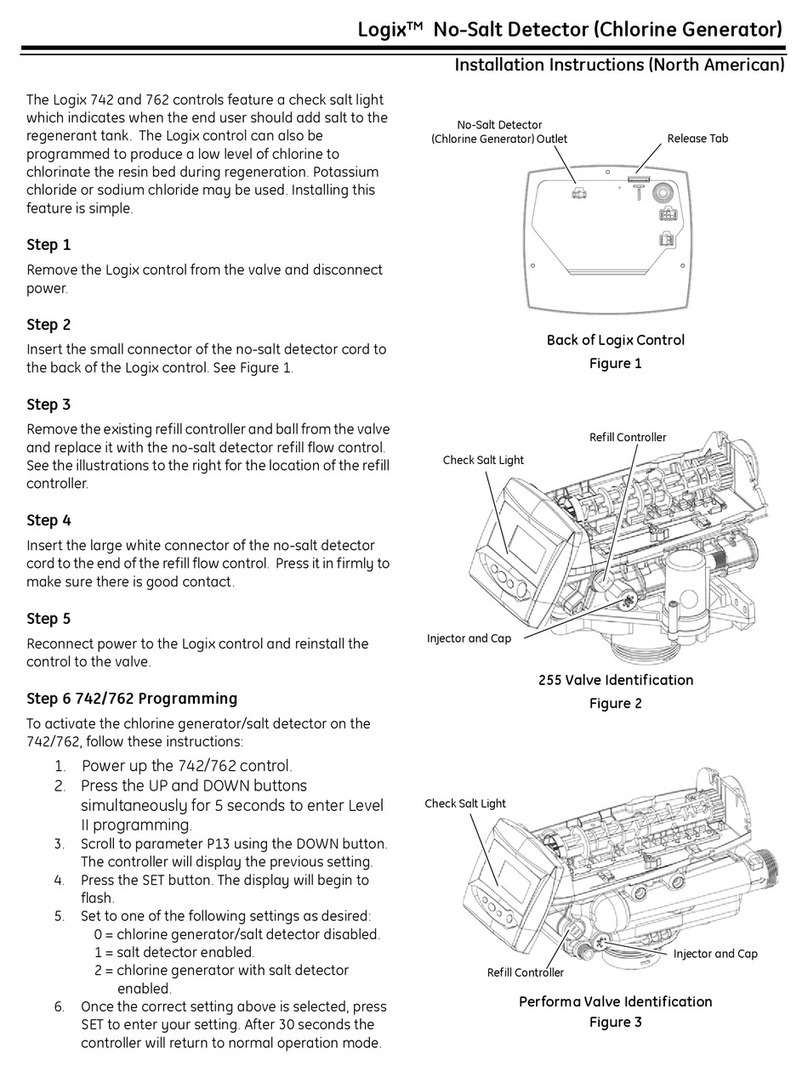

Figure 3

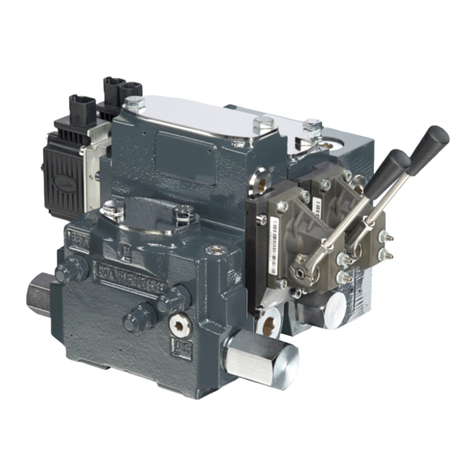

Figure 1

Figure 2

2" (DN 50) 5RRU

2" (DN 50) 5RRR