9

4.7 Checking the parts of a dismantled

valve

❑Clean the removed parts.

❑Check the shaft (5) and the thrust bearings (70).

❑Check the ball (3) and the ball seats (7).

❑Check the body gasket surfaces.

❑Replace any damaged parts.

4.8 Replacing parts

Replace soft parts whenever you dismantle the valve

for maintenance. Replace other parts when necessary.

By using original spare parts, you can ensure proper

functioning of the valve. For ordering the spare parts,

see Section 9 ('Ordering spare parts').

4.9 Reassembling the valve

4.9.1 Sizes 2"-6"

❑Place the valve in a standing position on the pipe

flange end so that the insert thread points upwards.

Use a surface that will not scratch the flanges.

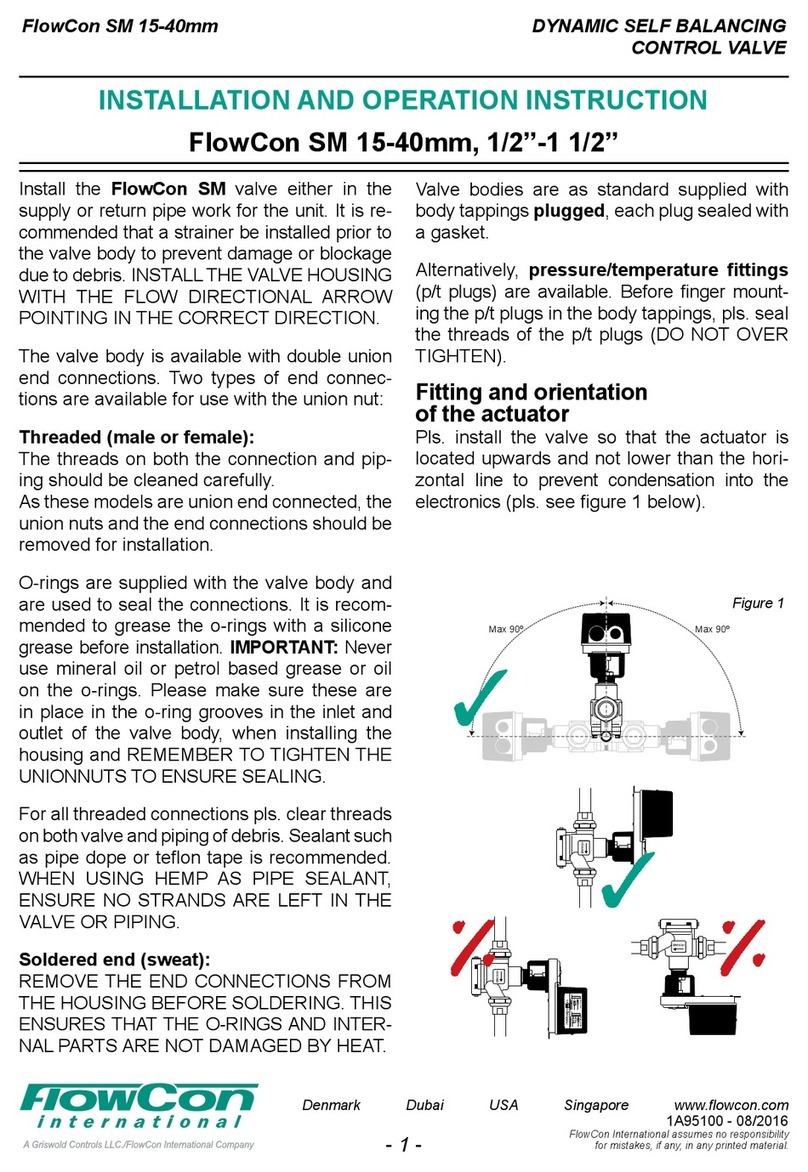

❑Screw the insert (2) into the body (1). Tighten the

insert slightly to ensure that it has gone all the way

in. Mark the position, e.g. with a felt tip marker

against the body at the point of the mark on the

insert, Fig. 17. Unscrew the insert and remove it

from the body.

❑Place the valve body on its pipe flange. Use a sur-

face that does not damage the pipe flanges.

❑In size 2" slip the thrust bearings (70) onto the shaft

and push them against the shaft shoulder. Put the

bonnet gasket (66) in its groove, replace the bonnet

(8) and tighten the studs (13). Tighten the nuts (17)

of the studs (13) evenly to achieve uniform com-

pression of the gasket (66). The torque is 25 Nm

when the threads have been lubricated.

❑Place the body gasket (65) into the body, on the

shoulder at the foot of the threads.

❑Insert the other ball seat (7) into the body (1).

❑Insert the ball (3) into the body (1) and other ball

seat (7) on the ball (3).

❑Screw the insert into the body. This is easiest to do if

the valve is in horizontal position. Tighten the insert

using a special tool until the cap reaches 5-10 mm

past the mark made earlier.The torque is 200 Nm.

❑Push the packing rings (69) into their place in the

bonnet (8). Tighten the studs (14). Place the gland

(9) on the packing (69). See Section 4.2 for packing

assembly instructions.

❑Mount the key (10).

❑Check the gland packing for leakage when the

valve is pressurized and re-tight the nuts carefully, if

necessary.

❑Install the valve in the pipeline, as carefully and

accurately as when removed it. Note the instruc-

tions in Section 3.

❑In sizes 3"-6" place the retaining ring (51) on the shaft

groove (5). Place the shaft partly inside the body from

above and place the thrust bearings (70) on the shaft

from inside the body. Place the spline driver (4) on the

shaft spline and lock it with a pin (50).

❑Insert the other ball seat (7) on the body.

❑Put the ball (3) in its position so that the spline

driver is in the ball slot. Pull the shaft to make sure

that the pin locks the spline driver properly to the

shaft. Place the thrust ring (67), packing (69), the

stud (14) and the gland (9) in their position. Place

the nuts (18) on the studs (14) and screw down

them gently.

❑Place the body gasket (65) and gasket (135) into

the body.

❑Screw the insert and seat assembly into the body.

This is easiest to do if the valve is in horizontal posi-

tion. Tighten the insert using a special tool until the

cap reaches 2-5 mm past the mark made earlier,

Fig. 17.

❑Deform the packing rings by tightening the gland

nuts without disc springs to the torque Tt, see the

value from Table 1, see Section 4.2.

❑Remove the gland nuts and one stud, mount the

retainer plates (42) and the removed stud and

place the disc spring sets (150) on the gland studs.

Tighten the nuts (18) so that the disc springs are

compressed to the height Hc, see Table 1. Lock the

nuts with locking compound e.g. Loctite 221.

❑Observe the same caution in reinstalling the valve

that you used in dismantling it. Please also note the

instructions in Section 3.

4.9.2 Size 8"

❑Place the valve body on its pipe flange. Use a sur-

face that does not damage the pipe flanges.

❑Place the retaining ring (51) on the shaft groove (5).

Place the shaft partly inside the body from above

and place the thrust bearings (70) on the shaft from

inside the body. Place the spline driver (4) on the

shaft spline and lock it with a pin (50).

❑Insert the other ball seat (7) into the body

❑Put the ball (3) in its position so that the spline

driver is in the ball slot. Pull the shaft to make sure

CAUTION:

For safety reasons the retainer plates (42) in sizes

3",4",6" and 8" MUST always be installed as shown

in 10.2.

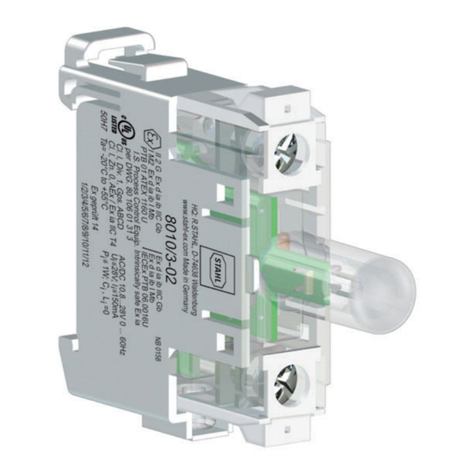

Fig. 17 Marking for the insert position

As marked After final assembly