9

3. Remove the shaft seal compression hardware as detailed

in Steps 1-4 in the SHAFT SEAL REPLACEMENT

Section. The seal material itself can be more easily

removed after the shaft has been removed from the

valve.

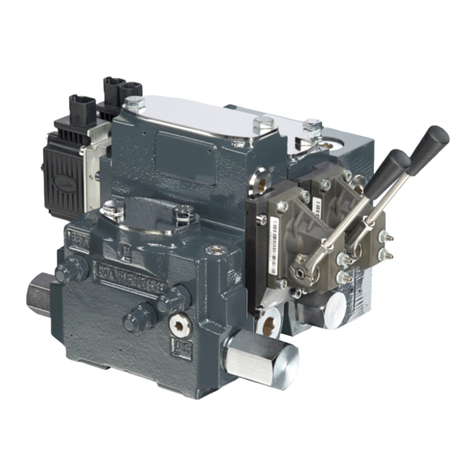

4. Remove the disc pin welds by grinding or machining

off the welds. Drive out the pins opposite the installation

direction shown in (Figure 5).

5. Remove screws (55) and cover plate (53), and remove

gasket (54).

6. Remove the shaft (4). NOTE: When removing the shaft

and freeing the disc,be careful not to scratch the sealing

surface of the disc.

7. Remove the disc (3) and upper and lower thrust

bearings (64).

8. Remove the top bearing (6) either through the top of

the valve or the waterway.

9. Remove the bottom bearing (6).

3.7 Valve Assembly

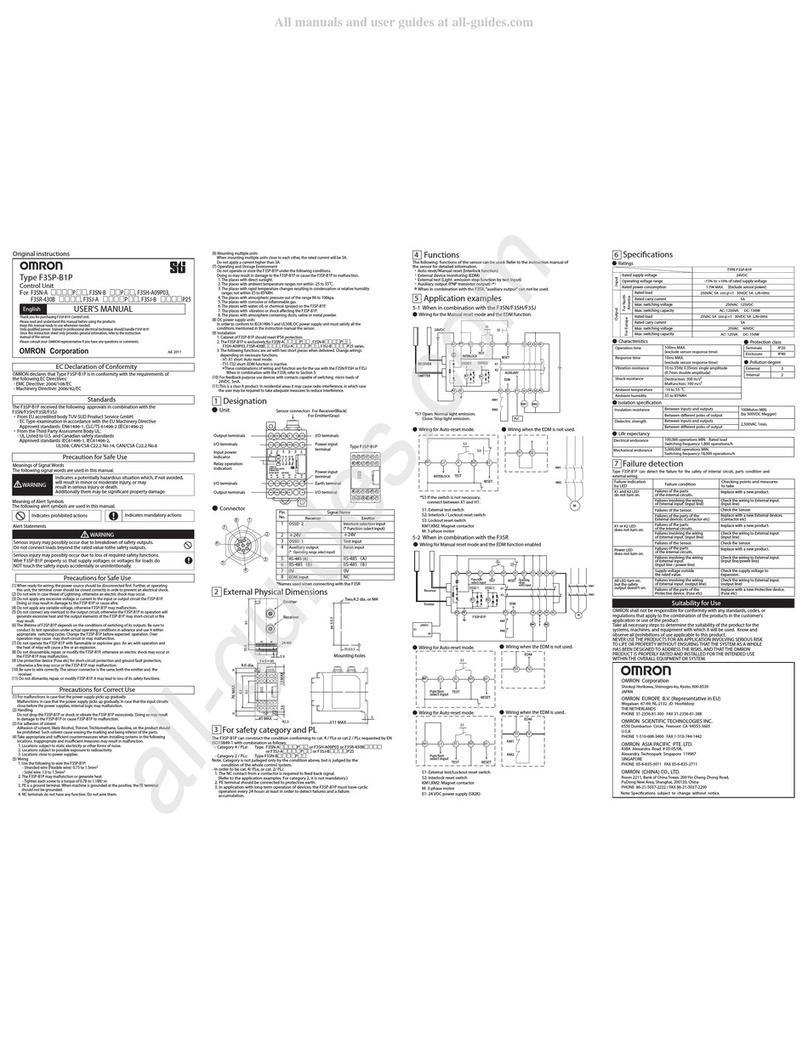

Numbers in ( ) refer to items shown in (Figure 5).

1. Clean all valve components.

2. Inspect all components for damage before assembling

the valve. Look for damage to the sealing areas on the

disc, shaft, and body, and for wear in the bearing areas.

3. Carefully clean and polish the disc sealing surface. It

should be free from all grooves and scratches.

4. If the disc is slightly damaged, it may be possible to

smooth the sealing surface with crocus cloth, a fine

stone,or the equivalent. If deep scratches are present,

replace the disc or return the valve to the factory for

service.

5. Install the bearings (6) into the body bores.

6. To ease assembly of the shaft into the disc, it may be

necessary to coat the shaft and the disc bore lightly

with a lubricant compatible with the media to be

handled by the valve.

7. Slide the shaft through the top bearing and engage

the top thrust bearing (64). With the two pin holes

toward the bonnet, place the disc in the waterway and

slide the shaft through the shaft bore in the disc.Place

the lower thrust bearing (64) below the disc, slide the

shaft through and into the lower shaft bearing (6). Use

caution to prevent damage to the shaft bearings and

disc sealing surface.

8. Insert the disc pins (13), as shown in (Figure 5), and

drive them into place. The pins must be driven so that

both pins are the same depth within 1/16” (1.56 mm).

When they are correctly installed the drive shaft will be

as shown in (Figures 1 and 2).Weld both ends of the

pins, small end first, grounding the shaft only (body on

blocks of wood).After the disc cools,clean the welds with

a wire brush.CAUTION: Use care to keep contamination

out of the valve.

9. Install the upper bearing spacer (41) when applicable,the

spacer (7) with chamfered side toward disc, the shaft

seal (8), the compression ring (9) and the retainer ring

(47). If the shaft seal is of the PTFE V-ring type, be certain

that it is installed in the orientation shown in (Figure 5).

10. If the studs (14) have been removed from the valve,

reinstall them in the holes shown in (Figure 5), using

Loctite® or other locking compound to prevent vibration

loosening. Stud protrusion should be 2” (50.8 mm) for

the 3”,4”,6” and 8” (DN 80, 100, 150 and 200) valves and

2-1/4”(57.15 mm) for the 10”and 12”(DN 250 and 300)

valves.

11. Install new gasket (54), and secure cover plate to valve

body using screws (55). To ensure even gasket loading

tighten screws, in an alternating sequence to torque in

(Table 2).

12. If the handle ratchet plate has been removed from the

valve, reinstall it in the orientation shown in (Figure 6).

Install lock washers and screws in the two bonnet

holes. Do not tighten the screws until the stops are set.

(See SETTING HANDLE STOP Section or ACTUATOR

MOUNTING INSTRUCTIONS Section.)

13. Place the compression plate (10) over the shaft (4) and

studs (14). Install the nuts (15), but do not tighten.

14. Cycle the valve fully closed. Install new unused seat and

body seal. See the SEAT REPLACEMENT Section for

details.

15. With the valve still closed, tighten the nuts (15) on the

compression plate evenly until the shaft seals are

adequately compressed to prevent leakage. This

should require tightening the nuts approximately 1-1/2

to 2 full turns after they have both come into contact

with the compression plate.

16. Set the handle or actuator stops as described in the

SETTING HANDLE STOP Section or ACTUATOR

MOUNTING INSTRUCTIONS Section. Tighten the

screws holding the ratchet plate.