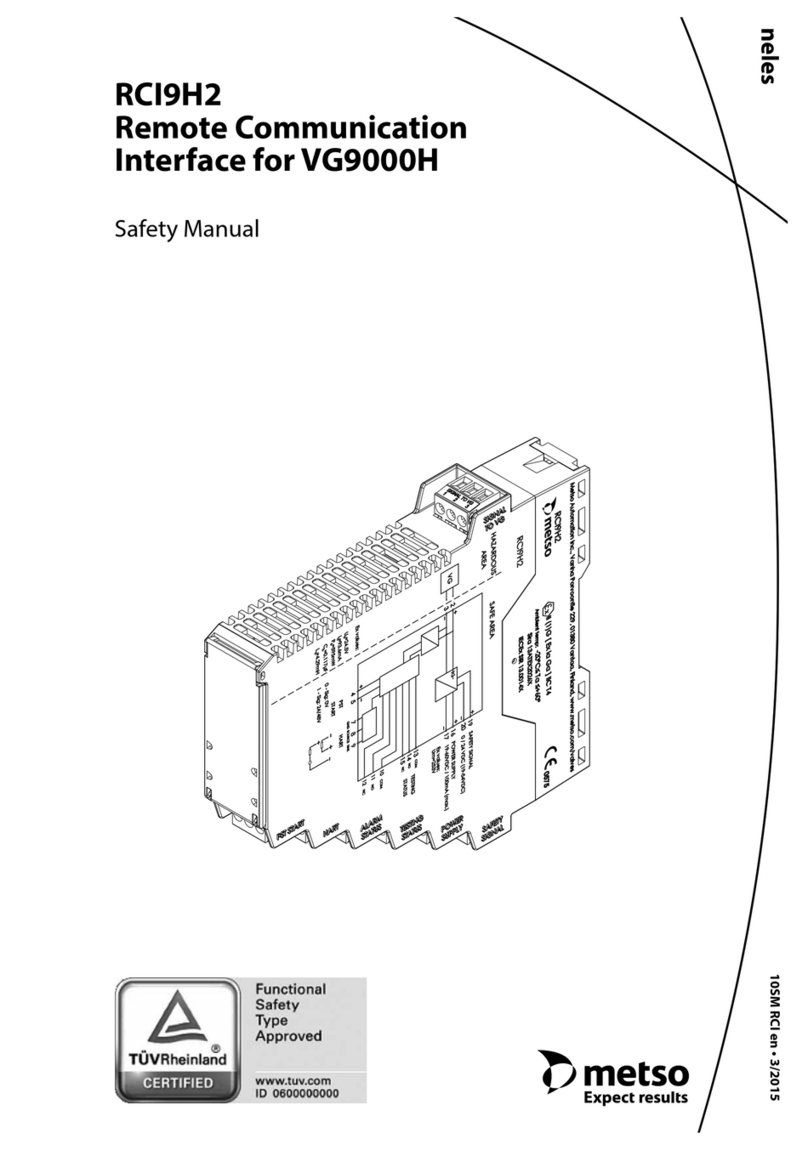

Metso Neles RCI9H2 Operating and maintenance manual

RCI9H2

Remote Communication Interface

for VG9000H

Installation, Maintenance and

Operating Instructions

7 RCI9H2 70 en • 8/2017

27 RCI9H2 70 en

READ THESE INSTRUCTIONS FIRST!

These instructions provide information about the safe handling and operation of the converter.

If you require additional assistance, please contact the manufacturer or manufacturer's representative.

Addresses and phone numbers are printed on the back cover.

See also www.metso.com/valves for the latest documentation.

SAVE THESE INSTRUCTIONS!

Subject to change without notice.

All trademarks are property of their respective owners.

Table of Contents

1 GENERAL...............................................................3

2 TECHNICAL SPECIFICATIONS ..............................3

3 RECYCLING AND DISPOSAL.................................4

4 SAFETY PRECAUTIONS ........................................4

5 TRANSPORTATION, RECEPTION AND STORAGE .4

6 INSTALLATION .....................................................4

6.1 Mounting..................................................................4

6.2 Dimensions..............................................................4

6.3 Electrical connections..........................................5

7 COMMISSIONING AND OPERATION ...................6

7.1 DIP Switches............................................................6

7.2 LEDs............................................................................6

8 MAINTENANCE .....................................................7

9 DIMENSIONS.........................................................7

10 EC DECLARATION OF CONFORMITY ...................8

7 RCI9H2 70 en 3

1 GENERAL

This manual incorporates Installation, Maintenance and

Operation Instructions for the Metso’s RCI9H2.

RCI9H2 is meant to be used together with Neles ValvGuard

VG9000H intelligent safety solenoid. It is needed when 24

VDC output (DO) is used in the safety system. RCI9H2 is con-

nected between the safety system and the field device

VG9000H as presented in Figure 1. The primary function of

RCI9H2 is to convert safety binary input from a safety DO

(Digital Output) system into a SIL 3 compatible 4-20 mA

current signal. RCI9H2 also provides relay outputs for moni-

toring the test and alarm status of the VG9000H and a dis-

crete input for commanding VG9000H to start a PST (Partial

Stroke Test). Additionally, RCI9H2 includes an isolated bar-

rier and can be used in intrinsically safe application.

RCI9H2 has local interface with status relays and LED’s,

which can be used to indicate the status information of the

VG9000H (Alarm and Test status).

RCI9H2 has two configuration switches. One switch is for to

connecting RCI9H2 internal HART loop resistor (250 Ω) to

HART loop and the other switch is configuring Mode A

(HART secondary master) / Mode B (HART monitor) selec-

tion.

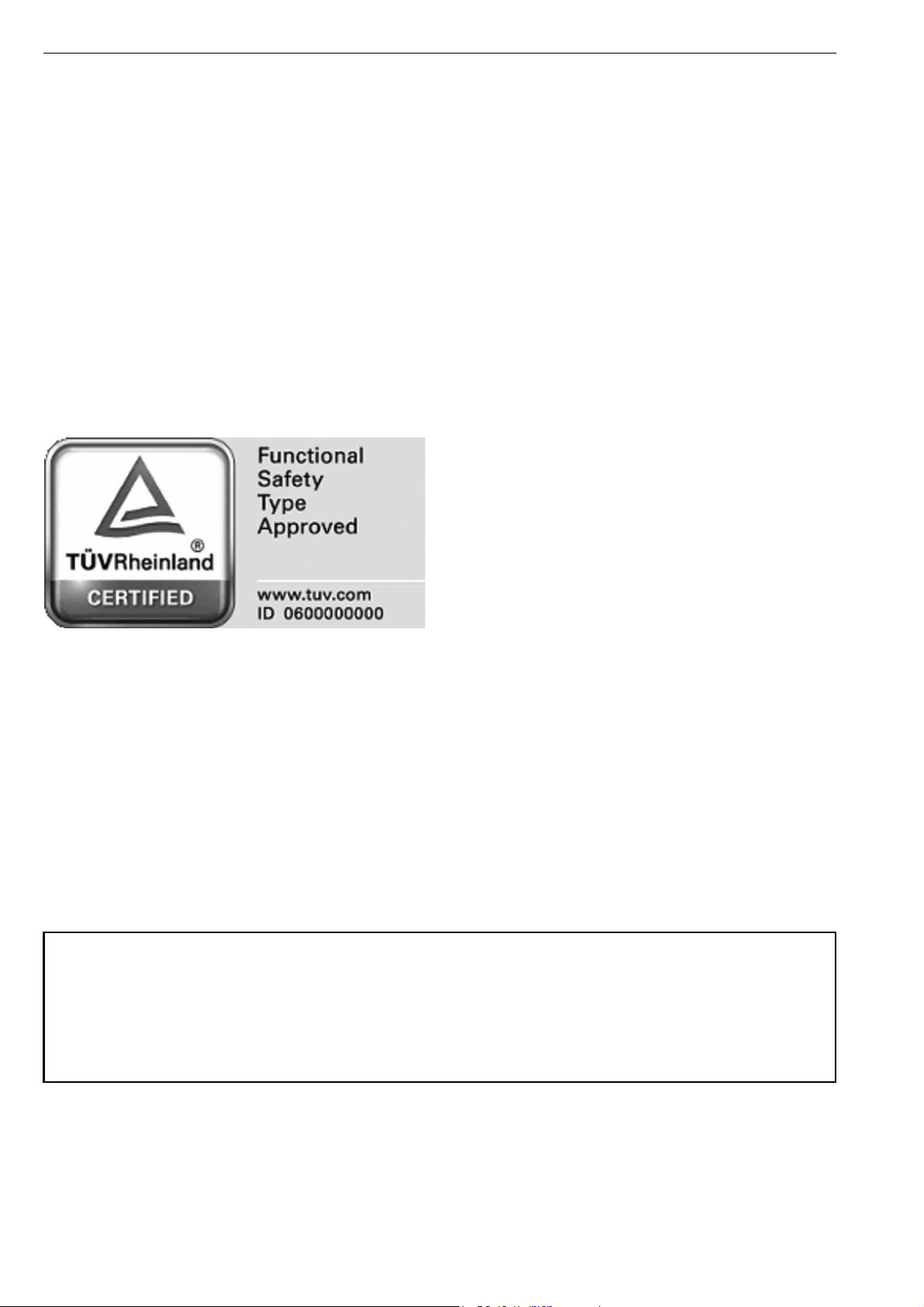

RCI9H2 is approved by TÜV Rheinland to be used in safety

applications up to and including safety integrity level 3

(SIL3).

2 TECHNICAL SPECIFICATIONS

Safety (input) signal:

Connection: Terminals 19+, 20-

Signal levels: 0-Signal: nominal 0 V

(-3–5 V) (leakage <2 mA)

1-Signal: nominal 24/48 V

(19–54 V DC)

Input Current: 26...38 mA (normal)

46.4 mA at 24 V DC (max)

47.9 mA at 48 V DC (max)

Max Voltage: 60 V DC

Polarity protection: -60 V DC

Over Voltage Protection: 60 V DC

Output to VG9000H:

Connection: Terminals 2+, 3-

Output current, normal mode:

0-Signal: nominal 4.2 mA,

(3.8–5.6 mA)

1-Signal: nominal 20.5 mA,

(18–22 mA)

Output current, loop powered mode 1 (power supply

not connected):

0-Signal: nominal 0 mA

1-Signal: nominal 16.4 mA,

(16–17 mA)

Output current, loop powered mode 2 (power supply

connected parallel with the safety signal):

0-Signal: nominal 0 mA

1-Signal: nominal 20.5 mA,

(18–22 mA)

Maximum load: 596 Ω

Response time: Input to output <100 ms

Power Supply:

Connection: Terminals 16+, 17-

Input voltage: 0-Signal: nominal 0 V (-3–5 V)

1-Signal: nominal 24/48 V

(19–54 V DC)

Input current: 57.4 mA at 24 V DC,

30.7 mA at 48 V DC

Max Voltage: 60 V DC

Polarity protection: -60 V DC

Over Voltage Protection: 60 V DC

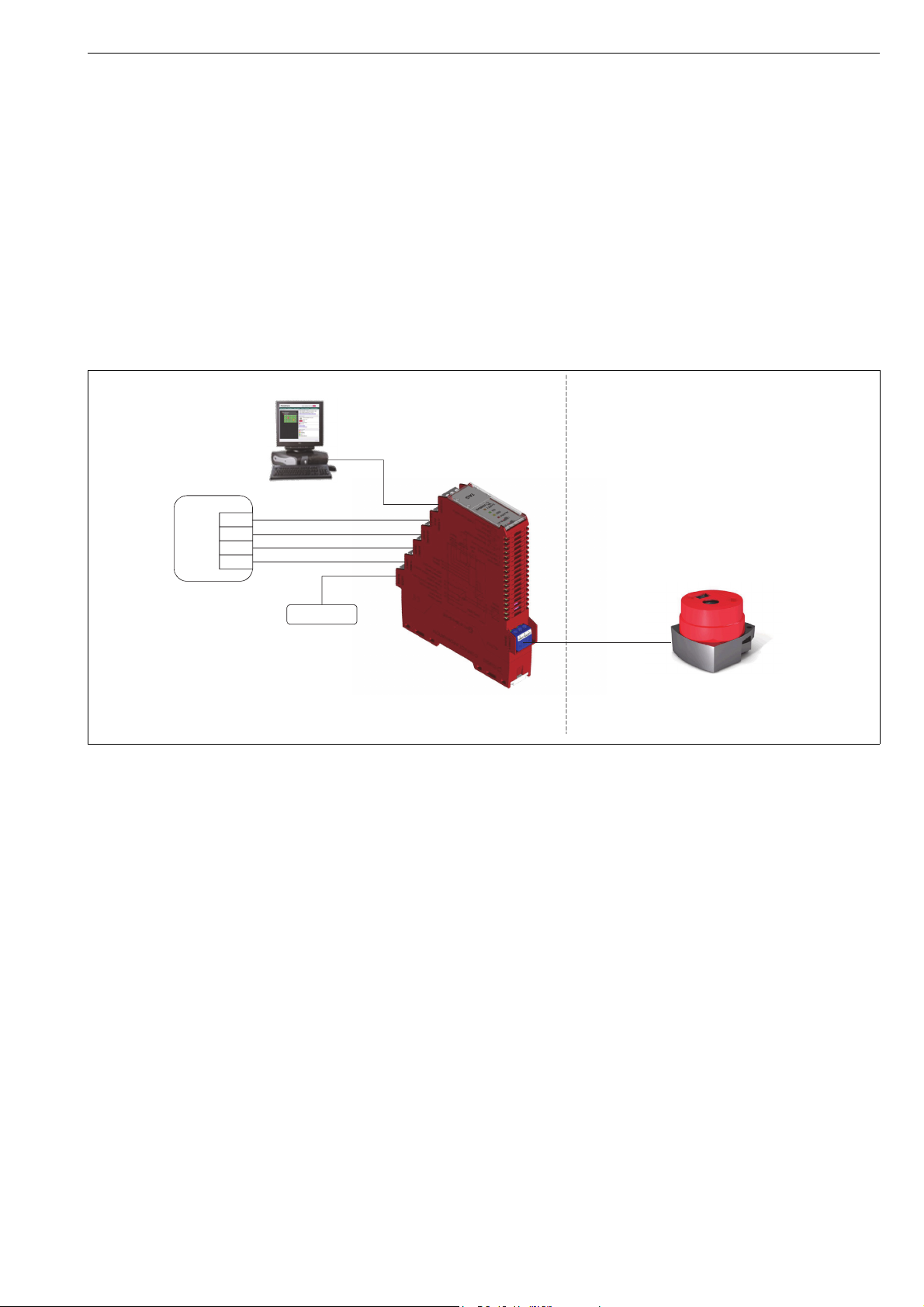

Fig. 1 RCI9H2 System Level Diagram

Power supply

Safety signal

Safe Area Hazardous Area

VG9000H

DO

Safety system

4/20 mA + HART

HART

RCI9H2

Testing status

Alarm status

PST start

DI

DI

DO

47 RCI9H2 70 en

HART:

Connection: Terminals 7-, 8+ (source)

Terminals 7-, 9+ (sink)

Input current: Fixed at 11 mA,

source or sink mode

Source mode:

Output voltage max 24 V DC

External load max 600 Ω

Sink mode:

Input voltage 24 V DC (nominal)

Internal load 230 Ω

PST start:

Connection: Terminals 4+, 5-

Signal level: 0-Signal: nominal 0 V (-3–5 V)

1-Signal: nominal 24/48 V

(19–54 V DC)

Signal type: Rising edge active

Input current 4.74 mA at 24 V DC,

9.47 mA at 48 V DC

Max Voltage: 60 V DC

Polarity protection: -60 V DC

Over Voltage Protection: 60 V DC

Testing Status:

Test Status relay OFF with Test Status LED OFF -indication

Connection: Terminals 13-14 open

Terminals 13-15 connected

Test Status relay ON with Test Status LED ON -indication

Connection: Terminals 13-15 open

Terminals 13-14 connected

Relay:

Type SPDT

Current 1A (max)

Voltage 24 V (nominal)

Alarm Status:

Alarm Status relay OFF with Alarm Status LED ON -

indication

Connection: Terminals 10-11 open

Terminals 10-12 connected

Alarm Status relay ON with Alarm Status LED OFF

Connection: Terminals 10-12 open

Terminals 10-11 connected

Relay:

Type SPDT

Current 1 A (max)

Voltage 24 V (nominal)

Ambient conditions:

Ambient temperature range: -20° to +60 °C

Mechanical specifications:

Protection degree: IP20

Weight: Approx. 215 g

Dimensions: 51.5 x 136.2 x 25.2 mm

Mounting: On 35 mm DIN mounting rail

acc. to EN 60715

Data for application in connection with Ex-areas:

ATEX/IECEx: Ex II (1) G [Ex ia Ga] IIC

cCSAus: Canada: [Ex ia] IIC

Class I, Division 1,

Groups A, B, C, D

U.S.: [AEx ia] IIC

Class 1 Zone 0, Class I,

Division 1, Groups A, B, C, D

Ex values: Uo = 24.5 V

Io = 93.6 mA

Po = 595 mW

Co = 0.117 μF

Lo = 4.29 mH

Approvals

Safety: Certified by TUV Rheinland

up to and including SIL3

according to IEC61508

IECEx: IECEx Sira 13.0014X

ATEX: Sira 13ATEX2026X

cCSAus

Electromagnetic compatibility:

According to EN61326,

EN61000-6-2, EN61000-6-4

3 RECYCLING AND DISPOSAL

Most parts can be recycled if sorted according to material.

Most parts have material marking. In addition, separate

recycling and disposal instructions are available from the

manufacturer. Device may also be returned to the manufac-

turer for recycling and disposal. There will be a charge for

this.

4SAFETYPRECAUTIONS

The quoted entity parameters of Co and Lo are applicable

for the distributed capacitance and inductance in cable.

Where there is circuit capacitance or inductance in the con-

nected equipment (represented by Ci and Li respectively),

then these values shall not exceed 50% of the quoted Co

and Lo.

5 TRANSPORTATION, RECEPTION AND

STORAGE

The RCI9H2 is a sophisticated device, handle it with care.

Check the device for any damage that may have

occurred during transportation.

Store the device preferably indoors; keep it away

from rain and dust.

Do not unpack the device until installing it.

Keep the original packaging. Always store and trans-

port the device in the original packaging.

Do not drop the device.

7 RCI9H2 70 en 5

6 INSTALLATION

6.1 Mounting

Open the two DIN rail retaining clips on the bottom of the

device. Mount the device onto the DIN mounting rail. Push

the retaining clips inwards to lock the device to the DIN rail.

Low heat dissipation of the device allows vertical and hori-

zontal wall mounting without spacing.

6.2 Dimensions

The mechanical dimensions of the device are shown in

Chapter 9.

6.3 Electrical connections

Safety Signal

Connect the safety signal (19-54 V DC) from the

safety system DO to terminals 19 +, 20-.

This signal controls the input signal to VG9000H (4/

20 mA).

Power Supply

Normal mode

Connect 24 V DC or 48 V DC power supply to termi-

nals 16+, 17-.

Loop powered mode 1

If power supply is disconnected, it will not affect the

valve position, but the HART communication, PST

input and Test & Alarm relays are not active.

Loop powered mode 2

Power supply can also be connected in parallel with

safety signal. In that case, the RCI9H2 is fully func-

tional (i.e. HART communication, PST input and Test

& Alarm relays are active) while safety signal is in “1”

state (19-54 V DC).

Signal to VG

Connect the VG9000H field wire to power supply can

also be terminals 2+, 3-.

Cable shall be one or more single-twisted pair

shielded or multiple-twisted pair with overall shield.

Single and multiple pair may be combined in a given

network provided all current input devices associ-

ated with multiple pairs of the same cable shall be

located nominally at one end of the multi-pair cable.

Unshielded cable may be used if it is demonstrated

that ambient noise or crosstalk does not affect com-

munication or functions of the ValvGuard.

HART communication

Source mode:

Connect HART master (e.g. HART multiplexer or

modem) without external power supply to terminals

7-, 8+. RCI9H2 is in current source mode and supplies

the 11 mA current to the HART terminals.

HART communication loop requires a load to be

present in the loop. This load can be set by the

switch S1. In this case the switch S1 needs to be set

to position III. In position III the HART loop resistor is

coupled between terminals 7 & 8 inside the device.

In position II the HART loop resistor is not coupled.

Do not set the switch S1 to position I in this case.

Sink mode:

Connect HART master (e.g. DCS AI), which is provid-

ing power to terminals 7-, 9+. RCI9H2 is in current

sink mode and does not supply the current to the

HART terminals. RCI9H2 will control the loop current

to the 11 mA.

HART communication loop requires a load to be

present in the loop. This load can be set by the

switch S1. In this case the switch S1 needs to be set

to position I. In position I the HART loop resistor is

coupled between terminals 7 & 9 inside the device.

In position II the HART loop resistor is not coupled.

Do not set the switch S1 to position III in this case.

PST Start

Partial Stroke Test can be started remotely via

RCI9H2 by providing binary signal (19-54 V DC) to

terminals 4+, 5-. The rising edge of this signal com-

mands VG9000H to start PST. VG9000H will run the

manual PST test, which is programmed in it's mem-

ory. The switch S2 need to be in position I to make

this input active.

Testing Status

Connect testing status output to relay terminals 13,

14 (normally open) or 13, 15 (normally connected).

When testing is active the relay is exited, resulting

terminals 13, 14 to be connected and terminals 13,

15 to be open.

The testing status is only available if the system is

configured properly. Please see the Chapter 2 “Tech-

nical specifications” and Chapter 7“Commissioning

and operation”.

Alarm Status

Connect alarm status output to relay terminals 10, 11

(normally open) or 10, 12 (normally closed). When

alarm is active the relay is NOT exited, resulting ter-

minals 10, 11 to be open and terminals 10, 12 to be

connected.

The alarm status is only available if the system is con-

figured properly. Please see the Chapter 2 “Technical

specifications” and Chapter 7“Commissioning and

operation”.

Fig. 2 Wiring connections

COM

NC

NO

10

12

11

0 / 24 VDC (19-54VDC)

HAZARDOUS

ARE A

+

VG

19

20

17

16

14

15

13

89

75

4

PST

START

HART

NO

NC

COM TESTING

STATUS

19-60VDC / 100mA (max.)

0 - Sig: 0V

1 - Sig: 24/48V

SAFE AREA

2

3

+

++

+

SAFETY SIGNAL

POWER SUPPLY

SOURCE

SINK

ALARM

STATUS

+

67 RCI9H2 70 en

7 COMMISSIONING AND OPERATION

7.1 DIP Switches

The RCI9H2 has two DIP switches; switch 1 (S1) and switch

2(S2).

7.1.1 Switch S1

Switch S1 S1 is for HART loop resistor configuration. S1 con-

figuration is explained in Chapter 6.3 “Electrical connections”.

7.1.2 Switch S2

Switch S2 is for HART mode selection.

S2 position I, HART secondary master mode

In this mode, full RCI9H2 functionality is available. PST start

input is functional and ALARM and TEST status outputs are

available. HART handheld communicator cannot be used if

HART primary master is present in the HART loop. In HART

loop, there can be only two masters and the handheld

would be the third one, which is not allowed.

S2 position II, HART monitor mode

In this mode, HART handheld can be used. PST input is not

functional. ALARM and TEST statuses are available if

VG9000H is configured to send HART burst status messages

to RCI9H2. This configuration can be made via VG9000H

DTM/EDD as follows:

Set the burst mode command to 169 (Read short sta-

tus).

Set the burst mode control parameter to ON to acti-

vate the burst mode. Default is OFF.

7.2 LEDs

Fig. 3 Terminals, switches and LEDs

Signal to VG

Switch 1 (HART loop resistor)

Switch 2 (HART mode)

PST start

HART

Alarm status

Test status

Power supply

Safety signal

Alarm (red)

Test (yellow)

Power supply (green)

Safety signal (orange)

Table 1 Switch selections

Switch S1 HART loop resistor Mode / Teminals

IYesSink(7,9)

II No (factory default) Source or sink

III Yes Source (7, 8)

Switch S2 HART mode

I Secondary master

(factory default)

II Monitor

Table 2 LED message explanation

LED Name Color Function Display Reason

ALARM Red Indication of an alarm ON - VG9000H is in alarm state or

- HART Communication timeout between VG9000H

and RCI9H2 because of wrong configuration or failure

in wiring between RCI9H2 and VG9000H or

- RCI9H2 internal memory test has failed.

- RCI is in monitor mode, but the burst mode is OFF in VG

OFF - No active alarms or errors

- If alarms are active in VG, but the RCI power supply is not

connected, they won’t be shown in RCI.

TEST Yellow Indication of partial stroke test ON VG9000H has on-going test or test warning time has started.

NOTE: Test LED / status relay is showing the test warning time

with VG9000H firmware revision 1.32 and onwards when using

the HART monitor mode.

OFF No test is running

OK Green Indication of presence of

power supply ON Power supply is present, no alarm

OFF Power supply not present or device is faulty

Blinking Power supply is present and alarm is active

SAFETY Orange Indication of presence of

safety signal ON Safety signal is present.

OFF Safety signal is not present.

- Safety system DO is in “0”state or

- Safety signal is not connected to terminals or

-Failureinwiring

7 RCI9H2 70 en 7

8 MAINTENANCE

If RCI9H2 unit becomes faulty, the complete unit needs to

be replaced with a new unit.

Replace the unit by following these instructions.

1. Note that the replacement of the RCI9H2 will

disconnect VG9000H from operation and the valve

will move to fail-safe position.

2. Pull out the wire terminals by help of a small flat

screwdriver. Make sure that you are able to

reconnect the terminals in the same order.

3. Pull the DIN rail retaining clips outwards using a flat

screwdriver.

4. Take RCI9H2 off the DIN rail and replace with a new

one.

5. Push the DIN rail retaining clips inwards to lock the

unit to the DIN rail.

6. Push wire terminals back to the RCI9H2. Make sure

that you reconnect the terminals in the correct

positions.

7. No special tools needed for maintenance.

9 DIMENSIONS

25.20

151.5

146.0

136.2

Metso Flow Control Inc.

Europe, Vanha Porvoontie 229, P.O. Box 304, FI-01301 Vantaa, Finland. Tel. +358 20 483 150. Fax +358 20 483 151

North America, 44 Bowditch Drive, P.O. Box 8044, Shrewsbury, M A 01545, USA. Tel. +1 508 852 0200. Fax +1 508 852 8172

South America, Av. Independéncia, 2500-Iporanga, 18087-101, Sorocaba-São Paulo, Brazil. Tel. +55 15 2102 9700. Fax +55 15 2102 9748

Asia Pacic, 238B Thomson Road, #17-01 Novena Square Tower B, Singapore 307685. Tel. +65 6511 1011. Fax +65 6250 0830

China, 11/F, China Youth Plaza, No.19 North Rd of East 3rd Ring Rd, Chaoyang District, Beijing 100020, China. Tel. +86 10 6566 6600. Fax +86 10 6566 2583

Middle East, Roundabout 8, Unit AB-07, P.O. Box 17175, Jebel Ali Freezone, Dubai, United Arab Emirates. Tel. +971 4 883 6974. Fax +971 4 883 6836

www.metso.com/valves

87 RCI9H2 70 en

10 EC DECLARATION OF CONFORMITY

EC DECLARATION OF CONFORMITY

Manufacturer:

Metso Automation Oy

01301 Vantaa

Finland

Product: Remote communication interface RCI9H2

Approvals:

Approval EC Type examination Certificate

(EMC 2004/108/EC) EN61326,

EN61000-6-2, EN61000-6-4

TÜV 01200131001

Ex II (1) G [Ex ia Ga] IIC Sira 13ATEX2026X

Applicable directives:

EMC 2004/108/EC Electrical

ATEX 94/9/EC (until 19 April 2016)

ATEX 2014/34/EU (from 20 April 2016)

Approved and Ex marked types

As the products within our sole responsibility of design and manufacture may be used as parts

or components in machinery and are not alone performing functions as described in Article 6(2)

in the Machinery Directive (2006/42/EC), we declare that our product(s) to which this

Declaration of Conformity relates must NOT be put into service until the relevant machinery into

which it is to be incorporated has been declared in conformity with the provisions of the

Machinery Directive.

The product above is manufactured in compliance with the applicable European directives and

technical specifications/standards.

Protection from e.g. static electricity caused by the process or connected equipment must be

considered by the user (EN 60079-14 §6).

The product do not possess any residual risk according to hazard analyses made under the

applicable directives providing that the procedures stated by the Installation, Operation and

Maintenance manual are followed and the product is used under conditions mentioned in the

technical specifications.

Manufacturer´s certificates:

Standard / Directive Notified Body Certificate No.

ISO 9001:2008 DNV 73538-2010-AQ-FIN-FINAS

ATEX 94/9/EC Annex IV DNV 0575 DNV-2006-OSL-ATEX-0260Q

Vantaa 7th January 2016

Ralf Liljestrand, Manager, Product safety and compliance

This manual suits for next models

1

Table of contents

Other Metso Recording Equipment manuals