Metso PDP Series Operating instructions

Model PDP DPU

Installation, Preparation

and Adjustment

277573 Rev. A1

Metso Automation MAX Controls •

••

•277573 •

••

•

Refer to this publication for complete and accurate information that helps you better operate and service Metso

Automation MAX Controls equipment. Your comments and suggestions are welcome.

Metso Automation MAX Controls

1180 Church Road

Lansdale, PA 19446

Attention: Manager, Technical Publications

Copyright 1999-2001 by Metso Automation MAX Controls Inc.

Printed in the United States of America

All rights reserved

Metso Automation MAX Controls •

••

•277573 •

••

•

Contents

PREFACE ........................................................................................................................... III

CHAPTER 1 ......................................................................................................................1-1

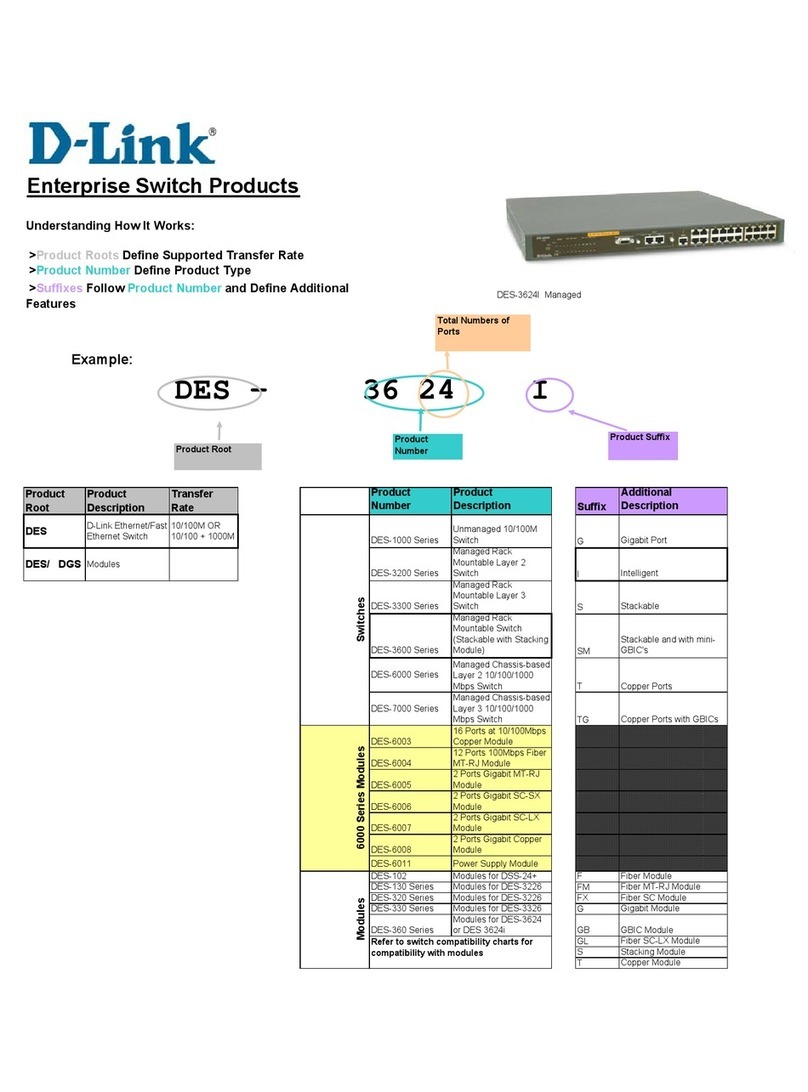

Introduction................................................................................................................................................................. 1-1

Distributed Processing Unit Functionality ................................................................................................................ 1-1

Distributed Processing Unit Hardware.............................................................................................................. 1-1

Distributed Processing Unit Specifications....................................................................................................... 1-2

Mounting the DPU................................................................................................................................................ 1-2

Positioning the DPU.......................................................................................................................................... 1-2

Mounting Procedures ........................................................................................................................................ 1-3

Wiring the DPU .................................................................................................................................................... 1-3

CHAPTER 2 ......................................................................................................................2-1

DPU Front Panel.........................................................................................................................................................2-1

Overview................................................................................................................................................................... 2-1

Mode Select DIP Switch Settings.......................................................................................................................... 2-1

Data Highway Area............................................................................................................................................... 2-2

Using Rotary Switches to Set Station Address.................................................................................................. 2-2

Two LED Displays............................................................................................................................................ 2-3

IOM Load.......................................................................................................................................................... 2-3

Status Section (LEDs)........................................................................................................................................... 2-4

DPU Hardware Status LEDs............................................................................................................................. 2-4

Serial I/O and DPU Status Section.................................................................................................................... 2-4

Backup Status LEDs.......................................................................................................................................... 2-5

Reset Button.......................................................................................................................................................... 2-6

Backup Link.......................................................................................................................................................... 2-6

CPU Load.............................................................................................................................................................. 2-6

Takeover Button.................................................................................................................................................... 2-6

Backup DIP Switch Settings ................................................................................................................................. 2-6

DPU Keyswitch..................................................................................................................................................... 2-7

CHAPTER 3 ......................................................................................................................3-1

Input/Output Connections..........................................................................................................................................3-1

Data Highway............................................................................................................................................................ 3-1

ACSII Ports....................................................................................................................................................... 3-1

Model PDP DPU Installation, Preparation and Adjustment

Metso Automation MAX Controls •

••

•277573 •

••

•

CHAPTER 4.......................................................................................................................4-1

DPU Battery and Fuse Maintenance.........................................................................................................................4-1

Battery Types............................................................................................................................................................4-1

Replacing the NiCd Battery Pack (Battery #2)......................................................................................................4-1

Replacing the Lithium Battery (Battery #1)..........................................................................................................4-2

Replacing DPU Fuses............................................................................................................................................4-3

CHAPTER 5.......................................................................................................................5-1

Backing up the DPU....................................................................................................................................................5-1

Overview...................................................................................................................................................................5-1

Automatic Failover/Manual Takeover...............................................................................................................5-1

Automatic Failover............................................................................................................................................5-1

Manual Takeover...............................................................................................................................................5-1

Cable Disconnect...............................................................................................................................................5-2

CHAPTER 6.......................................................................................................................6-1

Starting the DPU.........................................................................................................................................................6-1

Startup States.............................................................................................................................................................6-1

Demanding a Cold Startup ....................................................................................................................................6-2

Starting a Standalone DPU....................................................................................................................................6-2

Starting a Backup Pair of DPUs............................................................................................................................6-3

Replacing a DPU in a Backup Pair........................................................................................................................6-5

CHAPTER 7......................................................................................................................7-1

Using Interaction Pages.............................................................................................................................................7-1

Accessing Displays....................................................................................................................................................7-1

Using Interaction Page 9 Display with a Workstation...........................................................................................7-1

Startup...............................................................................................................................................................7-1

Backup Option...................................................................................................................................................7-1

Digital Input Filter Time Field ..........................................................................................................................7-2

Serial Ports Field...............................................................................................................................................7-2

Lockout and Log Options Field.........................................................................................................................7-2

Using Interaction Page 9 Display with an Operator Station..................................................................................7-2

Startup...............................................................................................................................................................7-4

Backup Option Field .........................................................................................................................................7-4

Stat Page Field...................................................................................................................................................7-4

DIO Inventory Field..........................................................................................................................................7-4

Digital Input Filter Time Field ..........................................................................................................................7-5

Analog Input Inventory Field ............................................................................................................................7-5

Redundant I/O Address Ranges Field................................................................................................................7-5

Lockout and Log Options Field.........................................................................................................................7-5

Serial Ports Field...............................................................................................................................................7-5

Interaction Page 10................................................................................................................................................7-6

Event Queue Pointer Information......................................................................................................................7-7

Interaction Page 11................................................................................................................................................7-8

Interaction Page 12................................................................................................................................................7-9

Interaction Page 13..............................................................................................................................................7-10

Contents

v

CHAPTER 8 .....................................................................................................................8-1

Alarms and Diagnostics..............................................................................................................................................8-1

Annunciation of Alarms............................................................................................................................................ 8-1

Front Panel Numeric LEDs............................................................................................................................... 8-1

Metso Automation MAX Controls •

••

•277573 •

••

•

Preface

The Distributed Processing Unit described in this publication consists of two

models, the Model PDP001 Series and the Model PDP100 Series. From a

hardware perspective, the two models are virtually identical. At the software

level, however, the two models contain different firmware. The Version 7.1

Firmware makes the Model PDP100 Series compatible with the IEC 1131-3

toolset. The Model PDP001 Series supports Metso Automation MAX

Controls EXtended Control Engineering Language (ExCEL), a Metso

Automation MAX Controls programming language, and ladder logic.

In addition to DPU front panel controls, to a limited extent you may control

a DPU from the maxSTATION running maxVUE Runtime software.

maxVUE Runtime also lets you monitor DPU status, DPU-related alarms,

and access DPU Interaction Pages, containing data and system statistics

stored in the DPU. Interaction Pages are described in Chapter 3. For

maxVUE Runtime information, refer to Publication 277557, MaxSTATION

Operator' s Guide. You may reload a DPU's configuration from the

maxSTATION running maxTOOLS software. Refer to the maxTOOLS

online help supplied with the package for configuration installation

instructions.

Metso Automation MAX Controls •

••

•277573 •

••

•

Chapter 1

Introduction

Distributed Processing Unit Functionality

The Model PDP Distributed Processing Unit (DPU) performs primary data

acquisition, control, and data processing functions for the maxDNA

Distributed Control System. The DPU is a self-contained microprocessor-

based, rack-mounted unit, which occupies a single slot in a Remote

Processing Unit cabinet. It is designed to operate with user-defined

combinations of maxDNA Model IOP Input/Output Modules, and to

communicate with other devices, such as Programmable Logic Controllers

and Remote Terminal Units.

As a station on the DPU Bus, the DPU scans and processes information for

use by other devices in the maxDNA system. Each DPU performs:

•Comprehensive alarming and calculations.

•Logging of Sequence of Events (SOE) data.

•Acquisition of trend information.

•Continuous scanning of Model IOP I/O modules.

•Execution of predefined Control and Data Blocks for process control and

data acquisition.

•Execution of user written programs using IEC1131-3 Toolset or Metso

Automation MAX Controls EXtended Control Engineering Language

(ExCEL).

•Ladder logic processing.

•Assurance of secure link-level data highway communications.

Distributed Processing Unit Hardware

A DPU consists of three circuit cards installed in a rack-mounted chassis.

The right front chassis panel contains two clockwise and counter-clockwise

connectors, two serial ports, 10 terminal blocks, and the DPU keylock.

Model PDP DPU Installation, Preparation and Adjustment

Metso Automation MAX Controls •

••

•277573 •

••

•

1-2

The processor cards mounted behind the gray and white front panel consist

of the motherboard, Data Highway Card, and the Control Processor Card.

The Data Highway Card and Control Processor Card are mounted as

daughter cards on the motherboard.

Except for the Control Processor Card, the front edge of each processor card

features switches, indicator lamps, and rotary dials that are visible and

accessible from the DPU front panel.

Distributed Processing Unit Specifications

Operating temperature range 0 to 60 degrees C

Storage temperature range (-)25 to 70 degrees C

Relative humidity range 5 to 90% noncondensing

Power requirements 24 Vdc ±4 Vdc, 1.2 amps

Mounting the DPU The Model PDP Distributed Processing Unit (DPU) is mounted on the

Input/Output (I/O) backplane with Model IOP Input/Output modules.

Positioning the DPU

The DPU must be mounted in the right most position of the Model IOP rack

since the DPU is wider than the I/O cards and requires good air flow. In a

six-wide I/O rack, the mounting bracket to the left of the DPU must be

removed since the DPU requires an I/O panel.

When using a second DPU for backup, it must be mounted vertically

adjacent to the primary DPU.

When the DPU is installed in the right most slot, the DPU cover extends

over the J3 and J4 connectors on the back panel. The standard daisy-chain

cable (064353) is low profile, however, and will not cause any interference.

Any cables higher than 1 inch above the surface of the backplane, and any

terminators, will interfere with the cover. Some older cables, in particular,

will interfere with the DPU cover. It may be possible to move the terminator

to the other end of the daisy-chain or to rearrange the order of the

daisy-chain cables to eliminate the interference.

If this is not possible, a cable adapter is available (Metso Automation MAX

Controls Part Number 081580). This adapter has a metal bracket which

mounts to the power strut and a 12-inch connecting cable plugs into J3 or J4

on the back panel. It is a male-female adapter so that the original cable or

Introduction

Metso Automation MAX Controls •

••

•277573 •

••

•1-3

terminator can be plugged directly into the adapter out of the way of

interference with the DPU.

The DPU is designed to allow installation and removal with the +24 V dc

power supply turned on.

Mounting Procedures

Before mounting any hardware, refer to the cabling and field wiring sections

of Publication 277563, Model IOP Input/Output System Installation and Pre-

paration, for information also pertinent to mounting.

To install the DPU in the rack, refer to Chapter 6.

Wiring the DPU With the exception of the 10 point terminal block on the front panel of the

DPU chassis, no hard wiring is required. All connections between the DPU

module and the DPU chassis are made upon installation into the I/O rack.

Use maxTOOLS to create input designations for each DPU during

configuration.

Ten terminal board connectors, with #6 screws, are positioned at the lower

left side of the DPU chassis. Pin-outs are as follows:

Table 1-1. Ten Point Terminal Block

PIN No. Pur

p

ose

1-6 Reserved

7 Open

8, 9 DPU offline contact (photovoltaic relay, opens when the DPU is

offline)

Peak operating voltage = ±300V

Maximum load = 60 mA

On resistance = 30 Ohms

Off resistance = 1 mOhms (Contact is closed if DPU is online)

10 Circuit Groun

d

Metso Automation MAX Controls •

••

•277573 •

••

•

Mode Select

10

8

4

2

1

CW

CCW

Off

On

Data Highway Off

On

Status Jabber

IOM

Load

Stn No.

G Active

R Offline

Y Inactive State

Battery

Power

G- Tx

R- Rx

1

Serial Ports

2

G- Active

R- Error

DI

DO

Per IO

Prog IO

Tx

Backup

Rx

Reset

CPU Load

Backup

Link

Takeover

Pri

PIO

SIO1

SIO2 Sep

Com

Sec

DistributedProcessingUnit

Chapter 2

DPU Front Panel

Overview All DPU controls, indicator lamps,

keylock, and switches are located on the

DPU front panel. Refer to Figure 2-1,

DPU Front Panel. Use this front panel to

monitor or control different aspects of

the DPU. This chapter describes and

illustrates individual sections. The

various front panel features are generally

positioned in two vertical panel areas

corresponding to supporting processor

card positions mounted behind the front

panel.

Mode Select DIP Switch Settings

The mode switches, located at the top of

the front panel, are used during DPU

manufacturing and testing. For normal

DPU operation, all four switches should

be set to the left. Setting the B (Blank

database) SW8, 2, 1 to the left, and SW4

to the right during power on or reset

causes the DPU to erase its database and

come up cold. Once the DPU is

operational (DPU on DPU Bus), be sure

to set the mode switches back to the left.

Figure 2-1. DPU

Front Panel

Model PDP DPU Installation, Preparation and Adjustment

Metso Automation MAX Controls •

••

•277573 •

••

•

2-2

Data Highway Area The Data Highway Area, (Figure 2-2), located in the upper right area of the

gray front panel, consists of:

•Two toggle switches used to intentionally break the CW and/or CCW

highway connections to this DPU to simulate communications loss for

systems testing (e.g., cable break reporting) without actually disconnecting

cables.

•Jabberhalt error LED to indicate timeout of excessively long transmissions.

•Two rotary switches to provide the station address; refer to next section.

•Two LED displays; refer to "Two LED Displays."

There are no internal switches or jumpers to be set during installation.

Figure 2-2. Upper Front Panel Area

DPU Front Panel

Metso Automation MAX Controls •

••

•277573 •

••

•2-3

Using Rotary Switches to Set Station Address

Use the two rotary switches to configure a unique DPU highway station

address, a number ranging from 32 and 63; the station number is set in

hexadecimal (hex). The upper switch sets the most significant digit of the

address (e.g., 3 for Station 50). The lower switch sets the least significant

digit for the address (e.g., 2 for Station 50).

Hexadecimal Decimal

00

11

22

33

44

55

66

77

88

99

A10

B11

C12

D13

E14

F15

To convert a two-digit hexadecimal number

to decimal, multiply the first digit by 16 and

add the decimal value of the second digit.

2C hex = 2 * 16 + C

= 32 + 12

= 44

To convert decimal to hexadecimal, divide

the decimal number by 16 until a remainder

of less than 16 is obtained:

50 decimal = 50÷16 = 3 (hex)

with 2 (2 hex) remainder

= 32 hex

Two LED Displays

The two seven-segment LED displays report highway status using hex

numbers. During DPU startup, the LEDs display FF. When the DPU

concludes its startup phase, the LEDs alternately display the codes 03, 04,

and 07 to indicate:

(03) query response transfer is in progress

(04) token passing is in progress

(07 the DPU is executing normal background functions

If an error occurs in the DPU, causing it to fail, these LEDs display an error

code. Refer to Chapter 8 for a listing of error codes.

IOM Load

Metso Automation MAX Controls Factory Service use only.

Model PDP DPU Installation, Preparation and Adjustment

Metso Automation MAX Controls •

••

•277573 •

••

•

2-4

Status Section (LEDs)

The middle area of the front panel contains 11 tri-colored LEDs (green, red,

and yellow). Refer to Figure 2-3. The LEDs indicate the status of a variety of

tasks, such as I/O bus scanning. Refer to the following tables for a list of

definitions for the color-coded LEDs.

DPU Hardware Status LEDs

The first three LEDs specifically relate to DPU hardware status.

LED What the Colors Mean

Active Green = DPU online and active.

Offline Red = DPU offline.

Inactive Yellow = DPU online but inactive (backup pair).

Battery Red = nickel cadmium or lithium battery bad.

Yellow = nickel cadmium battery under test.

Green = both batteries good.

Power Green = DPU powered.

Figure 2-3. Status LEDs

DPU Front Panel

Metso Automation MAX Controls •

••

•277573 •

••

•2-5

Serial I/O and DPU Status Section

LED What the Colors Mean

Serial port1 Green = serial port 1 transmitting.

Red = serial port 1 receiving.

Serial port2 Green = serial port 2 transmitting.

Red = serial port 2 receiving.

Status Section LED Indicators

DI Fast Digital Input Scanning:

green = all points good

red = all points bad

yellow = some points good and some points bad

off = no points executing

DO Fast Digital Output Scanning:

green = all points good

red = all points bad

yellow = some points good and some points bad

off = no points executing

Per IO Periodic Input/Output scanning Analog

Inputs, Control Blocks, Data Blocks

green = all points good

red = all points bad

yellow = some points good and some points bad

off = no points executing

Prog IO ExCEL Input/Output Scanning

green = all points good

red = all points bad

yellow = some points good and some points bad

off = no points executing

Backup Status LEDs

The following two LEDs report backup link status.

LED What the Colors Mean

RX green = Receiving data.

TX green = Transmitting data.

Model PDP DPU Installation, Preparation and Adjustment

Metso Automation MAX Controls •

••

•277573 •

••

•

2-6

Reset Button The Reset pushbutton does not produce a true hard reset; when you press

this button, the DPU receives a false indication of impending +24 Volt

power loss, causing the DPU to save the database into flash memory and

wait for a power down that never occurs. However, a deadman timer

associated with the Control Processor Card will cause a true hard reset after

this routine finishes, after which a cool initialization will occur.

Backup Link When used with a backup DPU, a cable (Part 081387) runs between this

connector on both DPUs.

When used without a backup DPU, a terminator (Part 081388) must be

installed in this connector.

CPU Load For Metso Automation MAX Controls Factory Service use only.

Takeover Button When two DPUs are used in a backup configuration, press the Takeover

button on one of the DPUs to force that DPU to take control, making the

other inactive.

Backup DIP Switch Settings

Use the four-position backup DIP switch to select various DPU backup

configurations. If backup is not configured, the top most switch should be set

to the right and the others to the left. Refer to Chapter 5.

The first position (top) on the DIP switch lets you designate the DPU as

primary or secondary. Primary is to the right.

The second position designates a separate or shared parallel input/output

bus. Common (Shared) is to the left. Separate is to the right.

Note: if you are configuring a mixed I/O system using some shared and some

separate I/O with a Y-Adapter, select Separate.

DPU Front Panel

Metso Automation MAX Controls •

••

•277573 •

••

•2-7

The third position designates a separate or shared link connected to serial

port 1. Separate is to the right. Common (Shared) is to the left.

The fourth position designates a separate or shared link connected to serial

port 2. Separate is to the right. Common (Shared) is to the left.

DPU Keyswitch Use the DPU keyswitch, located at the bottom part of the DPU chassis, to

select one of three operator modes. The DPU can operate with the key in

place or removed; you can remove the key from the switch regardless of key

position.

The keyswitch may be placed in one of the following three positions:

Run Keyslot horizontal

The DPU executes the functions defined in its point

database. In this mode, you are permitted to reload a DPU

database; however you cannot configure Interaction Page 9.

Offline Keyslot diagonal, one-quarter turn counterclockwise from

Run.

In this mode, the DPU scans inputs but does not execute

outputs. To service the DPU, you may manually select

offline by turning the keyswitch to this position.

Offline is imposed automatically with the keyswitch in run or

locked position when a fatal diagnostic is detected.

Locked Keyslot diagonal, one-quarter turn clockwise from Run.

In this mode, the DPU executes the functions defined in its

point database. Reloads and database changes may or may

not be permitted, depending on the DPU configuration as

shown on Interaction Page 9.

Metso Automation MAX Controls •

••

•277573 •

••

•

Chapter 3

Input/Output

Connections

Data Highway The upper left portion of the DPU chassis features two groups of male and

female 9-pin D-type connectors used to connect the clockwise (CW) and

counter-clockwise (CCW) DPU Bus cables. Positions J2 and J3 are for CW

connections, and J4 and J5 are for CCW. For additional information on

Input/Output connections, refer to Publication 277580, DPU Bus Cabling.

ACSII Ports

Directly below the DPU Bus connections are two female 25-pin D-type

connectors (J6 and J7) which serve as ASCII serial ports. Table 3-1 provides

the pin-outs for both ports. These two ASCII ports provide linkage to

programmable logic controllers, remote multiplexers, etc. Connections can

be RS-232, RS-422, or RS-485, chosen without jumpers, with proper

connection to the 25-pin D-Connectors. When you define a DPU via

maxTOOLS, you may configure setup parameters, such as baud rate, parity,

and number of stop bits. You may also enter setup information directly on

Interaction Page 9. Remember, when you add this information, you must

take the DPU offline.

Table 3-1. ASCII Port Pin-outs (usable via ExCEL, Rev. 2)

Pin No. Purpose

24 Transmit Data TxD + (RS-422)

2 Transmit Data TxD - (RS-422), or TxD (RS-232/423)

23 Receive Data RxD + (RS-422)

3 Receive Data RxD - (RS-422), or RxD (RS-232/423)

4 Request-to-Send RTS (RS-232/423)

5 Clear-to-Send CTS (RS-232/423)

7 Circuit Ground

1 Chassis Ground

Metso Automation MAX Controls •

••

•277573 •

••

•

Chapter 4

DPU Battery and

Fuse Maintenance

Battery Types The Model PDP DPU uses two battery types that must be replaced

periodically. A Nickel Cadmium (NiCd) rechargeable battery pack, mounted

on the motherboard, allows the DPU to preserve its database when power

goes down. This battery, tested for one minute every hour, will raise a "bat-

tery #2 weak" battery low alarm if it fails.

The DPU Control Processor Card uses a 360 maH Lithium battery to

preserve CMOS settings and time and date. If this battery fails, a "battery #1

weak" battery low alarm will be raised. The battery has a shelf life of 10

years under "no load" conditions. When the DPU is powered, the battery is

electronically disconnected. The Control Processor Card battery will last for

more than two years if no power is applied to the board.

Caution: The DPU contains devices that can be damaged by electrostatic

discharge. It is imperative that the DPU be carried in antistatic protective

bags. Grounded workstations and wrist straps must be used when

adjusting or performing any work on the DPU. If soldering irons are used,

they must also be grounded.

Replacing the NiCd Battery Pack (Battery #2)

Note: when the DPU is shipped or put in storage, always unplug the NiCd

battery pack from the P10 connector.

The DPU NiCd battery pack (Part number 081537) should be replaced at

least every three years. Spare NiCd battery packs have a shelf life of 5 to 7

years.

The battery is located in an accessible compartment on the upper right side

of the DPU. To access the battery, you must remove the DPU from the rack

as described in the following procedure:

Model PDP DPU Installation, Preparation and Adjustment

Metso Automation MAX Controls •

••

•277573 •

••

•

4-2

To replace the battery:

1. Important: If the DPU to be serviced is part of a DPU pair, use the

instructions in Chapter 6, "Replacing a DPU in a Backup Pair," to

extract the DPU. If the DPU to be serviced is configured standalone,

place the keyswitch in the offline position and use the following

instructions.

Gently slide the DPU module out of the cabinet rack and set the unit

down on an appropriate work surface, component side up.

2. Locate the battery compartment on the upper right side.

3. Remove the battery plug connector from the P10 port.

4. Remove the failed battery from its holder clips and dispose of it

appropriately.

5. Slide the new battery pack in between the holder clips and plug the

battery's plug connector into the P10 port.

6. Install the DPU in the chassis using the appropriate procedure found in

Chapter 6," Starting a Standalone DPU," or "Replacing a DPU in a

Backup Pair."

Replacing the Lithium Battery (Battery #1)

The Lithium battery is mounted on the Control Processor board. Replace the

battery with a 360mAh TLS186 Tadiran battery or equivalent. (Part number

081558).

To replace the battery:

1. Important: If the DPU to be serviced is part of a DPU pair, use the

instructions in Chapter 6, "Replacing a DPU in a Backup Pair" to

extract the DPU. If the DPU to be serviced is configured standalone,

place the keyswitch in the offline position and use the following

instructions.

Gently slide the DPU module out of the cabinet rack and set the unit

down on an appropriate work surface, component side up.

2. Remove the top metal cover.

3. Locate the battery. It is on the top side of the Control Processor board

near the DB25 connector.

4. Carefully remove the battery by pulling it straight up. Do not use any

metal tools since they could short the battery leads. Additionally, do

DPU Battery and Fuse Maintenance

Metso Automation MAX Controls •

••

•277573 •

••

•4-3

not place any pressure on the circuits near the battery.

5. Install the battery into the same connector from which the old battery

was removed (B1). Make sure that the (+) lead, the center of the

battery, plugs into the end pin of the connector marked with the (+) on

the board. The second lead (-) should go into the fourth pin on

connector B1.

6. Install the metal cover.

7. Install the DPU in the chassis using the appropriate procedure found

in Chapter 6," Starting a Standalone DPU," or "Replacing a DPU in a

Backup Pair."

Replacing DPU Fuses

The DPU has two fuses, located on the motherboard, marked F1 and F2.

Both fuses are subminiatures (resemble resistors). Fuse F1, 3A (Part number

014257), is used for external battery power. Fuse 2, 3A (Part number

014257), is used for 24V power. They are both mounted directly to the board

by their leads and plugged into sockets.

To change the fuses, follow the same procedure for changing the lithium

battery, as described in the previous section, locate and replace the fuses.

This manual suits for next models

2

Table of contents

Other Metso Switch manuals

Popular Switch manuals by other brands

D-Link

D-Link DGS-3024 user guide

Lights Alive

Lights Alive FireFly FF-151 Instructions and specifications

Pepperl+Fuchs

Pepperl+Fuchs LVL-M4 instruction manual

FS

FS S3150-8T2FP Configuration guide

ADC

ADC PowerWorx Circuit Breaker Panel With Reset... user manual

foxunhd

foxunhd FX-SDI-201 operating instructions