METVISA BIMG MCG8110M604 User manual

1

2

CONGRATULATIONS,

You have just purchased a IMG-BRASIL equipment, product of the highest quality, safety

and efficiency.

Founded in 1989, IMG-BRASIL is a respected company as one of the best and most

complete companies in the field of gastronomy equipment manufacturing.

Constant innovation and improvement of its products, using top-of-line raw materials, ensure

superior products consumed in Brazil and in more than 25 countries worldwide.

THE RELIABILITY AND CERTAINTY OF A GOOD PRODUCT ARE IN THE NAME

IMPORTANT:

PRODUCT FOR PROFESSIONAL USE. DONOT USE BEFORE READING THE MANUAL CAREFULLY.

IN CASEOFQUESTIONS,PLEASECONTACTUS:

IMG-BRASIL Gastronomy Machinery Industry Ltda.

CNPJ 11.193.347/0001-14 - CREA 131726-3

Road. Antônio Heil –KM 23 Nº 5825 –Neighborhood: Limoeiro –ZIP CODE 88352-502

Phone/fax. +55 47 3251-5555 - Website: www.metvisa.com.br

3

INDEX

1. Safety Information......................................................................................................................... 4

1.1 General Warnings...................................................................................................................... 4

2. Technical Characteristics............................................................................................................. 5

2.1 Main Components...................................................................................................................... 5

2.2 Technical Data........................................................................................................................... 6

3. Installation..................................................................................................................................... 6

3.1 Equipment Layout...................................................................................................................... 6

3.2 Electrical Connection................................................................................................................. 7

4. Equipment Use.............................................................................................................................. 9

4.1 Utility.......................................................................................................................................... 9

4.2 Commands................................................................................................................................ 9

4.3 Operating Procedures.............................................................................................................. 10

5. Cleaning and Maintenance ......................................................................................................... 13

5.1 Cleaning Procedures and Products Used ................................................................................ 13

5.2 Breakdown Maintenance and Procedures................................................................................ 14

6. ANEXXES..................................................................................................................................... 16

Electrical Schematic Single-phase –Voltage 110 V or 220 V ........................................................ 16

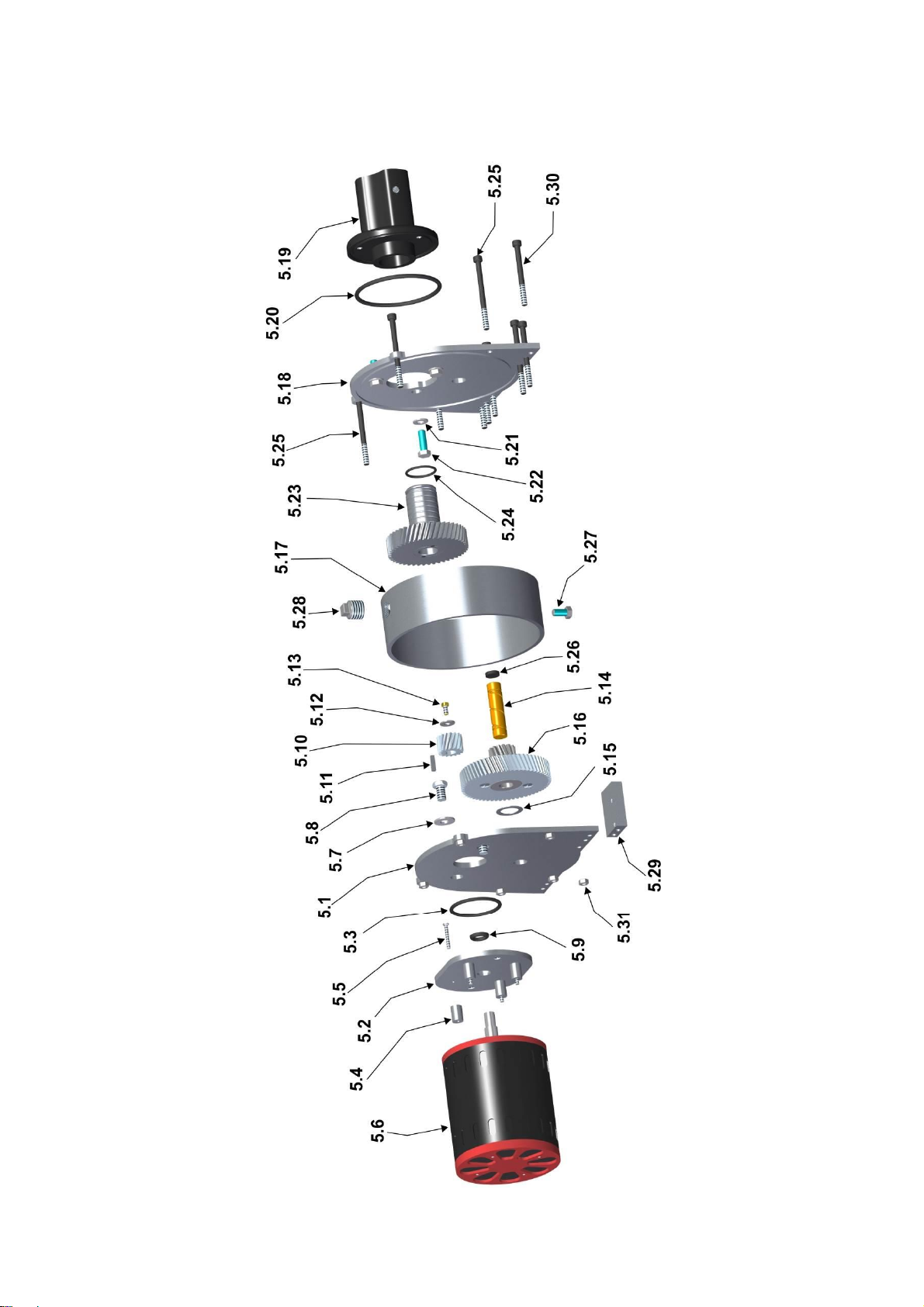

Exploded View Drawing................................................................................................................. 17

Exploded View Drawing................................................................................................................. 18

Spare Parts List............................................................................................................................. 19

ATTENTION!

The characteristics, pictures and figures presented in this manual should be considered for

information. IMG BRASIL reserves the right to make such modifications as may be deemed

necessary without prior notice.

4

1. Safety Information

1.1 General Warnings

• Cautions / precautions must be observed when installing, using, maintaining and discontinuing use

of this equipment;

• Before carrying out any operation (assembly, use, maintenance and reuse after prolonged use of the

equipment), read the manual carefully;

• The equipment must be used by trained personnel familiar with the use and safety regulations

described in this manual;

• This equipment is not intended for use by persons (including children) with reduced physical,

sensory or mental capacities, or people with lack of experience and knowledge, unless they have

received instructions regarding the use of the appliance or are under the supervision of a person

responsible for their safety.

• It is recommended that children be supervised to ensure that they are not playing with the

equipment;

• In case of rotation of the personnel that will work with the equipment, the new operator must be

educated about the standards and the operation of the same one;

• The operator must use the Adequate PPE (Personal Protective Equipment). As for example: use a

hair cap to prevent them from getting stuck in the moving parts of the equipment;

• The operator must always be aware of situations that can cause a risk of accidents and avoid them.

For example: avoid working with loose uniform sleeves, where they can lock in moving parts, causing

accidents;

• After reading and clarifying all doubts, this manual should be carefully stored in an easily accessible

location, known to all persons who will operate the equipment and make it available to those who will

carry out maintenance for any inquiries. Whenever any questions arise, be sure to check the manual.

Do not operate the equipment in any way with doubts;

• In the installation, it is essential to make this manual available to the professionals who will do the

same;

• Never put your hands, fingers or objects inside the head with the equipment on, as this may cause

an accident. Do not start the grinder without the funnel attached to the head;

• Before starting cleaning and any type of maintenance, it is essential to disconnect the equipment

from the power supply;

• Periodically check the condition of cables and electrical parts;

• Do not leave the equipment switched on unattended.

• This equipment is intended to be used for commercial applications, for example in restaurant

kitchens, canteens, hospitals and in commercial enterprises such as bakeries, butchers, etc., but not

for continuous mass production of food.

5

ATTENTION!

Do not perform repairs on your own. Refer servicing to qualified service personnel. Only use

original parts in your equipment.

2. Technical Characteristics

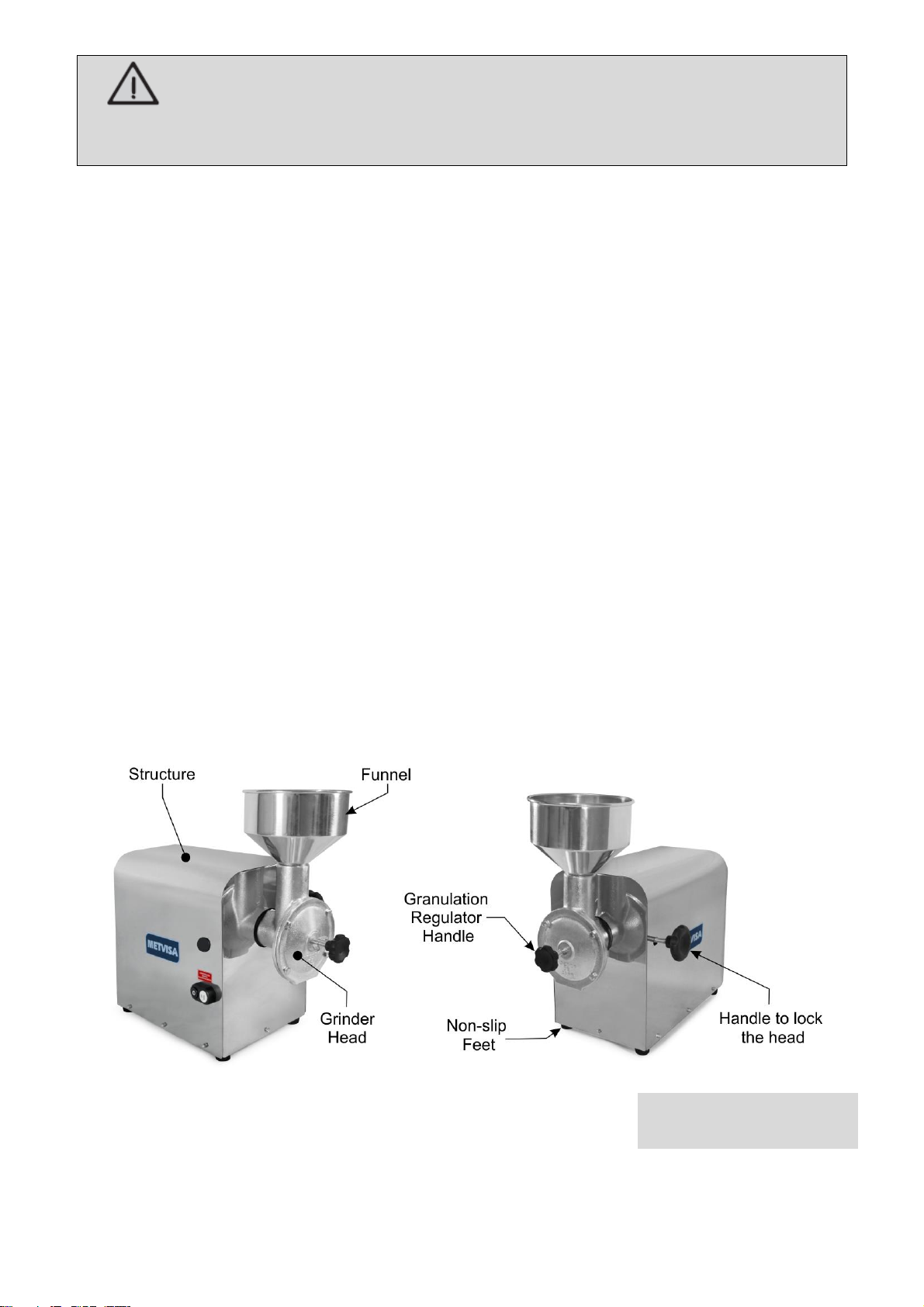

2.1 Main Components

For the equipment described in this manual, safety in use, cleaning, maintenance and

maximum hygiene are guaranteed by the design and special design of all parts, as well as the use of

stainless steel and other materials suitable for contact with the foods.

The equipment was designed with the following characteristics:

• Structure made of stainless steel, which has superior corrosion resistance than other steels. It is a

material resistant to the attack of several corrosive agents;

• Grinding head is made of tin-coated carbon steel, protecting the steel surface against corrosion.

Non-toxic material and ideal for contact with food.

• Funnel made of aluminum. It is a lightweight material, durable and resistant to the attack of corrosive

agents.

See below the main components of the equipment:

Note: For exploded drawing with

spare parts list, see annexes.

6

2.2 Technical Data

Model

Nominal Measures

LxHxW

(mm)*

Net

Weight

(kg)

Voltage

(V)

Rate

(A)

Capacity

(kg/h) **

Lubricant

SAE140

(ml)

MCG8110M604

280x480x500

20.9

127

4.4

8

200

MCG8220M501

280x480x500

20.9

220

2.15

8

200

MCG8220M502

280x480x500

20.9

220

2.15

8

200

MCG8220M504

280x480x500

20.9

220

2.15

8

200

MCG8220M507

280x480x500

20.9

220

2.15

8

200

MCG8220M604

280x480x500

20.9

220

2.5

8

200

* For all grinder models, the height measurement was considered with the funnel mounted.

** It may vary due to the user's working speed and according to the thickness used and product processed.

Noise level: 75 dB.

ATTENTION!

Characteristics like: model, serial number and voltage of the equipment are provided on the

label (figure below). Before installation, check that the power supply voltage of the

equipment corresponds to that of the mains.

3. Installation

3.1 Equipment Layout

Connection to the electrical network and provision for operation must be carried out by a

qualified professional. Check that the voltage of the equipment is in accordance with that of the

electrical network.

When installing, it is essential to make this manual available to the professionals who will

carry it out.

To ensure correct operation and safety, the appliance must be positioned in an airy

environment and on a sufficiently wide, well-leveled, dry and stable bench, away from sources of heat

7

and water taps, and at an average height of 80 m. cm. Install your equipment leaving a clear area at

the front, a distance of at least 60 cm above the equipment and a distance of at least 30 cm around it,

so that you have enough space for inspection, maintenance, cleaning and use.

ATTENTION!

The installation and the place where the equipment will be placed must comply with the

rules of risk prevention and safety at work (Regulatory Norm NR-12 for Brazil or according

to the regulatory standard in force in your country).

The manufacturer is not responsible for possible direct or indirect damages caused by non-

compliance with said standards and other instructions presented in this manual.

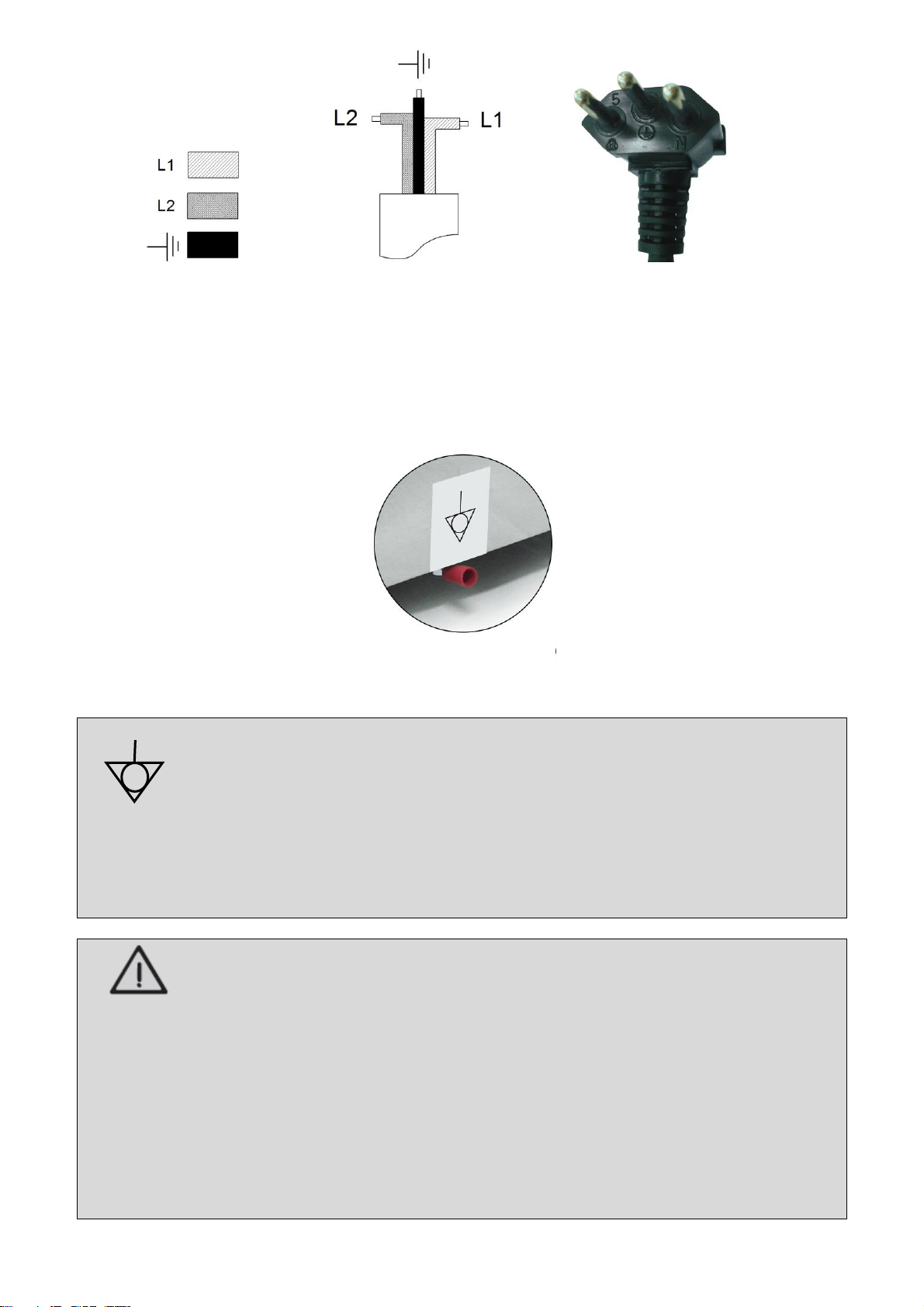

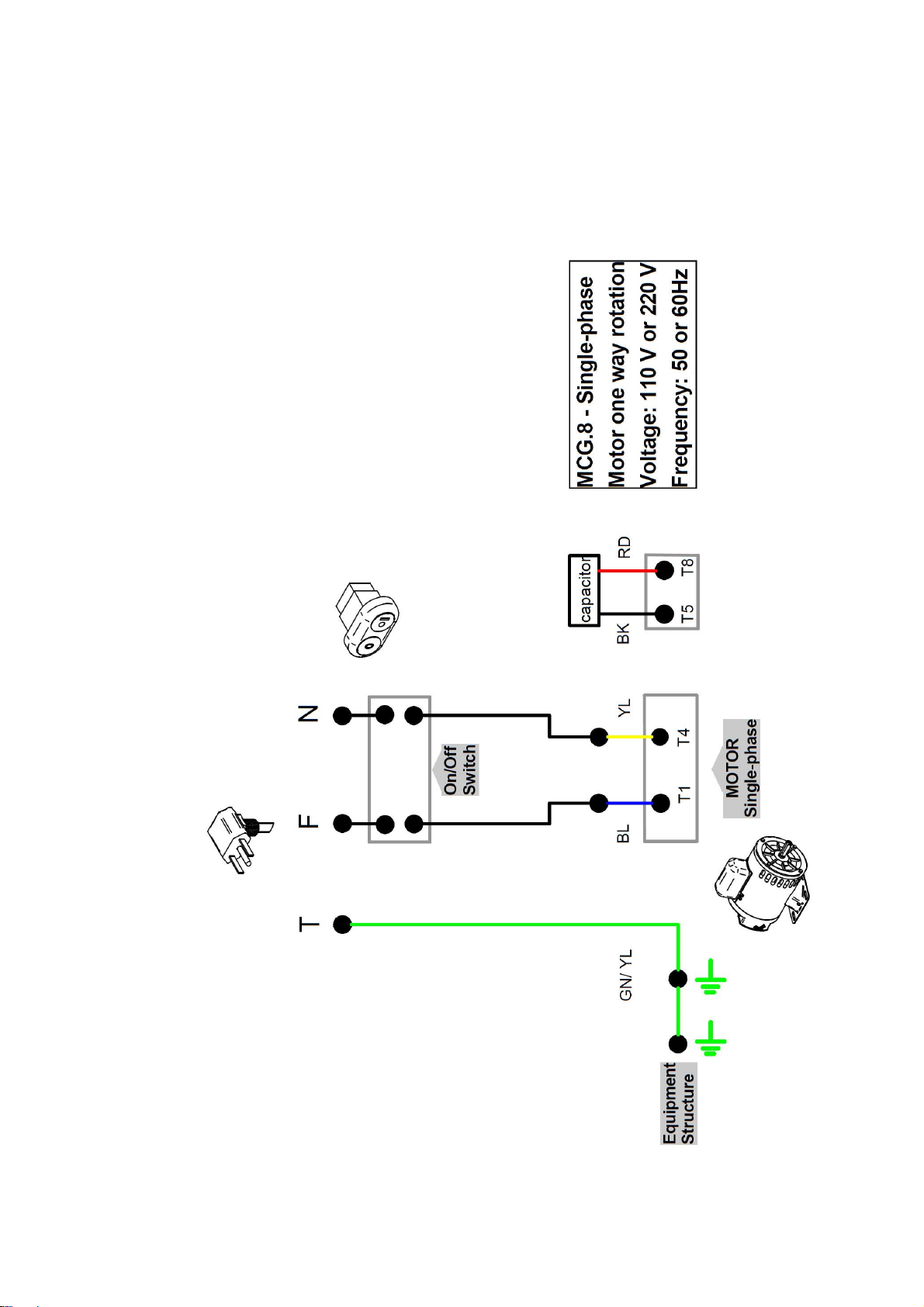

3.2 Electrical Connection

The equipment is supplied with a power cord to be connected to an electrical network.

The grinders described in this manual are single-phase and supplied with power cables with

stamped plugs of the 2P+T type (2 poles + ground), following current regulations. These plugs have 3

round pins, there being just below each pin, a corresponding marking for each one (phase, ground

and neutral). It is mandatory to make a good ground connection, following current regulations.

8

The maintenance procedure on the power cord and/or the power plug of the appliance must

be carried out by an authorized agent or qualified person.

The equipments are shipped with a single voltage, that is, 110 V or 220 V. If it is necessary

to change the voltage, contact the manufacturer or an authorized dealer.

The equipments are supplied with an equipotential grounding terminal, located on the right

side base.

The terminal identified in the figure aside is an additional protection to

the grounding that is provided for in the electrical network, it must be

connected to a grounding terminals, regardless of the connection to the

electrical network, and the other products that have accessible metallic parts,

and that are stationary, must also be connected to this bus as well as the

service bench itself, if it is made of metallic material. In this way, all these

products will be under the same electrical potential, avoiding undesirable

leakage currents.

ATTENTION!

Before turning on your equipment, always check that the mains supply voltage is the same

as the equipment voltage. If it is not the same, contact the manufacturer or authorized

dealer.

The supply voltage of this equipment is 110 V (60 Hz) or 220 V (50 or 60 Hz) single-phase, as

can be verified on the voltage label affixed to the power cable or as indicated on the

nameplate data label, which is located on the right side of the equipment (see the figure on

this label in item 2.2 of this manual).

Make sure that the voltage of the electrical network where the equipment will be installed is

compatible with the voltage indicated on these labels.

Phase

Neutral

Ground

Equipotential

Grounding Terminal

9

For more details on the rest of the electrical part of the equipment, refer to the electrical diagram in

the annexes of the manual.

IMPORTANT

The manufacturer is not responsible for possible direct or indirect damages caused by non-

compliance with said standards and other instructions presented in this manual.

4. Equipment Use

4.1 Utility

This equipment is exclusively intended for grinding coffee and some types of dry grains, cereals and

spices.

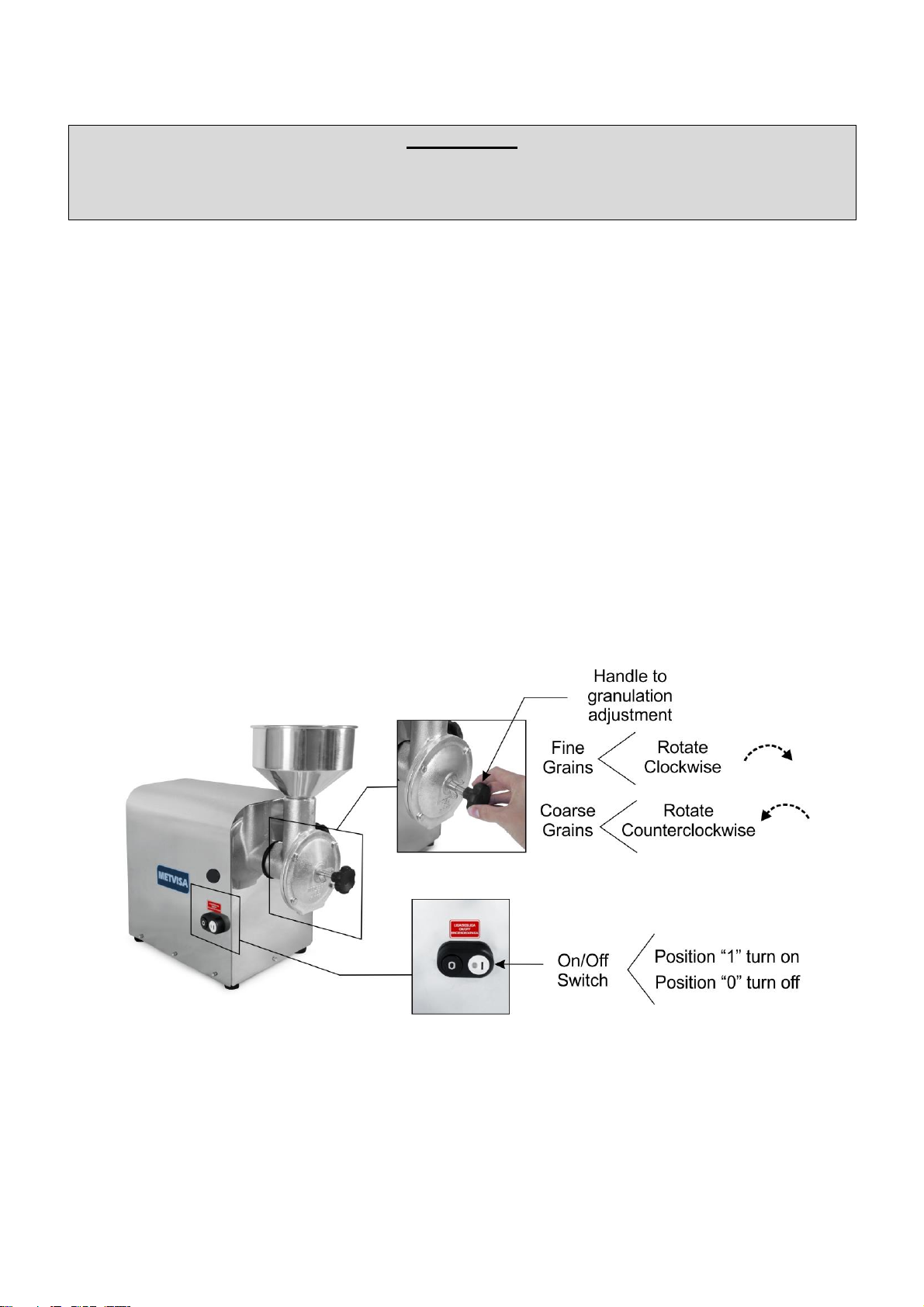

4.2 Commands

The equipment has an on/off switch and a handle for granulation adjustment.

When positioning itself in front of the grinder head, the switch is located on the left side of the

equipment and the granulation adjustment handle is located on the front of the grinder head.

See description of each command below:

• Handle for Granulation Adjustment –regulates the type of granulation of the grains to be ground.

Before turning the handle, it is necessary to loosen the wing nut. To obtain a fine grain, rotate the

handle clockwise. For coarse grain, rotate counterclockwise. Tighten the wing nut at each granulation

setting.

10

ATTENTION!

Be careful when adjusting the granulation. The handle cannot be tightened excessively, it must

simply be pressed against the end of the thread. Tightening it excessively will wear out and

strain the engine, possibly burning it.

The handle cannot be loosened too much either, as in this case a ball located between the

handle and the back of the head could come loose. Without the ball, the operator will have

difficulties to regulate the granulation. Do not adjust the granulation without the handle ball.

• On/off Switch –used to turn the equipment on and off. In position “1” it switches on, in position “0” it

switches off.

4.3 Operating Procedures

Before operating your equipment, disassemble the components (instructions below) that will

have contact with the grains (funnel and grinding head), and clean them. Carry out cleaning with the

appliance disconnected from the mains. Follow the cleaning instructions in item 5 of this manual.

Check the disassembly and assembly processes described below.

• Disassembly:

11

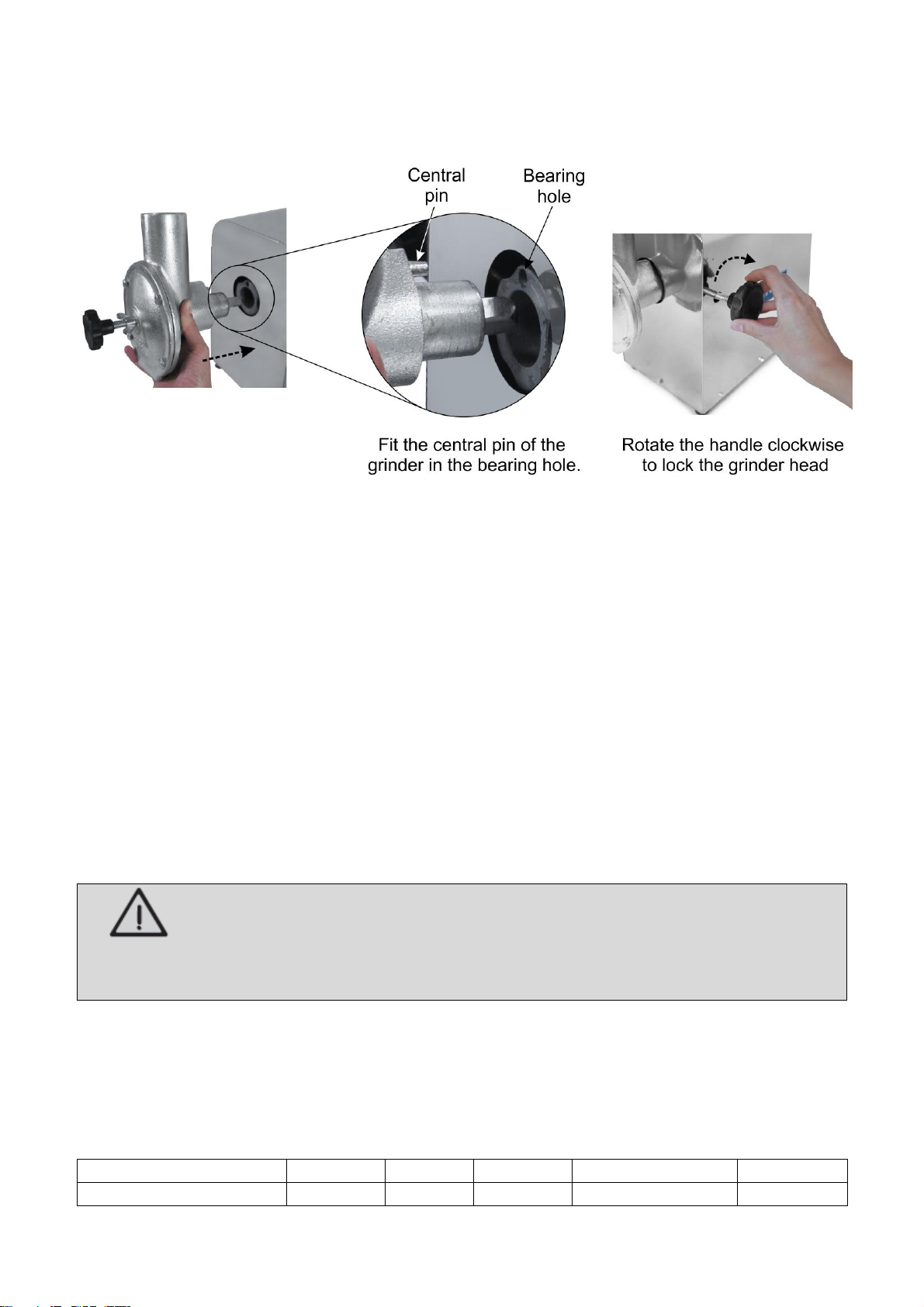

• Assembly: The assembly procedure is the reverse of disassembly. With the grinder head mounted,

fit it into the bearing according to the instructions below:

All parts must be fixed perfectly so that there is no jamming or wear, and so that the safety of

the operator is guaranteed. If any part has not been fitted correctly, repeat the operation and without

success, contact technical assistance.

• Operation: Before turning on the equipment, make sure that the supply voltage of the

equipment is in accordance with that of the electrical network. Also check that the funnel is fitted to

the head and filled with grains.

After checking these items, follow the equipment operation processes below:

• Connect the power cord to the electrical network;

• Place a container to store the ground grains below the outlet head;

• With the funnel already filled with the roasted grains, activate the on/off switch in position

“0” (off) and then “1” (on);

ATTENTION!

Always fill the funnel with roasted and low-moisture grains so that they do not adhere to the

grinding disc, causing poor performance and engine stalling.

• Leave the equipment on for a few seconds to check the grain granulation;

• Adjust the grinding setting using the handle for granulation adjustment (adjustment instructions in

item 4.2).

Type of the Granulation

Turkish

Express

Italian

Filtered

Pressed

Granulation

Very Fine

Fine

Medium

Medium to Coarse

Coarse

12

• With the setting defined, start grinding by pressing the on/off switch in position “1” (on);

• Leave the equipment working until the grinding is finished;

• After the end of the process, turn off the equipment by pressing the on/off switch in position “0” (off).

ATTENTION!

Do not start the appliance without grains, as this will damage the grinding disc and the

motor.

After ground coffee, we do not recommend putting the powder back into the funnel for a

smaller granulation, as the powder clogs the head causing damage to the appliance.

Only use the grinding disc supplied with this unit. Under no circumstances make use of

discs with other formats or dimensions.

TIP

Buy grains in small quantities to reduce storage time, and only store for a maximum of one

week at a time.

Do not store the grains in the grinder. After the process is complete, store them in an

airtight container.

For optimal flavor, use the coffee grains between 5 and 20 days after the roast date.

Store ground coffee grains in a dark, cool, dry place. If possible, vacuum pack.

Once ground, coffee quickly loses its flavor and aroma.

Regularly clean the funnel and grinding disc.

ATTENTION!

If you notice that the equipment is unable to process the grains or that it is stopping

processing, reduce the amount or check that the grains are toasted and free of moisture

before inserting them into the funnel.

Also check if the granulation adjustment handle is too tight. Excessively tightened handle

(setting for grinding too fine) can force and stop the motor causing damage.

Failure to observe this guideline will be considered an unsafe act and abusive use of the

equipment.

In case of any irregularity, contact the nearest authorized technical assistance service.

13

ATTENTION!

Do not remove the funnel from the grinder head with the equipment on, nor should you put

your fingers, hands or objects (such as spoons and knives) inside the feeding head, as this

may cause accidents. In case of any irregularity, contact the nearest authorized technical

assistance service.

IMPORTANT

The operator must use the appropriate PPE (personal protective equipment). For example:

use a hair cap to prevent it from getting stuck in the moving parts of the equipment and

appropriate gloves that, in addition to guaranteeing hygiene in grain handling, protect the

operator during food processing.

5. Cleaning and Maintenance

5.1 Cleaning Procedures and Products Used

Your equipment was built with first-line materials, so use it properly and you will obtain great

satisfaction. Always keep your equipment clean and well-cared for, which will make it much more

durable.

Daily cleaning of the equipment must be carried out for good operation and durability.

Preventing the accumulation of bacteria which can cause contamination in food.

ATTENTION!

Before carrying out maintenance or cleaning, make sure that the on/off switch is in the “0”

(off) position, that the plug is disconnected from the mains.

ATTENTION!

Do not use a water jet or steam cleaner to clean the equipment.

IMPORTANT

This equipment is not intended to be immersed in water for cleaning.

Follow the instructions below to learn the parts that can be immersed and what special care

is taken with the other parts.

Removable parts (funnel and grinder head) must be removed from the equipment and washed

with hot water and neutral soap. Clean the corners well, eliminating grain residues.

The rest of the equipment should be cleaned as often as possible to prevent food residues

from drying out and sticking to the parts. For cleaning, dilute the soap or neutral detergent in warm

water and apply with a soft, damp cloth. With a cloth dampened with water, rinse and then dry the

parts with a soft, dry cloth.

14

Never use abrasive products or sponges and substances containing acids or chlorine to clean

metal parts, as they can scratch or damage the surface of the parts causing corrosion points. Do not

pour water over the motor and electrical parts for cleaning, otherwise, when turning it on, it may cause

an electric shock or even burn the equipment.

ATTENTION!

It is extremely important that the products used for cleaning ensure maximum hygiene and

that they are non-toxic.

5.2 Breakdown Maintenance and Procedures

The operator must be instructed to carry out routine inspections, making small adjustments,

cleaning and observing signs of breakdowns that may occur. Examples include: checking for strange

noises; equipment power loss; the non-execution by the equipment to the service to which it is

proposed; among others. Actions like these are indispensable to guarantee a longer equipment life.

ATTENTION!

When maintenance is carried out (even if minor adjustments are made), always check that the

equipment is turned off and disconnected from the network.

It is recommended that each 6 months be made preventive maintenance, checking and

adjusting the loose, cleaning the internal parts, and others. Detecting broke parts or without the

correct functionality the worker needs to exchange the parts, always using original parts only.

ATTENTION!

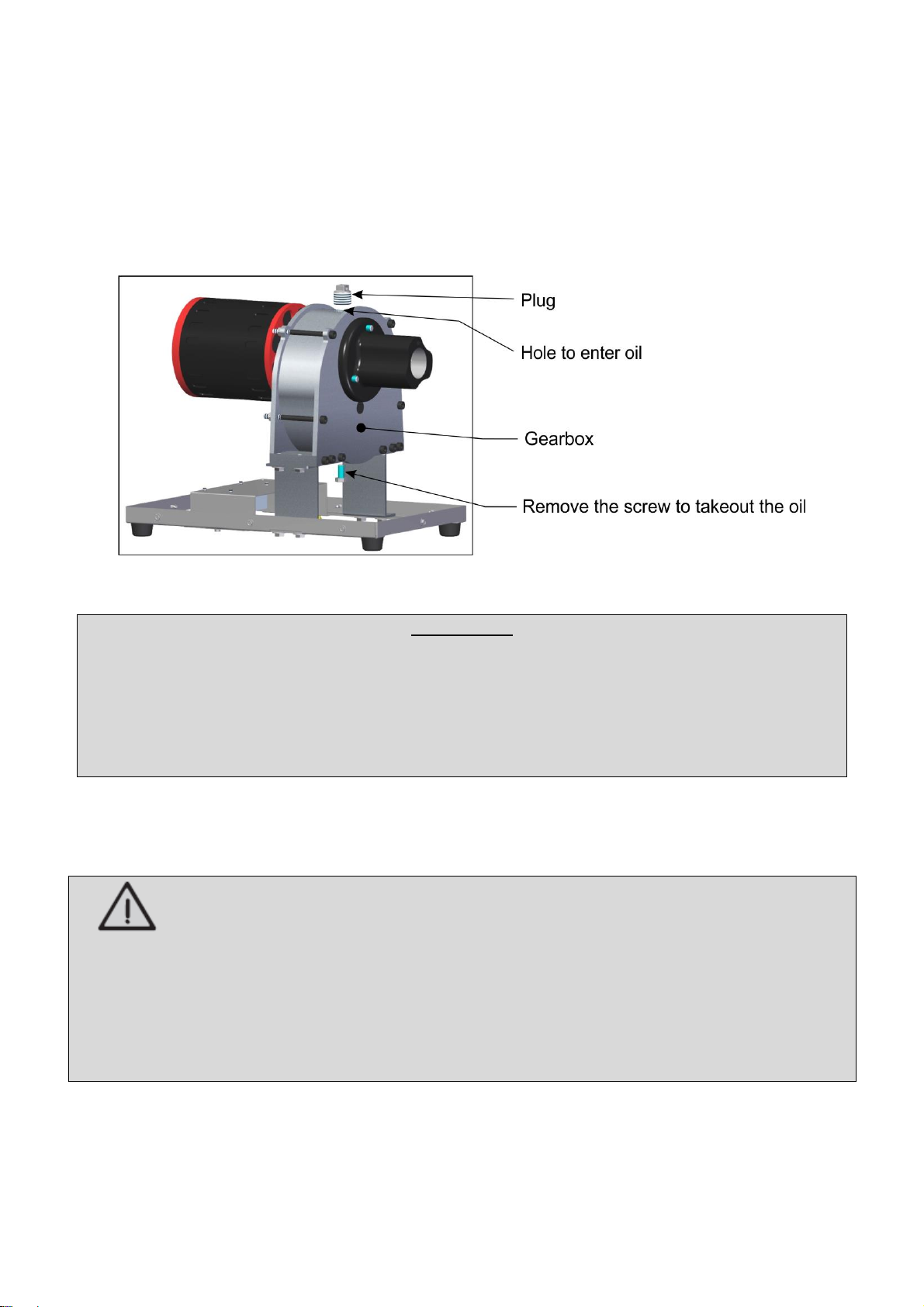

Never let your equipment work without oil in the gearbox, as it will damage your equipment.

Always check the oil level.

It is recommended to change the oil after 6 months of use.

To find out about the quantity and type of oil used in each equipment model, consult the table

in item 2.1 (Technical Data) of this manual.

When changing the oil, use Personal Protective Equipment (PPE) to avoid direct contact with

the oil, such as waterproof PVC gloves.

Follow the instructions below to change the oil in your equipment:

•Disconnect the equipment from the mains;

•Remove the funnel and the grinder head (instructions in item 4.3). Remove the case by removing the

fixing screws;

•Place a container under the gearbox to store the oil to be removed;

•Remove the screw located under the gearbox. Wait until all the oil comes out of the screw hole.

15

•After all the oil is removed, screw the screw with sealing tape again;

•To put in the new oil, remove the plug located on top of the gearbox;

•Using a funnel, add the oil. Check the amount of oil for each model of grinder in the table in item 2.2

(Technical Data);

•Screw the plug with thread sealing tape. Reassemble the case fixing it with the screws.

IMPORTANT

After changing the oil, the equipment must work level. Follow the instructions in item 3.1

(Equipment Layout) for optimal equipment positioning.

Oil is a recyclable product. Dispose of it at authorized service station facilities in accordance

with local laws and regulations regarding the disposal of waste petroleum products. Do not

pour into sewers, surface waters.

By carrying out preventive maintenance, the inconvenience of having the equipment stopped

when it is most needed is eliminated, the cost of maintenance is reduced and the risk of accidents is

reduced.

ATTENTION!

Preventive maintenance requires a trained professional.

Always check if the equipment is disconnected from the network.

Whenever an item related to the safety of the equipment is removed (such as when performing

maintenance), put it back in its proper place and confirm that they are performing their

function correctly.

Detecting broke parts or without the correct functionality, please contact the nearest

authorized service center.

16

6. ANEXXES

Electrical Schematic Single-phase –Voltage 110 V or 220 V

17

Exploded View Drawing

18

Exploded View Drawing

19

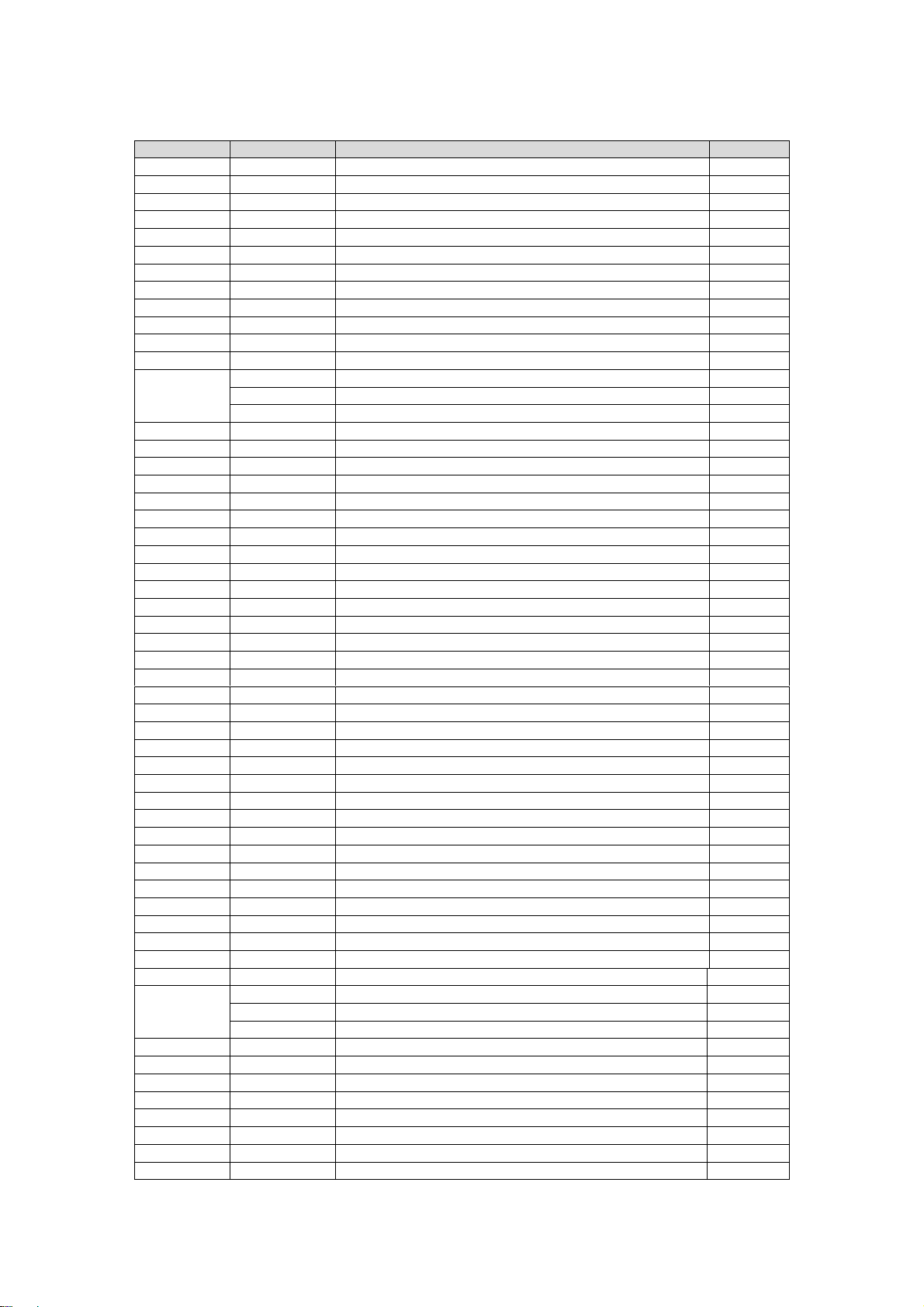

Spare Parts List

Position

Code

Description

Quantity

1

BAS138

Base

01

1.1

PEP004

Rubber Foot Hole

04

1.2

PRR015

Round Machine Screw

04

2

SBT518

Gearbox Support

02

3

ARL004

Flat washer

08

4

PRS010

Hex Screw

08

5

CAIXA

Full Transmission

01

5.1

CRC1387

Transmission Box Bottom Plate

01

5.2

CRC1304

Flange Coupling

01

5.3

ORG027

O-ring

01

5.4

BGT100

Motor Spacer

04

5.5

PRC011

Stainless Steel Flat Machine Screw

04

5.6

MTE294

Electric Motor 1/3 HP 4P 220 V 50 Hz

01

MTE295

Electric Motor 1/3 HP 4P 110 V 60 Hz

01

MTE296

Electric Motor 1/3 HP 4P 220 V 60 Hz

01

5.7

ARL002

Flat washer

02

5.8

PRS027

Hex Screw

02

5.9

RET011

Retentor

01

5.10

EGG052

Motor Helical Gear

01

5.11

CHV014

Square Key

01

5.12

ARL004

Flat washer

01

5.13

PCC003

Machine Screw Cylindrical

01

5.14

EIX124

Intermediate Axis

01

5.15

ARE003

Flat washer

01

5.16

EGG054

Fiber Helical Gear

01

5.17

PCT078

Transmission Box Body

01

5.18

CRC1388

Transmission Box Cover Plate

01

5.19

MAC079

Head Bearing

01

5.20

ORG011

O-ring

01

5.21

ARL007

Flat washer

03

5.22

PRS006

Hex Screw

03

5.23

EGG055

Helical Gear

01

5.24

ORG002

O-ring

01

5.25

PRT055

Allen Screw with Head

06

5.26

BCH069

Oil Seal Rubber

01

5.27

PRS008

Hex Screw

01

5.28

BUJ005

Plug

01

5.29

CRC1389

Fixing Plate Foot Transmission Box

02

5.30

PRT056

Allen Screw with Head

04

5.31

POS018

Hex Nut

06

6

SBT122

Electronic Board Fixation Support

01

7

PRA008

Drilling Hex Screw

10

8

TCE013

Female Terminal

02

9

GAB218

Structure

01

10

MNL047

Stainless Steel Handle

01

11

FNL005

Aluminum Funnel

01

12

TCE073

Cable Gland

01

13

CBE023

Electric Cable Plug Type 1

01

CBE029

Electric Cable Plug Type 2

01

CBE030

Electric Cable Plug Type 4

01

14

BCH058

Straight Frame of the On/Off Button

01

15

CHE064

On/Off Switch

01

16

BCH036

Round Black Cap

01

17

BCA024

Complete Grinder Head

01

18

CBE104

Electric Cable 460 mm Terra

01

19

CBE078

Electric Cable 400 mm

02

20

TCE004

Fit Terminal

02

21

TCE033

Orange Threaded Connector

02

20

IMG BRASIL Gastronomy Machinery Industry Ltda.

CNPJ 11.193.347/0001-14 - CREA 131726-3

Road. Antônio Heil - KM 23 Nº 5825 - Neighborhood: Limoeiro

ZIP CODE 88352-502 - Brusque - SC - Brazil

Phone/fax. +55 47 3251-5555 - Web Site: www.metvisa.com.br

This manual suits for next models

5

Table of contents