Contents

Safety ................................................................................................ 1

1.1. Definition of Symbols ...................................................................................1

1.2. Safety Advice................................................................................................1

1.3. Correct operation.........................................................................................2

1.4. Extended use................................................................................................2

Description of functions .................................................................... 3

Installation........................................................................................ 4

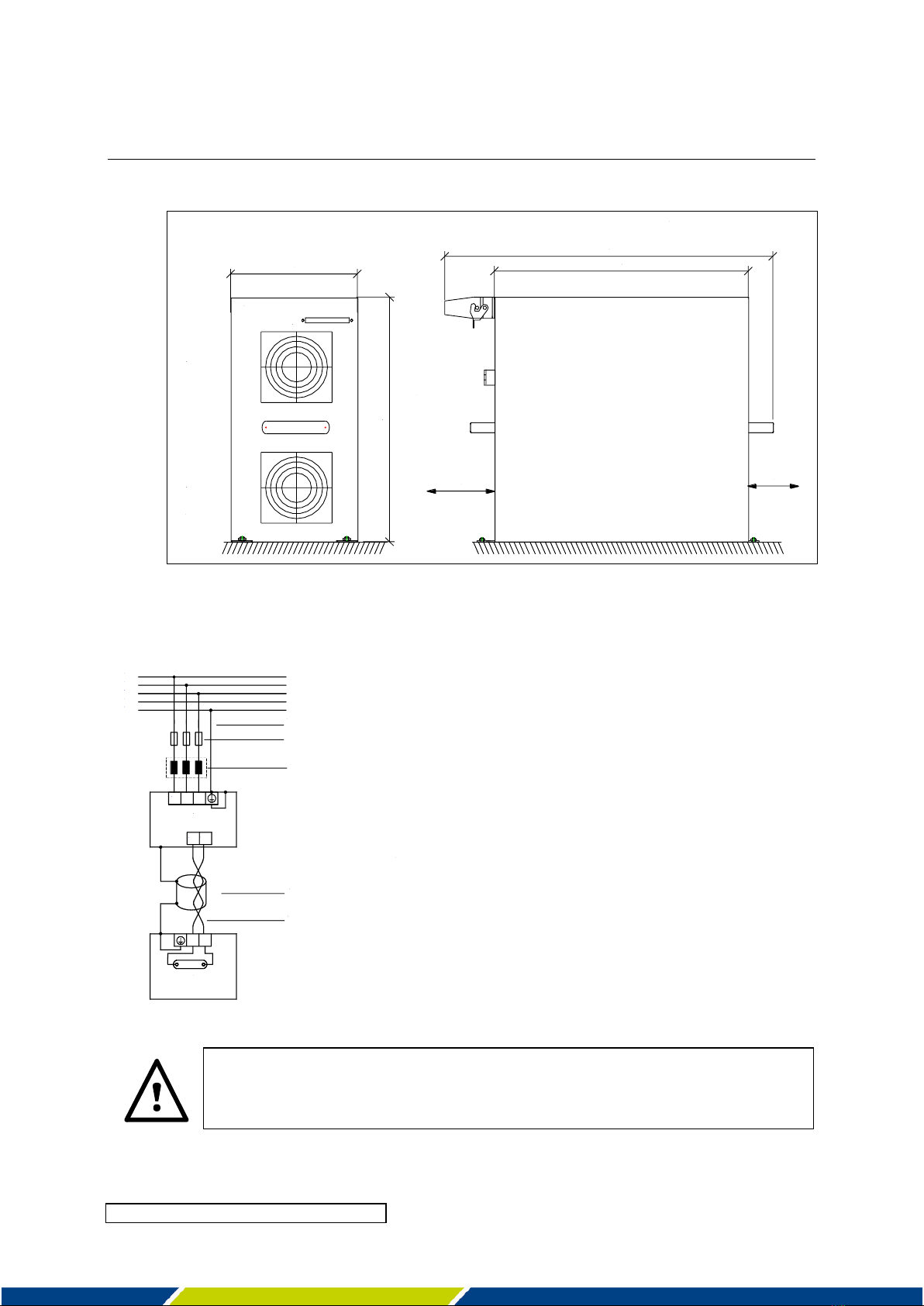

3.1. Mounting of casing .......................................................................................4

3.1.1. Vertical installation position............................................................................. 5

3.1.2. Horizontal installation position ........................................................................ 6

3.2. Power connections.......................................................................................6

3.2.1. Mains connection ............................................................................................. 7

3.2.2. Connecting the lamp feeder cable ................................................................... 7

3.3. Control- and bus connections ....................................................................10

3.3.1. Mounting of the strain relief............................................................................10

3.3.2. Connecting bus cables ....................................................................................10

3.3.3. Coding and pin assignment.............................................................................12

3.4. Comments on the safety functions of the ELC ...........................................16

3.4.1. Safety relay......................................................................................................16

3.4.2. Initialisation signal ..........................................................................................16

3.5. Configuration .............................................................................................17

3.5.1. Setting up the PROFIBUS address..................................................................18

3.5.2. Checking the PROFIBUS connection...............................................................18

3.5.3. Setting lamp power via PROFIBUS..................................................................19

3.5.4. To read out ELC serial number and softwareversion .....................................21

3.5.5. Temperature derating for PE35B....................................................................22