MEVOCO RP800 User manual

DW652322

Self & Dual Powered

Overcurrent & Earth Fault

Protection Relay

User Manual

Mevoco nv, Industrielaan 33A, 9800 Deinze, Belgium

+32 (0)9/380 30 49 • info@mevoco.be • www.mevoco.be

2

!

©2022 Mevoco nv

All rights reserved.

The information provided may not be reproduced and/or published in any way (electronically or

mechanically) without the express prior written permission of Mevoco nv.

The information provided is subject to change insofar as it is based on general data regarding

constructions, material properties and working methods known at the time of publication.

The information provided applies to the RP800 as a standard model. Mevoco nv cannot therefore

be held liable for any damage resulting from specifications of the RP800 that deviate from the

standard model.

The available information has been compiled with the greatest possible care. Mevoco nv does not

accept responsibility for any errors that may occur in this document or for their possible

consequences.

The general designations, trade names, brands, etc. used by Mevoco nv are protected by

trademark law.

3

!

TABLE OF CONTENTS! 2!

1!RECEPTION, HANDLING & INSTALLATION! 6!

1.1!UNPACKING! 6!

1.2!RECEPTION OF RELAYS! 6!

1.3!HANDLING ELECTRONIC RELAY! 6!

1.4!INSTALLATION, COMMISSIONING AND SERVICE! 7!

1.5!STORAGE! 7!

1.6!RECYCLING! 7!

2!DIMENSIONS AND CONNECTION DIAGRAMS! 1!

2.1!FRONT VIEW! 1!

2.2!CASE DIMENSIONS! 1!

2.3!CONNECTION DIAGRAM! 3!

2.3.1!STANDARD CURRENT TRANSFORMERS! 3!

2.3.2!STANDARD CURRENT TRANSFORMERS! 3!

2.4!TERMINALS! 4!

3!DESCRIPTION! 6!

3.1!INTRODUCTION! 6!

3.2!RELAY DESCRIPTION! 6!

3.3!FUNCTIONAL DIAGRAM! 9!

3.4!FUNCTION SHB. SECOND HARMONIC BLOCKING!10!

3.5!FUNCTION 50. INSTANTANEOUS PHASE OVERCURRENT!10!

3.6!FUNCTION 51. INVERSE TIME PHASE OVERCURRENT!11!

3.7!FUNCTION 50G. INSTANTANEOUS NEUTRAL OVERCURRENT!11!

3.8!FUNCTION 51G. INVERSE TIME NEUTRAL OVERCURRENT!12!

3.9!FUNCTION 49. THERMAL IMAGE PROTECTION!12!

3.9.1!THERMAL IMAGE MEASUREMENT EVOLUTION GRAPHIC!13!

3.9.2!THERMAL IMAGE WITH MEMORY!15!

3.9.3!THERMAL IMAGE MEASUREMENT DISPLAY. RESET.!15!

3.9.4!THERMAL PROTECTION CURVES!15!

3.10!FUNCTION 52. CIRCUIT BREAKER MONITORING!16!

3.11!CIRCUIT BREAKER OPENING AND CLOSING COMMANDS!19!

3.12!COUNTER TO REGISTER THE NUMBER OF OPENINGS!19!

3.13!ACCUMULATED AMPS COUNTER : I2T!19!

3.14!MAXIMUM OPENINGS IN A TIME WINDOW!19!

3.15!FUNCTION 49T. EXTERNAL TRIP!20!

3.16!SETTINGS GROUPS!20!

3.17!IEC60255-151 CURVES!20!

3.18!IEEE CURVES!26!

4!MONITORING AND CONTROL!30!

4.1!MEASUREMENTS!30!

4.2!LOAD DATA PROFILING!30!

4

!

4.3!COUNTERS!31!

4.4!DEADBAND!31!

4.5!STATES AND EVENTS!31!

4.6!DATE AND TIME BY REAL TIME CLOCK (RTC)!35!

4.7!SELF-DIAGNOSIS!35!

4.8!DISTURBANCE FAULT RECORDING!37!

4.9!CONFIGURABLE INPUTS!40!

4.10!DIGITAL OUTPUTS!40!

4.11!PROGRAMMABLE LOGIC CONTROL!40!

4.11.1!OUTPUTS!41!

4.11.2!LEDS!42!

4.12!COMMANDS!45!

4.13!TEST MENU!45!

4.14!POWER SUPPLY!46!

4.14.1!SELF-POWERED RELAY WITH STANDARD CURRENT TRANSFORMERS!46!

4.14.2!24-230 VAC, 50/60 HZ AUXILIARY POWER!46!

4.14.3!24-230 VDC AUXILIARY POWER SUPPLY!46!

4.14.4!BATTERY POWER: 5 V, WITH A KITCOM ADAPTOR!47!

4.14.5!COMMISSIONING BATTERY!47!

4.15!SWITCH ON TO FAULT (SOTF) CHARACTERISTIC!51!

4.16!OPENING MECHANISM: STRIKER!52!

5!TECHNICAL SPECIFICATIONS AND STANDARDS!53!

5.1!TECHNICAL SPECIFICATIONS!53!

5.2!THERMAL RESISTANCE!55!

6!COMMUNICATION AND HMI!55!

6.1!FRONT COMMUNICATION: USB!55!

6.2!REAR COMMUNICATION: RS485!55!

6.3!LED INDICATORS!56!

6.4!LCD AND KEYPAD!56!

6.5!SICOM COMMUNICATIONS PROGRAM!57!

6.5.1!HOW TO INSTALL THE SICOM SOFTWARE!57!

6.6!SETTING-UP THE SESSION: PASSWORD AND ACCESS LEVELS!58!

6.7!MENUS!59!

6.7.1!STANDBY MODE SCREEN!59!

6.7.2!ACCESSING THE MENUS!59!

6.7.3!DATE-TIME MENU!59!

6.7.4!VERSIONS!60!

6.7.5!COMMUNICATION PARAMETERS!60!

6.7.6!CONTRAST!60!

6.7.7!FAULT REPORT!60!

6.7.8!TESTMENU!61!

6.7.9!FUNCTIONSMENU!62!

6.7.10!MEASUREMENTS MENU! 64!

6.7.11!STATES MENU!65!

6.7.12!SETTINGS MENU!74!

6.7.13!EVENTS MENU!81!

5

!

6.7.14!COUNTERS MENU!82!

6.7.15!COMMANDS MENU!83!

6.7.16!LOAD DATA PROFILING!84!

6.7.17!FAULT REPORTS!84!

6.7.18!PGC AND OUTPUTS CONFIGURATION MENU!85!

7!COMMISSIONING!89!

7.1!CHECKLIST FOR COMMISSIONING!89!

7.2!ELECTROSTATIC DISCHARGE!89!

7.3!VISUAL INSPECTION!89!

7.4!EARTHING!89!

7.5!CURRENT TRANSFORMERS!89!

7.6!AUXILIARY POWER!89!

7.7!FRONT COMMUNICATIONS PORT!89!

7.8!COMMISSIONING!89!

8!APPENDIX!90!

8.1!IDENTIFICATION!90!

8.2!CHECKS!90!

8.3!TEST MENU!90!

8.4!REGISTER OF COMMISSIONING SETTINGS!90!

8.5!INPUTS!92!

8.6!OUTPUTS!92!

8.7!LEDS!92!

8.8!COMMENTS!92!

!

6

!

1 RECEPTION, HANDLING & INSTALLATION

1.1 Unpacking

Relays must only be handled by qualified personnel and special care must be taken

to protect all of their parts from any damage while they are being unpacked and

installed. The use of good illumination is recommended to facilitate the relay visual

inspection.

The facility must be clean and dry, and relays should not be stored in places that are

exposed to dust or humidity. Special care must be taken if construction work is taking

place.

1.2 Reception of relays

It is necessary to inspect the relay at the time it is delivered to ensure that the

relays have not been damaged during transport.

If any defect is found, the transport company and Mevoco should be informed

immediately. If the relays are not for immediate use, they should be returned to their

original packaging.

1.3 Handling electronic relay

Relays contain an electronic component that is sensitive to electrostatic discharges.

Just by moving, a person can build up an electrostatic potential of several thousand

volts. Discharging this energy into electronic components can cause serious damage

to electronic circuits. It is possible that this damage may not be detected straight

away, but the electronic circuit reliability and life will be reduced. This electronic

component in the relay is well protected by the metal housing, which should not be

removed as the relay cannot be adjusted internally.

If it is necessary to disassemble the electronic component, this must be carried out

with care and contact with electronic components, printed circuits and connections

must be avoided to prevent an electrostatic discharge that could damage one of the

components. If the electronic components are stored outside the metal housing, they

must be placed in an antistatic conductive bag.

If it is necessary to open a module, care must be taken to preserve the relay

reliability and the duration of the life cycle as designed by the manufacturer by taking

the following actions

● Touch the housing to ensure that you have the same potential

● Avoid touching the electronic components and handle the module by its

edges.

● Remember that everyone who handles the module must have the same

potential.

● Use a conductive bag to transport the module.

For more information about how to handle electronic circuits, consult official

documents such as the IEC 147-OF

7

!

1.4 Installation, commissioning and service

The personnel in charge of installing, commissioning and maintaining this relay must

be qualified and must be aware of the procedures for handling it. The product

documentation should be read before installing, commissioning or carrying out

maintenance work on the relay.

Personnel should take specific protection measures to avoid the risk of electronic

discharge when access is unlocked on the rear part of the relay.

In order to guarantee safety, the crimp terminal and a suitable group tool must be

used to meet isolation requirements on the terminal strip. Crimped terminations must

be used for the voltage and current connections.

It is necessary to connect the relay to earth through the corresponding terminal,

using the shortest possible cable. As well as guaranteeing safety for the personnel,

this connection allows high frequency noise to be evacuated directly to earth.

The following checks must be performed before the relay is supplied:

● The rated voltage and polarity.

● The power rating of the CT circuit and the integrity of the connections.

● The integrity of the earth connection.

The relay must be used within the stipulated electrical and environmental limits.

Note: Regarding the current transformer circuits: Do not open a live CT secondary

circuit. The high voltage produced as a result could damage the isolation and

threaten lives.

1.5 Storage

If the relays are not going to be installed immediately, they must be stored in a dust-

and humidity free environment after the visual inspection has been performed.

1.6 Recycling

Before recycling the relay, the capacitors should be discharged through the external

terminals. All electrical power sources should be removed before performing this

operation to avoid the risk of electrical discharge.

This product must be disposed of in a safe way. It should not be incinerated or

brought into contact with water sources like rivers, lakes, etc.

Fanox Electronic, S.L. adheres itself to the 1st additional disposal of the Spanish

11/97 Standard in which it is said that the final user of the containers should give

them, properly segregated by materials, to an authorized recovery, recycler or valuer

company.

DW652322

2 DIMENSIONS AND CONNECTION DIAGRAMS

2.1 Front view

2.2 Case dimensions

The dimensions are in mm:

Option 1: Rear power terminals for 2.5 mm2 cable:

2

!

Option 2: Rear power supply terminals with ring terminals (cable 4 mm2 – model

RP800):

Cut-out pattern

3

!

2.3 Connection diagram

2.3.1 Standard current transformers

2.3.2 Standard current transformers

Note! trigger: 6 - 24 Vdc & <= 0.135 W.s

4

!

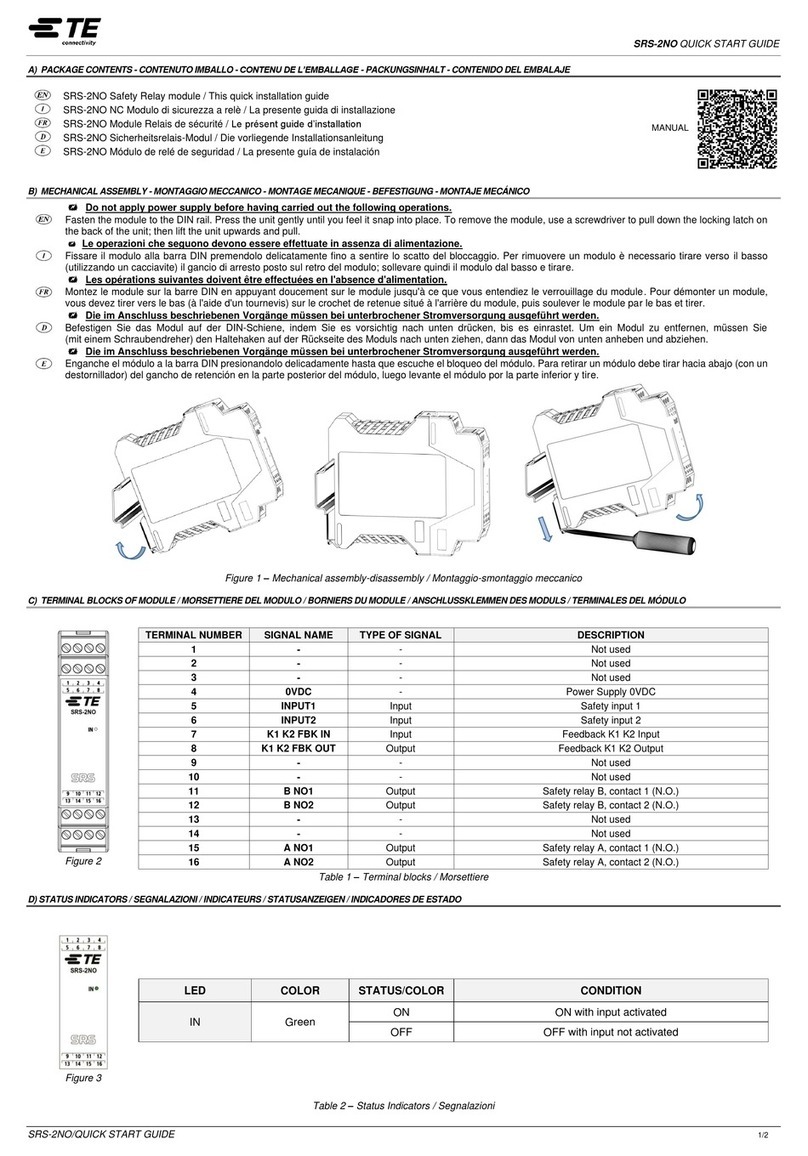

2.4 Terminals

A1!

Phase!A!current!input!for!measurement!and!self-power!

A2!

Phase!A!current!output!for!measurement!and!self-power!

A3!

Phase!B!current!input!for!measurement!and!self-power!

A4!

Fase!B!stroomuitgang!voor!meting!en!eigen!voeding.!

A5!

Phase!C!current!input!for!measurement!and!self-power!

A6!

Phase!C!current!output!for!measurement!and!self-!power!

A7!

Neutral!current!input!for!measurement!

A8!

Neutral!current!output!for!measurement!

B1!

Auxiliary!power!supply!+!

B2!

Auxiliary!power!supply!-!

B3!

Common!of!the!Inputs!

B4!

Input!1!

B5!

Input!2!

B6!

Input!3!

B7!

Trip!output!low!energy!trip!coil+!

B8!

Trip!output!low!energy!trip!coil!-!

B9!

Digital!1!common!output!

B10!

Digital!output!1!NC!

B11!

Digitale!output!1!NO!

B12!

Digital!output!!2!common!output!

B13!

Digital!output!!2!NC!

B14!

Digital!output!!2!NO!

B15!

Digital!output!!3!commune!

B16!

Digital!output!!3!NC!

B17!

Digital!output!!3!NO!

B18-B19!

RS485!Remote!communication!

Use only copper conductors with a minimum temperature of 75ºC.

5

!

There are 2 options for the current rear terminals:

Option 1: Rear terminals for 24 AWG - 12 AWG cable: 0.25 - 2.5 mm2 with a torque

of 0.5 Nm-0.6 Nm :

Option 2: Rear power supply terminals with ring clamps (12 AWG - 22 AWG: 4 - 0.3

mm2 cable with torque of 0.79 Nm - Model SIABxxxxx7xx) :

The other terminals (inputs, outputs, communication and auxiliary power supply) are

designed for 24 AWG - 12 AWG cable: 0.25 - 2.5 mm2 with a tightening torque of 0.5

Nm-0.6 Nm.

6

!

3 DESCRIPTION

3.1 Introduction

Worldwide, the energy sector is currently undergoing a profound change as a result

of high levels of energy demand; more distribution lines and advanced supervision

systems are required. Given the need for creating intelligent infrastructure, Mevoco

has developed the RP800 family of products to carry out this function.

The family of Mevoco relays is designed to protect the secondary transformation and

distribution centers of electricity grids. Protection features include protection against

instantaneous and inverse time overcurrent (for the phases and the neutral), and it

also has external trip support (temperature, pressure, etc.) depending on the

characteristics of each model.

The protection functions can be enabled selectively by using both the front panel and

the communications links to the SICom program, allowing for precise coordination

with another relay.

Additional benefits include that all of the models have been designed to be supplied

from an external battery. This is aimed at facilitating event management and the

commissioning of centers, as well as allowing it to operate properly under adverse

conditions.

3.2 Relay description

The RP800 relay is a protection relay designed for secondary distribution. One of its

main characteristics is the ability to power itself by using the cell current. Standard 1A

secondary current transformers are used for this, which allow self-powering with

lower levels of current.

The relay powers itself from 160 mA with single-phase current, 100 mA with 2-phase

and 75 mA with three-phase current. It is important to consider that, despite of the

device starts up with those values and trip output is activated in those values, to

activate the optional outputs, it is needed a minimum of 270 mA single-phase current

and a minimum of 90 mA three-phase current.

The relay is maintenance free when this type of power supply is used, as it does not

require auxiliary power components (batteries). As a result, it is especially useful in

any centers were auxiliary power is not available or cannot be guaranteed.

The RP800 relay is housed in a metal box with galvanic isolation on all its

measurement inputs and outputs (except for communications ports and battery

power supply, as these are sporadic connections). This fact allows the relay to have

the best possible level of electromagnetic compatibility, both in terms of emission of,

and immunity from, radiated and conducted interferences. These levels are the same

as those established for primary substations.

The relay has an LCD with two lines and twenty columns and a membrane keyboard

with six buttons. These allow the display of the relay state, the current measurements

in the primary and the events or incidents associated with the relay, and adjustments

to be made to the protection criteria.

7

!

There are four LED indicators on the front of the RP800 relay indicating the relay

status and in case of fault trip the type of fault:

LEDS!

DEFAULT!CONFIGURATION!

LED!1!

Ready!

LED!2!

Neutral/Earth!fault!trip!!

LED!3!

Overcurrent!trip!

LED!4!

Thermal!trip!!

Besides, the relay is provided with 3 signaling outputs that are also configurable by

the user. By default:

Signaling!outputs!

DEFAULT!CONFIGURATION!

Output!1!

Watchdog!

Output!2!

Phase!Trip!

Output!3!

Ground!trip!

The RP800 relay has storage for up to 1024 events, allowing any registered incidents

to be analyzed. RTC (Real Time Clock) is available for all RP800 models.

To facilitate the analysis of events, it is fitted with 20 fault reports (16 events per fault

report) and 10 records in COMTRADE format (50 cycles per record). Fault reports

start when any of the protection functions picks-up and it finishes when any of the

mentioned functions trips.

Current measurements are performed using RMS values. Standard current

transformers (CTs) are used.

The relay has a frontal communication port (micro USB, cable not included). This port

allows a PC to be connected, which can be used to monitor the relay using the

SICom communications program. Besides, the frontal port can be used to power the

relay by using an USB cable which can be directly connected with PC.

The protective functions provided, easy-to-use interface, low amount of maintenance

and simple integration make the RP800 a precise and practical solution for protecting

both industrial and public electrical grids and transformation and distribution centers.

The main features of the relay are listed below, and these features will be explained

in the rest of the manual:

8

!

• Events registered in the FRAM are maintained when there is a power fault, as it is a non-volatile memory. A maximum of 1024

events can be stored.

• Fault reports registered in the FRAM are maintained when there is a power fault, as it is a non-volatile memory. A maximum of

20 fault reports and 10 records in COMTRADE format can be stored.

Function!

Description!

RP-800!

Protection!

50_1!

Phase!instantaneous!overcurrent!protection!function!

!

50G_1!

Ground!nstantaneous!overcurrent!protection!function!

!

50/51!

Phase!!inverse!time!overcurrent!protection!function!

!

50/51G!

Ground!nstantaneous!overcurrent!protection!function!

!

49T!

External!trip!

!

SHB!

Second!harmonic!Blocking!

!

49!

Thermal!image!

!

PGC!

Programmable!Logic!Control!!

!

Circuit!Breaker!monitoring!

52!

State!and!control!of!the!circuit!breaker!

!

Number!of!openings!counter!

!

Accumulated!amperes!counter:!!

!

Maximum!openings!in!a!time!window!

!

Measurements!

!

Phase!and!neutral!RMS!measurement!with!±2%!over!±20%!over!

the!nominal!current!and!±4%!of!±5!mA!in!the!rest!of!the!range.!!

!

Inputs!and!Outputs!

!

External!trip!input!(without!power!supply)!

Via!configureerbare!

ingangen!

!

Configurable!inputs!(without!power!supply)!

3!

Trip!output!for!STRIKER!(135!mJ)!

1!

Configurable!signaling!out!(10A!@!30VDC-250)!

!

3!(NO-NC)!

Communication!and!IHM!

!

Front!port:!micro!USB!(Modbus!RTU)!

!

Rear!port:!RS485!(Modbus!RTU!of!DNP3.0!Serial)!

!

SICom-!!Program!

!

HMI:!LCD,!20x2!and!6!keys!+!1!reset!button!+!1!Battery!key!

!

LED!-indicators!

4!

Power!supply!

!

Self-powering!with!standard!CT’s:!

!

Auxiliary!power!:!24-230!Vdc!/!Vac,!(50/60!Hz)!

!

Internal!comissioning!battery!

!

Monitoring!and!recording!

!

Events!saved!in!the!non-volatile!FRAM*!memory!

1024!

!

Commands!

!

!

Settings!groups!

4!

!

Real-Time!Clock!!(RTC)!

!

!

Disturbance!Fault!Recording!!(DFR)!

!

20!fault!(16!events!

each!one)!10!record!

in!COMTRADE!format!

(50!cycles!per!record)!

!

!

Testmenu!

!

!

Self-diagnosis!

!

9

!

3.3 Functional Diagram

10

!

3.4 Function SHB. Second Harmonic Blocking

The second harmonic blocking is used to avoid an undesirable behavior due to

inrush current when energizing a machine like a transformer or a generator.

Group!

Description!

Minimum!

Maximum!

Step!

Unit!

Default!

SHB!

Second!harmonic!blocking!

Function!Enable!

-!

-!

Yes/No!

-!

No!

Current!tap!

5!

50!

1!

%!

5!

Reset!time!

0.00!

300.00!

0.01!

s!

0.00!

Block!Threshold!

0.07!

20.0!

0.01!

xIn!

10!

In order to avoid these undesirable trips, if the second harmonic percentage is higher

than the pre-set value, the trip will be blocked during the time set in reset time

parameter.

The function picks-up at 100% off the adjusted input and the dropout is at 95%. The

reset type will depend on the adjusted reset time.

The SHB will only be applied in functions that have this option in the “function enable”

setting”. When the Function Enable of these protection functions is set to “SHB”, the

relay will supervise the second harmonic content in order to trip or block the trip

depending on the percentage of second harmonic present in the current signal.

The block threshold is activated at 100% and deactivated at 95% of its value.

3.5 Function 50. Instantaneous phase overcurrent

This protection function can be set by using three parameters:

Function!

Description!

Minimum!

Maximum!

Step!

Unit!

50_1!

!

Instantaneous!phase!overcurrent!

Function!Enable!

-!

-!

Yes/No/SHB!

-!

Current!Tap!

0.2!

20.00!

0.01!

xIn!

Time!Delay!

0.02!

3!

0.01!

s!

The Time Delay is independent from the operating current flowing through the relay,

so if the phase current exceeds its predetermined value for an equal or greater

amount of time than this pre-set value, the protection function activates (trips) and

does not reset itself until the value of the phase drops below the point of current tap.

When the Function Enable is set to “YES”; the accuracy of the Time Delay is equal to

the pre-set time ±30 ms or ±0.5% (whichever is greater). If the Function Enable is set

to “SHB”, the accuracy of the Time Delay is equal to the pre-set time ±50 ms or

±0.5% (whichever is greater).

The function activates at 100% of the pre-set input and deactivates at 95%. The reset

is instantaneous

11

!

3.6 Function 51. Inverse time phase overcurrent

This protection function can be set by using five parameters:

Function!

Description!

Minimum!

Maximum!

Step!

Unit!

51!

Inverse!time!phase!overcurrent!!

Function!

Enbale!

-!

-!

Ja/Nee/SHB!

-!

Curve!type!!

!

-!

-!

(1*)!

!

Time!Dial!

(TMS)!

0,01!

1,5!

0,01!

!

Current!Tap!!

0,2!

7,00!

0,01!

xln!

Time!Delay!!

!

0,02!

3!

0,01!

s!

(1*) IEC Inverse, IEC Very inverse, IEC Extremely inverse, IEC Long time inverse,

Defined time, IEEE Inverse, IEEE Very inverse, IEEE Extremely inverse.

If the option “Defined time” is selected for the curve setting, the unit behaves like an

instantaneous overcurrent unit. In this case, when the Function Enable is set to

“YES”; the accuracy of the Time Delay is equal to the pre-set time ±30 ms or ±0.5%

(whichever is greater). If the Function Enable is set to “SHB”, the accuracy of the

Time Delay is equal to the pre-set time ±50 ms or ±0.5% (whichever is greater). In

this case, the function is activated at 100% of the set tap value, and it deactivates at

95%. If a curve (inverse, very inverse or extremely inverse) is selected for the curve

setting, the trip time depends on the curve, time dial and current tap settings. When

the Function Enable is set to “YES”; the accuracy of the trip time is equal to the

theoretical trip time ±30 ms or ±5% (whichever is greater). If the Function Enable is

set to “SHB”, the accuracy of the trip time is equal to the theoretical trip time ±50 ms

or ±5% (whichever is greater). In this case, the function is activated at 110% of the

set tap value, and it deactivates at 100%. Instantaneous reset in both cases.

The curves used are IEC 60255-151 and IEEE, which are described in their section.

3.7 Function 50G. Instantaneous neutral overcurrent

This protection function can be set by using three parameters:

Function!

Description!

Minimum!

Maximum!

Step!

Unit!

50G_1!

Instantaneous!neutral!overvcurrent!!

Function!enable!

-!

-!

Ja/Nee/SHB!

-!

Current!Tap!!

0,2!

10,00!

0,01!

xln!

Time!Delay!

!

0,02!

2!

0,01!

s!

The Time Delay is completely independent from the operating current that flows

through the relay, so if the neutral current exceeds its predetermined value for an

equal or greater amount of time than this pre- set value, the protection function

12

!

activates (trips) and does not reset itself until the value of the phase drops below the

point of current pick-up.

When the Function Enable is set to “YES”; the accuracy of the Time Delay is equal to

the pre-set time

±30 ms or ±0.5% (whichever is greater). If the Function Enable is set to “SHB”, the

accuracy of the Time Delay is equal to the pre-set time ±50 ms or ±0.5% (whichever

is greater).

The function activates at 100% of the pre-set input and deactivates at 90%. The reset

is instantaneous.

3.8 Function 51G. Inverse time neutral overcurrent

This protection function can be set by using the following parameters:

Function!

Description!

Minimum!

Maximum!

Step!

Eenheid!

51!

Inverse!time!neutral!overcurrent!

Functie!Enable!

-!

-!

Ja/Nee/SHB!

-!

Curve!type!

-!

-!

(1*)!

!

Time!Dial!

(TMS)!

0,01!

1,5!

0,01!

!

Current!Tap!!

0,2!

7,00!

0,01!

xln!

Time!Delay!

0,02!

2!

0,01!

s!

(1*) IEC Inverse, IEC Very Inverse, IEC Extremely Inverse, IEC Long Time Inverse, Defined Time,

IEEE Inverse, IEEE Very Inverse, IEEE Extremely Inverse

If the option “Defined time” is selected for the curve setting, the unit behaves like an

instantaneous overcurrent unit. In this case, when the Function Enable is set to

“YES”; the accuracy of the Time Delay is equal to the pre-set time ±30 ms or ±0.5%

(whichever is greater). If the Function Enable is set to “SHB”, the accuracy of the

Time Delay is equal to the pre-set time ±50 ms or ±0.5% (whichever is greater). In

this case, the function is activated at 100% of the set tap value, and it deactivates at

95%.

If a curve (inverse, very inverse or extremely inverse) is selected for the curve

setting, the trip time depends on the curve, time dial and current tap settings. When

the Function Enable is set to “YES”; the accuracy of the trip time is equal to the

theoretical trip time ±30 ms or ±5% (whichever is greater). If the Function Enable is

set to “SHB”, the accuracy of the trip time is equal to the theoretical trip time ±50 ms

or ±5% (whichever is greater). In this case, the function is activated at 110% of the

set tap value, and it deactivates at 100%.

Instantaneous reset in both cases.

The curves used are IEC 60255-151 and IEEE,

3.9 Function 49. Thermal Image Protection

Thermal image is a measure of heating and cooling of an electric machine. Unlike

overcurrent protection, it does not start counting the time when it detects a fault, but it

is continuously determining the thermal state of the machine that monitors. The trip

13

!

time depends on the thermal constants adjusted, the current flowing and the prior

thermal state of the machine.

The thermal image is calculated based on the following equation:

θ = 100 x (I/It)2 x (1 - e-t/ζ) + θ'0 x e-t/ζ

Where :

I, maximum R.M.S.-current of three phases

It, adjusted tap current

ζ, thermal constant

θ'0, initial thermal state

The trip time is given by the equation:

t = ζ x ln x {[(I/It) 2 - (θ'0 / 100)] / [(I/It) 2 - 1]}

The algorithm uses the maximum of the three phase currents. If the maximum is

greater than 15% of the adjusted tap, heating thermal constant is applied. If the

maximum is less than 15% of the adjusted tap cooling thermal constant is

considered.

The overload function trips when the thermal image reaches the value of 100%. This

value is reached in time when the current is equal to the function adjusted in thermal

function.

It provides an adjustable level of thermal imaging to generate an alarm. If the trip

occurs, the function is reset when the thermal image falls below the set alarm level.

As the current measurement algorithm used is R.M.S., in the thermal model is

considered the heat produced by the harmonics.

This protection function is adjusted by setting five different parameters:

Function!!

Description!

Minimum!

Maximum!

Pitch!

Default!

Defect!

49!

Thermal!image!protection!function!!

Function!Enable!

-!

-!

Yes/No!

-!

No!

Current!Tap!!

0,10!

2,40!

0,01!

x!In!

1,2!

ζ!heating!

3!

600!

1!

min!

3!

ζ!cooling!

1!

6!

1!

ζ!heating!

1!

Alarm!

20!

99!

1!

%!

80!

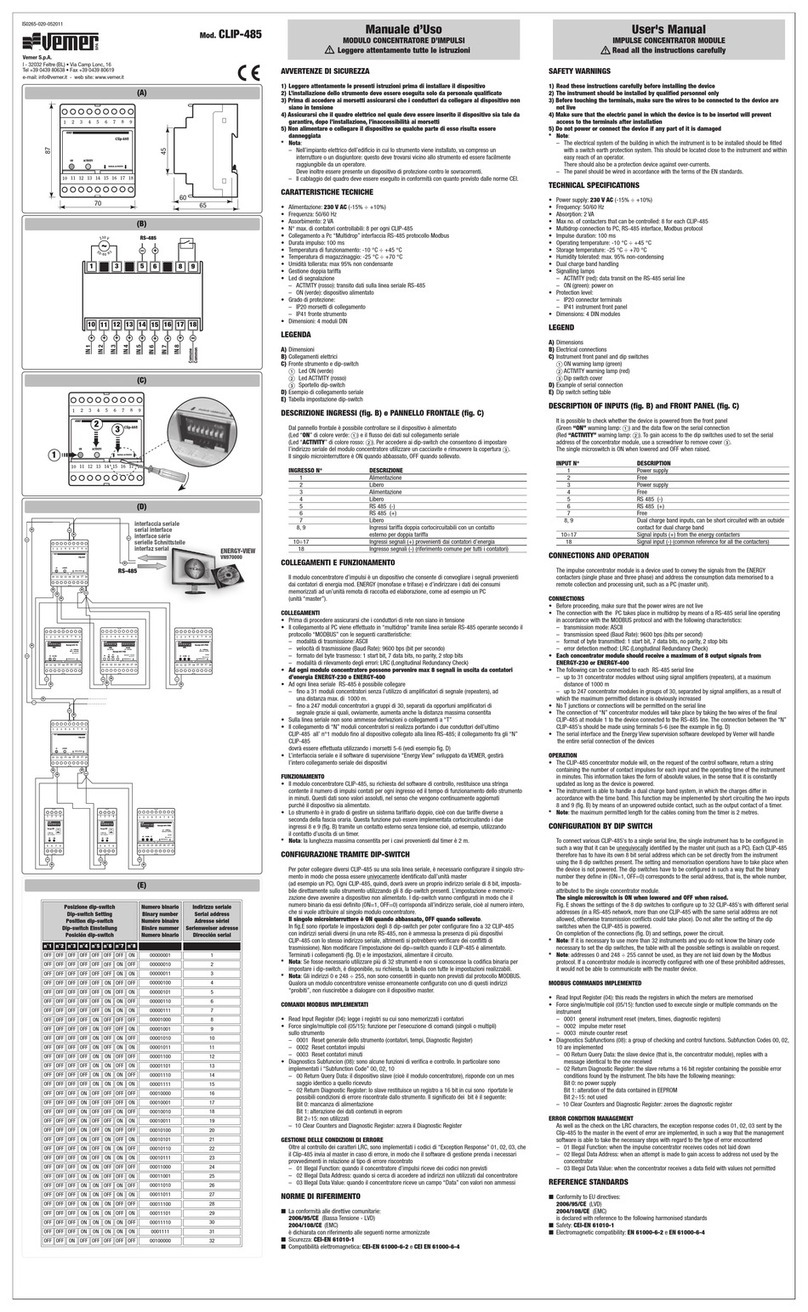

3.9.1 Thermal image measurement evolution graphic

On next graphic, thermal image measurement evolution can be observed depending

on applied current:

Table of contents