MexAir RC X4MR 250 User manual

X4MR250 MexAir RC

1

X4MR Manual

(See our website www.mexairrc.com for our upcoming video series on X4MR Construction))

Introduction

Congratulations on your purchase of the MexAir RC X4MR 250 FPV Race Quadcopter. This quad has

some very unique design features that allow for advanced flight characteristics. The built-in

configurations enhance maneuverability, speed and load handling capability. Some of these are

described below and throughout the build sections of this manual. Besides the advantages described

below are the less obvious materials making up the airframe. Most quality multirotors use some form of

carbon fiber in their design. We have chosen the more costly but highest quality aerospace quasi-

isotropic carbon fiber. Rather than describe the benefits of this material, especially when used in

conjunction with a light-weight core, you may wish to simply “Google” the terms to find the vast amount

of technical data supporting the use of this grade of carbon fiber in light-weight rugged, rigid, and strong

applications.

MexAir RC, located in Central New York, is the designer and manufacturer of the X4MR 250 Class

Racing Quad airframe. We specialize in the design and construction of the airframe. Since the various

electronic components and peripherals are widely available through many sources, our focus is on

providing a unique platform for the already available devices. The experienced builder will already know

much of the information –but we decided to cover details not always found in build manuals –

especially considering some of the unique features of the X4MR.

The X4MR carbon fiber laminated airframe design, materials, and methods of construction create an

assembly that allows for:

Enhanced aerodynamics due to the ability to embed wiring within airframe structural

components thus reducing turbulence and drag

Elimination of the typical “lightening holes” in areas of the airframe to improve strength and

rigidity, additionally reduce turbulence, while at the same time reducing airframe weight when

compared to typical solid carbon fiber frame materials used in many other multirotor copters

Reduced induced vibration through use of vibration damping body & arm core material –

resulting in better video quality

Electronic component placement flexibility due to:

oease of mounting additional accessory items to the CF frame using simple self tapping

screws

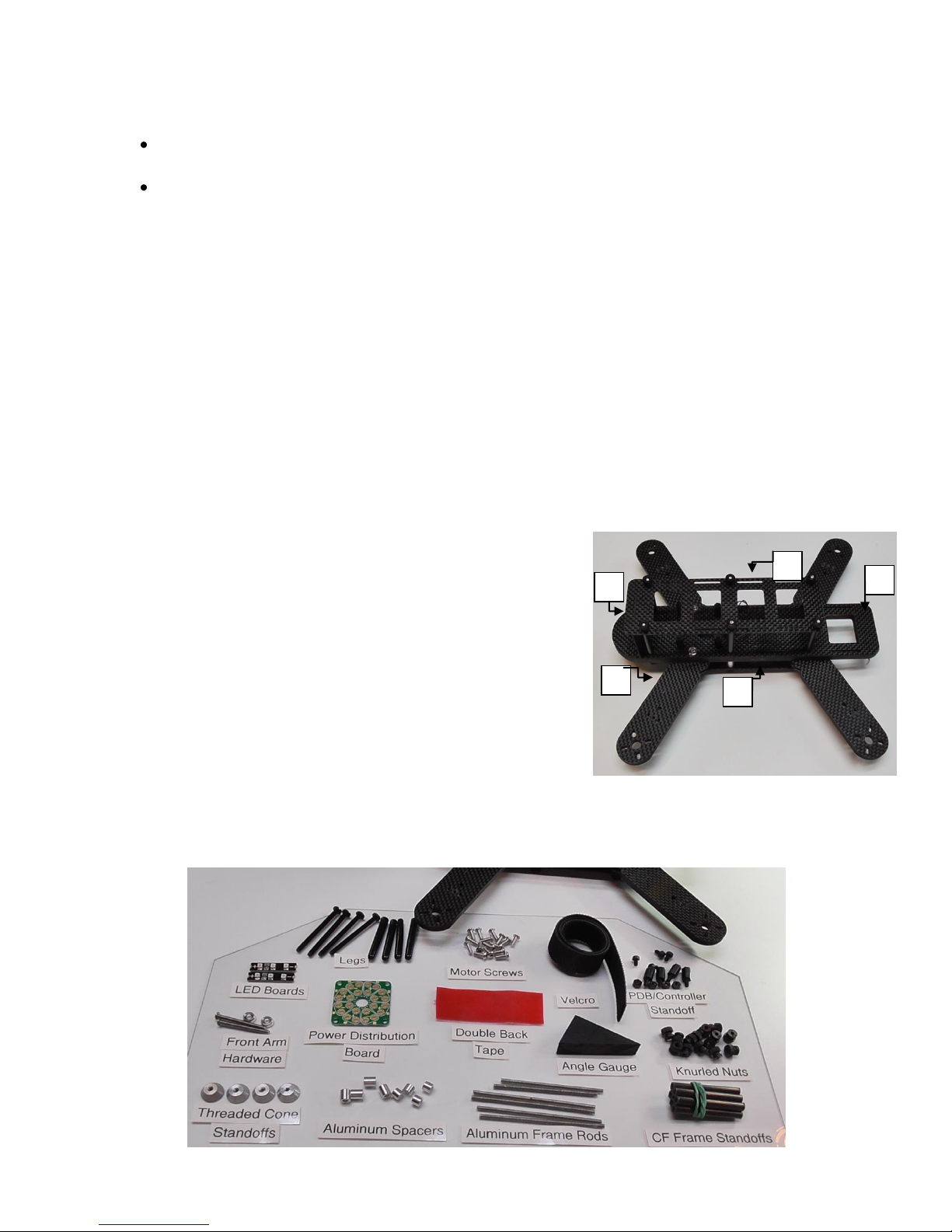

Completed X4MR Airframe

Total Weight as

Pictured: 111 Grams

X4MR250 MexAir RC

2

oadditional space on certain surfaces of the frame when using embedded wiring

Top and bottom plate mounting using thru-layer tie-rods and fasteners creating a rigid structure

required by high power motor systems

Variable motor arm positioning that allows for

oFine adjustments to center of gravity

ovariable motor placement to enhance maneuverability

omotor arm “swing away” deflection on a hard-hit thus reducing crash damage potential

The X4MR 250 kit includes all the frame components and fasteners necessary to construct a 250 class

racing quad using electronics of your choice. You will receive the airframe in an already assembled state.

We have done this for you so that you can see how the frame should look when completely assembled.

It is expected that you will disassemble some of it during the build. The instructions that follow assume

that you simply received the kit in a completely disassembled state.

The airframe comes configured to mount the supplied Power Distribution Board with the included PDB

standoffs and predrilled main frame mounting holes. This PDB mount allows for “piggy-back” mounting

of a 30.5mm controller board using additional standoffs. The frame body already has embedded wire

leads to solder the included LEDs to both the front and rear to assist in visual orientation during flight.

The motor arms have internal wire cavities that allow for embedding the motor wires up to the main

frame and the speed control bottom plate.

X4MR Kit Contents: (See Accompanying Pictures)

1. Main Frame Body w/preinstalled LED wiring

2. Motor Arms (4)

3. Top Plate [To mount FPV Gear]

4. Bottom Plate [To mount ESCs]

5. Camera Plate [To mount forward looking camera]

6. Landing Gear Legs, Boots, and Mounting Hardware (4 sets)

7. Power Distribution Board [3oz copper PDB for higher

current applications]

8. LED Boards, 4S LiPo Capable (Front & Rear)

9. PDB Mounting Standoff Set

10. Plate Mounting Standoffs/Hardware Set

11. “Hook & Loop” Battery Strapping Material

12. Alternate 3mm motor mounting screws (16) if your motor screws will not fit properly

13. Double Backed Insulating Tape

1

2

3

4

5

X4MR250 MexAir RC

3

Other “stuff”typically installed on a racing multirotor frame includes:

Flight Controller Board

Motors

Propellers

Speed Controls (ESCs)

FPV Gear and cameras

Batteries and Battery Connectors

In some frame designs, including the X4MR, there are varying options for positioning and mounting

components. We listed options for those that have shown to be useful and tested successfully with the

X4MRs we build in-house.

Recommended Options:

Voltage Regulator(s)

oNote: If you do not have 5V and/or 12V supplies that may be necessary for your camera

systems, these can be handy add-ons wired direct to the supplied PDB.

Satellite receiver vs. standard receiver?

oTesting with a Spektrum satellite receiver showed no adverse effects on range or signal

reception. It is a good lightweight alternative to traditional receivers due to small size

and less wiring as might otherwise be necessary. It can be mounted almost anywhere

on the X4MR airframe.

General Guidance to make assembly faster, easier and safer:

1. Read through the assembly instructions completely PRIOR to beginning construction.

2. Inventory all kit supplied parts, your electronics and tools, organizing them according to your

intended build. Do not forget about any general supplies such as solder, heat shrink, small tools,

etc.

3. Use small amounts of blue loctite thread locker on all metal-to-metal screw contact surfaces,

especially motor mounting screws.

4. “Dry-fit” and test all electronics and FPV gear, to the extent possible during the build, so

disassembly will not be required after you have completed the frame assembly.

5. Pre-plan purchase of motors that have sufficient motor wire length and diameter to allow for

embedding the wires into the motor arms. The minimum length of the leads should be 4 inches.

The wire diameter, including insulation, should be a maximum of 1/16” (~20 gauge) to fit into

the arm holes. If larger, the holes can be widened as described in this manual. Alternately, any

wire length or diameter can be used by surface mounting them.

6. Take care in soldering components to prevent shorting between solder pads or overheating any

sensitive electronic components.

7. Although the skills, techniques, and “hazards” associated with this build are typical for many

hobby related activities, we always strive for safe and efficient construction techniques. We

therefore repeat here what you have likely learned from your previous experiences:

a. The X4MR airframe kit does not require any drilling for the typical build. If drilling

holes in the carbon fiber (CF) for self tapping screws or larger component attachments

use a sharp drill bit and work with light pressure and a relatively high speed drill. CF can

not be “punch marked” for drilling. A small electric rotary tool or drill press is

recommended to prevent the bit from “wandering” as you start the hole. Wear

appropriate safety gear, including air mask/filter, if creating carbon dust.

X4MR250 MexAir RC

4

b. Always wear appropriate safely gear or take other precautions during any operation

that could create a hazardous condition –including soldering, drilling, cutting and

grinding.

8. Carbon fiber is a conductive material. Never allow bare battery terminals or other

powered connections to physically come into contact with the carbon fiber or metal

components of the frame. Contact may create short circuits that may damage

electrical components and/or become a fire hazard. Always insulate powered

terminals from the frame using nonconductive materials such as electrical insulating

tape, heat shrink tubing, or plastic/nylon standoffs or mounts.

9. NEVER attempt to screw any component into the carbon fiber frame without first

carefully drilling the appropriately sized hole at the fastener location. Self tapping

screw/bolt hole sizes are slightly larger than the inner diameter of the threaded

portion of the fastener. When tightening a self tapping fastener, it may be necessary

to start tightening it, back it out slightly, repeating this process until the fastener is

threaded to the proper depth. This creates a threaded hole that should hold firmly

without any other aid. For added assurance, use the time-tested technique of

“hardening” the laminate core material AFTER you create the threads using the self

tapping fastener. Remove the fastener from the hole and carefully drip 2 –3 small

drops of thin CA into the hole. The CA will “wick” into the core thread area and harden

the core material. Allow sufficient time (usually only a couple of minutes) for the CA to

completely dry prior to reinserting the fastener. You do not want to glue the fastener

permanently in the hole! Hardening the laminate core material, although not typically

necessary, is only done if you intend to insert a threaded fastener that will be

tightened across the laminated surfaces causing significant compressive forces on the

laminate structure. Hardening reduces “dimpling” the surface when compressed. The

laminate structure is sufficiently strong and some dimpling is not a bad thing –it

actually acts to further reduce the possibility of fasteners loosening. Excessive

tightening is unnecessary.

X4MR250 MexAir RC

5

Construction of the X4MR Airframe

1. LEDs (LED Boards supplied with this kit can be run direct to 4S LiPo power without any

voltage regulator)

a. The preinstalled LED power leads feed through the body of the frame and exit the

frame conveniently below the PDB position. Do not permanently connect the power

side of the leads to the PDB or power source at this time. Permanent installation

should be done after final placement of the PDB, any necessary voltage regulators,

and speed controls.

b. Place the main frame body upside down. First, gently push the LED wires a slight

amount into the wire exit hole and then pull gently to see how much slack wire you

have to work with. Note the slack amount. Strip the remaining insulation leaving the

amount of insulation you determined as slack.

c. Cut the excess bare wire leaving about ¼” bare. Tin the bare end.

d. If your kit was supplied with single color wires, trace the wire from the LED location

to the planned source end with an ohm-meter. Mark both the positive (+) and

negative (-) wire ends at the main body hole (the large elongated hole). You can

always trace the polarity later during the build if you forget to do it now. If supplied

with colored wires, the red (or white) wire will always be intended as the positive (+).

The other wire is the negative (-).

e. Solder the LED board to the wires paying attention to the proper polarity. Measure

and cut a small strip of supplied double backed tape the same size as the LED board.

[This is very sticky stuff! You may want to handle it with the tip of a small hobby

knife blade rather than your fingers.] Apply the sticky side between the wire holes

on the body underside. Remove the remaining tape backing.

f. At this time you should be able to push the soldered wires of the assembly slightly

into the body so the board will lay flat to the tape. Readjust as necessary.

g. Verify that the bare metal of your solder joint is not touching the carbon frame body

and the board is fully insulated from the body by the tape.

Wires Fully Extended

Partially into Body

Insulation Stripped

Soldered to Board

Double Backed Tape Applied to

Bottom of Board or Frame

Tape Backing

Removed, wires

pushed into holes &

LEDs Pressed Into

Place