(5)

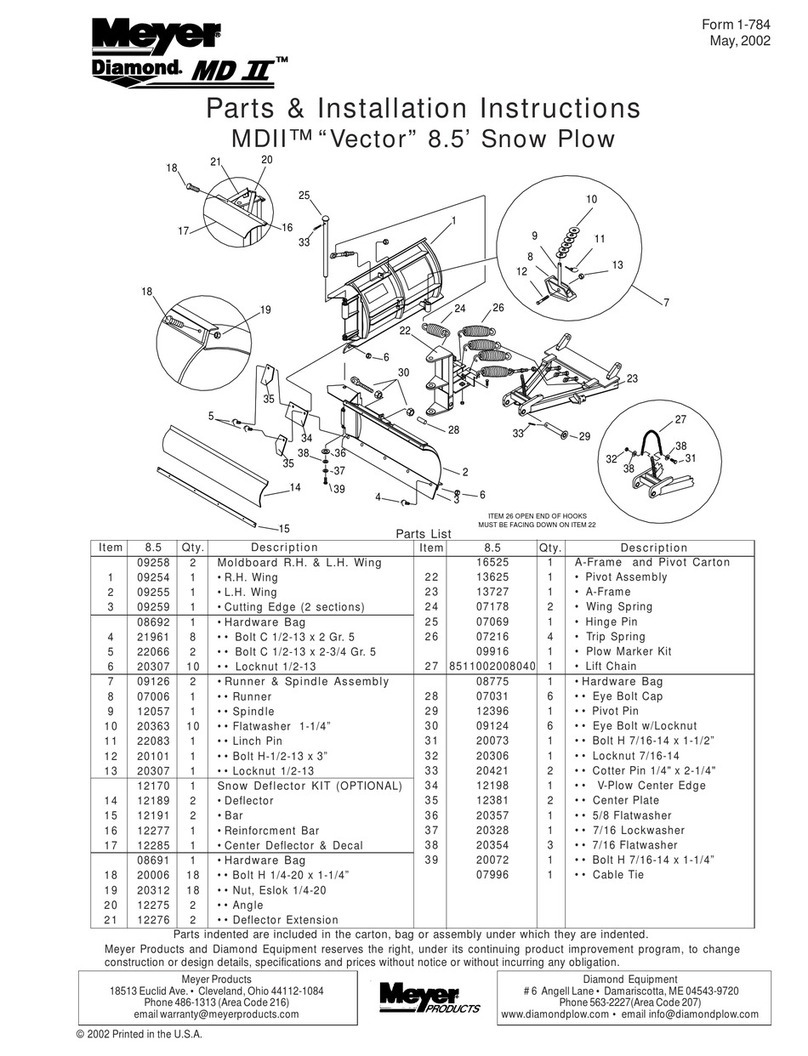

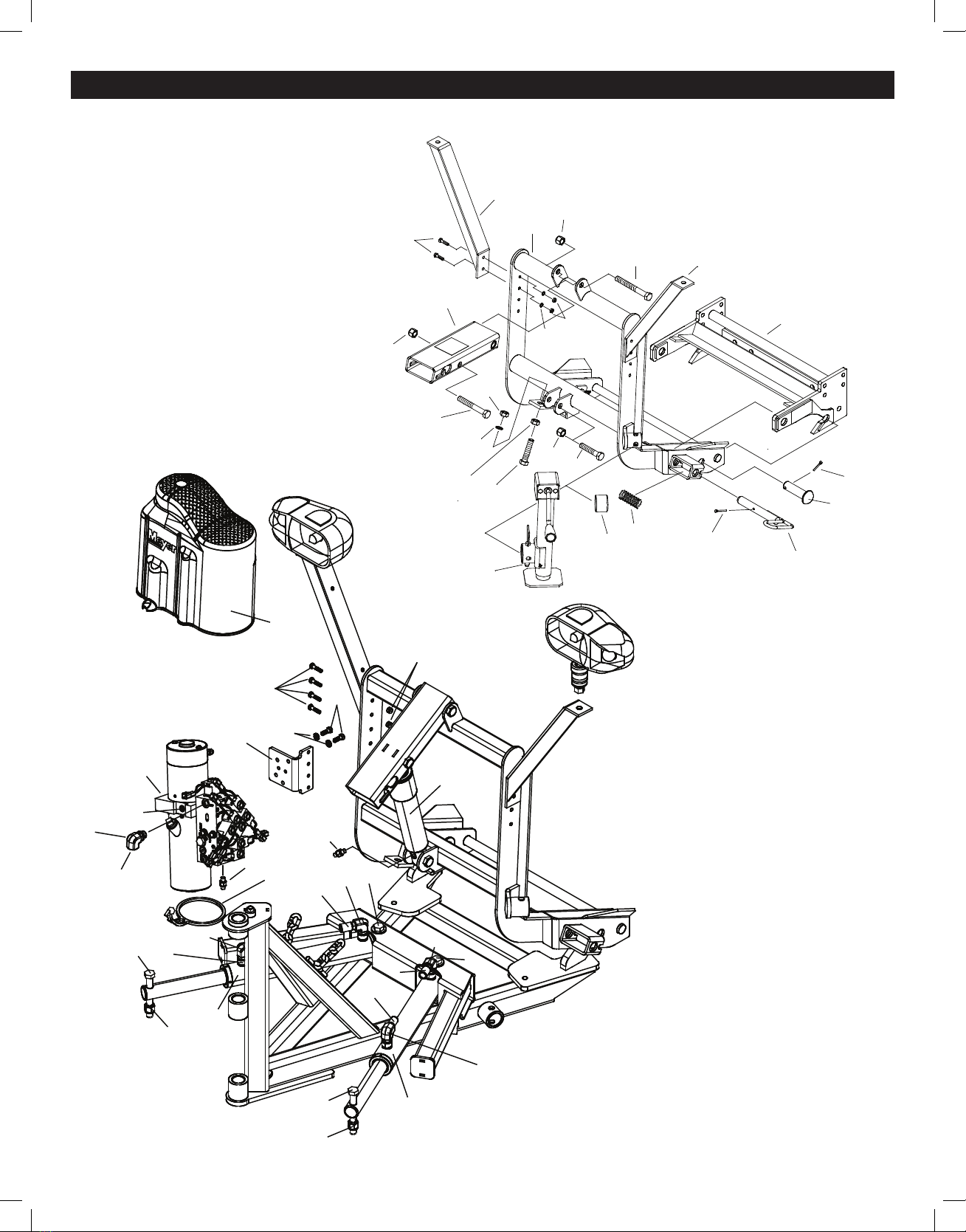

Building Super V Plow

1. Position wing assemblies 75 & 76 face down on cardboard as not to

damage the painted surfaces. Grease the bushings on both left and right

wings. Position the wings so pivot bushings align. Note: Cutting Edges

will be inline at this time.

2. Remove 1/2”-13 x 1” set screw located in top of A-Frame (37) tower. Grease

A-Frame (37) bushings and Pivot Pin (36). With a helper, lift the A-Frame (37) and

insert its bushings in alignment with the wing bushings.

3. Insert Pivot Pin (36) through bushings. Install and tighten 1/2” x 1.50” bolt

(56) and 1/2” lockwasher (59) to top of A-Frame holding Pivot Pin (36) in

place. Note: Wipe o any excess grease at this time.

4. Using the A-Frame as leverage tilt the moldboard assembly raising the

Cutting Edges o the ground. Support Cutting Edges (87) 5 to 6 inches

o the ground.

5. Install the Bottom Belt (71) to left and right wing at Tripedge (77) using

1/2” x 2” carriage bolt (61) and locknut (58). Note: Be sure that Belt (71)

folds are upward and notches are toward the A-Frame (37). Assemble

Backing Plate (54) so bent end is facing the cutting edge forcing the belt

against the Tripedge (77).

6. Using the A-Frame as leverage tilt the moldboard assembly raising the

Cutting Edges o the supports. Remove supports and set moldboard

assembly to the upright position.

7. Assemble Snow Deector Brace (53) to Pivot Pin (36). Place brace under

the pivot pin plate. Attach using two 5/16” x 1-1/4” bolts (55), 5/16

washers (60) and 5/16 locknuts (57).

8. Position moldboard assembly in the “Vee”position.

9. Assemble Top Snow Deector (70) positioning the deector under

deector brace (53). Attach deector ends under left and right wing

gussets using 5/16” x 1-1/4” bolts (55), 5/16 locknuts (57) and 5/16

washers (60). Tighten locknuts such that washers slightly compress the

rubber surface.

Note: Snow Deector Belt should fold/loop downward between brace

and each wing gusset when wings are not in the “Vee” position.

10. Assemble Lift Frame (38) tp A-frame (37) using 1 x 3” Pin (49) and 1/4 x 2”

Cotter Pin (47).

11. Assemble Blue Handle Pin (69) to lift frame (38) by inserting the Blue

Handle Pin (69) through the outer lift frame plates, through the center

of the spring (50). At this time align the small blue leg on the handle

through the notch on the outermost plate. Compress the spring (50)

slightly with your ngers and insert the 3/16” x 1-1/2” Cotter Pin (46)

through the small hole towards the center of the pin. With cotter pin (46)

fully inserted, pull the blue handle until the spring is fully compressed

and rotate the handle one full turn to bend the cotter pin in place.

Realign the small blue leg with the notch on the outermost plate to

lock in place. Repeat assembly process until both pins are assembled.

Note: Lubricate the stainless steel pins and Lift Frame bearing surfaces

with chassis grease or anti-seize lubricant periodically for easier

disengagement of pins.

12. Assemble adjustable stacking stop bolts to lift frame (38) using 5/8-11

x 3” bolts (51), lockwasher (52) and jamnuts (52) per gure1. Note:

Adjustment must be made after moldboard assembly is installed.

Adjustment bolts (51) should make contact with the a-frame before

any part of the A-Frame or moldboard come in contact with the lift arm

and, or hydraulic unit while raising the snowplow or stacking snow.

Moldboard should be checked in all positions.

13. Attach L.H. and R.H. Light Brackets (66 & 67) to the side plates of Lift

Frame (38) in the upper two holes using 5/16”-18 x 1-1/4” bolts (39), 5/16”

lockwashers (44), and 5/16”-18 hex nuts (48). Note: Light brackets may

be adjusted down two levels in height for better appearance on lower

prole vehicles. Tighten all fasteners to their proper torque.

14. Attach lift arm (73) to lift frame (38) using 5/8-11 x 5-1/2” bolt (42) and 5/8-11

locknut (43).

15. Install the V-70 Mounting Bracket (28) to the Lift Frame and Light Bracket

(Passenger Side) using 5/16-18 x 1-1/2” Bolts (16) and 5/16-18 Locknuts

(20). Install the V-70 Lift Assembly (29) to V-70 Mounting Bracket Assem-

bly using Bolt H 3/8-16 x 1-1/4” (17) and 3/8 Lockwasher (22). Remove

shipping plug on V-70 Lift Assembly and install Breather (14).

16. Attach the Lift Cylinder (2) to the Lift Frame using Bolt H 5/8-11 x 3-1/4”

( 40) and 5/8-11 Locknut (43). Attach the Lift Cylinder (2) to the Lift Arm

using Bolt H 5/8-11 x 4-3/4” (41) and 5/8-11 Locknut (43). Attach elbow

(26) to V-70 Lift Assembly (29) along with Hose (34) and attach hose (34)

to Lift Cylinder (2) using Straight Fitting (27).

17. Attach xed end of Wing Cylinders (5) to the A-Frame with a 5/8-11 x 5”

bolt (18) and 5/8-11 locknut (21) on each side. Attach live end of Wing

Cylinder rod (5) to the Wings using a 5/8-11 x 5” bolt (19) and 5/8-11

locknut (21) on each side.

18. Attach Wing Cylinders hoses to the V-70 Lift Assembly (29) by removing

the caps from the hoses (6 & 7) and plugs from the V-70 Lift Assembly

(1). Install Straight Fittings (27) to bottom of PA Block on V-70 Hydraulic

Unit and connect hoses. See below. Use zip ties to route hoses away from

moving plow parts to prevent chang.

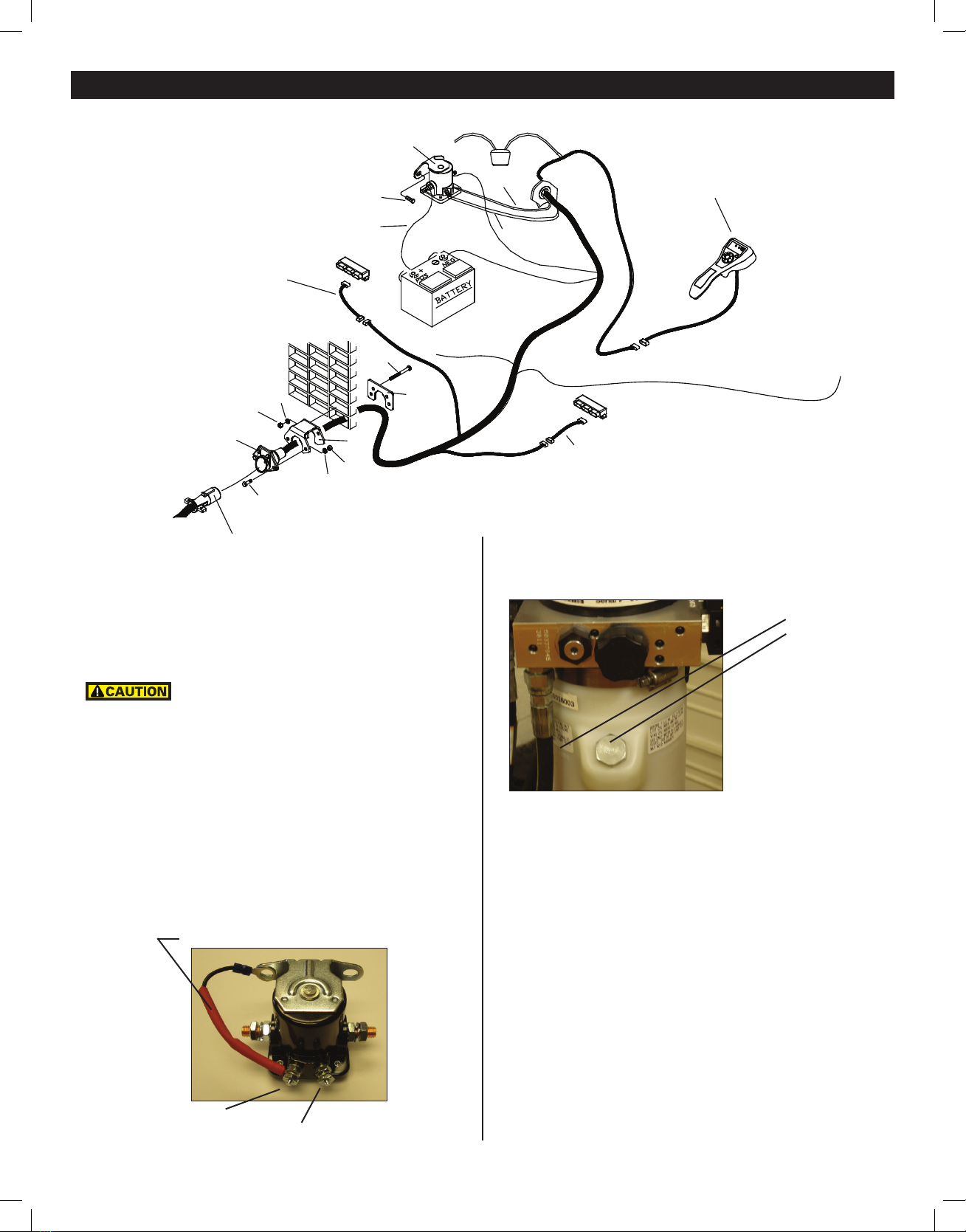

19. Connect Super V Plow Side Harness (33) toV-70 Hydraulic Unit (29) as

shown below.

Pass Side

Live End

(1/4 Hose)

Driver Side

Live End

(1/4 Hose)

Pass Side

Fixed End

(3/8 Hose)

Driver Side

Fixed End

(3/8 Hose)

Drain

Fill

S1

S2

S3

S4

S5

S6

S7

S8

Lift

Cylinder

Hose

Port

S1 - RED WIRE

S2 & S7 - BLACK WIRE

S3 - GREEN WIRE

S4 - YELLOW WIRE

S8 & S8 - BLUE w/WHITE STRIPE

S6 - PURPLE WIRE