Item Part No. Part No. Qty. Description

28301 28301 1 • Accessory Box

41 23025 23025 1 •• Power Cable - 36”

42 12978 12978 2 •• Trip Spring

09917 09917 1 •• Plow Marker Kit

43 08214 08214 2 ••• Plow Marker

44 20027 20027 4 ••• Bolt H 5/16-18 x 1 Gr. 2

45 20304 20304 4 ••• Locknut 5/16-18

46 20352 20352 8 ••• Flatwasher 5/16”

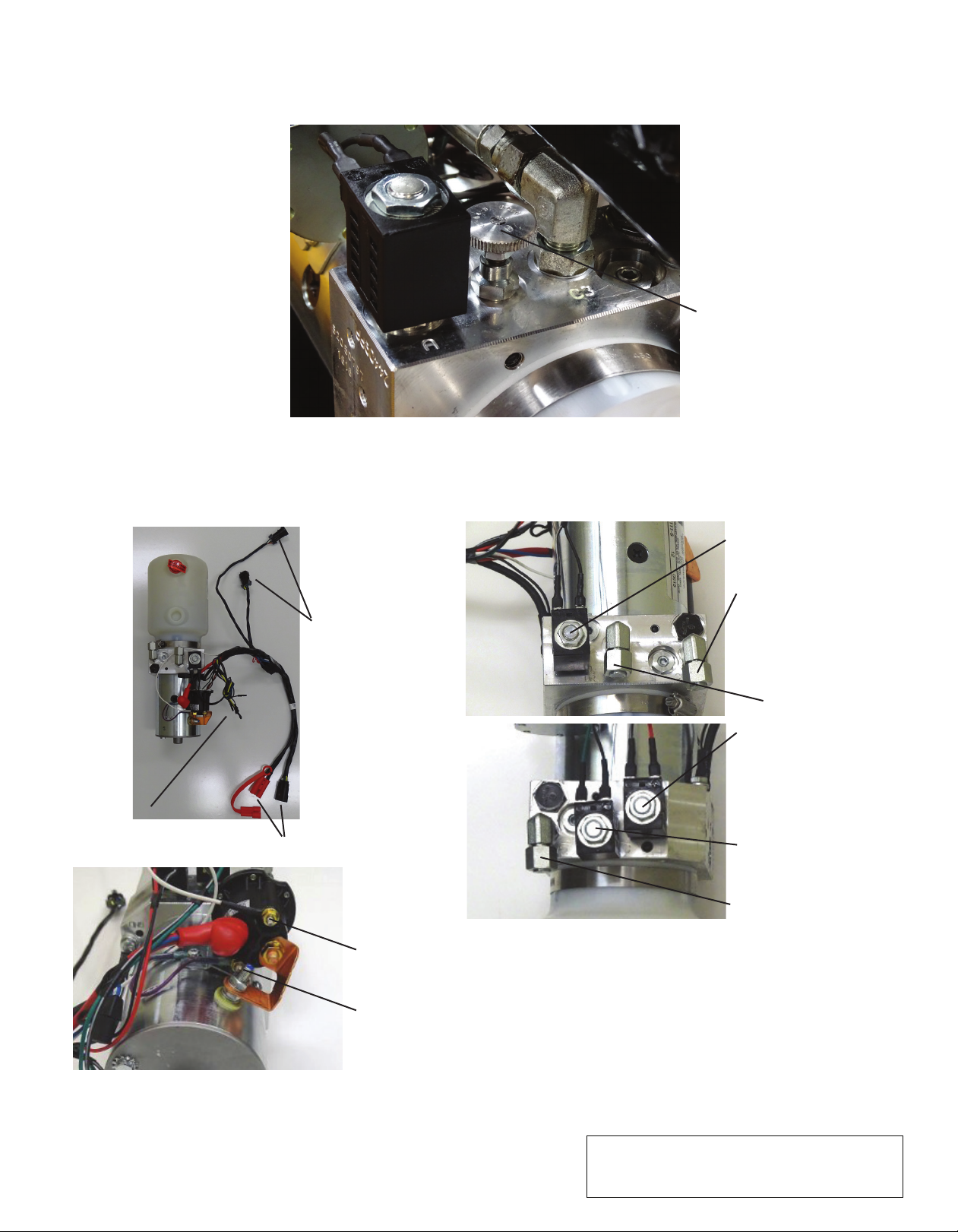

47 15372 15372 1 •• Starter Solenoid - 12 volt

48 21832 21832 1 •• Split Bushing

49 23047 23047 1 •• Controller

50 23059 23059 1 •• Truck Side Harness

41102 41102 1 •• Hardware Bag

51 09124 09124 2 ••• Eye Bolt

52 20357 20357 2 ••• Flatwasher 5/8”

53 20385 20385 2 ••• Cotter Pin 1/8 x 1-1/4”

54 22989 22989 2 ••• Pivot Pin 5/8 x 5-3/4”

55 20357 20357 2 ••• Flatwasher 5/8”

56 22686 22686 2 ••• Trip Bumper

57 15187 15187 1 • Breather

58 23057 23057 1 • T-Connector

59 07810 07810 1 • Light Set Nite Saber 3

60 14065 14065 1 • Dp Std Caster Kit

61 08571 08571 1 •• Hdwe Bag Hairpin Cotter

62 14062 14062 3 ••lm Xl Caster Assy

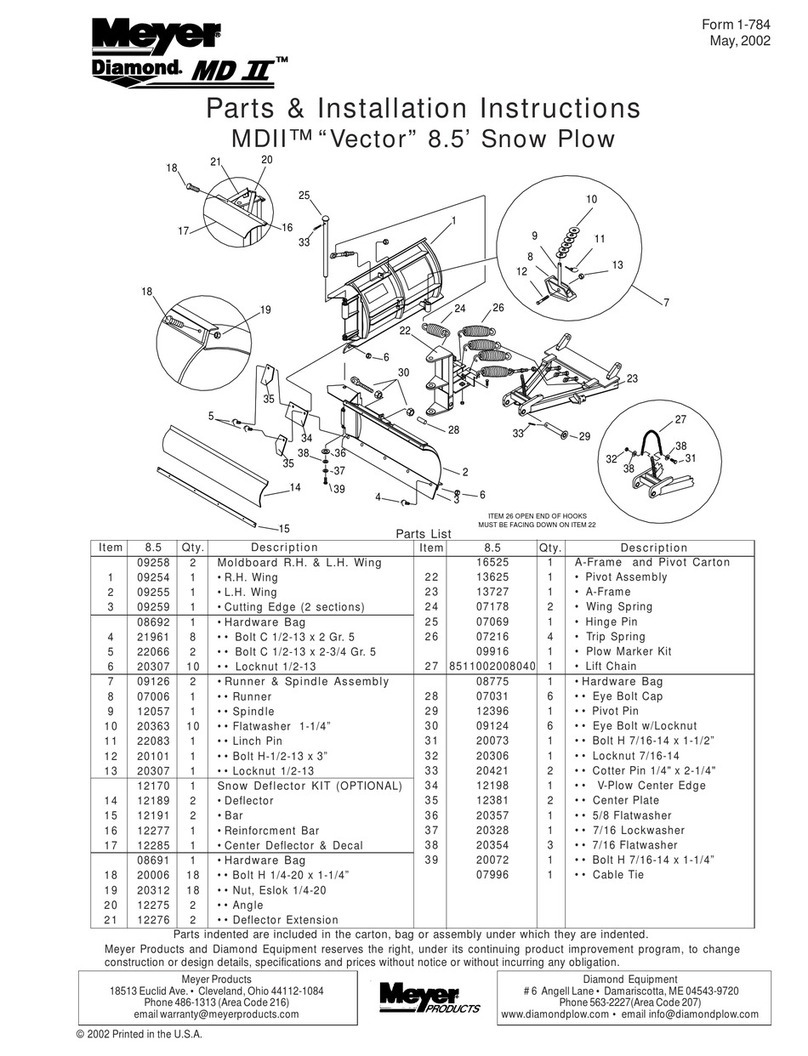

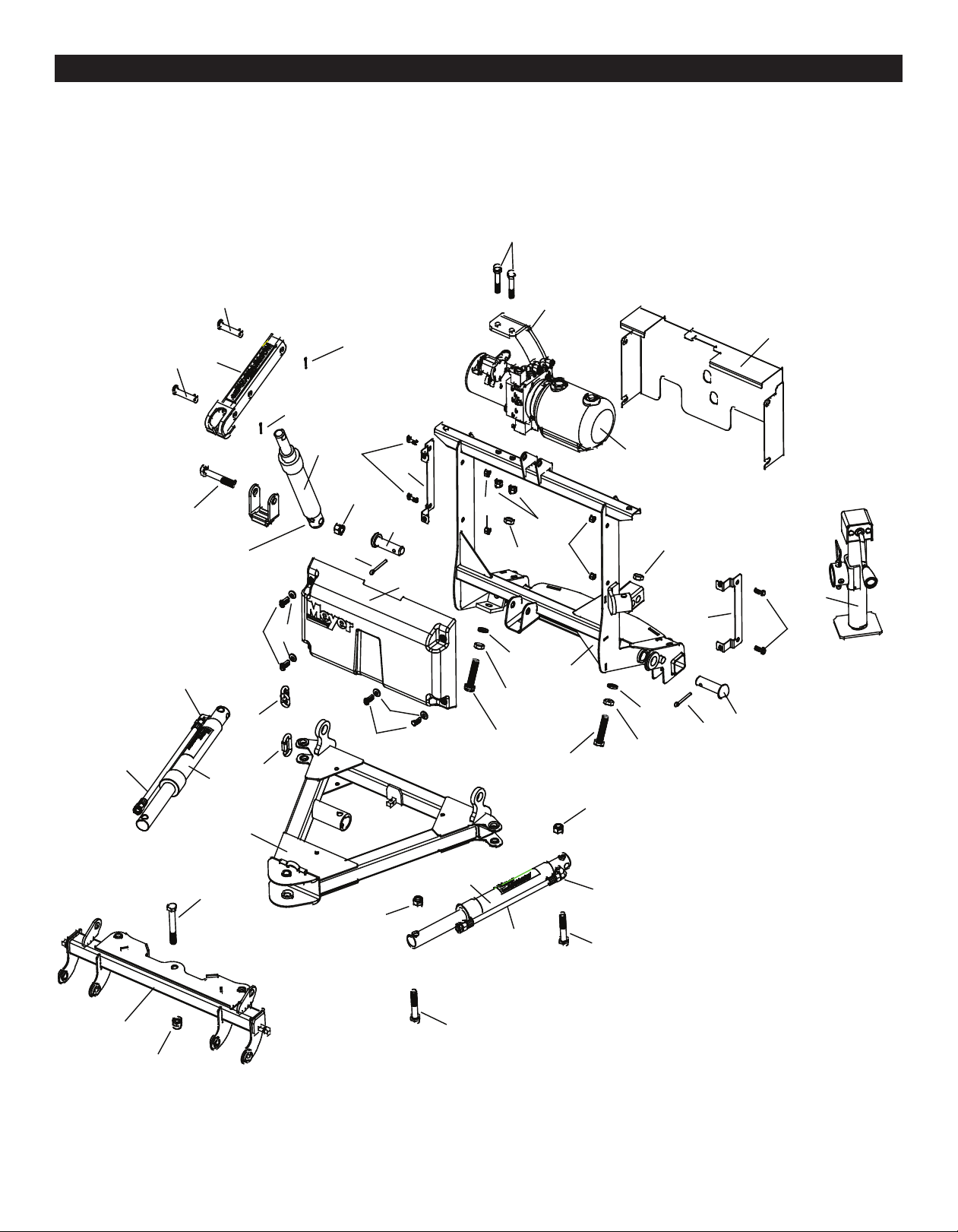

Parts List

Meyer Products LLC reserves the right, under its continuing product

improvement program, to change construction or design details,

specifications and prices without notice or without incurring any

obligation.

Parts indented are included in the carton, bag or assembly under which they are indented.

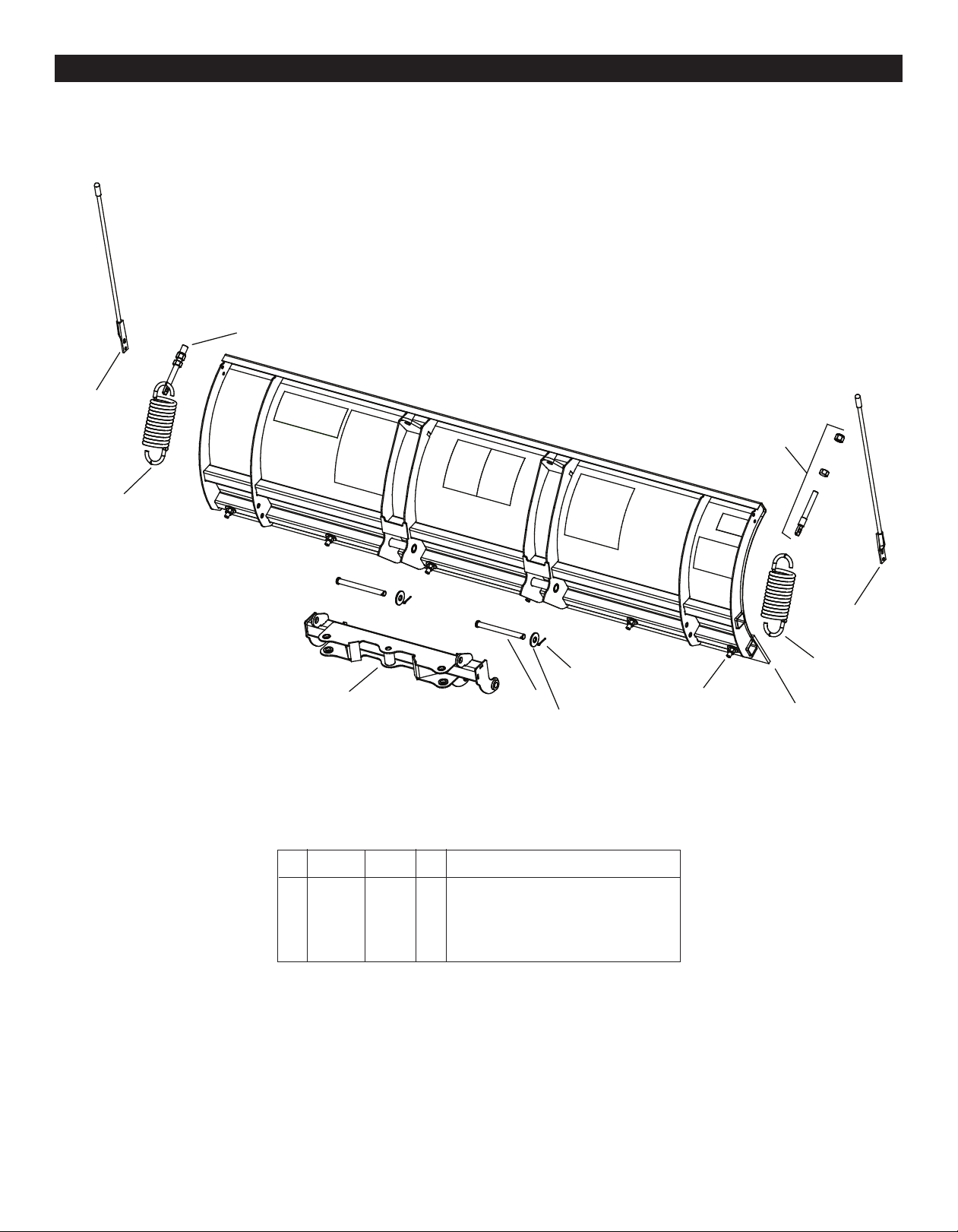

28300 & 28310 E-73 EZ Build

Item Part No. Part No. Qty. Description

28300 --------- 1 WM 6.8 2” Rec E-73 DP Mount Assy.

--------- 28310 1 WM 7.6 2” Rec E-73 DP Mount Assy.

1 05888 05888 1 • Lift Ram 1-1/2 x 8”

07772 07772 1 • LH Ram with Hose & Fittings

2 05887 05887 1 •• Ram (1-1/2” x 10”)

3 22866 22866 1 •• SAE 6 x 90 Degree Elbow

4 22885 22885 1 •• Hose Assy 1/4 x 54” M-6

07783 07783 1 • RH Ram with Hose & Fittings

2 05887 05887 1 •• Ram (1-1/2” x 10”)

3 22866 22866 1 •• SAE 6 x 90 Degree Elbow

4 22921 22921 1 •• Hose Assy 1/4 x 38” M-6

5 10514 10514 1 • Lift Arm

6 14250 14250 1 • Pivot Bar Drive Pro 6.8

7 14185 14185 1 • E-73 DP Mounting Bracket

8 14232 14232 1 • A-Frame Drive Pro

9 14289 14289 1 • E-73 Lift Unit Cover Front

10 14288 14288 1 • E-73 Lift Unit Cover Rear

11 14290 14290 2 • Lift Unit Cover Bracket

12 16027 16027 1 • E-73 Lift Ass’y. (Unit only)

13 18926 18926 1 • Lift Frame

14 20146 20146 1 • Bolt H 5/8 - 11 x 3-1/4” Gr. 5

15 20147 20147 4 • Bolt H 5/8 - 11 x 3-1/2” Gr. 5

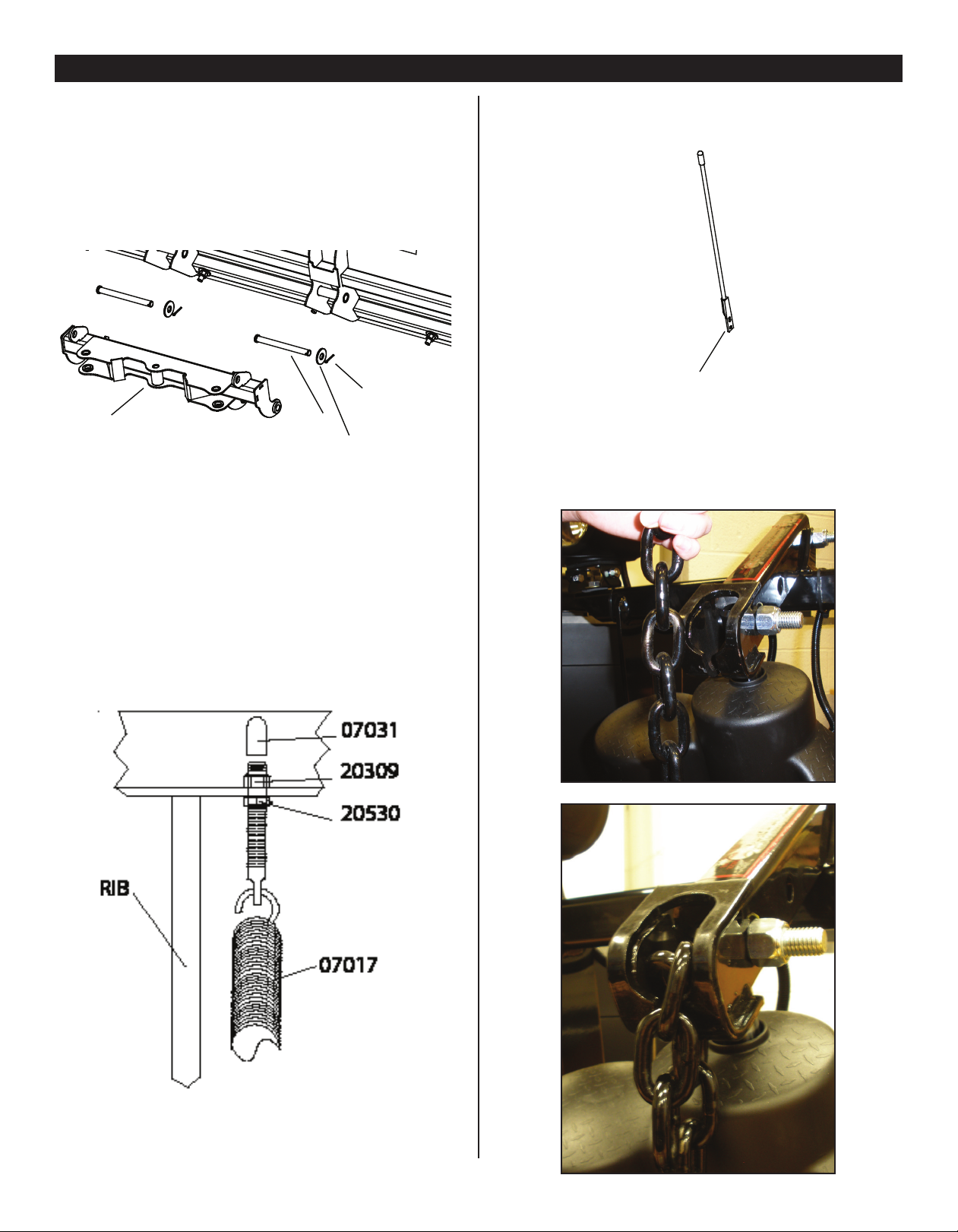

16 20309 20309 6 • Locknut 5/8 - 11

17 20331 20331 2 • Lockwasher 5/8”

18 20357 20357 2 • Flatwasher 5/8”

19 20385 20385 2 • Cotter Pin 1/8 x 1-1/4”

20 22845 22845 1 • Hair Pin

21 20420 20420 2 • Cotter Pin 1/4 x 2”

22 22000 22000 1 • Bolt H 5/8-11 x 4-1/2” Gr. 8

23 22022 22022 1 • Crankstand

24 22436 22436 2 • Pin 1 x 3”

25 23023 23023 1 • Plow Side Harness

26 22719 22719 2 • Pivot Pin 5/8 x 3”

27 22866 22866 1 • SAE Mx3/8 90 Degree Elbow

28 22884 22884 1 • Hose 1/4 x 33”

29 20027 20027 4 • Bolt H 5/16-18 x 1” Gr. 2

30 20049 20049 4 • Bolt H 3/8-16 x 1 Gr. 2

31 20100 20100 2 • Bolt H 1/2-13 x 2-3/4” Gr. 5

32 20305 20305 4 • Locknut 3/8-16

33 20307 20307 2 • Locknut 1/2-13

34 8501003013 8501003013 4 • 5/8-11 Finish Nut

35 20800 20800 1 • Quick Link 5/16”

36 21543 21543 1 • Chain 5/16” x 29”

37 11101 11101 1 • Hinge Pin

38 22083 22083 1 • Lynch Pin

39 20352 20352 4 • Flatwasher 5/16”

40 8500003307001 8500003307001 2 • Bolt H 5/8-11 x 3” Gr. 5

(2)

Parts Diagram