Mezger Z 23 P User manual

Compressed-air Stapling Plier

Z 23 P

Page: 1

Mod.: 01/2022

ET

Seite 1 von 34 31.01.22 P:\Technik\ZANGEN\Z 23 P\Bedienungsanleitung\Englisch\Manual Z 23 P Pneum en_01_2022.docx

Operation Manual

Compressed-air Stapling Plier

Z 23 P

IMPORTANT

Before the first commissioning read this manual thoroughly and completely and keep it in a safe

place.

Observe and follow the safety instructions and only use the machine if you are sure that you

have completely understood all the instructions.

Failure to comply can lead to injuries!

If you have any questions, contact

MEZGER Heftsysteme GmbH

Saganer Straße 24

90475 Nürnberg

Germany

Compressed-air Stapling Plier

Z 23 P

Page: 2

Mod.: 01/2022

ET

Seite 2 von 34 31.01.22 P:\Technik\ZANGEN\Z 23 P\Bedienungsanleitung\Englisch\Manual Z 23 P Pneum en_01_2022.docx

Modell

Type/description:

Preface

For a safe operation of the stapling machine it is necessary to acquire the knowledge conveyed

by these ORIGINAL OPERATING INSTRUCTIONS. The information is presented in brief and clear

form. The chapters are sorted by numbers.

Copyright

The copyright of this operation manual remains with MEZGER Heftsysteme GmbH.

Contents overview

1Safety information......................................................................................................... 4

2Design features.............................................................................................................. 5

2.1 General design features ........................................................................................................... 5

2.2 Features of hazard warnings.................................................................................................... 5

2.3 Features of warnings about damage to property or the environment ................................. 6

2.4 Safety ......................................................................................................................................... 6

2.5 Avoid risk of fatal injuries ......................................................................................................... 6

2.6 Avoid explosion hazards........................................................................................................... 6

2.7 Avoid injury hazards.................................................................................................................. 6

2.8 Avoid damage to the stapling device ....................................................................................... 7

3Intended use, general.................................................................................................... 7

3.1 Intended use.............................................................................................................................. 7

3.2 Use other than as intended...................................................................................................... 8

4Warranty and liability .................................................................................................... 8

5Ambient conditions/Emission ....................................................................................... 8

6Operating Personnel ..................................................................................................... 8

7Initial commissioning..................................................................................................... 9

8Basics of working technique and handling ................................................................... 9

9Shutting down.............................................................................................................. 10

10 Maintenance and care................................................................................................. 10

11 Description................................................................................................................... 12

11.1 Overview of device and scope of delivery ZH 23 P ............................................................... 12

11.2 Functionality ............................................................................................................................ 12

11.3 Product features...................................................................................................................... 13

11.4 Safety equipment .................................................................................................................... 13

11.5 Warning labels on the stapling device ................................................................................... 13

11.6 Information on the rating plate.............................................................................................. 14

12 Preparing the stapling device...................................................................................... 14

See label

Compressed-air Stapling Plier

Z 23 P

Page: 3

Mod.: 01/2022

ET

Seite 3 von 34 31.01.22 P:\Technik\ZANGEN\Z 23 P\Bedienungsanleitung\Englisch\Manual Z 23 P Pneum en_01_2022.docx

12.1 Unpack the stapling device..................................................................................................... 14

12.2 Check condition....................................................................................................................... 15

12.3 Connect stapling device to air supply .................................................................................... 15

13 Stapling device operation............................................................................................ 17

13.1 Open the magazin ................................................................................................................... 17

13.2 Insert staples ........................................................................................................................... 18

13.3 Close magazine ....................................................................................................................... 19

13.4 Adjust vent............................................................................................................................... 20

13.5 Check functionality.................................................................................................................. 20

13.6 Contact triggering.................................................................................................................... 21

13.7 Set drive depth ........................................................................................................................ 21

13.8 Controlling operating pressure .............................................................................................. 21

13.8.1 Set drive depth with bottom retaining clip ................................................................... 21

13.9 Check drive depth ................................................................................................................... 22

13.10 Drive staples........................................................................................................................ 22

13.11 Triggering the stapling device ............................................................................................ 23

13.12 Select carton thickness ....................................................................................................... 23

14 After operation ............................................................................................................ 24

14.1 Disconnect the air supply ....................................................................................................... 24

14.2 Empty the magazine ............................................................................................................... 24

15 Transporting and storing the stapling device ............................................................. 25

15.1 Packing..................................................................................................................................... 25

15.2 Transporting ............................................................................................................................ 25

15.2.1 Transporting over short distances ................................................................................ 25

15.3 Trabsporting over long distances........................................................................................... 26

15.4 Storage..................................................................................................................................... 26

16 Maintaining the stapling device .................................................................................. 26

16.1 Clean the housing and outer surfaces................................................................................... 26

16.1.1 Light soiling ..................................................................................................................... 26

16.1.2 Heavy soiling ................................................................................................................... 27

16.2 Oiling the stapling device........................................................................................................ 27

17 Faults............................................................................................................................ 27

17.1 Removing jammed staples ..................................................................................................... 28

17.2 Other faults.............................................................................................................................. 29

17.3 Fault overview ......................................................................................................................... 29

17.4 staples...................................................................................................................................... 30

18 Disposing of the stapling device ................................................................................. 30

19 Technical data.............................................................................................................. 31

20 Notice of residual risks ................................................................................................ 32

21 Technical documentation............................................................................................ 33

21.1 Spare parts .............................................................................................................................. 33

21.2 Declaration of Conformity ...................................................................................................... 34

Compressed-air Stapling Plier

Z 23 P

Page: 4

Mod.: 01/2022

ET

Seite 4 von 34 31.01.22 P:\Technik\ZANGEN\Z 23 P\Bedienungsanleitung\Englisch\Manual Z 23 P Pneum en_01_2022.docx

1Safety information

Safety instructions and important explanations are labelled with the following pictograms.

The symbols used in the operating instructions have the following meaning:

Symbol

Signal

word

Meaning

Warning

notice

Warning of possible injuries to persons or possible damage to

property

Warning of possible defects or destruction of the machine

Prohibition

Indicates general prohibitions!

Warning

notice

Risk of fingers being crushed!

Prohibition

Protect from moisture!

Warning

notice

Accidental activation when connecting to the compressed air

supply could result in death or serious injury.

Do not point the driving tool at yourself, other people or animals.

Empty the magazine before connecting

Warning

notice

Damaged hose lines can burst and lead to injuries.

Check the compressed air system and the driving tool for

damage before connecting.

Only connect the driving tool to a functioning compressed air

system.

Warning

notice

Risk of injury from electric shock.

Before triggering, make sure no power line is hit.

Warning

notice

During operation, damage to the eyes or other injuries from flying

splinters is possible.

Wear protective goggles and suitable protective clothing during

operation.

Observe the applicable occupational health and safety regulations.

Compressed-air Stapling Plier

Z 23 P

Page: 5

Mod.: 01/2022

ET

Seite 5 von 34 31.01.22 P:\Technik\ZANGEN\Z 23 P\Bedienungsanleitung\Englisch\Manual Z 23 P Pneum en_01_2022.docx

Read all these instructions before using the stapling device and keep the safety instructions in a

safe place.

The operating personnel must be trained in the handling of the stapling device and they must

have fully read and understood the operating instruction.

To avoid injury or damage, the operator must additionally observe the company's internal safety

guidelines!

In addition, we would like to refer to further national rules and safety provisions which are not

contained in this manual.

Keep persons who are not instructed away from your work area!

If damage to the device is determined by the operator during production, the device may no

longer be used and must be repaired by a professional!

The required personal protective equipment must be provided by the operator.

Only original parts may be used as spare parts!

2Design features

2.1 General design features

Certain elements of the instructions for use have defined design features. This lets you easily see whether

a passage is

•normal text,

•a list of items, or

•an action to be taken.

Tips provide additional information, such as special details about how to use the stapling

device cost-effectively.

2.2 Features of hazard warnings

All hazard warnings in these instructions for use follow the same pattern. To the left is a symbol

that indicates the type of hazard. To the right is a signal word that designates the severity of the

hazard. Below this is a description of the source of the hazard and instructions on how to avoid

the hazard.

Compressed-air Stapling Plier

Z 23 P

Page: 6

Mod.: 01/2022

ET

Seite 6 von 34 31.01.22 P:\Technik\ZANGEN\Z 23 P\Bedienungsanleitung\Englisch\Manual Z 23 P Pneum en_01_2022.docx

DANGER

Notes with the word DANGER warn of hazards that lead directly to severe or

fatal injuries.

WARNING

Notes with the word WARNING warn of hazards that can potentially cause

severe or fatal injuries.

CAUTION

Notes with the word CAUTION warn of hazards that can potentially cause

minor to moderate injuries.

2.3 Features of warnings about damage to property or the environment

ATTENTION

These notes warn of hazards that can lead to damage to property or the environment.

2.4 Safety

When using the stapling device, note and adhere to all warnings and instructions in these

instructions for use and on the stapling device itself. The enclosed spare parts list is part of these

instructions for use.

2.5 Avoid risk of fatal injuries

Make sure that no part of the body is between the discharge opening and the anvil, and at any

time the stapling device is connected to the air supply.

Actuate the stapling device only when the tip of the tool is pressed against the workpiece.

Make sure that the staples is not driven into a power line.

2.6 Avoid explosion hazards

Do not use the stapling device in explosion hazard areas.

Never operate the stapling device with oxygen or other flammable gases or gas mixtures.

2.7 Avoid injury hazards

Keep the stapling device out of the reach of unauthorized persons.

Disconnect the stapling device from the air supply before transport.

Wear safety glasses, hearing protection, and sturdy work clothing when operating the stapling

device.

Hold the stapling device so that you cannot be injured by any possible recoil.

Only use the stapling device when you are able to stand securely.

Compressed-air Stapling Plier

Z 23 P

Page: 7

Mod.: 01/2022

ET

Seite 7 von 34 31.01.22 P:\Technik\ZANGEN\Z 23 P\Bedienungsanleitung\Englisch\Manual Z 23 P Pneum en_01_2022.docx

2.8 Avoid damage to the stapling device

Never open the stapling device. Leave repair work to qualified technical personnel.

Do not use the stapling device if it has been dropped or damaged. Have it checked by qualified

technical personnel before resuming use.

Do not connect the stapling device to an air supply that exceeds the maximum operating

pressure of

8 bar.

Install fixed stapling devices only in securely anchored mounting devices. The stapling device

must not be able to rotate or shift. The mounting device must not damage the stapling device

or its accessories.

3Intended use, general

The stapler may only be used for its intended purpose. It must be used, operated, and

maintained in accordance with the information in these operating instructions.

Only the materials and staples defined for the respective stapler are to be used, as

otherwise malfunctions and damage to the stapler may occur. The stapler may only be

used for the purpose specified in these operating instructions. Other applications are only

permitted with the prior consent and written approval of the manufacturer.

Any other use is not intended and can lead to personal injury or property damage. In the event

of improper use, the operator alone is liable for any resulting damage.

The operator must ensure that the stapler is only operated as intended and that all kinds of

dangers to the life and health of the user or third parties are avoided. In addition, compliance

with the accident prevention regulations and other safety rules and laws must be observed.

Other usage can cause damage to tool and person.

This is in the responsibility of the operator.

3.1 Intended use

Stapling devices are used to drive staples into paper and carton materials. Using the stapling

device with other materials is permissible only after consulting with the manufacturer. The

intended use also includes compliance with accident prevention rules and the regulations and

standards in force at the place of use. Any other use is not as intended and can lead to property

damage or even to personal injury.

Compressed-air Stapling Plier

Z 23 P

Page: 8

Mod.: 01/2022

ET

Seite 8 von 34 31.01.22 P:\Technik\ZANGEN\Z 23 P\Bedienungsanleitung\Englisch\Manual Z 23 P Pneum en_01_2022.docx

3.2 Use other than as intended

Uses particularly contrary to the intended use include:

Use by persons unfamiliar with the use of stapling devices and the materials in use.

Use with safety devices bypassed.

Use of stapling devices that have been modified without permission.

Use of any accessories not indicated in these instructions for use.

Use of compressed air sources not listed in these instructions for use.

MEZGER Heftsysteme GmbH GmbH does not accept any liability for damage caused by use other

than as intended.

4Warranty and liability

Our “General Terms of Sale and Delivery” shall generally apply.

These terms were made available to the operator by the time of contract award at the latest.

Any warranty and liability claim in the case of personal and material damage shall be

excluded, if such damage occurred as a result of:

-Improper use of the tool (not in compliance with intended use).

-Non-compliance with the specification provided in the operating instructions as regards

transport, storage, assembly, commissioning, operation, maintenance and setup of the

equipment.

-Operation of the tool with defective safety equipment or improperly installed or non-

functional safety and protection facilities.

-Improper monitoring of tool parts which are subject to wear and improperly executed

repair work.

-Any type of manipulation of the tool.

5Ambient conditions/Emission

The device should be operated at room temperature, protected against environmental

influences.

Use within an explosive atmosphere is permitted only with prior consent and written permission

of the manufacturer.

The noise emission is less than 70 dB(A).

Non-atmospheric gases are not released during the stapling process.

6Operating Personnel

Only trained, competent personnel are permitted to operate the stapler.

Note: Anyone who has sufficient knowledge in the field of staplers due to their training and

experience and is familiar enough with the relevant state occupational safety regulations,

accident prevention regulations, guidelines and generally recognized rules of technology (e.g.

Compressed-air Stapling Plier

Z 23 P

Page: 9

Mod.: 01/2022

ET

Seite 9 von 34 31.01.22 P:\Technik\ZANGEN\Z 23 P\Bedienungsanleitung\Englisch\Manual Z 23 P Pneum en_01_2022.docx

DIN standards, VDE regulations) is competent can assess the safe condition of machines,

especially stapling machines.

7Initial commissioning

Before the stapling device is put into operation, please read all instructions in this manual. This

stapling machine may only be put into operation by trained personnel.

To make the stapling device ready for operation after delivery, the following tasks must be

carried out:

- Check the equipment for completeness

- Load the tool with staples

- Connect the compressed air

The air pressure is 5 - 8 bar overpressure.

It is necessary to connect a filter regulator consisting of a filter, water separator and pressure

reducer upstream.

A hose with a clear width of 8 mm is required as the connection hose.

When the stapling machine is ready for operation, it is prohibited to touch the

stapling ejection opening or the running stapler! DANGER OF INJURY!

Oxygen or combustible gases may not be used as a propulsion source for

pressure driven machines.

8Basics of working technique and handling

Before the operator uses the stapler, he must find out about the respective application and

check whether the stapler is suitable for it. Follow all safety instructions exactly!

Make sure that the stapler is not damaged and that it can be operated safely!

The operationally safe condition of the stapler must be checked continuously before starting

work!

Safety devices must not be bypassed or made ineffective!

Keep your work area tidy.

Clutter in the work area can lead to accidents.

Use only ORIGINAL staples that are specially manufactured for this quality device. Foreign

staples can lead to malfunctions and considerable damage.

Compressed-air Stapling Plier

Z 23 P

Page: 10

Mod.: 01/2022

ET

Seite 10 von 34 31.01.22 P:\Technik\ZANGEN\Z 23 P\Bedienungsanleitung\Englisch\Manual Z 23 P Pneum en_01_2022.docx

Never staple without stapling material. Do not remove the stapler until the stapling process is

complete.

Do not staple in hard or brittle materials or on a hard surface

If a stapling fault occurs, clear it immediately and do not initiate any

further stapling

Turn off the stapler after use

If possible, the stapler should be hung above the packing station.

The following accessories are available:

B 2/4 balancer (weight equalizer) with rotatable load hook

DS DS 75 spiral hose with an extended length of 7.5 m

Filter regulator

W / UNIT maintenance unit

consisting of pressure reducer, water separator, oil nebuliser

9Shutting down

In case the tool will not be handled for some time, please disconnect the air pressure and

remove all staples.

10 Maintenance and care

ATTENTION! Before every maintenance, the compressed air supply must be

removed.

Only original spare parts from the manufacturer are to be used

(see appendix "Spare parts list").

Any kind of alteration to the device (e.g. drilling of holes) is only permitted

with prior consent and written permission of the manufacturer.

Manipulation of the safety device(s) is prohibited.

Compressed-air Stapling Plier

Z 23 P

Page: 11

Mod.: 01/2022

ET

Seite 11 von 34 31.01.22 P:\Technik\ZANGEN\Z 23 P\Bedienungsanleitung\Englisch\Manual Z 23 P Pneum en_01_2022.docx

In order to maintain the operational readiness and function of the stapler, it must be regularly

checked, serviced and cleaned by the operator or/and by qualified personnel.

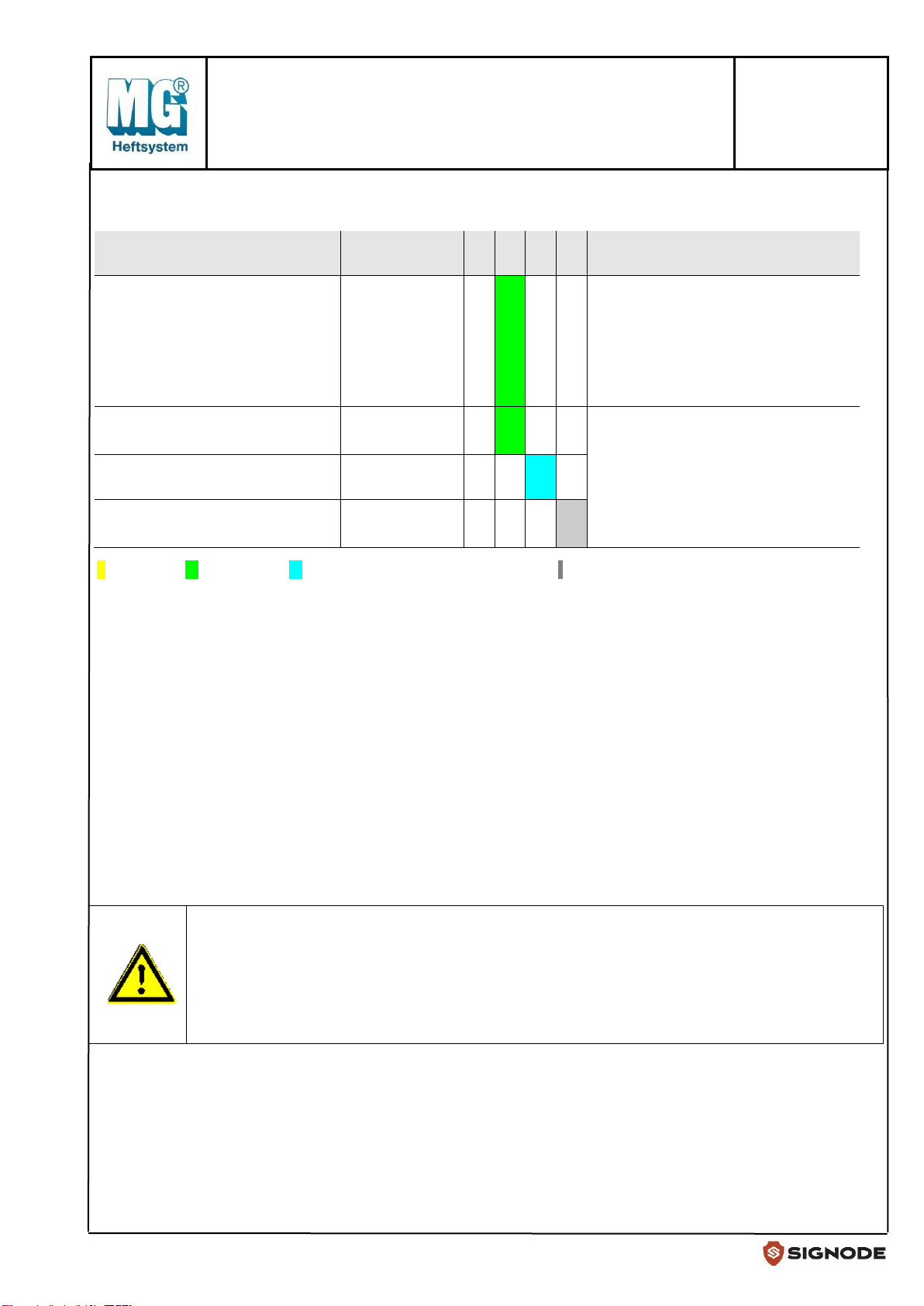

Test area

Activity /

examination

T

W

M

J

Area

Stapling device

Clean/check

prüfen

⚫

Stapling area

Stapling device

Clean and

lightly oil

⚫

Stapling area

Clean/check

⚫

Pneumatic hoses, tightness,

Damage

check

⚫

Pneumatic

Check screw connections for tight

fit

check

⚫

Filter regulator

clean /

drain

⚫

T= daily / W = weekly / M = monthly (6M = alle 6 Monate) / yJ = yearly

•All friction points/movable parts should be lightly oiled from time to time.

•Do not use aggressive cleaning agents or solvents (damage seals) or abrasive media used for

cleaning.

•Cleaning with compressed air is also to be avoided as there are dirt particles get into the

sealing areas and damage them.

•Do not use foot wash for cleaning.

•Soiling must be removed directly from the operator after machining operations.

The following work / inspections should be carried out regularly by qualified personnel:

•Regularly oil the moving parts (no graphite oil!) (Weekly)

•Check the filter regulator for condensation. The condensation water may have to be

removed.

Only ORIGINAL spare parts may be used. (see “spare parts list”)

In case no ORIGINAL spare parts are used each warranty claim, or any liability

is excluded!

All technical equipment, especially the safety equipment, must be checked

regularly by specialists, especially after repairs.

Compressed-air Stapling Plier

Z 23 P

Page: 12

Mod.: 01/2022

ET

Seite 12 von 34 31.01.22 P:\Technik\ZANGEN\Z 23 P\Bedienungsanleitung\Englisch\Manual Z 23 P Pneum en_01_2022.docx

11 Description

11.1 Overview of device and scope of delivery ZH 23 P

11.2 Functionality

The stapling device drives and bends staples one at a time into carton materials using

compressed air. Excess pressure is vented through pressure relief valves.

You can adjust the stapling device to the carton thickness being processed.

No.

Description

1

Trigger

2

Retaining ring (locking pin)

3

Clip

4

Spacer

5

anvil

6

Discharge opening

7

Locking pin

8

Clamp lever

9

Holes

10

Label for carton thickness

Compressed-air Stapling Plier

Z 23 P

Page: 13

Mod.: 01/2022

ET

Seite 13 von 34 31.01.22 P:\Technik\ZANGEN\Z 23 P\Bedienungsanleitung\Englisch\Manual Z 23 P Pneum en_01_2022.docx

11.3 Product features

The stapling device has the following features:

Trigger safety

Contact trigger

Magazine with top-loader system

Adjustable air discharge 360°

Adjustable drive depth with bottom retaining clip

11.4 Safety equipment

Trigger safety

The stapling device is equipped with a trigger safety at the discharge opening. The trigger is

enabled only when the trigger safety is pressed.

WARNING

Severe injury if the stapling device is operated with a defective or bypassed

trigger safety.

Use the stapling device only with a functioning trigger safety.

Actuate the stapling device only when the tip of the tool is pressed firmly

against the workpiece.

Warning labels on the stapling device

For the trigger setting, “Trigger repeat,” the following types of use are not permissible:

Work that requires moving across scaffolding, stairs, ladders, or ladder-like structures.

Use to close crates or boxes or to attach transport locks.

The appropriate warning symbol (see below) is applied to the front side of the

stapling device.

Rating plate

Triangle pointing downward (This triangle indicates that you are only permitted

to use the device if the trigger safety is functional)

11.5 Warning labels on the stapling device

Rating plate

Triangle pointing downward (This triangle indicates that you are only permitted to use the

device if the trigger safety is functional.)

Compressed-air Stapling Plier

Z 23 P

Page: 14

Mod.: 01/2022

ET

Seite 14 von 34 31.01.22 P:\Technik\ZANGEN\Z 23 P\Bedienungsanleitung\Englisch\Manual Z 23 P Pneum en_01_2022.docx

11.6 Information on the rating plate

The rating plate is applied to the magazine. It contains the following information:

Company name and full address of the manufacturer

Type designation of the stapling device

Type designation of compatible mounting devices

Maximum permissible operating pressure

CE mark (The product complies with the standards listed in the enclosed Declaration of

Conformity.)

GS mark (The product has passed a safety inspection according to the Equipment and Product

Safety Act.)

Triangle pointing downward (This triangle indicates that you are only permitted to use the

device if the trigger safety is functional.)

Year built

12 Preparing the stapling device

12.1 Unpack the stapling device

Remove the stapling device from the packaging.

Remove all packaging material, such as film, filler material, and the packaging carton.

WARNING

Suffocation hazard playing with packaging film.

Do not play with packaging film.

Keep the packaging material for later use.

Keep the transport case for transporting the stapling device.

Transporting the stapling device is only allowed in the transport case.

Compressed-air Stapling Plier

Z 23 P

Page: 15

Mod.: 01/2022

ET

Seite 15 von 34 31.01.22 P:\Technik\ZANGEN\Z 23 P\Bedienungsanleitung\Englisch\Manual Z 23 P Pneum en_01_2022.docx

12.2 Check condition

WARNING

Risk of injury when operating a damaged stapling device or if accessories are

not attached correctly.

Check the condition of the stapling device before each use.

Make sure the stapling device is not damaged.

Check the following points in particular:

•All parts of the stapling device and all accessories must be attached securely.

•The safety equipment must not be blocked or otherwise hindered in function.

•The spring on the trigger safety must not be damaged.

•No part of the stapling device or accessories may show external damage such as scratches

or dents.

•The hose must be undamaged.

Scratches on the paint of the housing or the magazine are not damage.

Do not connect a damaged stapling device to an air supply.

If the stapling device is damaged, have it repaired by technical personnel before resuming

use.

12.3 Connect stapling device to air supply

You can connect the stapling device to a compressor or a compressed air system.

Operation with a compressor or a compressed air system is permissible only under the following

conditions

The operating pressure of the compressor or the compressed air system must not be more

than 10% greater than the maximum operating pressure of the stapling device. Information

on the operating pressure of stapling devices can be found on page 23 in this section.

For compressed air systems with higher pressure, a pressure regulating valve (pressure

reducer) with a pressure relief valve connected downstream must be installed in the

compressed air line.

The compressed air must be filtered, dry, and oiled with special oil.

A compressed air preparation unit must be installed on the coupling side at the outlets for the

compressed air line to the stapling device. It must include

•a filter

•a water separator

•an oiler

Compressed-air Stapling Plier

Z 23 P

Page: 16

Mod.: 01/2022

ET

Seite 16 von 34 31.01.22 P:\Technik\ZANGEN\Z 23 P\Bedienungsanleitung\Englisch\Manual Z 23 P Pneum en_01_2022.docx

If no oiler is installed, the length of the air line to the stapling device must not exceed 10 m.

Otherwise, you must add three to five drops of special oil directly into the air inlet of the

stapling device every day prior to starting operation.

The compressed air system must be able to maintain operating pressure even when the

desired amount of air is being used.

The inner diameter of the air line must be at least 8 mm.

The connector for the stapling device must be equipped with a quick-connect coupling with

nominal diameter of 7.2 and at least 6.5 mm inner diameter.

CAUTION

Operation with compressed air systems that do not meet the above conditions

can cause damage to the stapling device.

Operate the stapling device only with a suitable compressed air system.

Use the stapling device only if it is flawless condition.

Check the condition of the stapling device.

Remove the plug from the connector for the air hose.

Check the connector for the air hose for foreign objects and dirt and clean it if needed.

Set the operating pressure at the pressure regulator on the compressor to 5–8 bar.

WARNING

Accidentally triggering when connecting to the compressed air supply can cause

severe or fatal injury.

Do not point the stapling device at people or animals.

Empty the magazine before connecting.

CAUTION

Damaged air lines can burst and cause injury.

Check the compressed air system and the stapling device for damage before connecting.

Connect the stapling device only to a functioning compressed air system.

ATTENTION

Damaged hoses can burst and cause property damage due to escaping compressed air.

Check the compressed air system and the stapling device for damage before connecting.

Connect the stapling device only to a functioning compressed air system.

Set the operating pressure at the pressure regulator on the compressor to a maximum of 8 bar.

Check the connector for the pressure hose and the quick-connect on the pressure hose for

foreign objects and dirt and clean them if needed.

Compressed-air Stapling Plier

Z 23 P

Page: 17

Mod.: 01/2022

ET

Seite 17 von 34 31.01.22 P:\Technik\ZANGEN\Z 23 P\Bedienungsanleitung\Englisch\Manual Z 23 P Pneum en_01_2022.docx

Slide the quick-connect lock (1) on the compressed air hose onto the connector (2) until it

audibly engages.

Check the operating pressure at the pressure gage on the compressor.

The maximum permissible operating pressure is 8 bar.

WARNING

Risk of explosion if maximum operating pressure is exceeded.

In this case, disconnect the air hose from the stapling device immediately.

13 Stapling device operation

13.1 Open the magazin

To open the magazine, slide the

slider (1) back in the direction of the

arrow until it engages with the

locking pin (4).

Compressed-air Stapling Plier

Z 23 P

Page: 18

Mod.: 01/2022

ET

Seite 18 von 34 31.01.22 P:\Technik\ZANGEN\Z 23 P\Bedienungsanleitung\Englisch\Manual Z 23 P Pneum en_01_2022.docx

13.2 Insert staples

WARNING

Accidentally triggering when loading the magazine can cause severe or fatal

injury.

Do not point the stapling device at yourself, people or animals.

CAUTION

Incorrect staples can cause injury, interfere with proper functionality of the

stapling device, or damage the stapling device.

Hold the magazine cover (3) against the magazine holder to load a stack of staples into the

magazine (2) with the points facing downward.

Slide the staples as far as possible in the direction of the arrow toward the front of the intake.

Compressed-air Stapling Plier

Z 23 P

Page: 19

Mod.: 01/2022

ET

Seite 19 von 34 31.01.22 P:\Technik\ZANGEN\Z 23 P\Bedienungsanleitung\Englisch\Manual Z 23 P Pneum en_01_2022.docx

13.3 Close magazine

To close the magazine, release the lock (4) and slide the slider (1) in the direction of the arrow

against the staples (5).

Compressed-air Stapling Plier

Z 23 P

Page: 20

Mod.: 01/2022

ET

Seite 20 von 34 31.01.22 P:\Technik\ZANGEN\Z 23 P\Bedienungsanleitung\Englisch\Manual Z 23 P Pneum en_01_2022.docx

13.4 Adjust vent

To adjust the exhaust vent, turn the adjuster (1) in the desired direction.

Turn the exhaust vent so that the exhaust air does not hit you or other persons.

13.5 Check functionality

To ensure trouble-free functionality of the stapling device, proceed as follows:

ATTENTION

Observe the Hazard Warnings in the “Safety” section,

Position a carton at least 16 mm thick in the opening between the anvil and discharge

opening.

Trigger the stapling device.

Check the following properties:

- Triggering occurs only when the trigger safety is pressed.

- One staples must be driven into the carton material for each pull of the trigger.

- Exhaust air must not blow towards the face.

To obtain the desired bending profile if needed, change the operating pressure, the bottom

retaining clip, or the carton thickness setting (see page Fehler! Textmarke nicht definiert.).

Repeat these steps as needed.

The stapling device is now ready for operation.

Table of contents