ME1-1768 Duval Band Yagi

hist

-

niet

-

ion Manna'

MFJ-1768

Instruction Manual

1NTRODECTION

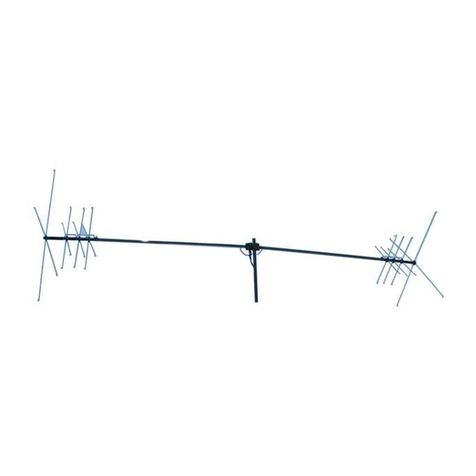

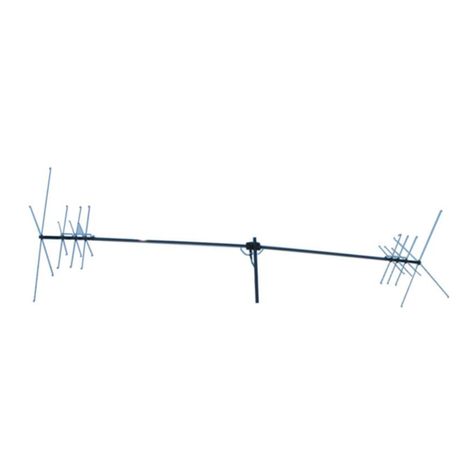

The MO-1768 is a National Bureau of Standards (NBS) style yagi that provides optimum gain and

front to back ratio on both the 2 meter and the 70 centimeter bands. On the 2 meter band the MFJ-1768

is a 4 element antenna, on the 70 centimeter band the MR1-1768 is a 7 element antenna. It is constructed

using lightweight and strong 6061-T6 aluminum material for both the elements and the boom. The MFJ

1768 elements are insulated from the boom to eliminate the problem of poor electrical contact to the

boom. This antenna uses a dual balante driven element that provides a clean pattern with minimal

skewing. The antenna's 1/4" diameter driven elements provide wille bandwidth that covers both bands

with a low SWR. This antenna uses a single feedline with a ferrite decoupled current balup for both

hands. This technique eliminates the need for extra coax tables, and stops all the parallel RF current. on

the coax shield. This prevents unwanted radiation.

The MH-1768 is an excellent antenna for use with dual band transceivers. Since the MD-1768 is a dual

band antenna there is no need to switch antennas when changing bands. With the use of a duplexer

(such as the MD-016) you can connect two different radios (two different bands) to the ML1-1768 at

the same time.

CHOOSING A 1,OCA1 ION FOR THE ANTENNA

The NIFJ-1768can be mounted on any 1" to 1 1/2" mast

(conduclive or non-conduclive)

capable of

supporting the weiglit of the antenna and the torque developed by the boom. The MFT-1768 can he

mounted vertically (generally used for FM transmission), or horizontally (commonly used for SSB

transmission).

The best performance on receiving and transmitting will be obtained by mounting the antenna as high as

possible in a clear location above or away from buildings, feed biles, utility wires, and other antennas.

Your ingenttity and particular circumstances will determine the final mounting method.

The MD-1768 is a directional antenna with a major high gain forward lobe and fewer lover gain side

and back lobes. The operating frequency of this antenna is used only in line of site communication. For

that reason it is best to molmt the MD-1768 on a rotor and be able to orient its major lobe toward the

desired location and obtain maximum performance. Also since the side and the back lobe exist but with

low gain, it is possible to use these lobcs for local area communication without rotating the antenna