MFJ-1762 Instruction Manual

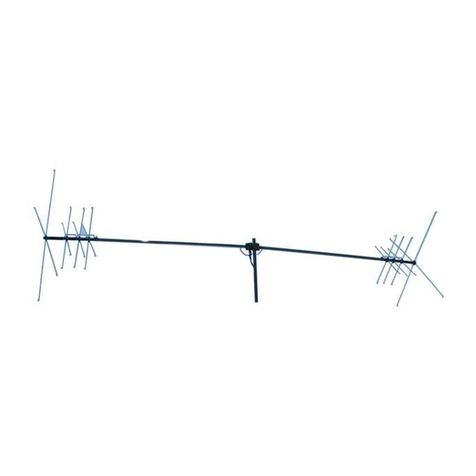

Introduction: Thank you for purchasing the MFJ-1762 three-element six-meter Yagi.

The MFJ-1762 is a light-weight directional antenna especially designed for installation

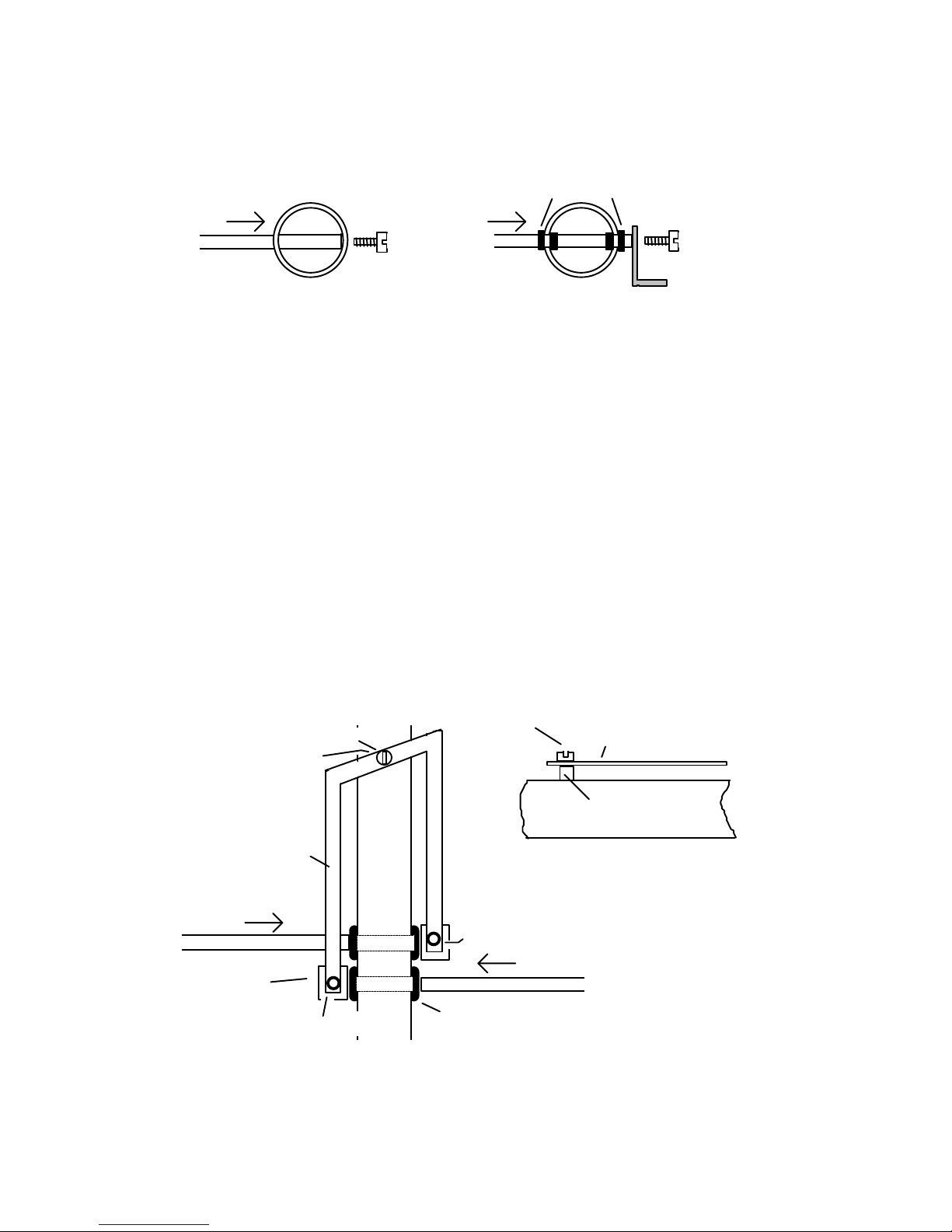

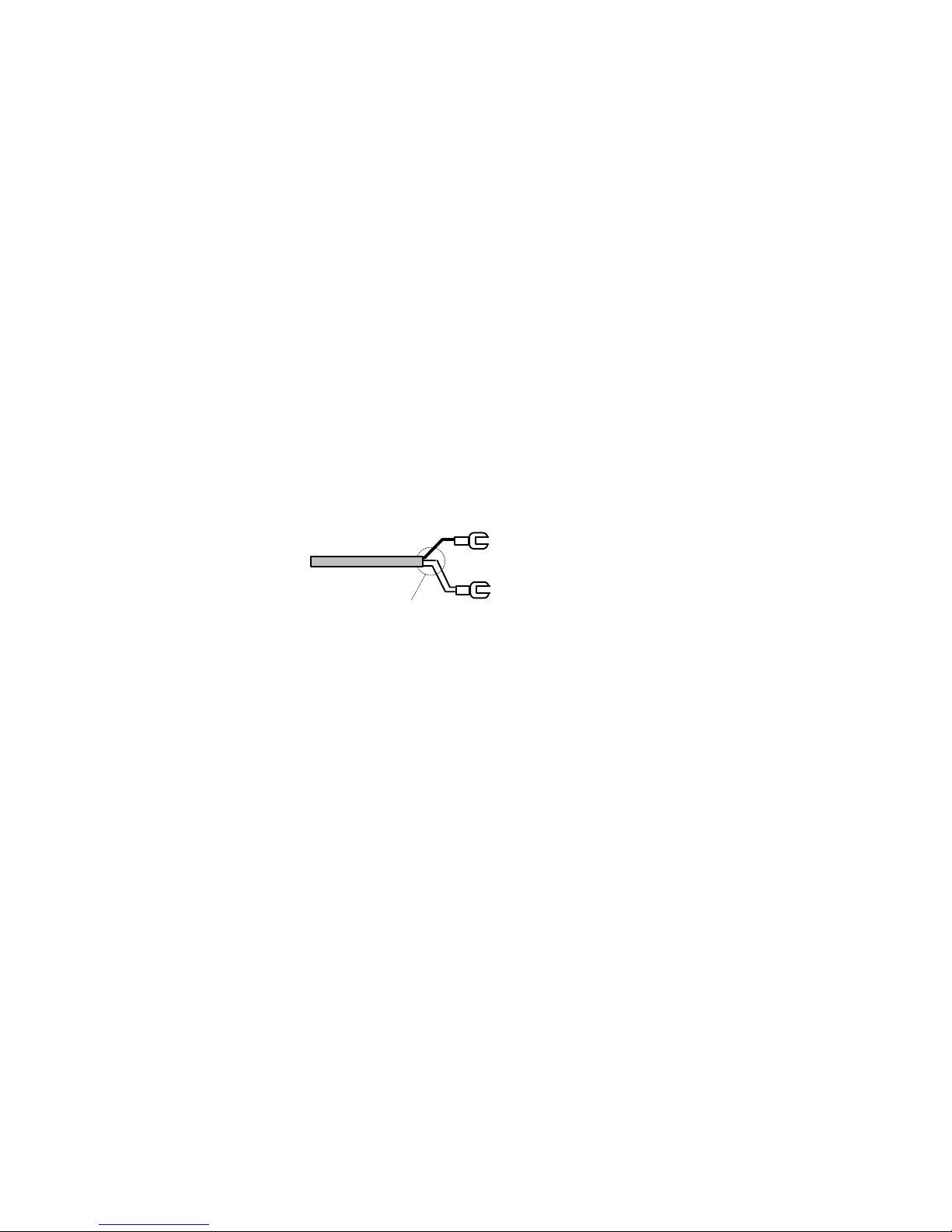

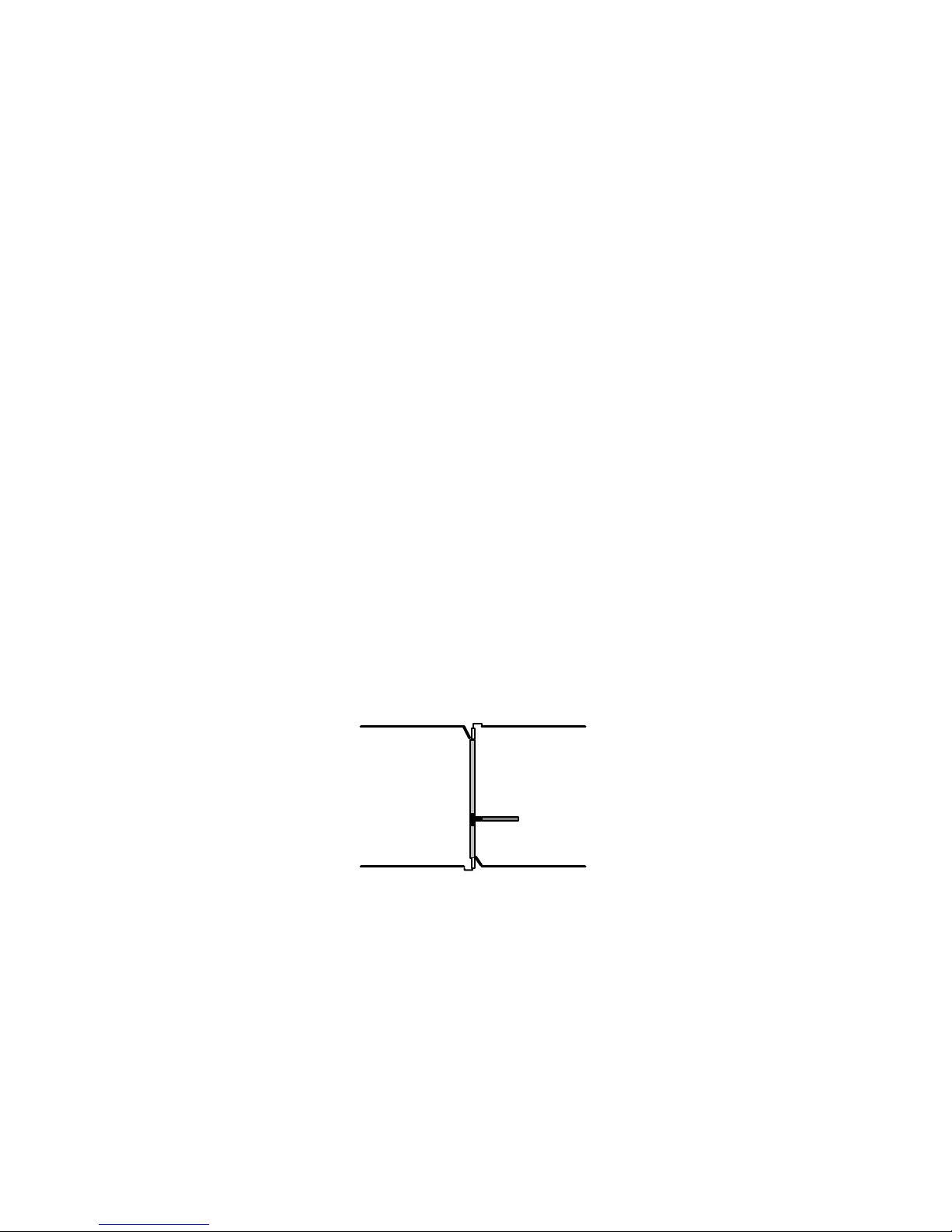

with readily-available TV-type masts, mounts, and hardware. The driven element employs

a "no-tune" hairpin impedance matching system, and all elements are cut to exact length at

the factory. No adjustment should be needed for coverage of the 50-MHz SSB band (see

page 8 for FM-segment tuning instructions). Because of its compact size, light weight,

and unique construction, the MFJ-1762 is also a excellent choice for six-meter portable or

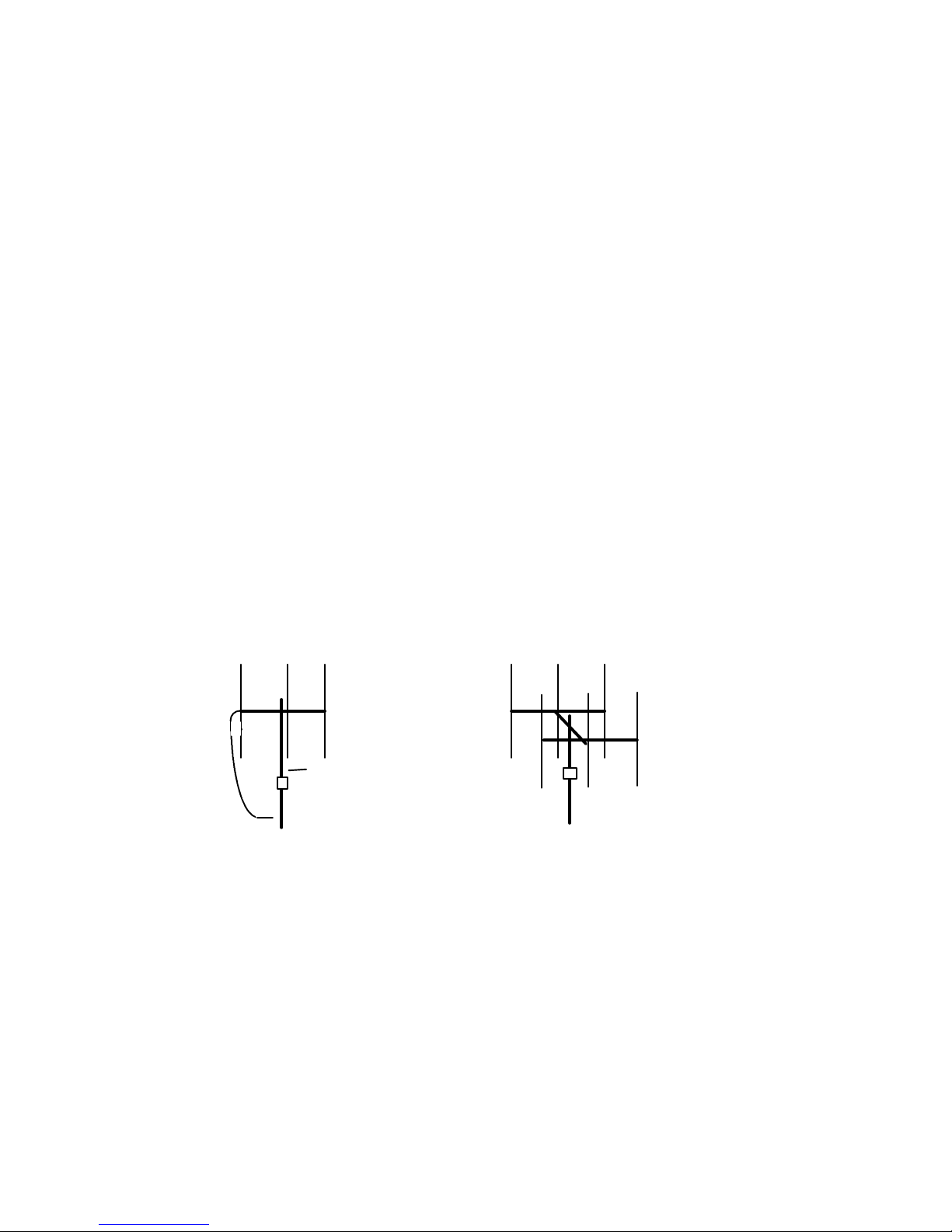

"rover" operation. In weak-signal DX applications, two MFJ-1762s may be stacked for

increased capture area and 3-dB additional gain. The MFJ-1762 has been computer

modeled on both ELNECand YAto confirm design integrity, and has been thoroughly

field tested in northern climates for winter survivability.

Typical Specifications:

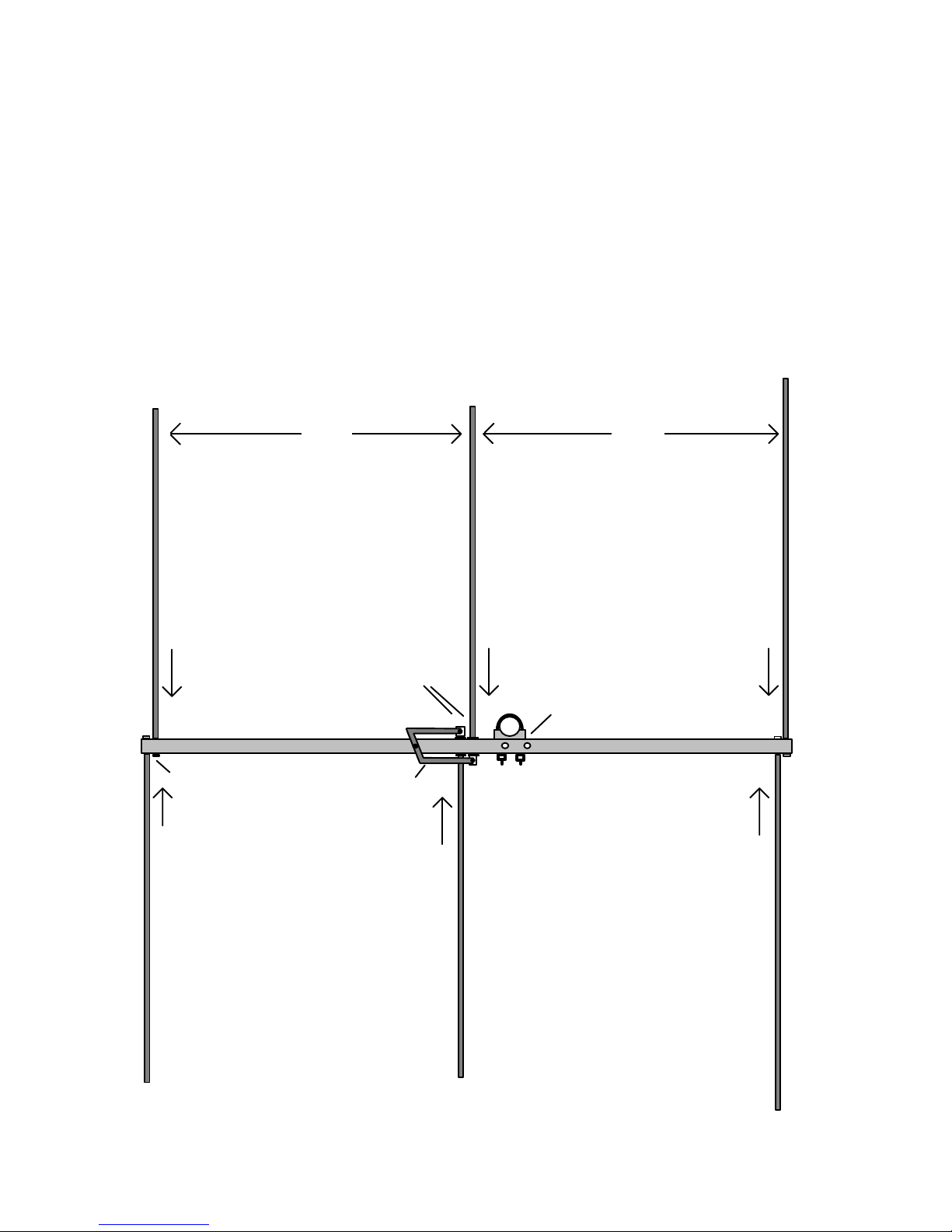

Boom length......................6'

Turning Radius..................5' 8"

Longest Element...............117-1/2"

Weight..............................2.5 Lbs.

Feed Impedance...............50Ω

Resonant Frequency..........50.3 MHz

1.5:1 VSWR Bandwidth...1.7 MHz

Forward Gain....................6.0 dBd (8.2 dBi)

Front-to-Rear Ratio........>18 dB measured

Maximum Power...............150 Watts

Safety Precautions: Before assembling, please read the following safety notice:

This antenna is an electrical conductor--do not handle or mount near power lines, service

entrances, or other dangerous power sources. Mount out of the reach of adults, children,

and animals. Antenna elements develop lethal voltages and may cause severe RF burns

during transmitter operation. For lightning protection, always ground your supporting

mast to two or more outdoor ground rods. Disconnect the feedline from your radio when

not in use. Do not expose pacemakers or other bio-medical equipment to strong RF

radiation. To avoid personal injury or damage to the antenna, plan all mechanical aspects

of your installation carefully. Avoid handling heavy or unwieldy masts by yourself, and

make sure a second person is available to assist you in an emergency. Never work on a

roof or climb a tower alone!