MFZ Ovitor FS 345 User manual

Operating Instructions for FS 345 with FS 101 and CS 300 FS GB

FS 345 Door Controls / Rev.A 0.0 – 1

2 – FS 345 Door Controls / Rev. A 0.0

1. Contents

1. Contents 2

2. Information in this document 2

3. General safety instructions 3

4. Overview of products 4

5. Commissioning 5

6. Limit switches 16

7. Programming with the LCD monitor 18

8. Navigator (LCD monitor only) 20

9. Overview of functions 22

10. Rechargeable battery and battery charger 30

11. Motor brake and auxiliary motor 34

12. Technical data 36

13. Maintenance 36

14. EC Declaration of Incorporation 37

Original operating instructions

− Protectedbycopyright.

− Nopartoftheseinstructionsmaybereproducedwithout

our prior approval.

− Subjecttoalterationsintheinterestoftechnicalprogress.

− Alldimensionsaregiveninmillimetres.

− Theillustrationsarenottruetoscale.

Meaning of symbols

DANGER!

Safetynoticeindicatingadangerthatwilldirectlyresultin

deathorsevereinjury.

WARNING!

Safetynoticeindicatingadangerthatcouldresultindeath

orsevereinjury.

CAUTION!

Safetynoticeindicatingadangerthatcanresultinslightor

moderateinjuries.

NOTICE

Safetynoticeindicatingadangerthatcanresultindamage

to property or in irreparable damage to the product.

CHECK

Reference to a check that needs to be carried out.

REFERENCE

Reference to separate documents that must be observed.

Instruction requiring action

− List,itemisation

Reference to other sections of this document

2. Information in this document

GB

FS 345 Door Controls / Rev.A 0.0 – 3

3. General safety instructions

DANGER!

Failure to comply with the documentation could

result in life-threatening danger!

Be sure to follow all the safety instructions in this docu-

ment.

Warranty

The function and safety of the equipment is only guaranteed if

the warning and safety instructions included in these operat-

ing instructions are adhered to.

MFZAntriebeGmbH+Co.KGisnotliableforpersonalinjury

or damage to property if these occur as a result of the warn-

ings and safety advice being disregarded.

MFZ does not accept any liability or warranty for damage due

to the use of non-approved spare parts and accessories.

Intended use

TheFS345controlisintendedexclusivelyforcontrollingdoor

systems with mechanical limit switches.

Target group

Onlyqualiedandtrainedelectriciansmayconnect,pro-

gramme and service the control.

Qualiedandtrainedelectriciansmustmeetthefollowing

requirements:

− Knowledgeofthegeneralandspecicsafetyandaccident

preventionregulations,

− Knowledgeoftherelevantelectricalregulations,

− Trainingintheuseandcareofappropriatesafetyequip-

ment,

− Capableofrecognisingthedangersassociatedwithelec-

tricity.

Instructions regarding installation and connection

− ThecontrolisdesignedwithXtypeterminals.

− Thecontrolmustbedisconnectedfromtheelectricity

supply before carrying out any electrical work. It must be

ensured that the electricity supply remains disconnected for

the duration of the work.

− Localprotectiveregulationsmustbecompliedwith.

Information concerning operation

− Unauthorisedpersons(particularlychildren)shouldnotbe

allowedtoplaywithpermanentlyinstalledadjustingor

control devices.

− Keepremotecontrolbeyondthereachofchildren.

Regulations and bases for testing

Forconnecting,programmingandservicing,thefollowing

regulations must be observed (the list is not exhaustive).

Construction product standards

− EN13241-1(Productswithoutreresistanceorsmoke

control characteristics)

− EN12445(Safetyinuseofpoweroperateddoors-Test

methods)

− EN12453(Safetyinuseofpoweroperateddoors-Re-

quirements)

− EN12978(Safetydevicesforpoweroperateddoorsand

gates - Requirements and test methods)

EMC

− EN55014-1(Electromagneticcompatibility-Requirements

for household appliances)

− EN61000-3-2(Disturbancesinsupplysystems-harmonic

currents)

− EN61000-3-3(Disturbancesinsupplysystems-voltage

uctuations)

− DINEN61000-6-2(Electromagneticcompatibility(EMC)

- Part 6-2: Generic standards – Immunity for industrial

environments)

− DINEN61000-6-3(Electromagneticcompatibility(EMC)

- Part 6-3: Generic standards – Emission standard for

residential,commercialandlight-industrialenvironments)

Machinery Directive

− EN60204-1(Safetyofmachinery,electricalequipmentof

machines Part 1: General requirements)

− ENISO12100(Safetyofmachinery–generalprinciplesfor

design - risk assessment and risk reduction)

4 – FS 345 Door Controls / Rev. A 0.0

Low voltage

− DINEN60335-1(Householdandsimilarelectricalappli-

ances-Safety-Part1:Part1:Generalrequirements)

− DINEN60335-2-103(Householdandsimilarelectrical

appliances-Safety-Part2-103:Particularrequirementsfor

drivesforgates,doorsandwindows)

CommitteeforWorkplaces(ASTA)

− ASRA1.7(Workplaceregulation“Doorsandgates“)

General safety instructions

− Toenablefault-freeoperationtobeguaranteed,itis

imperative that the rechargeable battery be replaced after

every two years of operation. If this maintenance instruc-

tionisdisregarded,thefunctionalsafetyofthesystemand

thus also the safety of buildings and persons cannot be

guaranteed.

− Toensurethatthesystemalwaysfunctionsconsistently,the

realarmfunctionmustbecheckedonceeveryfourweeks.

In order to check at the same time that the rechargeable

batteryalsofunctionscorrectly,thecontrolmustbediscon-

nectedfromthemains.Inthisway,theemergencyfunction

can be checked to ensure that the door is closed automati-

cally by the auxiliary motor.

− Emergencyoperationisnotpossibleifthereisafaultinthe

safety circuit of the door operator.

− Toavoidadeepdischargeoftherechargeablebattery,the

batteryshouldnotbeconnectedtotheFS101unituntil

thesystemisputintooperationforthersttime.Ifdeep

dischargeoccurs,thebatterycannotberechargedagain

and must be replaced immediately.

4. Overview of products

4.1 Product description

TheFS345controlcanbeusedinconnectionwithFDF,FT,

FTAandFDSre-protectiondrivesaswellaswithhydraulic

drives.InversionFS345HY,hydraulicdrivesareused.

TheFS345controlconsistofaCS300FSdoorcontrolunit,

anFS101auxiliarycircuitboardandarechargeablebattery

foremergencypowersupply,magneticcouplings,DC-operat-

edmotors,24Vmotorbrakes.

Incaseofreorpowercuts,theemergencyrechargeable

battery provides the energy required for the auxiliary motor

to close the door or for the motor brake to hold the door in

position.

Theremodeistriggeredbyacontinuouscommandinthe

realarmcontactoristimeactivatedifthemainspowersup-

plyfails.Inthecaseofre,thedoorcloseswiththeclosing

edgesystemdeactivated,or,optionally,withtheclosingedge

activated.

4.2 Various options

ThefollowingmodelsofFS345controlcanbesupplied:

− FS345controlfordeadmanoperation

− FS345controlforautomaticoperation

− FS345controlforautomaticoperationwiththeclosing

edgesystemactivatedinthecaseofre

The following housing models are available:

− HousingwithOPEN-STOP-CLOSEbuttons

− HousingwithON/OFFkeyswitch

− Housingwithmainswitch

− HousingwithemergencyOFFswitch

The operating instructions describe the connection options

andmodelsoftheFS345control.

General safety instructions

GB

FS 345 Door Controls / Rev.A 0.0 – 5

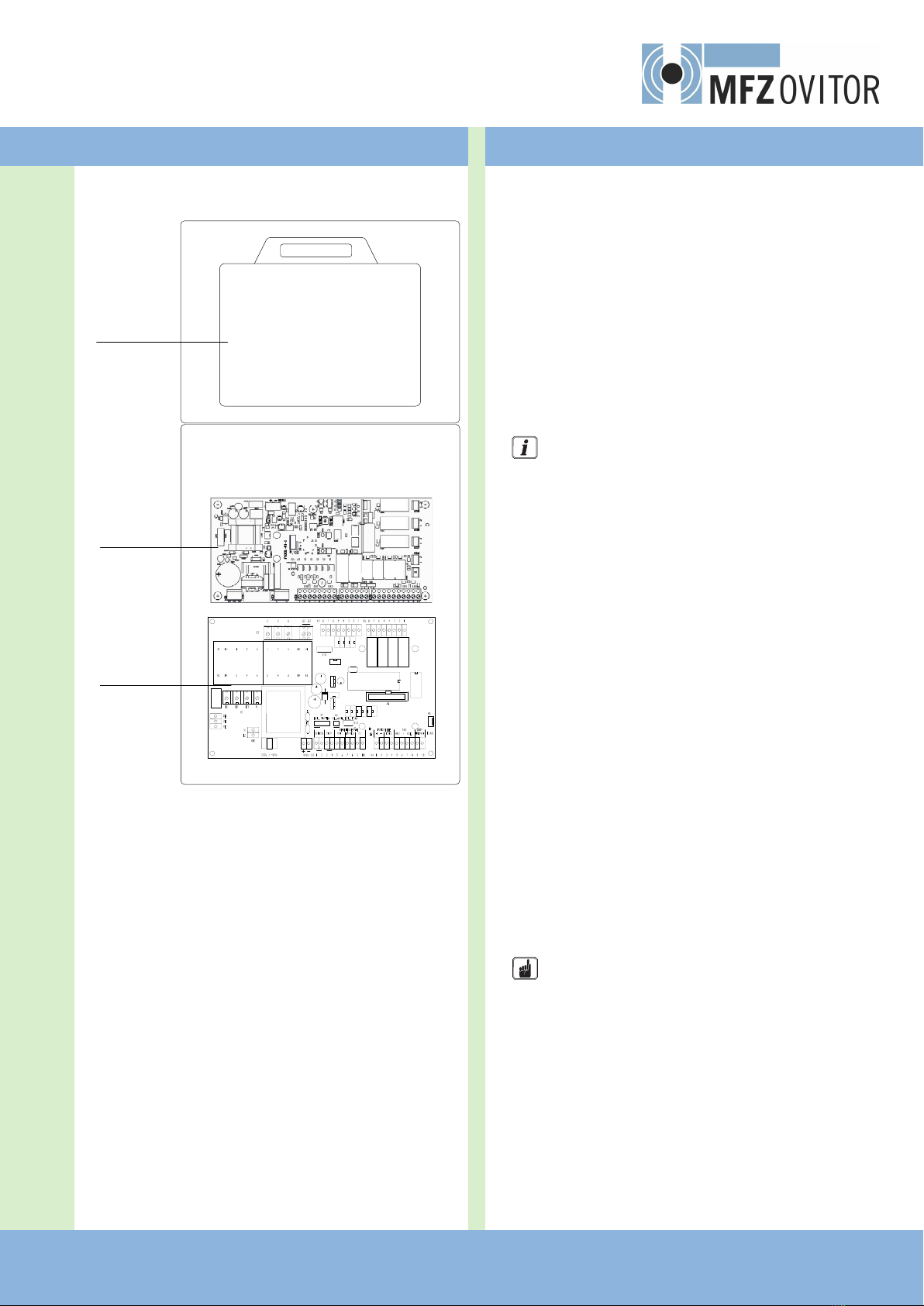

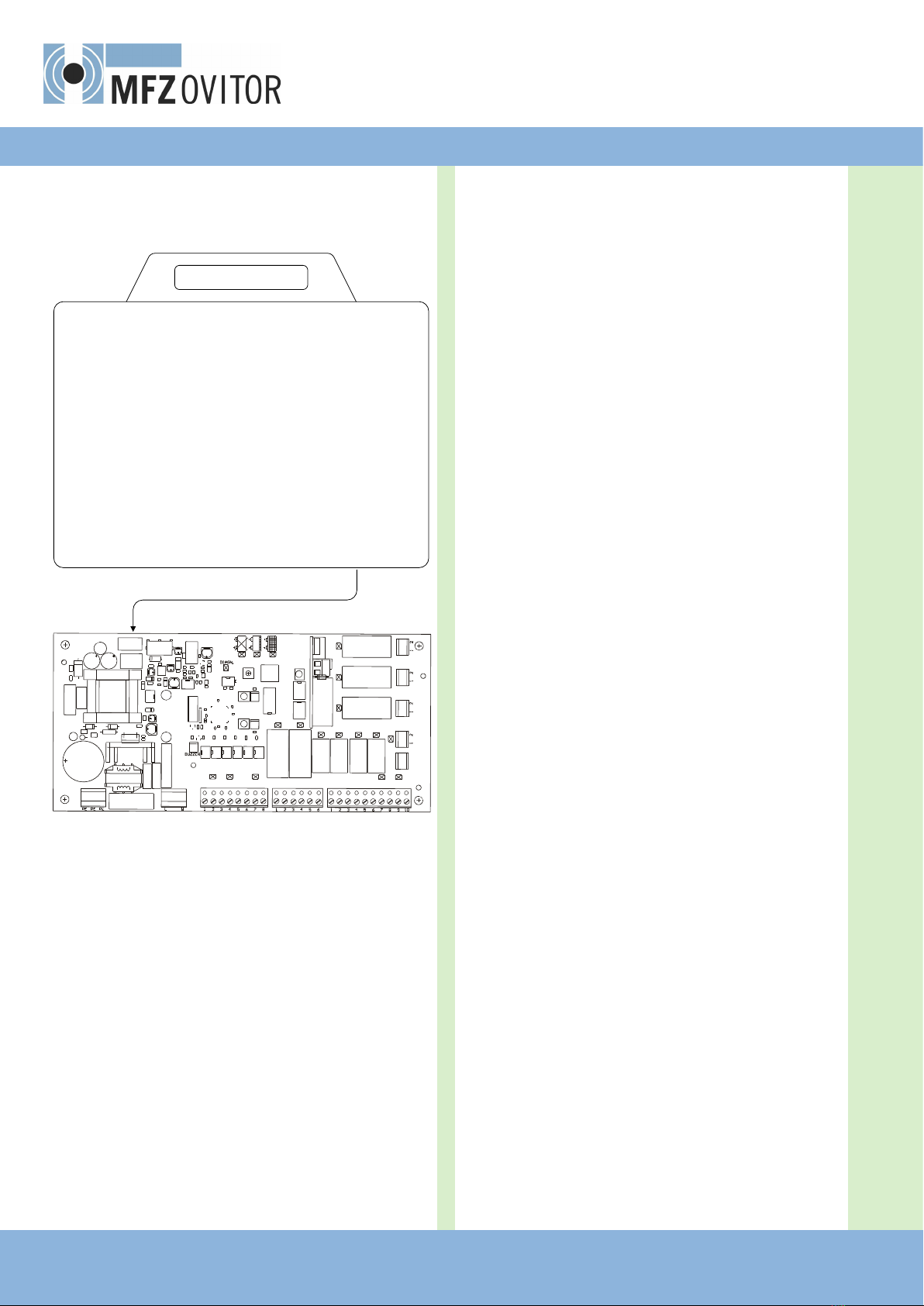

4.3 Product drawing of CS 300 FS with FS 101

K06

K04 K05 K06 K07 K08 K09

K10

K11

K12

CS300FS

circuit board

FS101

circuit board

Battery

5. Commissioning

5.1 General information

Toguaranteethattheequipmentfunctionsproperly,itmust

be ensured that:

− Thedoorisinstalledandoperational.

− TheMFZoperatormotorisinstalledandreadyforopera-

tion.

− Thecommandandsafetydevicesareinstalledandreadyfor

operation.

− ThecontrolhousingwiththeFS345controlisinstalled.

REFERENCE

The relevant manufacturers’ instructions must be adhered to

fortheinstallationofthedoor,theMFZoperatormotor,and

the command and safety devices.

5.2 Mains connection

Preconditions

Toguaranteethatthecontrolfunctionproperly,thefollowing

points must be ensured:

- The mains voltage must correspond to the voltage stated on

the type plate.

- The mains voltage must be the same as the voltage of the

operator.

-Forathree-phasecurrent,aclockwiserotatingeldis

required.

-Forapermanentconnection,anall-polemainswitchmust

be used.

-Forathree-phaseconnection,only3-wayautomaticcircuit

breakers(10A)maybeused.

NOTICE

Malfunctions can occur as a result of incorrect

installation of the control!

Beforeswitchingonthecontrolforthersttime,acheck

must be carried out after completing the wiring to ensure

that all the motor connections at the motor and at the con-

trolissecurelyxed.Allcontrolvoltageinputsaregalvani-

cally isolated from the supply.

6 – FS 345 Door Controls / Rev. A 0.0

5.3 Initial operation FS 101 emergency op-

eration circuit board

General

TheFS101circuitboardincludesachargerfortherecharge-

able battery and a microprocessor for controlling the auxiliary

drive or the motor brake.

ThecircuitboardisconnectedtotheCS300FSdoorcontrol

unit in the factory and if it is purchased together with a door

operator,thecorrectsettingsforthatoperatorarealsopreset

in the factory.

Allthatremainstobeconnectedisarealarm,andthe

rechargeablebatterymustbeconnectedtotheFS101circuit

board via a plug.

NOTICE

Malfunctions due to incorrect installation of the

battery!

Topreventdeepdischargeoftherechargeablebattery,

thebatteryshouldnotbeconnectedtotheFS101circuit

boarduntilthedoorisputintooperation.Topreventerrors,

thebatterymustbeconnectedtotheFS101circuitboard

before the connection is made to the mains power supply.

5.4 Circuit diagram for mains connection and

motor

CS 300 FS

L1 L2 L3 N

PE

PE

PE

~-

X1

T1

K2K1

U V W B1 B2X2

M

1

400V / 50Hz / 3 / N / PE

1 3 5

2 4 6

1 3 5

2 4 6

M

L1N

X12

Key:

K1: CLOSEcontactor

K2: OPENcontactor

M1: Motor

T1: Transformer

X1: Terminalblockformainsconnection

X2: Terminalblockformotor

Connection:

− Connectthecontroltothemainspowersupply.

− Connectthecontroltothemotor.

− Cablegroupsmustbesecuredclosetotheirrelevanttermi-

nals using a cable tie.

Initial operation

-+

Battery

FS101

circuit board

Battery

GB

FS 345 Door Controls / Rev.A 0.0 – 7

FS 101 - CS 300 FS (ready-wired)

FS101-P1-1

8 – FS 345 Door Controls / Rev. A 0.0

5.5 Mains power connection and motor

230 V AC version

CS 300 / FS 230 V AC, 3~

L1 L2 L3 N

PE

PE

PE

~-

X1

T1

K2K1

U V W B1 B2X2

M

1

230V / 50Hz / 3 / PE

1 3 5

2 4 6

1 3 5

2 4 6

M

L1N

X12

Key:

K1: CLOSEcontactor

K2: OPENcontactor

M1: Motor

T1: 230Vtransformer

X1: Terminalblockformainsconnection

X2: Terminalblockformotor

Connection:

− Connectthecontroltothemainspowersupply.

− Connectthecontroltothemotor.

− Cablegroupsmustbesecuredclosetotheirrelevanttermi-

nals using a cable tie.

CS 300 / FS 230 V AC, 1~

L1 N

PE

PE

PE

~-

X1

T1

K2K1

AUF ZU NB1 B2X2

M

1

230V / 50Hz / 1~ / PE

1 3 5

2 4 6

1 3 5

2 4 6

M

L1N

X12

Key:

K1: CLOSEcontactor

K2: OPENcontactor

M1: Motor

T1: 230Vtransformer

X1: Terminalblockformainsconnection

X2: Terminalblockformotor

Connection:

− Connectthecontroltothemainspowersupply.

− Connectthecontroltothemotor.

− Cablegroupsmustbesecuredclosetotheirrelevanttermi-

nals using a cable tie.

Initial operation

GB

FS 345 Door Controls / Rev.A 0.0 – 9

5.6 Connection of command and safety

devices for normal door operation X3/CS

300 FS

Command and safety devices can be connected via terminals

X3andX4.

X3 / CS 300 FS

X6 / CS 300 FS

X7 / CS 300 FS

-DOWNSWITCH

- Impulse button

-UPSWITCH

-STOPbutton

-Emergencyoff,slackropeswitch,

wicketdoorcontact,drawinprotection

-SocketsforinternalON-OFFswitch

-Socketsforinternal3-buttoninputunit

STOP

OPEN

CLOSE

10 – FS 345 Door Controls / Rev. A 0.0

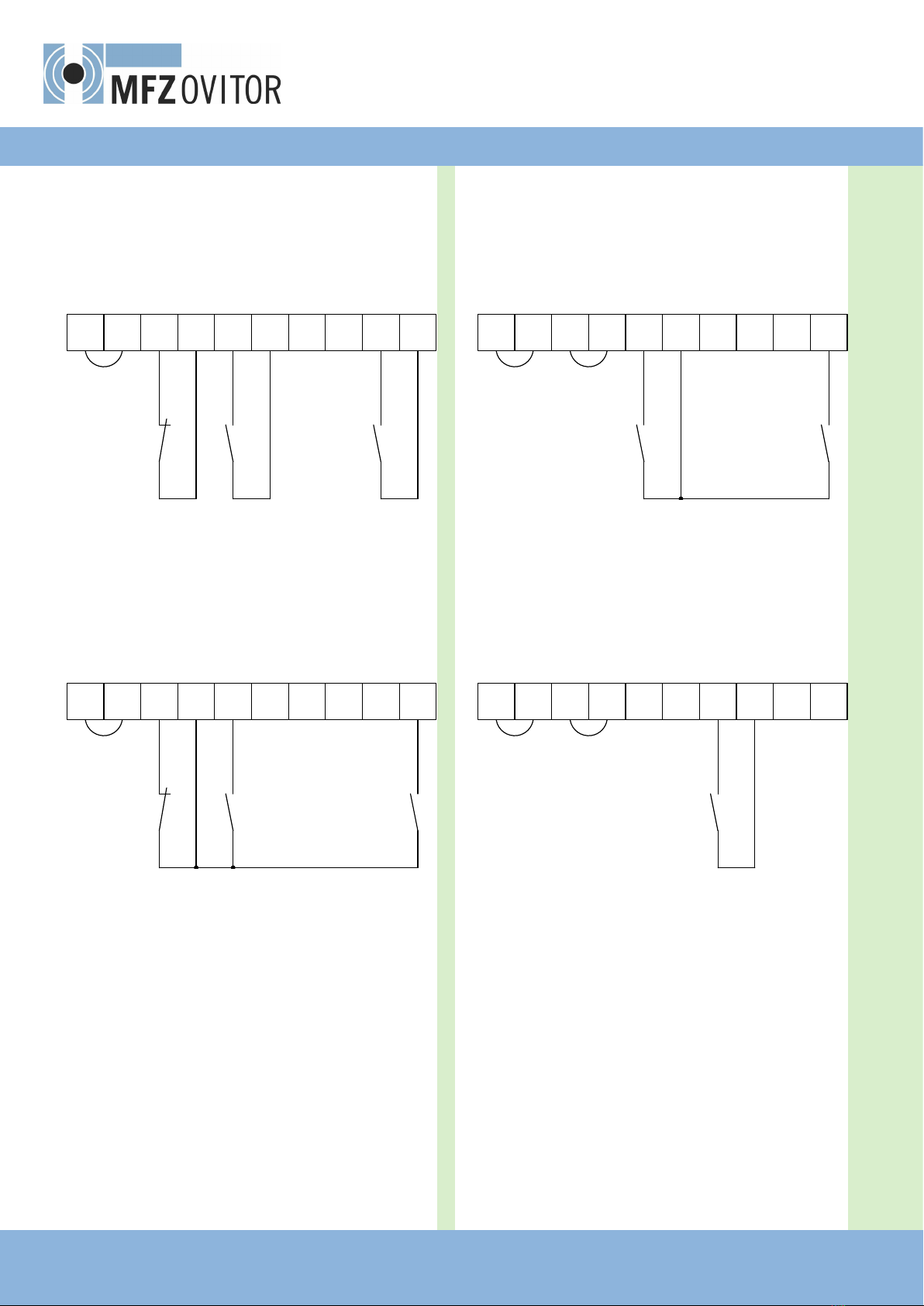

5.7 Connection examples for command and

safety devices (terminal block X3/CS 300

FS)

OPEN / STOP / CLOSE buttons

(6-lead solution)

12345678910

OPEN / STOP / CLOSE buttons

(4-lead solution)

12345678910

Button

STOP

Button

OPEN

Button

CLOSE

Button

STOP

Button

OPEN

Button

CLOSE

UP / DOWN key switch

12345678910

Impulse button key switch

(sequence control)

12345678910

Button

OPEN

Button

CLOSE

Button

IMPULSE

Initial operation

GB

FS 345 Door Controls / Rev.A 0.0 – 11

5.8 Connection examples for safety devices

X4/CS 300 FS

Terminal block X4

8.2 kOhm closing edge safety device

Terminal block X4

Optoelectronic closing edge safety system

+-

9

10

1

2

3

4

5

6

7

8

wt

gr

br

Gnd

Signal

+12V DC

24VDCforexternal

switching devices

Photoelectric drive-

through barrier*

8.2 kOhm closing edge

safety device*

HALFOPENlimitswitch

24VDCforexternal

switching devices

Photoelectric drive-

through barrier*

HALFOPENlimitswitch

Opto closing edge

safety device*

Terminal block X4

Pneumatic safety edge protection - pressure sensor test

8k2

Terminal block X4

MFZ-type leading photoelectric barrier

+-

9

10

1

2

3

4

5

6

7

8

wt

gr

br

Gnd

Signal

+12V DC

1

2

3

4

5

6

7

8

8k2

A 24VDCforexternalswitchingdevices

B Drive-through photoelectric barrier*

C Leading photoelectric barrier

D HALFOPENlimitswitch

Adjustmentofthepre-limitswitchCLOSEfortheleading

photoelectric barrier

− OntheCS300FS,setthemodeforrelay1to11(pre-limit

switchCLOSE)

− Drivethedoorinthe“close”directionuntiltheleading

photocelljusttouchestheground.

− Intheinputmenu,setthepre-limitswitchCLOSEtothis

position

* effective in down direction only

24VDCforexternal

switching devices

Photoelectric drive-

through barrier*

HALFOPENlimitswitch

Closing edge safety

device

DW-Test*

A

B

C

D

X5 / CS 300 FS

X4 / CS 300 FS

Relay 1

MOD 11

12 – FS 345 Door Controls / Rev. A 0.0

5.9 Product drawing of FS 101 circuit board +

rechargeable battery

K04 K05 K06 K07 K08 K09

K10 K11 K12

FS101-P1-1

X01

X02

X03

X04

X05

X10

X06

X07

X08

X09

+ - AKKU

TEST

RESET

TIME2

TIME1

S303

F200

ON

Battery

FS 101 circuit board

Key to FS 101 circuit board

X01/X02 Powersupply230V/PE

X03 Limitswitchconnection

X04 Outputsfortheauxiliarymotor,brake,

auxiliary relay

X05 ActivationoftheCS300FScircuitboard

X06 Firealarmconnection

X07 Potential-freeoutputforfaultindicator

X08 Potential-freeoutputforrealarm

X09 Potential-freeoutputforclosingedgesafety

device

X10 Input,external24V

+-BATT Terminalblockforbatterypack

Time 1 Time-controlled closing if mains power supply

fails

Time 2 Timing element for door seal function

S303 DIPswitch

Reset Button – switch off buzzer

Test Button for testing emergency operation

F200 3.15Afuseforbatterycharger

ON Button

K04 Auxiliarymotorrelay

K05 Motorbrakerelay

K06 OPEN/CLOSEcommandrelay

K07 Upperswitchrelay

K07 Lowerswitchrelay

K09 Stoprelay

K10 Operation/errorrelay

K11 Emergencyclosingrelay

K12 Closingedgesafetydevice(SKS)relay

Initial operation

GB

FS 345 Door Controls / Rev.A 0.0 – 13

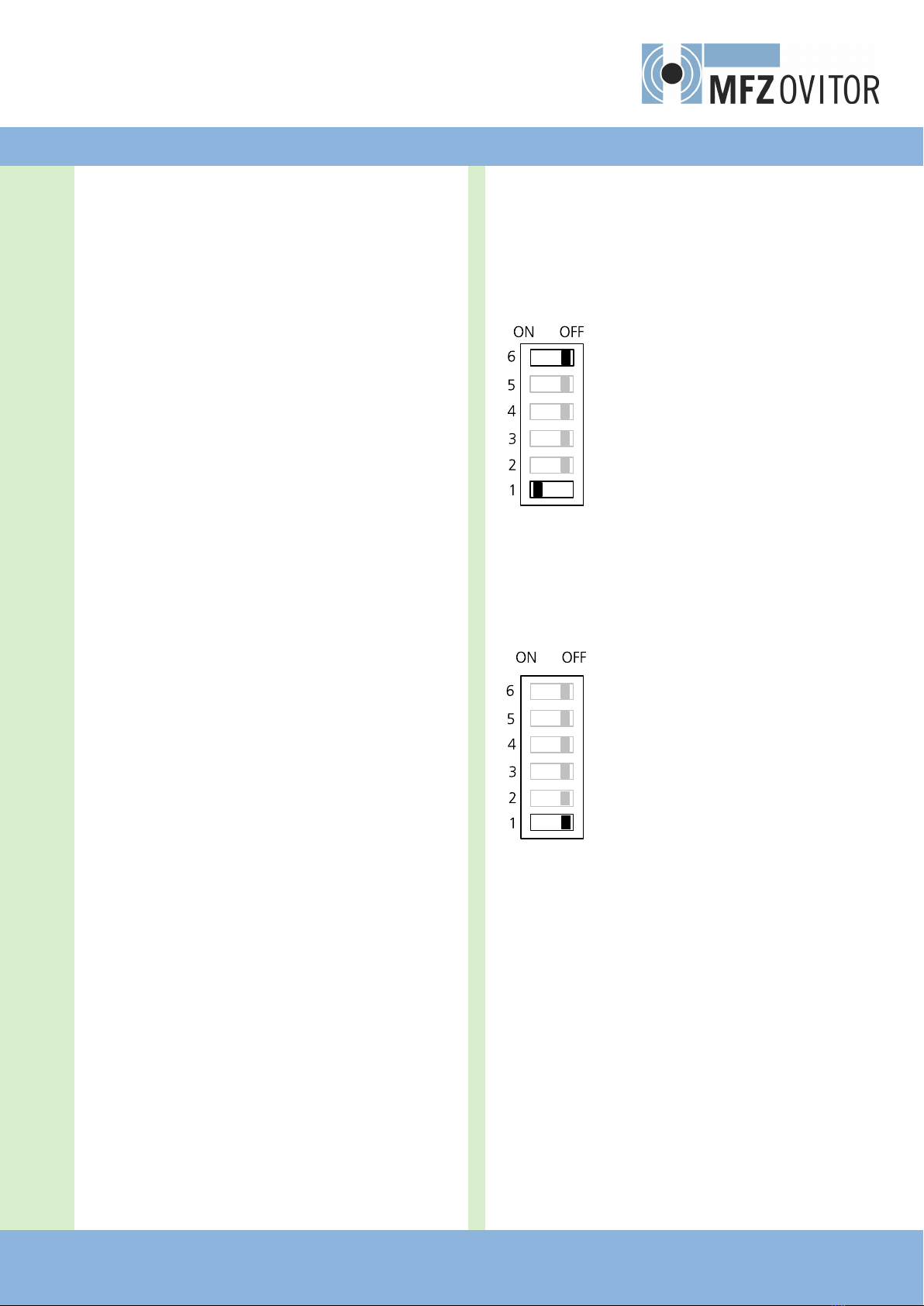

5.10 DIP switches:

1ON DooroperatortypesFT(+HY)*

1OFF DooroperatortypesFDF+FTA

2 ON Fire alarm as normally open contact

2 OFF Fire alarm as normally closed contact

3ON Emergencyclosingwith400VAC/24VDC

3OFF Emergencyclosingwith24VDC

4ON WithCESD(SKS)inemergencyoperation

4OFF WithoutCESD(SKS)inemergencyoperation

5 ON Door closes if an error occurs

5 OFF Door remains open if an error occurs

6ON (OperatortypeHY)*

6 OFF Operator type FT

WhenmakingchangestotheDIPswitchsettings,thefollow-

ing procedure must be observed:

1. Switchoffthemainsvoltage

2. Switchofftherechargeablebatteryvoltage

3. Change the DIP switch positions as required

4. Switchontherechargeablebatteryvoltage

5. Switchonthemainsvoltage

*versionHYonly

5.11 Types of door operator

TheFS345controlisdesignedforusewithtwodifferent

types of door operator.

FT operators

DIP 1 ON and DIP 6 OFF

1.FTdooroperatorswith24VDCmotor

braking.

Inemergencymode,thedoorisclosedviathe

24VDCauxiliarymotor.

The weight of the door is held by the ener-

gised motor brake.

The power supply comes from the mains

adapterontheFS101circuitboard;ifthe

mainspowerisinterrupted,powerissupplied

from the rechargeable battery.

(DIP6ONrequiredforversionHY)

FD (FDF, FTA, FDS) operators

DIP 1 OFF

1.FD(FDF,FTAandFDS)dooroperatorswith

a24VDCauxiliarymotorand24VDCmotor

brake(FDF5).Inemergencymode,thedooris

closedviathe24VDCauxiliarymotor.

The power supply comes from the mains

adapterontheFS101circuitboard;ifthe

mainspowerisinterrupted,powerissupplied

from the rechargeable battery.

14 – FS 345 Door Controls / Rev. A 0.0

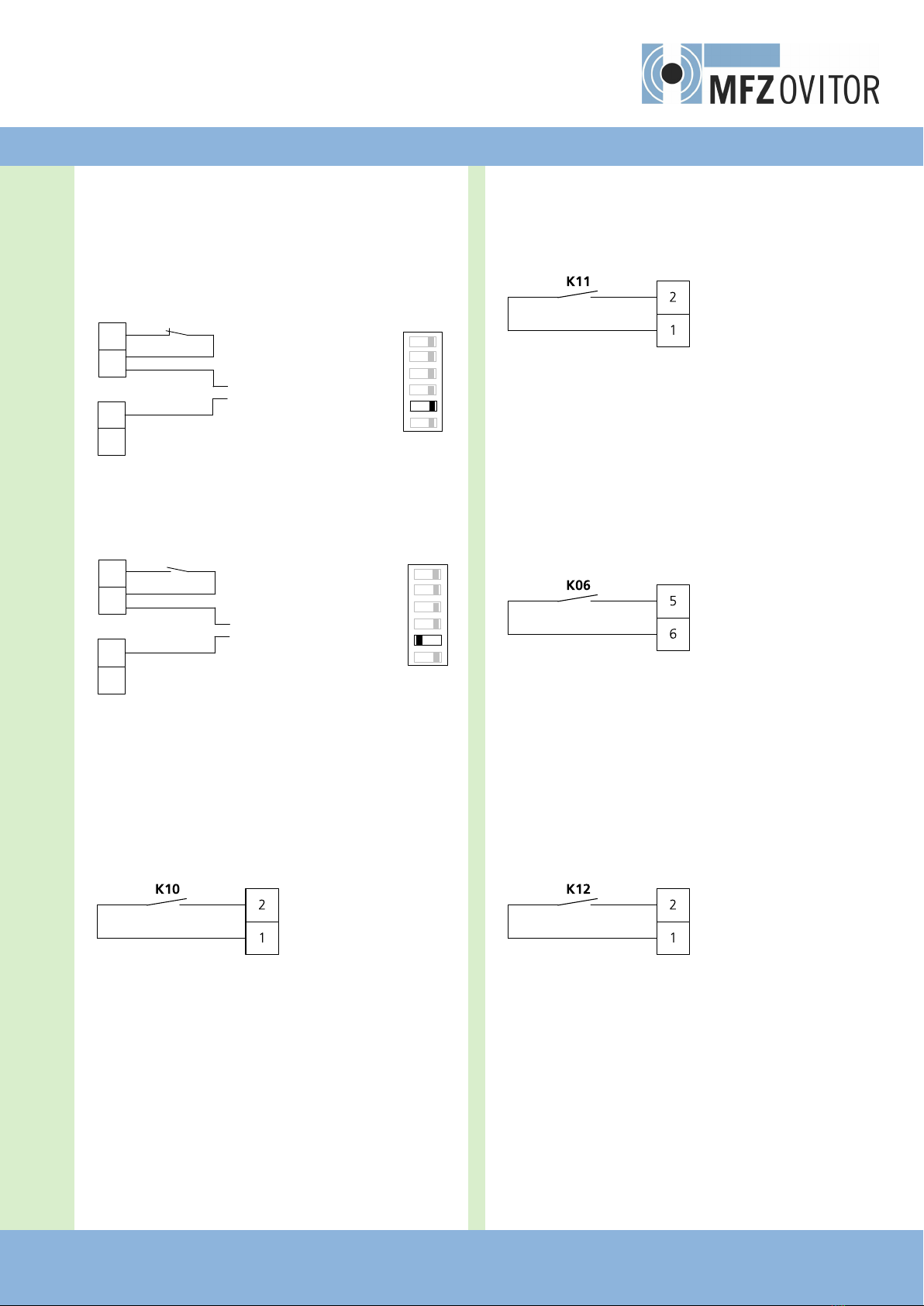

5.12 FS 101 connections

2

1

2

1

2

1

2

1

2

1

X09

X08

X07

X06

X10

X051 2 3 4 5 6X03

X04

M

+

-

* refer to the appendix for connection details for operators FT 3 and FDF 60

CESD(SKS)

Potential-free relay

EMERGENCYOPERATION

Potential-free relay

OPERATION/ERROR

Potential-free relay

INPUT

FIREALARM

24VDC/50mA

Potential-free relay

OPEN/CLOSEcommand

MotorbrakeforFT/FDFoperators*

Auxiliarymotor*

Initial operation

GB

FS 345 Door Controls / Rev.A 0.0 – 15

5.13 Connection example for re alarm con-

tact

Terminal strip X06

(potential-free continuous contact as normally closed contact)

2

1

X06/FS101 Dip 2 = OFF

1

2

3

4

ON OFF

5

6

2

X10/FS101 +

-

1

Terminal strip X06

(potential-free continuous contact as normally open contact)

Dip 2 = ON

1

2

3

4

ON OFF

5

6

2

1

X06/FS101

2

X10/FS101 +

-

1

5.14 Messages

Terminal strip X07

K10operation/errorrelay

X07/FS101

Innormaloperationcontactclosed,opensintheeventofan

error.

Rechargeablebatteryfault/mainspowerfailure:switchesif

the battery is defective or if the battery voltage is less than

19V.

Fire alarm contact

Supplyvoltage

24VDC,max.50mA

Fire alarm contact

Supplyvoltage

24VDC,max.50mA

Terminal strip X08

K11emergencyclosingrelay

X08/FS101

Potential-free switching contact for emergency operation is

active.Switchesintheeventofemergencyclosing(contact

closed).

Terminal block X4

K06operatorcommandrelay

X04/FS101

Potential-freeswitchingcontactforCLOSEorOPENcommand

depending on DIP switches 1 and 3.

(See12and13.1forwiringandfunction)

Terminal strip X09

K12closingedgesafetyedge(SKS)relay

X09/FS101

Potential-freeswitchingcontact,displaysstatusofCESD(SKS)

16 – FS 345 Door Controls / Rev. A 0.0

6. Limit switches

6.1 Limit switches

Connectionarrangementforlimitswitches(CS300terminals

X11,X10andFS101terminalsX03,X05)

1

2

3

4

5

6

7

8

X03/FS101**

1

2

3

4

5

6

7

8

9

10

8

7

6

5

4

3

2

1

6

5

4

3

2

1

5678

X05/FS101*

X11/CS300 FS

X10/CS300 FS*

1

2

3

1 Limit switch OPEN

2LimitswitchCLOSE

3Pre-limitswitchCLOSE

5Thermalprotection,motor*

6 Emergency operation (normally closed contact)**

7SafetylimitswitchCLOSE

8SafetylimitswitchOPEN

* ready wired

** ready wired if supplied with operator

The limit switches (with the exception of the pre-limit switch)

areanalysedbytheFS101circuitboard,andthevaluesare

passedontotheCS300FScircuitboard.

TheassignmentofterminalX11(limitswitch)isdifferent

fromtheassignmentgiventoterminalsintheAS130.This

mustbetakenintoaccountintheeventofretrots

Safety

circuit

-

+

CLOSE

OPEN

GB

FS 345 Door Controls / Rev.A 0.0 – 17

6.2 FDF / FTA / FDS limit switch settings

1. AdditionalOPENlimitswitch green

2. Limit switch OPEN green

3. SafetylimitswitchOPEN red

4. SafetylimitswitchCLOSED red

5. LimitswitchCLOSED white

6. AdditionallimitswitchCLOSED white

NOTICE

Damage to property or irreparable damage due to

incorrect adjustment!

The door can be damaged if it is driven beyond the end

positionwhileadjustmentsarebeingmade.

1. SelecttheADJUSTMENTmenuonthedisplay

2. MovethedoortothedesiredCLOSEDpositionwiththe+

and - buttons.

3. Setcontrolcam5(white)sothatthelimitswitchisactu-

ated.

4. TightenfasteningscrewA.

5. ScrewBcanbeusedtocarryoutnetuning.

6. MovethedoortothedesiredOPENpositionwiththe+

and - buttons.

7. Setcontrolcam2(green)sothatthelimitswitchisactu-

ated.

8. TightenfasteningscrewA.

9. Safetylimitswitches3and5(red)mustbesetsothat

they are triggered as soon as the control limit switches are

crossed.

10. Afterthetrialrun,checkthetightnessofthefastening

screws.

11. Auxiliarylimitswitches1and6haveapotential-free

changeover contact

18 – FS 345 Door Controls / Rev. A 0.0

7.1 Overview of the LCD monitor

AUTOMATIC O

STANDBY

A

B

C D E

F

G

H

Key:

A: Modeofoperation/DIAGNOSISinfo

B: Parameters/DIAGNOSISinfo

C Button(+)

D: Button (-)

E Button (P)

F Value/status

G Value/status

H Jumper

7.2 LCD monitor, modes of operation

The control has four modes of operation with the LCD moni-

tor:

1.AUTOMATIC

2.ADJUSTMENT

3.INPUT

4.DIAGNOSIS

IfjumperHisremoved,the(+)button,the(-)buttonandthe

(P) button have no function.

The display still functions.

Afterswitchingthecontrolon,itisinINITIALISATIONmode.

ThedisplayshowsINITPHASEandthecontrolisnotyetready

for use. This phase lasts approx. 5 seconds.

7. Programming with the LCD monitor

6.3 FT limit switch settings

2. Limit switch OPEN green

3. SafetylimitswitchOPEN red

4. SafetylimitswitchCLOSED red

5. LimitswitchCLOSED white

6. AuxiliarylimitswitchCLOSED white

NOTICE

Damage to property or irreparable damage due to

incorrect adjustment!

The door can be damaged if it is driven beyond the end

positionwhileadjustmentsarebeingmade.

1. SelecttheADJUSTMENTmenuonthedisplay

2. MovethedoortothedesiredCLOSEDpositionwiththe+

and - buttons.

3. Setcontrolcam5(white)sothatthelimitswitchisactu-

ated.

4. TightenfasteningscrewA.

5. ScrewBcanbeusedtocarryoutnetuning.

6. MovethedoortothedesiredOPENpositionwiththe+

and - buttons.

7. Setcontrolcam2(green)sothatthelimitswitchisactu-

ated.

8. TightenfasteningscrewA.

9. Safetylimitswitches3and4(red)mustbesetsothat

they are triggered as soon as the control limit switches are

crossed.

10. Afterthetrialrun,checkthatthefasteningscrewsarecor-

rectly tightened.

11. Auxiliarylimitswitches1and6haveapotential-free

changeover contact

Limit switches

GB

FS 345 Door Controls / Rev.A 0.0 – 19

ADJUSTMENT,INPUTandDIAGNOSISmodesareexitedau-

tomatically20secondsafterthelastbuttonwaspressed,and

thecontrolthengoesintoAUTOMATICmode.

Operating mode 1: AUTOMATIC

ThedoorsystemisoperatedinAUTOMATICoperatingmode.

Display:

− Displaystheactionbeingcarriedout

− Displaysanyerrors

Ifthe“PRESS/REL"parameterissettoMOD2orMOD3in

theinputmenu,thedisplaychangesfromAUTOMATICto

MANUAL.

Operating mode 2: ADJUSTMENT

InADJUSTMENTmode,theOPEN/CLOSEDendpositionsare

set.

NOTICE

Malfunctions can occur as a result of incorrect

operation of the control!

InADJUSTMENTmode,thedoorwillnotstopautomatically

when it reaches the travel limit position if electronic end

positions(AWG)areused.

The door can be damaged if driven beyond the end posi-

tion.

FineadjustmentscanbemadeintheINPUToperatingmode.

Display:

− Displaysthetravellimitvalue

Operating mode 3: INPUT

IntheINPUToperatingmode,thevaluesofvariousparam-

eters can be altered.

Display:

− Displaystheselectedparameter

− Displaysthecurrentvalueorstatus

Operating mode 4: DIAGNOSIS

IntheDIAGNOSISoperatingmode,door-speciccheckscan

be queried.

Display:

− Displaysthemonitoredfunction

− Displaysthestatusofthefunction

20 – FS 345 Door Controls / Rev. A 0.0

8. Navigator (LCD monitor only)

AUTOMATIC

STANDBY

P

> 1 second

ADJUSTMENT

STANDBY

+

->Position,DOOROPEN ADJUSTMENT

MAINUP Deadman operation

Setthemechanicallimit

switches as described in sec-

tion 22.

-

->PositionDOORCLOSED ADJUSTMENT

MAINDOWN

P

> 1 second

INPUT

+

and

-

> 2 sec. INPUT

ENGLISH : Scrollupthroughmenu:

+

> 2 sec.

Scrolldownthroughmenu:

-

> 2 sec.

Selectvalue:

P

> 1 sec.

Increase value:

+

Decrease value:

-

Savevalue:

P

Return to INPUTmode:

+

and

-

> 1 sec

INPUT

RUNTIME : 60

P

> 1 second

INPUT

OPEN TIME : 0

INPUT

PREWARNING : 0

INPUT

REVERS.TIME : 3

INPUT

MOD1-3STANDBY : MOD1

INPUT

QUICKCLOSE : OFF

INPUT

RELAY1 : MOD6

INPUT

RELAY2 : MOD7

INPUT

RELAY3 : MOD1

INPUT

RELAY4 : MOD19

INPUT

DW-TEST : OFF

INPUT

DELAYUP : OFF

INPUT

PRESS/REL : MOD1

INPUT

SU/WI : MOD1

INPUT

REVERS. : MOD1

DIAGNOSIS

Scrollupthroughmenu:

+

> 2 sec.

Scrolldownthroughmenu:

-

> 2 sec.

ReturntoAUTOMATICmode:

P

Only queries are possible.

UPPERSWITCH : ON

LOWERSWITCH : OFF

UPSWITCH : OFF

PARTUP : OFF

DOWNSWITCH : OFF

SKS : OFF

IMP.INPUT : OFF

SWITCHCLOCK : OFF

LIGHTBARR. : ON

STOPCIRCUIT : ON

S-POINT1 : ON

S-POINT2 : ON

CYCLE : XXXX

Table of contents

Other MFZ Ovitor Control System manuals

Popular Control System manuals by other brands

Carrier

Carrier AQUASNAP 30RA/RH Operation & maintenance instructions

Genius

Genius 433RC Series quick start guide

ICS

ICS Auto Sentry Petro installation guide

Faulhaber

Faulhaber 3564K024B CS instruction manual

TeeJet Technologies

TeeJet Technologies Dynajet FLEX 7140 INSTALLATION, SETUP AND USER GUIDE

Balboa

Balboa Hydro Air 20-0244 quick start guide