3

TABLE OF CONTENTS

OPERATING MANUAL .......................................................................................................5

1. INTENDED USE....................................................................................................5

1.1. Description.............................................................................................................5

2. OPERATOR RESPONSIBILITY – SAFETY INSTRUCTIONS..............................5

2.1. Disposal.................................................................................................................7

2.2. Technical specifications.........................................................................................8

2.3. Cooling water connection....................................................................................12

OPERATING INSTRUCTIONS .........................................................................................13

3. SAFETY NOTES FOR THE USER......................................................................13

3.1. Explanation of safety notes .................................................................................13

3.2. Explanation of other notes...................................................................................13

3.3. Safety instructions ...............................................................................................13

4. OPERATING CONTROLS AND FUNCTIONAL ELEMENTS..............................16

4.1. The Presto Plusprinciple with closed external system........................................22

5. PREPARATIONS ................................................................................................23

5.1. Bath fluids............................................................................................................23

5.2. Tubing..................................................................................................................25

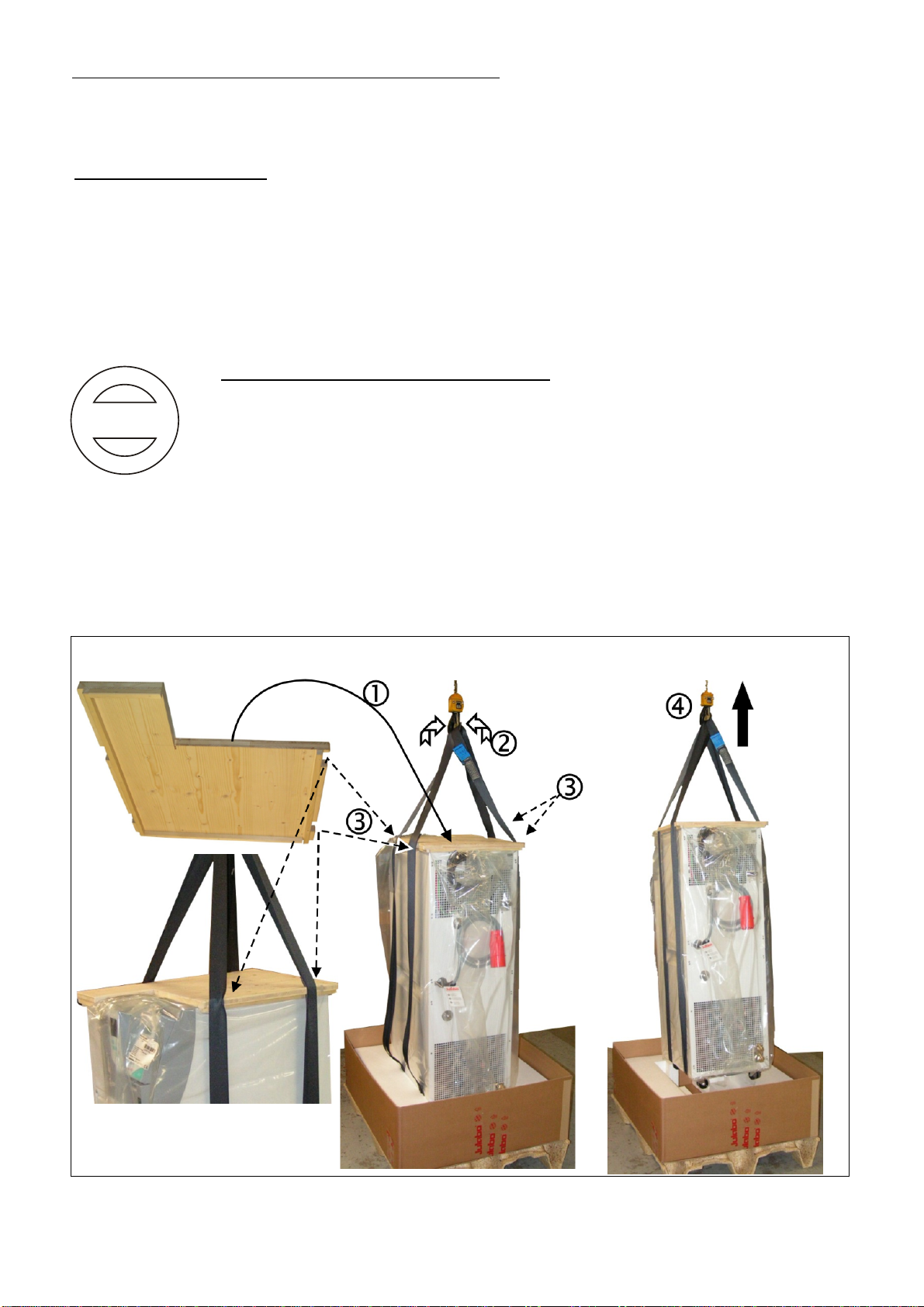

5.3. Installation ...........................................................................................................26

5.4. Connect the external system...............................................................................26

5.5. Cooling water connection LH 50..........................................................................28

5.6. Power connection................................................................................................29

5.7. Filling...................................................................................................................29

5.7.1. Filling of external, closed systems................................................................30

5.8. Degasifying..........................................................................................................32

5.9. Draining...............................................................................................................33

6. OPERATING PROCEDURES.............................................................................34

6.1. Switching on / Selecting the language.................................................................34

7. MANUAL OPERATION........................................................................................35

7.1. Start - Stop ..........................................................................................................35

7.2. Direct setting of the working temperature............................................................36

7.3. Settings in the SET menu....................................................................................36

7.3.1. Setting the working temperature...................................................................36

7.3.2. Warning functions.........................................................................................37

7.3.3. Setting the pump pressure stage..................................................................38

7.4. Setting the safety temperature (with shutdown function).....................................38

7.5. Internal / external control.....................................................................................40

8. MENU FUNCTIONS............................................................................................40