MFZ Ovitor MDF Series User manual

Operating

Instructions

for

Roll-Up

Door

Operators

/

MDF

GB

Roll-Up

Door

Operator

/

MDF

/

Rev.

0.0

–

1

1.

Contents

3.

General

safety

instructions

1. Contents 2

2.

Key

to

symbols

2

3. Generalsafetyinstructions 2

4. Overviewof products 3

5. Installation 4

6. InitialOperation 6

7.

Emergency

operation 13

8. Maintenance 15

9. Technicaldata 16

10.

EU

Declarationof Conformity 31

2.

Key

to

symbols

Danger

of

personal

injury!

The

safetyinstructionsmust

be

observed!

Warning!

Danger

to

property!

The

safetyinstructionsmust

be

observed!

Information

Specialinformation

OR

Reference

to other

sources

of

information

2

–

Roll-Up

Door

Operator

/

MDF

/

Rev.

0.0

Guarantee

The

functionand safetyof theequipmentis onlyguaranteed

if thewarningand safetyinstructionsincludedin theseopera-

tinginstructionsareadheredto.

MFZ

Antriebe

GmbH

+

Co.KG

isnot liablefor

any

personal

injuryor

damage

topropertythat

occurs

as

a

resultofthe

warningand safetyinstructionsbeingdisregarded.

MFZ

does

not accept

any

liabilityor warrantyfor

damage

due

to the

use

of non-approved

spare

partsand

accessories.

Using

the

equipment

for

its

intended

purpose

Operatorsof the

MDF/MDFC

rangearedesignedexclusively

foropeningand closingroll-up doors,rollershuttergrillesand

springlessorweight-counterbalancedsectionaldoors.

Target

group

Onlyqualifiedand trainedspecialistsarepermittedto install

and servicetheoperator.Qualifiedand trainedprofessionals

fulfil thefollowingrequirements:

-knowledgeof thegeneraland specificsafetyand accident

preventionregulations,

-Knowledgeof therelevantregulations,

-trainedinthe

use

and careof appropriatesafetyequipment,

-Capableof recognisingthedangersassociatedwith

installation.

Onlyqualifiedand trainedelectricians

may

connectthe

operatorand carryout electricalmaintenance.

Qualifiedand trainedelectriciansfulfilthefollowing

requirements:

-knowledgeof thegeneraland specificsafetyand accident

preventionregulations,

-knowledgeof therelevantelectricalregulations,

-trainedinthe

use

and careof appropriatesafetyequipment,

-capableof recognisingthedangersassociatedwith

electricity.

Instructions

for

installation

and

connection

-

The

controlsmust

be

disconnectedfromtheelectricitysup-

plybeforecarryingout electricalworks.It must

be

ensured

thattheelectricitysupplyremainsdisconnectedduringthe

works.

-Localprotectiveregulationsmust

be

compliedwith.

-Mainscablesand controlcablesmust

be

laidseparately.

4.

Overview

of

products

GB

Regulations

and

bases

for

testing

For

connecting,programmingandservicing,thefollowing

regulationsmust

be

observed(thelistis not exhaustive).

Constructionproductstandards

-

EN

13241-1(Productswithoutfire resistanceor

smoke

controlcharacteristics)

-

EN

12445 (Safetyin

use

of poweroperateddoors-

Test

methods)

-

EN

12453 (Safetyin

use

of poweroperateddoors-

Requirements)

-

EN

12635 (Industrial,commercialandgaragedoorsand

gates-Installationand use.)

-

EN

12978 (Safety

devices

forpoweroperateddoorsand

gates-Requirementsand testmethods)

Electromagneticcompatibility

-

EN

55014-1(Radiodisturbance,householdappliances)

-

EN

61000-3-2 (Disturbancesin supply

systems

-

harmoniccurrents)

-

EN

61000-3-3 (Disturbancesin supply

systems

-

voltagefluctuations)

-

EN

61000-6-2 (Electromagneticcompatibility

(EMC)

-

Part6-2:Genericstandards-Immunityforindustrial

environments)

-

EN

61000-6-3 (Electromagneticcompatibility

(EMC)

-

Part6-3:Genericstandards-

Emission

standardfor

residential,commercialand light-industrialenvironments)

Machineryguidelines

-

EN

60204-1(Safetyof machinery,electricalequipmentof

machines,part1: generalrequirements)

-

EN

12100-1(Safetyof machinery.

Basic

concepts,general

principlesfordesign.

Basic

terminology,methodology)

Low

voltage

-

EN

60335-1(Householdand similarelectricalappliances-

Safety)

-

EN

60335-2-103 (Particularrequirementsfordrivesfor

gates,doorsand windows)

Professionalassociation(D)

-

BGR

232 (DirectiveforPower-drivenWindows,

Doors

and

Gates)

4.1

Safety

catch

device

as

a

safety

feature

The

MDF

roll-updooroperatoris

a

slip-on drivewithan

incorporatedsafetycatchdevice.

The

safetycatchdeviceis

entrainedload-freeandwear-free.

If thedriveunitfails,thesafetycatchdeviceisautomatically

triggered.

The

load

moved

by

theoperatoris thensmoothly

broughtto

a

standstillinthepositionconcerned.

The

power

transmissionbetweenthemotorand thedoor shaftis inter-

ruptedafterthedriveunitfails.

The

operatoris no longerusableafterthesafetycatchdevice

has

been

triggeredandmust

be

replaced.

The

safetycatchdeviceis distinguished

by

thefollowing

features:

-Protectionagainstwormshaftandwormgear failure

-Independentof therotational

speed

-Independentof thedirectionof rotation

-

Can

be

mountedin

any

position

-Unsusceptibleto vibrations

-Maintenance-free

-Self-controlling

-Excellentdampingpropertieswhensafetycatchdeviceis

triggered

4.2

Various

options

The

followingpackageoptionsareavailableforthe

MDF

operator:

-

MDF

05-10-15

KU

-

MDF

05-14-12

KU

-

MDF

05-10-15

KE

-

MDF

05-14-12

KE

-

MDF

20-22-12

KU

-

MDF

20-15-17

KU

-

MDF

20-15-12 100%

KU

-

MDF

20-10-17 100%

KU

-

MDF

20-22-12

KE

-

MDF

20-15-17

KE

-

MDF

20-15-12 100%

KE

-

MDF

20-10-17 100%

KE

Roll-Up

Door

Operator

/

MDF

/

Rev.

0.0

–

3

4.

Overview

of

products

-

MDF

30-30-12

KU

-

MDF

30-42-12

KU

-

MDF

30-29-17

KU

-

MDF

30-27-12 100%

KU

-

MDF

30-19-17 100%

KU

-

MDF

30-50-12

KU

-

MDF

30-30-12

KE

-

MDF

30-42-12

KE

-

MDF

30-29-17

KE

-

MDF

30-27-12 100%

KE

-

MDF

30-19-17 100%

KE

-

MDF

30-50-12

KE

-

MDF

50-65-10

KU

-

MDF

50-75-10

KU

-

MDF

50-65-10

KE

-

MDF

50-75-10

KE

-

MDF

6-100-9

KU

-

MDF

6-100-9

KE

-

MDF

6-100-9100%

KU

5.

Installation

5.1

Preparation

Danger!

To

avoidinjury,thefollowingpointsmust

be

observed:

-

The

operatormust

be

installedfreeof

any

tension.

-

The

operatormustnot

move

on theshaft.

-

The

designand subsurfaceof allcomponents

must

be

suitablefortheforcesencountered.

Warning!

To

avoid

damage

totheoperatorand the

door,theoperatormustonly

be

fitted if

-theoperatoris undamaged,

-theambienttemperatureis-20

ºC

to

+60ºC.,

-thealtitudeof thelocation

does

not

exceed

1,000m,

-

a

suitableprotectiontype

has

been

selected.

☞

Beforeinstallation,

ensure

that

-theoperatoris not blocked,

-theoperator

has

been

newlypreparedafter

a

lengthy

-storageperiod,

-allconnections

have

been

carriedout correctly,

-thedirectionof rotationof thedrivemotoris correct,

-allmotorprotective

devices

areactive,

-no other

sources

of dangerexist,

-theinstallationsite

has

been

cordonedoffover

a

wide

area.

4

–

Roll-Up

Door

Operator

/

MDF

/

Rev.

0.0

GB

5.2

Slip-on

assembly

Warning!

A

To

avoid

damage

totheoperatorand to

thedoor,theoperatormust

be

mounted

C

on

a

bracketwith

a

pendulumfootor

a

torquesupportbracket

so

thatitis vibration

dampened.

Information:

The

relevantinstructionsforthedoor must

be

observedwhenfitting theoperatorto the

B

door.

E

D

E

B

☞

Insertthefeather

key

(A)intotheshaft(B).

☞

Slidetheoperator

(C)

ontotheshaft(B).

☞

Slidethecounterbearing(D)ontotheshaft(B).

☞

Fix

theshaft(B)withtheoperator

(C)

and counter

bearing(D)to thebrackets(E).

Roll-Up

Door

Operator

/

MDF

/

Rev.

0.0

–

5

5.

Installation

5.3

Installation

of

the

emergency

hand

chain

(only

for

operators

with

emergency

hand

chain)

Information:

To

ensure

thattheyworkcorrectly,thechain

linksmustnot

be

twisted.

6.

Initial

Operation

6.1

Preparation

Warning!

To

avoid

damage

totheoperator,the

followingpointsmust

be

observed:

-

The

typesof cableand theirdiametersmust

be

selectedaccordingto currentregulations.

-

The

nominalcurrentsand thetypeof

connectionmustcorrespondto thoseon the

motortypeplate.

-

The

drivedetailsmustagreewiththe

connectedloads.

Information:

When

operatedwithelectroniccontrolunits,

thecorrespondingstart-up instructionsand

circuitdiagramsmust

be

compliedwith.

☞

Jointhe

ends

of the

emergency

hand chaintogetherwith

thechainconnectinglink.

Warning!

To

avoid

damage

totheoperatorand the

door,the

emergency

hand chainmust

be

secured

whilethedoor isoperatedelectrically.

6

–

Roll-Up

Door

Operator

/

MDF

/

Rev.

0.0

GB

6.2

Connection

of

model

MDF

05

Open

the

operator

Danger!

To

avoidinjury,the

system

must

be

discon-

nectedfromthepowersupplyduringthe

cablingwork.

The

system

must

be

safeguard-

ed

againstbeingunintentionallyswitchedon

againduringthework.

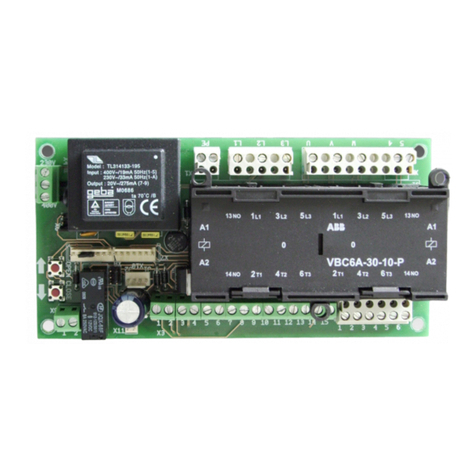

6.3

Connection

of

model

MDF

20

and

subsequent

models

Insert

the

cables

Danger!

To

avoidinjury,the

system

must

be

discon-

nectedfromthepowersupplyduringthe

cablingwork.

The

system

must

be

safeguard-

ed

againstbeingunintentionallyswitchedon

againduringthework.

☞

Remove

thecoverfromtheoperator.

Attach

the

cable

☞

Insertthecablesetplugintothelimitswitchcircuitboard.

☞

Connectup theoperatoraccordingto theelectricalwiring

diagramsbelow.

☞

Screw

on thecablesetholdingplate.

☞

Inserttheplugintothecircuitboard.

☞

Connectup theoperatoraccordingto theelectricalwiring

diagramsbelow.

☞

Replace

thecoverovertheoperator.

Roll-Up

Door

Operator

/

MDF

/

Rev.

0.0

–

7

6.

Initial

Operation

Close

the

operator

3

x

400

V

star

connection

(standard,

pluggable)

The

motoris factory-wiredforconnectionto

a

3

x

400

V

mainssupplyin starconnection.

☞

Place

the

cap

on theoperator.

☞

Screw

the

cap

on tightly.

A

B

C

D

E

☞

Place

thecoveroverthecap.

☞

Screw

thecoveron tightly.

F

G

☞

Connectallthecablesrequired.

8

–

Roll-Up

Door

Operator

/

MDF

/

Rev.

0.0

GB

Identification

of

wires

U1

Red

V1

Blue

W1

White

V2

Black

W2

Brown

U2

Green

A

Potential-freeconnection

OPEN

B

Potential-freeconnection

CLOSE

C

Switchoffsafetycircuit

D

Switchoff

OPEN

end position

E

Switchoff

CLOSED

end position

F

Internalsafetycircuit

G

Operator

S1

Additionallimitswitch,

OPEN

(standardonlyfor

operatorswithoutintegratedcontrolunit)

S2

Limitswitch,

OPEN

S3

Safetylimitswitch,

OPEN

S4

Safetylimitswitch,

CLOSED

S5

Limitswitch,

CLOSED

S6

Additionallimitswitch,

CLOSED

(standardonlyfor

operatorswithoutintegratedcontrolunit)

S7

Safetylimitswitchfor

emergency

manualoperation

F2

Thermal

overloadprotectionformotor

3

x

400

V

star

connection

1

4

2

S1

OPEN

additionallimit

switch(standardonlyin

the

case

of operators

withoutintegratedcontrol

unit)

S2

Limitswitch,

OPEN

S3

Safetylimitswitch,

OPEN

S4

Safetylimitswitch,

CLOSE

S5

Limitswitch

CLOSED

S6

CLOSED

additionallimit

switch(standardonly

in the

case

of operators

withoutintegratedcontrol

unit)

3

x

230

V

delta

connection

To

connecttheoperatorto

a

3

x

230

V

mainssupply,please

consultthemanufacturer.

Roll-Up

Door

Operator

/

MDF

/

Rev.

0.0

–

9

6.

Initial

Operation

6.4

Manual

settings

for

model

MDF

05

The

locking

screw

(H)is

used

to lockthecorresponding

control

cam

in thedesiredposition.Fineradjustment

can

be

A

BC

D

E

F

made

withthefineadjustment

screw

(G).

Set

the

CLOSED

end

position

A

Control

cam

foradditionallimitswitch,

OPEN

(green)

B

Control

cam

forlimitswitch,

OPEN

(green)

C

Control

cam

forsafetylimitswitch,

OPEN

(red)

D

Control

cam

forsafetylimitswitch,

CLOSED

(red)

E

Control

cam

forlimitswitch,

CLOSED

(white)

F

Control

cam

foradditionallimitswitch,

CLOSED

(white)

☞

Drivethedoor to the

CLOSED

end position.

☞

Set

thecontrol

cam

so

thatthe

CLOSED

limitswitch

(E)

is

actuated.

☞

Tightenthelocking

screw

(H).

The

CLOSED

safetylimitswitch(D)must

be

setin

such

a

way

thatit switchesimmediatelywhenthe

CLOSED

limitswitch

(E)

is

passed

over.

☞

Adjustthe

CLOSED

safetylimitswitch(D).

Set

the

OPEN

end

position

☞

Drivethedoor to the

OPEN

end position.

☞

Set

thecontrol

cam

so

thatthe

OPEN

limitswitch(B)is

actuated.

☞

Tightenthelocking

screw

(H).

The

OPEN

safetylimitswitch

(C)

must

be

setin

such

a

way

thatit switchesimmediatelywhenthe

OPEN

limitswitch(B)

is

passed

over.

☞

Adjustthe

OPEN

safetylimitswitch(C).

H

G

G

Fine

adjustment

screw

H

Locking

screw

Each

control

cam

has

a

locking

screw

(H)and

a

fineadjust-

ment

screw

(G).

10

–

Roll-Up

Door

Operator

/

MDF

/

Rev.

0.0

GB

6.5

Manual

settings

for

model

MDF

20

and

subsequent

models

A

B

C

D

E

F

A

Control

cam

foradditionallimitswitch,

OPEN

(green)

B

Control

cam

forlimitswitch,

OPEN

(green)

C

Control

cam

forsafetylimitswitch,

OPEN

(red)

D

Control

cam

forsafetylimitswitch,

CLOSED

(red)

E

Control

cam

forlimitswitch,

CLOSED

(white)

F

Control

cam

foradditionallimitswitch,

CLOSED

(white)

H

G

G

Fine

adjustment

screw

H

Locking

screw

Each

control

cam

has

a

locking

screw

(H)and

a

fineadjust-

ment

screw

(G).

The

locking

screw

(H)is

used

to lockthecorresponding

control

cam

in thedesiredposition.Fineradjustment

can

be

made

withthefineadjustment

screw

(G).

I

Use

theadjustingtool(I)to tunethefineadjustment

screw

and thelockingscrew.

Set

the

CLOSED

end

position

☞

Drivethedoor to the

CLOSED

end position.

☞

Set

thecontrol

cam

so

thatthe

CLOSED

limitswitch

(E)

is

actuated.

☞

Tightenthelocking

screw

(H).

The

CLOSED

safetylimitswitch(D)must

be

setin

such

a

way

thatit switchesimmediatelywhenthe

CLOSED

limitswitch

(E)

is

passed

over.

☞

Adjustthe

CLOSED

safetylimitswitch(D).

Set

the

OPEN

end

position

☞

Drivethedoor to the

OPEN

end position.

☞

Set

thecontrol

cam

so

thatthe

OPEN

limitswitch(B)is

actuated.

☞

Tightenthelocking

screw

(H).

The

OPEN

safetylimitswitch

(C)

must

be

setin

such

a

way

thatit switchesimmediatelywhenthe

OPEN

limitswitch(B)

is

passed

over.

☞

Adjustthe

OPEN

safetylimitswitch(C).

Roll-Up

Door

Operator

/

MDF

/

Rev.

0.0

–

11

AVE

(absolute

value

encoder)

plug

terminal

(7-12)

6.

Initial

Operation

6.6

Digital

settings

–

Limit

switch

and

safety

circuit

for

drive

Electronic

interface

A

B

A:

AVE

plug(absolutevalueencoderplug)

B:

AVE

plugterminal(absolutevalueencoderplug

terminal)

Information:

Please

referto thecontrolunitoperating

manualforinstructionson settingtheend

positions.

Wiring

allocation,

AVE

(absolute

value

encoder)

plug

The

numbers

on theplugarealsothewire-numbers.

4:

Safetycircuitinput

5:

RS

485

B

6:

GND

7:

RS485

A

8:

Safetycircuitoutput

9:

7...18V

DC

C:

Thermal

elementin thedrive

D: Manual

emergency

control

(emergency

crankor

emergency

chain)

12

–

Roll-Up

Door

Operator

/

MDF

/

Rev.

0.0

7.

Emergency

operation

GB

6.7

Check

the

system

Check

the

direction

of

travel

☞

Drivethedoor in the

CLOSED

direction.

The

operatormustclosethedoor.

☞

Drivethedoor in the

OPEN

direction.

The

operatormustopenthedoor.

Information:

If thedirectionof travelof thedoor

does

not

correspondto the

commands

keyed

in,then

thedirectionof rotationmust

be

changed.

Instructionsforchangingthedirectionof

rotationaregivenin thecontrolunitoperating

manual.

Afterthisthedirectionof travelmust

be

checked

again.

Check

the

limit

switch

settings

☞

Drivethedoor to the

CLOSED

end position.

The

operatormuststopin thedesiredposition.

☞

Drivethedoor to the

OPEN

end position.

The

operatormuststopin thedesiredposition.

☞

Check

theseatof thefixing

screws.

Check

the

mechanical

functions

Afterassemblingand installingallcomponentsthefunctions

of the

system

must

be

checked.

☞

Check

allthefunctionsof thesystem.

☞

Check

thattheoperatorrunssmoothly.

☞

Check

whethertheoperatorisleakingoil.

If theoperator

makes

unusualnoisesor leaksoil:

-

The

operatormust

be

takenout of serviceimmediately,

-

The

customerservicemust

be

informed.

Danger!

To

avoidinjury,thefollowingpointsmust

be

observed:

-

Emergency

operation

may

only

be

carried

out from

a

safestandingposition.

-

Emergency

operation

may

only

be

carried

out whenthemotoris stationary.

-

The

system

must

be

disconnectedfromthe

powersupplyduring

emergency

operation.

-Operatorswith

a

springbrakemust

be

actuatedagainsttheclosedbrakewhen

openingor closingthedoor.

-

For

safetyreasons,

brakes

in doorswithout

a

weightcounterbalancemustonly

be

ventedin thecloseddoor positionfortesting

purposes.

-Accidentalventingof thebrakemust

be

renderedimpossible

by

preventive

measures

at theinstallationsite.

Duringmaintenanceworksor in the

case

of an electricalfault,

thedoor

can

be

moved

towardsthe

OPEN

or

CLOSED

posi-

tionswiththehelpof the

emergency

operationequipment.

Information:

If thedoor is

moved

beyondthe

CLOSED

or

OPEN

end positions,theoperator

can

no

longer

be

activatedelectrically.

Roll-Up

Door

Operator

/

MDF

/

Rev.

0.0

–

13

7.

Emergency

operation

Operation

with

emergency

hand

crank

Operation

with

emergency

hand

chain

☞

Push

the

emergency

hand crankintotheoperator

as

far

as

it

will go.

The

controlvoltagewill

be

interruptedand thedoor

can

no longer

be

operatedelectrically.

☞

Move

thedoorin the

OPEN

or

CLOSE

direction

by

turning

the

emergency

hand crank.

☞

Remove

the

emergency

hand crankfromtheoperator

aftercompleting

emergency

manualoperation.

The

control

voltagewill

be

switchedon againand thedoor

can

be

operatedelectrically.

Releasing

☞

Gentlypullthechainwiththeredhandledownwards

as

far

as

possible.

The

controlvoltagewill

be

interruptedand the

door

can

no longer

be

operatedelectrically.

☞

Release

the

emergency

hand chainfromitsfixing.

☞

Move

thedoorin the

OPEN

or

CLOSE

direction

by

pullingon

the

emergency

hand chainon thesideconcerned.

Locking

☞

Gentlypullthechainwiththegreenhandledownwards

as

far

as

possible.

The

controlvoltagewill

be

switchedon again

and thedoor

can

be

operatedelectrically.

☞

Attachthe

emergency

hand chainto itsfixing.

The

door

can

now

be

moved

withtheoperator.

14

–

Roll-Up

Door

Operator

/

MDF

/

Rev.

0.0

8.

Maintenance

Warning!

To

avoid

damage

totheoperatorand door,

thefollowingpointsmust

be

observed:

-Maintenancemustonly

be

carriedout

by

authorizedpersons.

-Directive

BGR

232 must

be

compliedwith.

-

Worn

or faultypartsmust

be

replaced.

-Onlyapprovedparts

may

be

installed.

Allmaintenanceworkmust

be

documented.

Information:

The

driveunit

has

lifetimelubricationand is

maintenance-free.

☞

Check

thatallmountings

have

been

securelytightened.

☞

Check

thebrake(ifavailable).

☞

Check

thelimitswitchesand safetyswitches.

☞

Check

fornoisesand oil leaks.

☞

Check

themountingof theoperatorforcorrosion.

☞

Check

thehousingfor

damage.

GB

Roll-Up

Door

Operator

/

MDF

/

Rev.

0.0

–

15

9.

Technical

data

Type

(KU

/

KE):

MDF

05-10-15

KU

MDF

05-10-15

KE

MDF

05-14-12

KU

MDF

05-14-12

KE

MDF

20-22-12

KU

MDF

20-22-12

KE

MDF

20-15-17

KU

MDF

20-15-17

KE

MDF

20-15-12

KU

100%

MDF

20-15-12

KE

100%

MDF

20-10-17

KU

100%

MDF

20-10-17

KE

100%

Drivingtorque(Nm): 100 /140 220 /150 150 /100

Maximum

safetycatchtorque 692

1188

1188

(Nm):

Permissible

torque(Nm): 151 259 259

Drivingmotor

speed

(min-1): 15 /12 12 /17 12 /17

Motoroutput(kw): 0.37 0.75 0.55

Operatingvoltage(V): 400 /3~ 400 /3~ 400 /3~

Mainsfrequency

Hz:

50 50 50

Controlvoltage:(V): 24 24 24

Nominalmotorcurrent(A): 2.1 2.8/2.6 1,8/1.7

Motorduty

cycle

(%): 60 60 100

Cable

on site

(mm

2): 5

x

1.5 5

x

1.5 5

x

1.5

Fuse

protectiononsite(A): 10.0 10.0 10.0

Protectiontype(IP) 54 54 54

Temperature

range(°C): -20 /+60 -20 /+60 -20 /+60

Continuous

sound

pressure

level <70

<70

<70

(dB

(A)):

Weightper piece(kg): 22 /25 20 /23 /20 /23 22

Maximum

number

of 13

18

18

revolutionsof drivenshaft:

Hollowshaft(mm): 30 30 30

16

–

Roll-Up

Door

Operator

/

MDF

/

Rev.

0.0

GB

Type

(KU

/

KE):

MDF

30-42-12

KU

MDF

30-42-12

KE

MDF

30-29-17

KU

MDF

30-29-17

KE

MDF

30-27-12

KU

100%

MDF

30-27-12

KE

100%

MDF

30-19-17

KU

100%

MDF

30-19-17

KE

100%

MDF

30-50-12

KU

MDF

30-50-12

KE

MDF

30-45-15

KU

MDF

30-45-15

KE

MDF

30-30-12

KU

MDF

30-30-12

KE

Drivingtorque(Nm): 420 /290 270 /190 500 /450 300

Maximum

safetycatchtorque 1833

1833

1982

1188

(Nm):

Permissible

torque(Nm): 432 432 503 432

Drivingmotor

speed

(min-1): 12 /17 12 /17 12 /15 12

Motoroutput(kw): 1.1 0.75 1.1/1.3 1.1

Operatingvoltage(V): 400 /3~ 400 /3~ 400 /3~ 400/3~

Mainsfrequency

Hz:

50 50 50 50

Controlvoltage:(V): 24 24 24 24

Nominalmotorcurrent(A): 5.1/3.3 2.1/1.9 4.5/4.3 3.6

Motorduty

cycle

(%): 60 100 60 60

Cable

on site

(mm

2): 5

x

1.5 5

x

1.5 5

x

1.5 5

x

1.5

Fuse

protectiononsite(A): 10.0 10.0 10.0 10.0

Protectiontype(IP) 54 54 54 54

Temperature

range(°C): -20 /+60 -20 /+60 -20 /+60 -20 /+60

Continuous

sound

pressure

level <70

<70

<70

<70

(dB

(A)):

Weightper piece(kg): 27 /32 /27 /32 30 /35 /30 /35 29 /33 23 /26

Maximum

number

of 18

18

18

18

revolutionsof drivenshaft:

Hollowshaft(mm): 40 40 40 30

Roll-Up

Door

Operator

/

MDF

/

Rev.

0.0

–

17

9.

Technical

data

Type

(KU

/

KE):

MDF

50-65-10

KU

MDF

50-65-10

KE

MDF

50-75-10

KU

MDF

50-75-10

KE

MDF

6-100-9

KU

MDF

6-100-9

KE

MDF

6-100-9

KU

100%

Drivingtorque(Nm): 650 750 1000 1000

Maximum

safetycatchtorque 3494

3494

5599

5599

(Nm):

Permissible

torque(Nm): 763 763 1113 1113

Drivingmotor

speed

(min-1): 10 /16 10 /16 99

Motoroutput(kw): 1.2/1.8 1.4/2.1 1.5 1.5

Operatingvoltage(V): 400 /3~ 400 /3~ 400 /3~ 400 /3~

Mainsfrequency

Hz:

50 50 50 50

Controlvoltage:(V): 24 24 24 24

Nominalmotorcurrent(A): 4.2/4.0 5.8/5.6 6.1 6.1

Motorduty

cycle

(%): 60 60 60 60

Cable

on site

(mm

2): 5

x

1.5 5

x

1.5 5

x

1.5 5

x

1.5

Fuse

protectiononsite(A): 10.0 10.0 10.0 10.0

Protectiontype(IP) 54 54 54 54

Temperature

range(°C): -20 /+60 -20 /+60 -20 /+60 -20 /+60

Continuous

sound

pressure

level <70

<70

<70

<70

(dB

(A)):

Weightper piece(kg): 33 /37 33 /37 67 /72 67 /72

Maximum

number

of 36

36

36

36

revolutionsof drivenshaft:

Hollowshaft(mm): 50 50 50 50

18

–

Roll-Up

Door

Operator

/

MDF

/

Rev.

0.0

GB

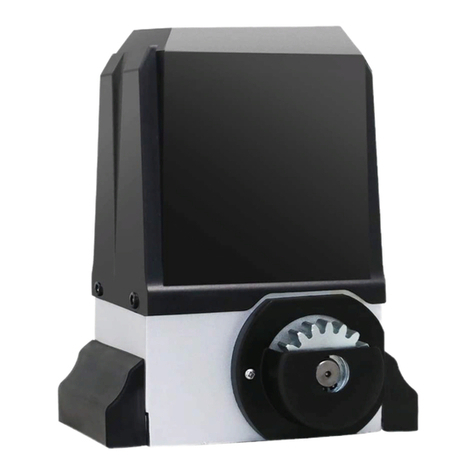

MDF

05-10-15

KU

(Crank)

MDF

05-14-12

KU

(Crank)

MDF

05-10-15

KE

(Chain)

MDF

05-14-12

KE

(Chain)

Roll-Up

Door

Operator

/

MDF

/

Rev.

0.0

–

19

9.

Technical

data

MDF

20-22-12

KU

(Crank)

MDF

20-15-17

KU

(Crank)

20

–

Roll-Up

Door

Operator

/

MDF

/

Rev.

0.0

This manual suits for next models

31

Table of contents

Other MFZ Ovitor Gate Opener manuals