MFZ Ovitor CS 300 RM User manual

Operating Instructions for CS 300 RM Controls EN

CS 300 RM Gate Controls Rev. B 1.0 – 1

2 – CS 300 RM Gate Controls / Rev. B 1.0

1. Contents 3. General safety instructions

2. Key to symbols

Original operating instructions

−Protected by copyright.

−No part of this manual may be reproduced without our

prior approval.

−Subject to alterations in the interest of technical progress.

−All dimensions are given in millimetres.

−The diagrams in this manual are not to scale.

Guarantee

The function and safety of the equipment is only guaranteed

if the warning and safety instructions included in these opera-

ting instructions are adhered to.

MFZ Antriebe GmbH + Co. KG is not liable for personal injury

or damage to property if these occur as a result of the war-

nings and safety advice being disregarded.

Using the equipment for its intended purpose

The CS 300 RM control unit is intended exclusively for the

purpose of controlling tubular drives that have mechanical

limit switch systems.

Target group

Only qualied and properly trained electricians are allowed to

connect up, programme or service the control unit.

Qualied and trained electricians must have the following:

− Knowledge of the general and specic safety and accident-

prevention regulations

−Knowledge of the relevant electrical regulations

−Training in the use and care of appropriate safety equip-

ment

−The ability to recognise the risks associated with electricity

Instructions relating to installation and connection

−Before commencing electrical works, the system must be

disconnected from the power supply. Measures must be

taken to ensure that the power supply remains switched off

for the duration of the works.

−The local safety regulations must be observed.

−Power cables must be laid separately from control cables.

Danger of personal injury!

The safety instructions must be observed!

Warning! Danger to property!

The safety instructions must be observed!

Information

Special information

OR

Reference to other sources of information

1. Contents 2

2. Key to symbols 2

3. General safety instructions 2

4. Overview of products 3

5. Initial operation 5

6. Programming with the LED module 10

7. Programming with the LCD monitor 12

8. Navigator (LCD monitor only) 14

9. Overview of functions 16

10. Error messages and rectication 23

11. Technical data 24

12. EC Declaration of Incorporation 25

13. Appendix 26

EN

CS 300 RM Gate Controls / Rev. B 1.0 – 3

Regulations and test specications

The following regulations must be complied with when

connecting, programming or servicing the unit. (The list is not

exhaustive.)

Construction product standards

− EN 13241-1 (Products without re resistance or smoke

control characteristics)

−EN 12445 (Safety in use of power operated doors -

Test methods)

−EN 12453 (Safety in use of power operated doors -

Requirements)

−EN 12978 (Safety devices for power operated doors and

doors - Requirements and test methods)

EMC

−EN 55014-1 (Electromagnetic compatibility - Requirements

for household appliances)

−EN 61000-3-2 (Limits for harmonic current emissions )

− EN 61000-3-3 (Limitation of voltage changes, voltage uc-

tuations and icker in public low-voltage supply systems)

−EN 61000-6-2 (Electromagnetic compatibility (EMC) - Part

6-2: Generic standards - Immunity for industrial environ-

ments)

−EN 61000-6-3 (Electromagnetic compatibility (EMC) - Part

6-3: Generic standards - Emission standard for residential,

commercial and light-industrial environments)

Machinery Directive

−EN 60204-1 (Safety of machinery, electrical equipment of

machines, Part 1: General requirements)

−EN 12100-1 (Safety of machinery - Basic concepts, general

principles for design, Part 1: Basic terminology, methodo-

logy)

Low voltage

−EN 60335-1 (Household and similar electrical appliances -

Safety)

−EN 60335-2-103 (Particular requirements for drives for

gates, doors and windows)

Committee for Workplaces (Ausschuss für Arbeitsstätten -

ASTA)

−ASR A1.7 (Technical Regulations for workplaces - Doors

and gates)

4.1 Various options

The following package options are available for the CS 300

RM controls:

−CS 300 RM control unit with LCD monitor

−CS 300 RM control unit with LCD monitor in housing

−CS 300 RM control unit with LED module for setting the

OPEN and CLOSED door positions (no further settings are

possible).

−CS 300 RM control unit without LED module and without

LCD monitor (a module or monitor is required for adjusting

the settings)

All the above options can be tted with a plug-in weekly

timer (switch clock) and a plug-in radio receiver.

The following options are available for the housing:

−Housing unit with 3-button input unit CS

−Housing unit with 3-button input unit KDT

−Housing with ON/OFF key switch

−Housing with mains switch

−Housing with emergency off button

The operating instructions describe the connection options

and programming procedures for the following models:

−CS 300 RM control unit with LED board

−CS 300 RM control unit with attached LCD display board

4. Overview of products

4 – CS 300 RM Gate Controls / Rev. B 1.0

4. Overview of products

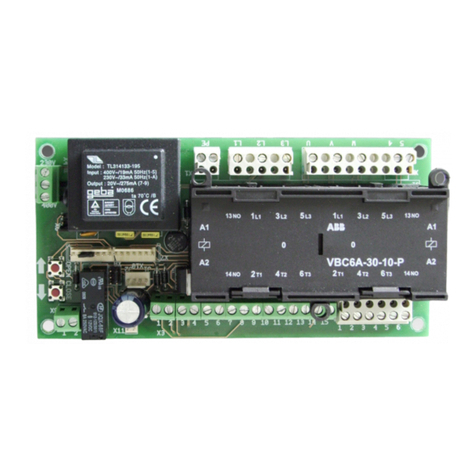

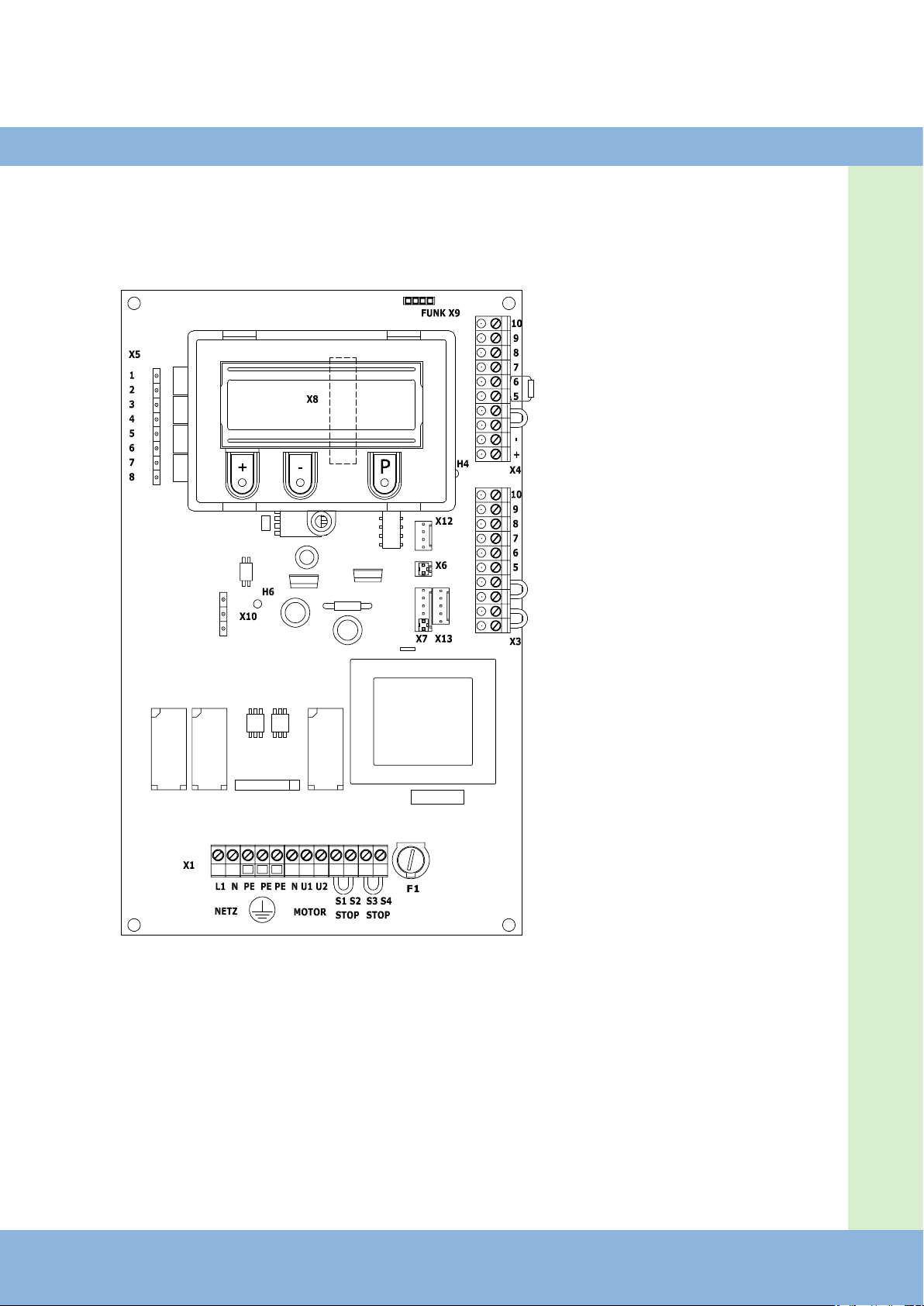

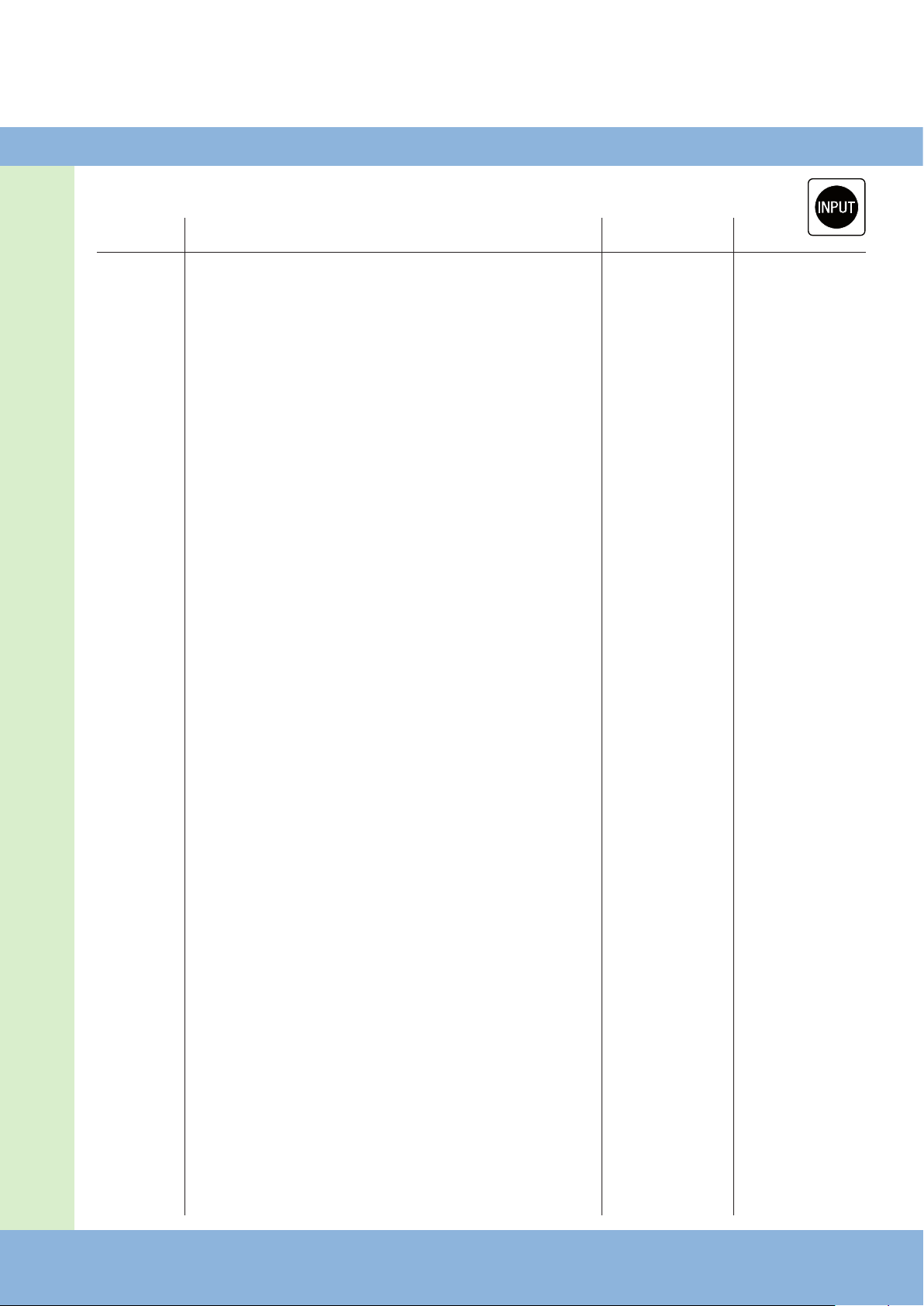

4.2 CS 300 RM main board

(with attached LCD display monitor)

Key:

X1: terminal block for mains

connection / motor

X3: terminal block for command

devices

X4: terminal block

safety devices / before-end

switch

X5: terminal block

relay

X6: terminals for internal ON-

OFF switch

X7: terminals for internal 3-but-

ton input unit

X8: socket for monitor

(under monitor)

X9: terminals for

radio receiver

X10: terminals for weekly timer

(switch clock)

X12: socket for external radio

receiver

X13: terminals for

CS 3-button input unit

H4: status display for safety edge

protection (SKS) – illumina-

ted when SKS is working

H6: Safety circuit status message

– lights up when the safety

circuit is closed

F1: 4A fuse

EN

CS 300 RM Gate Controls / Rev. B 1.0 – 5

5. Initial operation

5.1 General

Warning!

To guarantee that the equipment functions

properly, the following points must be

ensured:

The door is installed and operational.

- The MFZ tubular drive is installed and ready

for operation.

- The command and safety devices are instal-

led and ready for operation.

- The control housing with the CS 300 RM

control unit is installed.

Information:

For the installation of the gate/door, the MFZ

geared motor and the command and safety

devices, the relevant manufacturer’s instruc-

tions are to be adhered to.

5.2 Mains connection

Danger!

To ensure that the control unit functions pro-

perly, the following conditions must apply:

- The supply voltage must correspond to the

voltage shown on the type plate.

- The supply voltage must correspond to the

voltage of the door operator.

- If a permanent connection is to be made, an

all-pole mains switch must be installed.

Warning!

Before switching on the control unit for the

rst time, check to ensure that the cabling

works are complete and that all the motor

connections are secure at both the motor and

the control unit. All control voltage inputs are

separated galvanically from the mains power

supply.

6 – CS 300 RM Gate Controls / Rev. B 1.0

5. Initial operation

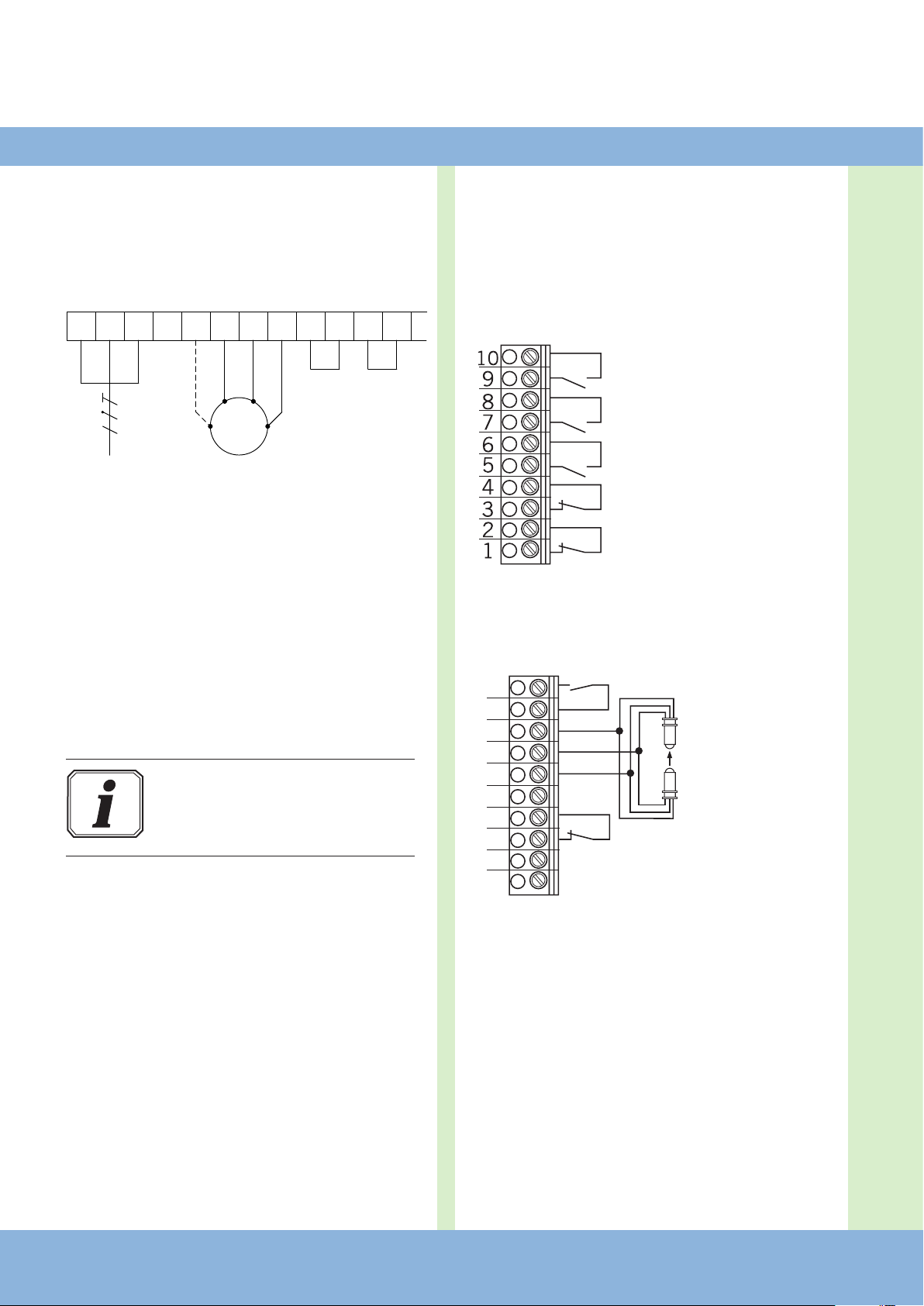

5.3 Assignment of connections for the motor

and the power supply

(terminal X1)

Terminal block X1

L1 N PE PE PE N U1 U2 S1 S2 S3 S4

M

230V / 1PH

230V / 1PH

S1-S4

Connection of mains switch (optional)

Connection:

Connect the control unit to the mains.

Connect the control unit to the motor.

Cable groups must be secured in place with a cable tie close

to their terminals.

Information:

Technical data, see page 24.

5.4 Assignment of connections for command

and safety devices

Command and safety devices can be connected to terminals

X3, X4 and X5.

Terminal block X3

- CLOSE button

- impulse button 1

- OPEN button

- STOP button

- Emergency off, slack rope switch,

wicket door contact, draw-in

protection

Terminal block X4

(for optoelectronic safety edge protection)

Part OPEN2

- safety edge protection

OPTO

- drive-through light

barrier3

- 24 V DC / 250 mA4

1 sequence control

2 button or selector switch

3 effective in down direction

4

for external switching devices (connection to terminals 1

and 2)

wt: white

gr: green

br: brown

1

2

3

4

5

6

7

8

9

10

+

-

wt

gr

br

EN

CS 300 RM Gate Controls / Rev. B 1.0 – 7

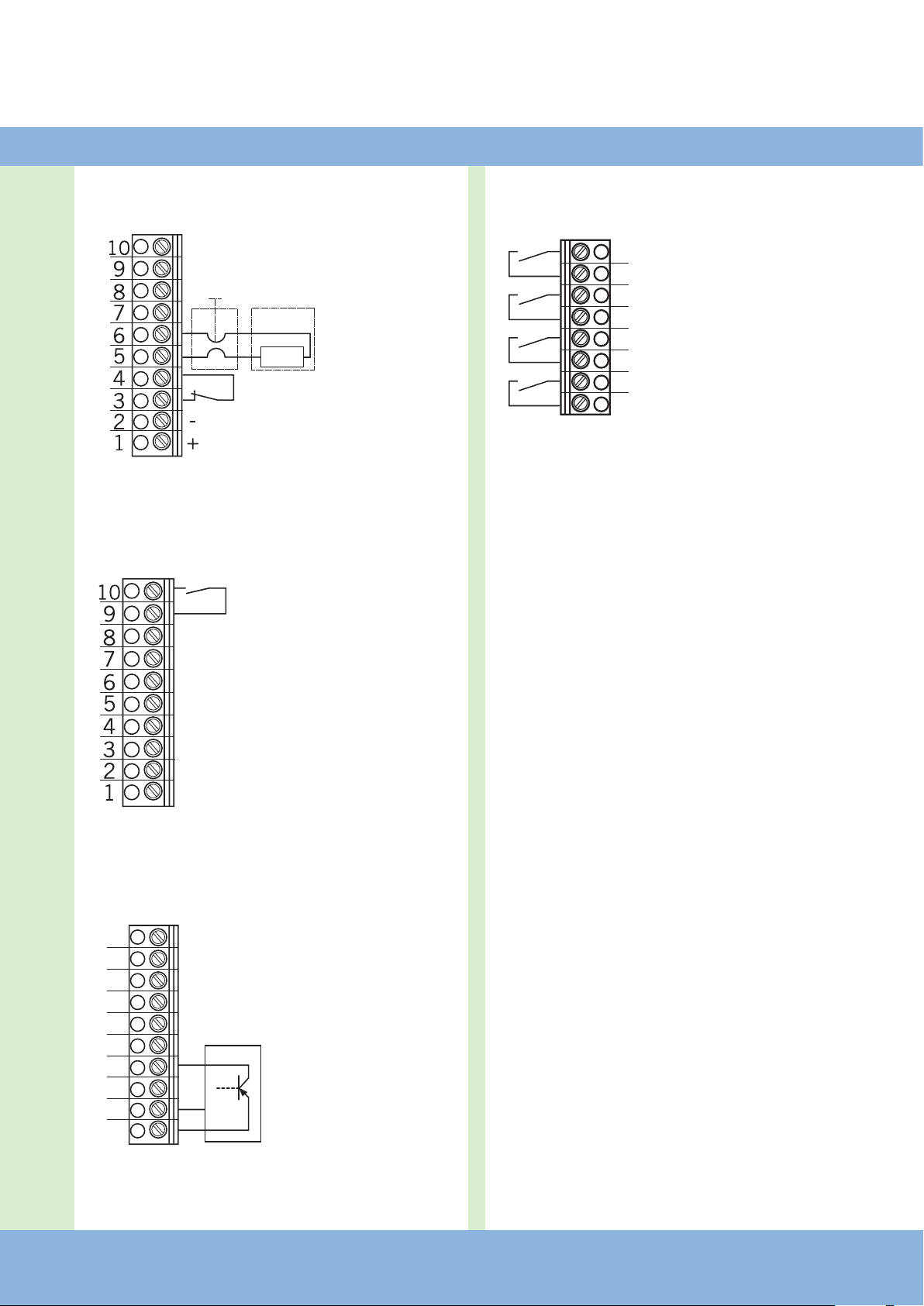

Terminal block X4

(for 8.2 kOhm safety edge protection)

- safety edge protec-

tion

- drive-through light

barrier -3

- 24 V DC / 250 mA4

Klemmleiste X4

(mit Vorendschalter für Reversierabschaltung)

- before-end switch

NO

Terminal block X4

(for 3-wire light barrier)

- 3-wire light barrier

Terminal block X5

(potential-free switch contacts)

- relay 1

- relay 2

- relay 3

- relay 4

8k2

1

2

3

4

5

6

7

8

9

10

24V

GND

1

2

3

4

5

6

7

8

8 – CS 300 RM Gate Controls / Rev. B 1.0

5. Initial operation

Key switch OPEN / CLOSE

- CLOSE

- OPEN

Impulse button

(sequence control)

- impulse button

Connection:

Connect any installed command and safety devices to the

control unit.

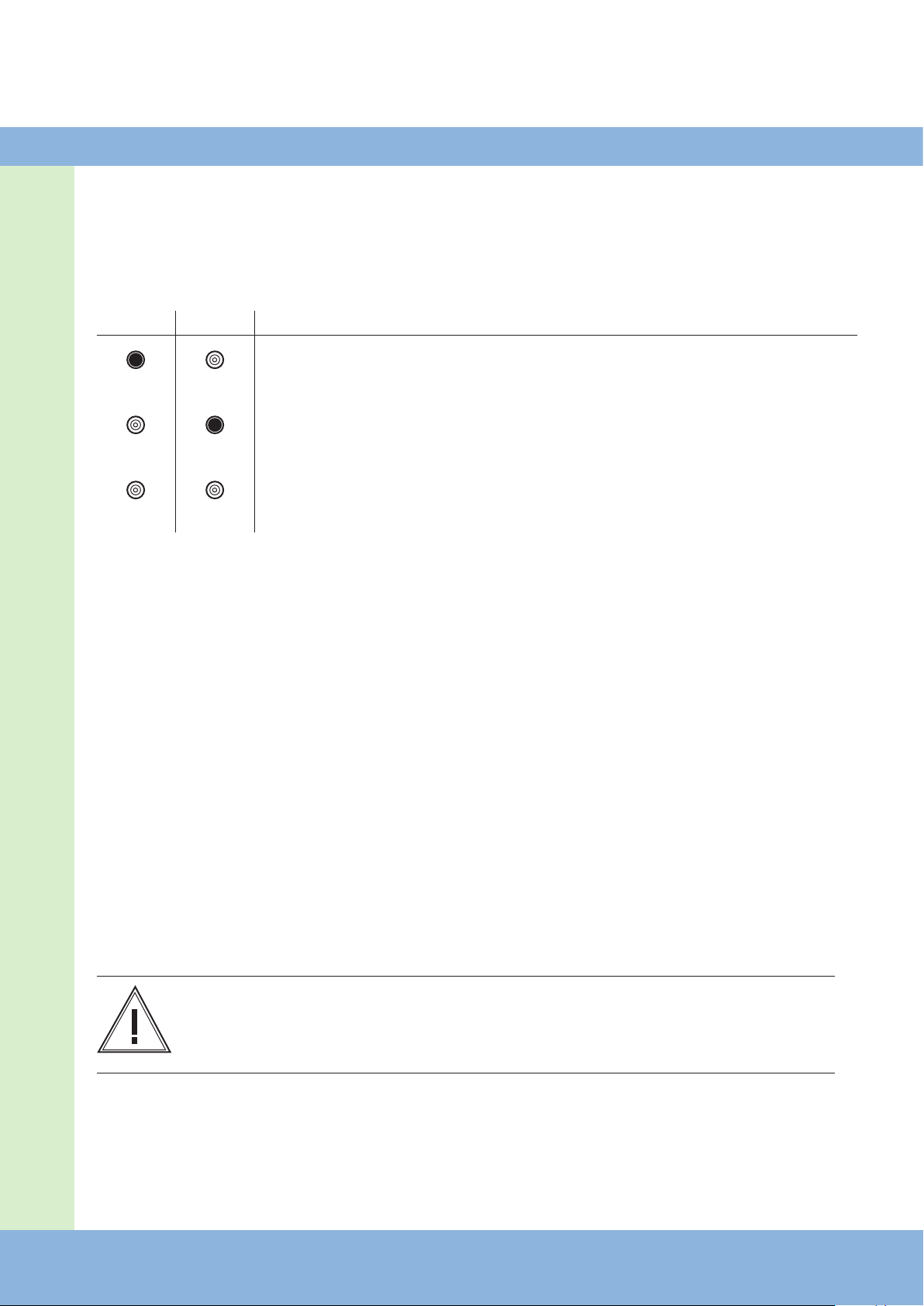

5.5 Connection examples for command and

safety devices (terminal X3)

OPEN / STOP / CLOSE buttons

(6-lead solution)

- CLOSE button

- OPEN button

- STOP button

OPEN / STOP / CLOSE buttons

(4-lead solution)

- CLOSE button

- OPEN button

- STOP button

EN

CS 300 RM Gate Controls / Rev. B 1.0 – 9

10 – CS 300 RM Gate Controls / Rev. B 1.0

6.1 Overview of the LED module

Key:

LED off

LED illuminated

LED ashing

6. Programming with the LED module

6.2 Operating modes of the LED module

With the LED module, the control unit has two modes of operation:

1. AUTOMATIC

2. ADJUSTMENT

Information:

The current mode of operation of the control unit is shown via the LEDs.

- In AUTOMATIC mode, no LEDs ash. The (+) and (-) buttons have no function.

- In the ADJUSTMENT mode, at least one LED ashes. The external buttons have no function.

Pressing the (P) button toggles between the modes of operation.

Operating mode 1: AUTOMATIC

In the AUTOMATIC operating mode the door system is operated automatically.

LED displays:

H1 H2 Status

The door is open. The OPEN limit switch has been reached.

The door is closed. The CLOSED limit switch has been reached.

The door is between end positions. No limit switch has been reached.

The OPEN and CLOSE limit switches have been interrupted

(illogical state = TERM SWITCH FAIL).

EN

CS 300 RM Gate Controls / Rev. B 1.0 – 11

Operating mode 2: ADJUSTMENT

In deadman mode, the OPEN/CLOSED end positions can be set.

LED displays:

H1 H2 Status

The OPEN end position is programmed at this door position.

The CLOSED end position is programmed at this door position.

The CLOSED and OPEN end positions are not programmed at this door position.

6.3 Setting the end positions

Setting the OPEN end position

Change the mode of operation to ADJUSTMENT by pressing the (P) button.

Press the (+) button to drive the door to the desired end position in the OPEN direction.

Adjust the mechanical limit switches.

Change to AUTOMATIC mode by pressing the (P) button.

Setting the CLOSED end position

Change the mode of operation to ADJUSTMENT by pressing the (P) button.

Press the (-) button to drive the door to the desired end position in the CLOSE direction.

Adjust the mechanical limit switches.

Change to AUTOMATIC mode by pressing the (P) button.

Warning!

The door can be damaged if driven beyond the end position.

12 – CS 300 RM Gate Controls / Rev. B 1.0

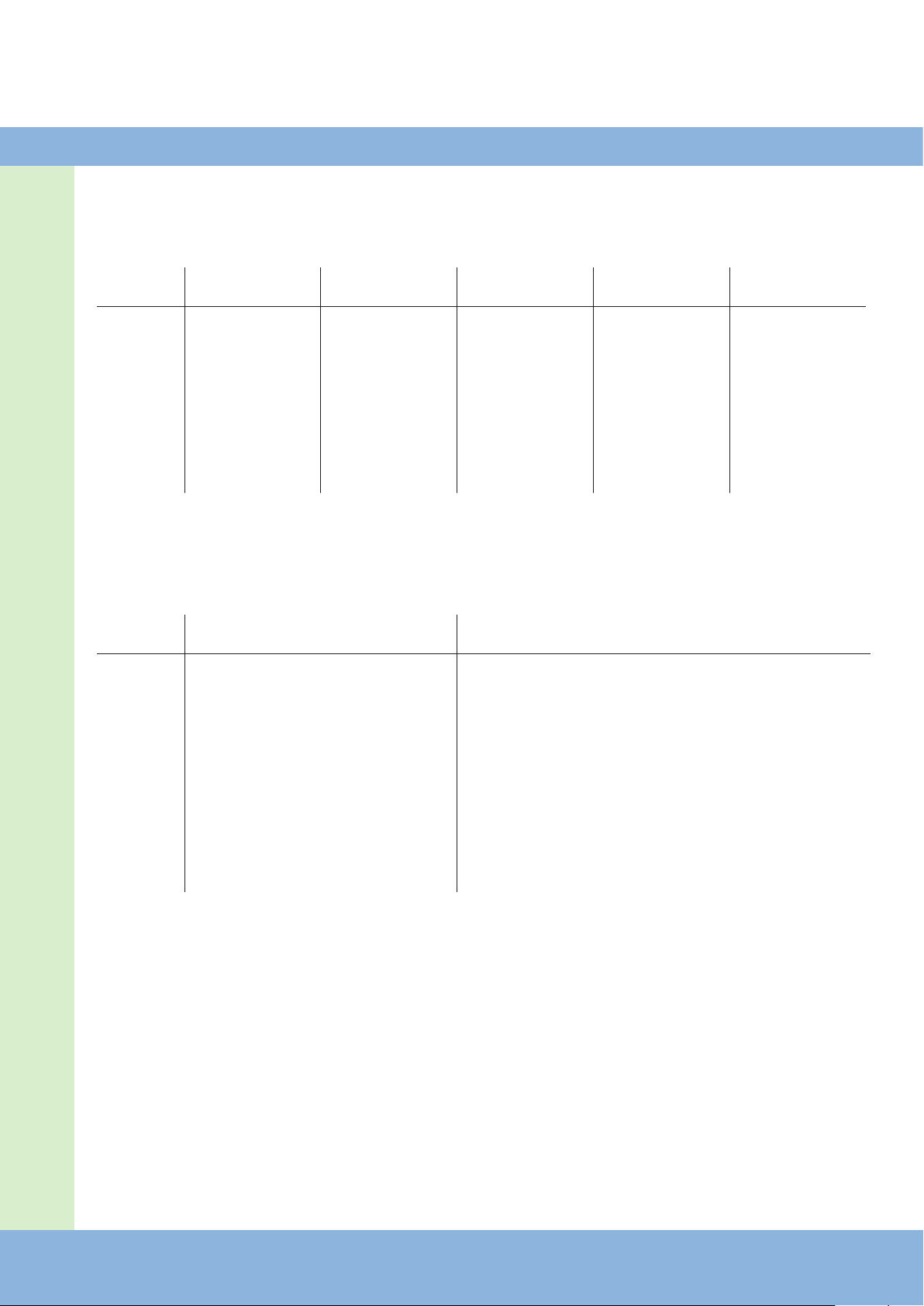

7.1 Overview of the LCD monitor

7. Programming with the LCD Monitor

A

B

C D E

AUTOMATIC

STANDBY

Key:

A: Operating mode /

Diagnosis info

B: Parameters /

Diagnosis info

C: (+) button

D: (-) button

E: (P) button

H: Jumper

H

EN

CS 300 RM Gate Controls / Rev. B 1.0 – 13

7.2 Operating modes of the LCD monitor

The control unit has four modes of operation with the LCD

monitor:

1. AUTOMATIC

2. ADJUSTMENT

3. INPUT

4. DIAGNOSIS

When the jumper H is removed, the

(+) button, the (-) button and the (P) button have no function.

The display still continues to function.

Operating mode 1: AUTOMATIC

In the AUTOMATIC operating mode the door system is opera-

ted automatically.

Display:

- Displays the action being carried out.

- Displays any errors.

If the “self locking” parameter in the Input menu is set to

MOD2 or MOD3, then the display changes from AUTOMATIC

to MANUAL.

The (+) and (-) buttons have no function.

Operating mode 2: ADJUSTMENT

In ADJUSTMENT mode, the door is driven to the OPEN/CLO-

SED end positions in deadman mode and the mechanical limit

switches are set.

Display:

- Displays the operating status

The external buttons have no function.

Operating mode 3: INPUT

In the INPUT operating mode, the values of various parame-

ters can be altered.

Display:

- Displays the selected parameter

- Displays the set value or status

Operating mode 4: DIAGNOSIS

In DIAGNOSIS mode, door-related monitoring can be carried

out.

Display:

- Displays the monitored function

- Displays the status of the function

14 – CS 300 RM Gate Controls / Rev. B 1.0

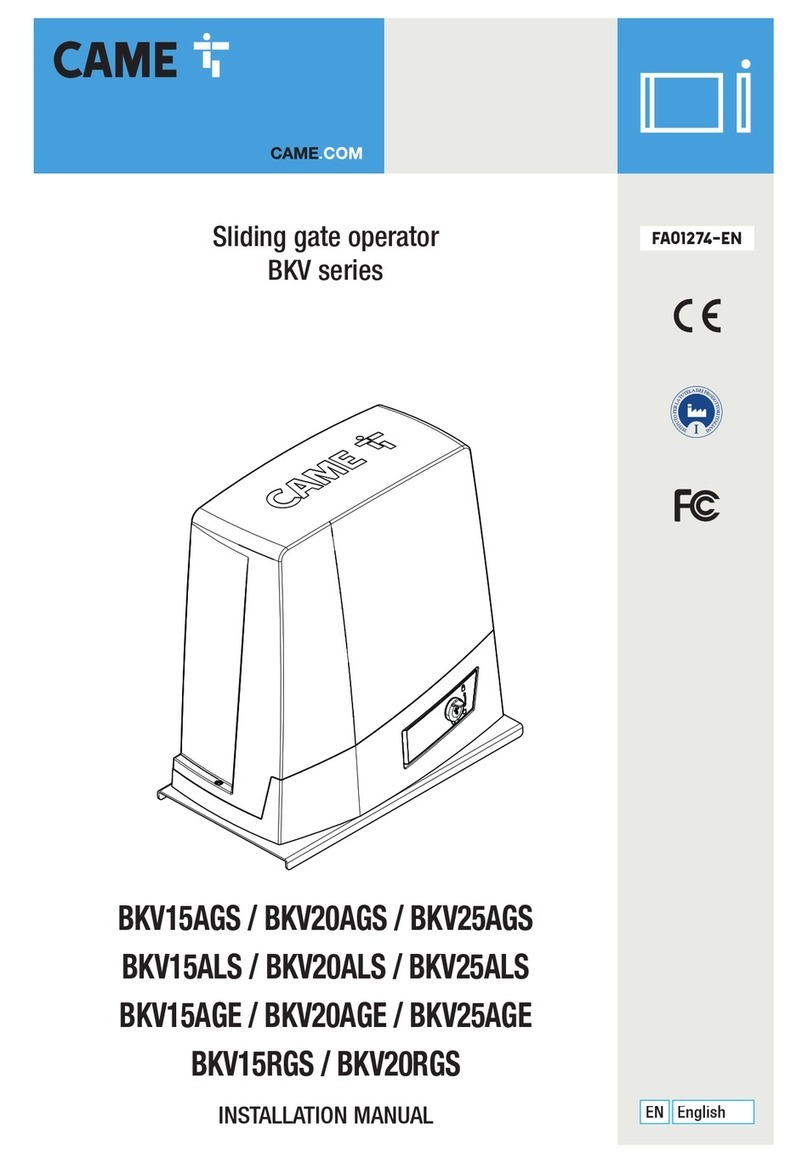

8. Navigator (LCD monitor only )

AUTOMATIC

STANDBY

P

> 1 second

ADJUSTMENT

STANDBY

+

-> Position, DOOR OPEN ADJUSTMENT

MAIN UP Deadman mode

-

-> Position DOOR CLOSED ADJUSTMENT

MAIN DOWN Deadman mode

P

> 1 second

INPUT

+

and

-

> 2 seconds INPUT

DEUTSCH : Scroll up through menu:

+

> 2 sec

Scroll down through menu:

-

> 2 seconds

Select value:

P

> 1 second

Increase value:

+

Decrease value:

-

Save value:

P

Return to mode: INPUT:

+

and

-

> 1 second

INPUT

RUNNINGTIME : 60

P

> 1 second

INPUT

OPEN TIME : 0

INPUT

FOREWARNING : 0

INPUT

REVERS.TIME : 0.3

INPUT

MOD1-3 STANDBY : Mod1

INPUT

FAST CL. : OFF

INPUT

RELAY 1 : Mod6

INPUT

RELAY 2 : Mod7

INPUT

RELAY 3 : Mod1

INPUT

RELAY 4 : Mod14

INPUT

DELAY-UP : OFF

INPUT

SELF LOCK : MOD1

INPUT

SU/WI : MOD1

INPUT

REVERS : MOD1

INPUT

LB OPEN : MOD2

INPUT

LB CLOSE : MOD1

INPUT

SKS LEAD : MOD1

DIAGNOSIS

Scroll up through menu:

+

> 2 seconds

Scroll down through menu:

-

> 2 seconds

Return to mode -AUTOMATIC:

P

Only query is possible

UP-SWITCH : OFF

SECT.-SWITCH : OFF

DOWN-SWITCH : OFF

SKS : ON

IMPULS : OFF

SWITCH CLOCK : OFF

LIGHT BARR : ON

STOP CHAIN : ON

BES-OPEN : ON

BES-CLOSE : ON

CYCLE : 4

EN

CS 300 RM Gate Controls / Rev. B 1.0 – 15

AUTOMATIC

STANDBY

P

> 1 second

ADJUSTMENT

STANDBY

+

-> Position, DOOR OPEN ADJUSTMENT

MAIN UP Deadman mode

-

-> Position DOOR CLOSED ADJUSTMENT

MAIN DOWN Deadman mode

P

> 1 second

INPUT

+

and

-

> 2 seconds INPUT

DEUTSCH : Scroll up through menu:

+

> 2 sec

Scroll down through menu:

-

> 2 seconds

Select value:

P

> 1 second

Increase value:

+

Decrease value:

-

Save value:

P

Return to mode: INPUT:

+

and

-

> 1 second

INPUT

RUNNINGTIME : 60

P

> 1 second

INPUT

OPEN TIME : 0

INPUT

FOREWARNING : 0

INPUT

REVERS.TIME : 0.3

INPUT

MOD1-3 STANDBY : Mod1

INPUT

FAST CL. : OFF

INPUT

RELAY 1 : Mod6

INPUT

RELAY 2 : Mod7

INPUT

RELAY 3 : Mod1

INPUT

RELAY 4 : Mod14

INPUT

DELAY-UP : OFF

INPUT

SELF LOCK : MOD1

INPUT

SU/WI : MOD1

INPUT

REVERS : MOD1

INPUT

LB OPEN : MOD2

INPUT

LB CLOSE : MOD1

INPUT

SKS LEAD : MOD1

DIAGNOSIS

Scroll up through menu:

+

> 2 seconds

Scroll down through menu:

-

> 2 seconds

Return to mode -AUTOMATIC:

P

Only query is possible

UP-SWITCH : OFF

SECT.-SWITCH : OFF

DOWN-SWITCH : OFF

SKS : ON

IMPULS : OFF

SWITCH CLOCK : OFF

LIGHT BARR : ON

STOP CHAIN : ON

BES-OPEN : ON

BES-CLOSE : ON

CYCLE : 4

16 – CS 300 RM Gate Controls / Rev. B 1.0

9. Overview of functions

9.1 Automatic operating mode

Display Description

AUTOMATIC

OPENING PHASE The door is driven to the OPEN end position

AUTOMATIC

CLOSING PHASE The door is driven to the CLOSED end position

AUTOMATIC

STANDBY The door is stationary

Information:

If the “self locking“ parameter in the Input menu is set to MOD2 or MOD3, then the display changes from AUTOMATIC

to MANUAL.

Display Description

MANUAL

MAIN UP The door is driven to the OPEN end position

MANUAL

MAN CLOSE The door is driven to the CLOSED end position

MANUAL

STANDBY The door is stationary

EN

CS 300 RM Gate Controls / Rev. B 1.0 – 17

9.2 Input operating mode

Function Description Possible settings Factory setting

ENGLISH Select the menu language DEUTSCH

ENGLISH

FRANCAIS

ESPANOL

NEDERLANDS

POLSKI

CESKY

ITALIANO

ENGLISH

RUNNING-

TIME

Monitors the maximum running time for an open and close movement 1 – 250 seconds 60 seconds

OPEN TIME After the door has opened, it runs in the CLOSE direction again after the set time has

elapsed.

Open time > 0 = impulse functions only in the OPEN direction

0 – 600 seconds 0 =

Auto close off

FOREWAR-

NING

The trafc light ashes before the door starts to close.

The preset forewarning time is only active if the open time is > 0 or if operated via

radio impulse.

0 – 120 seconds 0 = Off

REVERS.

TIME

Time spent stationary each time the door changes direction

0.1 - 2.0 seconds (in

1/10 second steps)

0.3 seconds

MOD1-3

STANDBY

MOD 1: OFF when resting

MOD 2: ON when resting

MOD1

MOD2

MOD1

FAST CL. ON: The open time is interrupted after a vehicle passes the light barrier (the

door then closes immediately).This function is also active if the open time

is set to 0.

OFF: The open time continues as usual

ON

OFF

OFF

RELAY 1

RELAY 2

RELAY 3

RELAY 4

All 4 relays can have a relay module of 1 to 28 assigned to them.

MOD1: Red trafc light lights up during door movement and ashes as a war-

ning before door movement starts

MOD2: Red trafc light ashes during door movement and as a warning before

door movement starts

MOD3: Red trafc light lights up during door movement and as a warning before

door movement starts

These 3 modes are affected by the parameter M1-3 STANDBY

MOD4: Impulse when OPEN command is given

MOD5: Error message

MOD6: OPEN end position

MOD7: CLOSE end position

MOD8: OPEN end position negated

MOD9: CLOSE end position negated

MOD11: Pre-limit position CLOSE

MOD12: Pre-limit CLOSE position to CLOSE end position

MOD13: Magnetic lock function

MOD14: Brake

MOD15: Brake negated

MOD16: Brake remains ON during open time

MOD17: Safety edge protection (SKS) activated

MOD18: (Red trafc light 4)

Forewarning - ashing

Door movement - off

MOD20: Activation of the optoelectronic transmission system

MOD21: Test of draw-in protection before door opening run (additional module

required)

MOD22: Test of external safety devices before door closing run (additional module

required)

MOD1 – MOD28

MOD1 – MOD28

MOD1 – MOD28

MOD1 – MOD28

MOD6

MOD7

MOD1

MOD14

18 – CS 300 RM Gate Controls / Rev. B 1.0

Function Description Possible settings Factory setting

MOD23: (Green trafc light)

OPEN end position - light on

Forewarning - OFF

Door movement - OFF

MOD25: Yard light function 2 minutes after OPEN command

MOD26: Activation of radio transmission system

MOD27: Impulse signal after end position in the OPEN direction has been

reached.

MOD28: Relay OFF

DELAY-UP ON: Gives forewarning before opening

OFF: Opens immediately

ON

OFF

OFF

SELF LOCK MOD1: Automatic operation

MOD2: Manual operation for OPEN + CLOSE

MOD3: Manual operation for CLOSE

MOD1 - MOD3 MOD1

SU/WI Connection to terminal block X4 (9 + 10)

MOD1: Pre-limit switch CLOSE (N.O.)

MOD6: Activation of automatic closing

Closed: No automatic closing of the door

Open: Automatic closing of the door is active

MOD7: External input for timer (switch clock)

The door opens as soon as the contact closes and then remains at the

OPEN position until the contact opens. The door then closes automatical-

ly. This function can be aborted by pressing the CLOSE button. The door

then closes.

MOD9: Continuous CLOSE signal 1

Closed Door CLOSES with safety devices activated and remains in

CLOSED position until contact opens. OPEN commands are

ignored. If the safety edge protection (SKS) is triggered 3

times, the door then remains in the OPEN position.

Open: Normal function

MOD1 - MOD10 MOD1

MOD10: Continuous CLOSE signal 2

As for MOD9 except that after the SKS has been triggered 3 times, the

door reverses for 750 ms and then remains stationary in that position.

REVERS MOD1: No reversing takes place if the pre-limit switch CLOSE is activated.

MOD2: No reversing takes place even when the pre-limit switch CLOSE is activa-

ted.

MOD1

MOD2

MOD1

LB CLOSE MOD1: Stop when triggered

MOD2: Stop and reverse when triggered

MOD 1

MOD 2

MOD 2

LB OPEN MOD1: Light barrier not active

MOD2: If the light barrier is triggered between the pre-limit CLOSE position and

the CLOSE end position, the door stops moving. The red trafc light

lights up. The pre-limit switch CLOSE is set automatically to the CLOSED

end position + 600.

MOD 1

MOD 2

MOD 1

SKS LEAD MOD1: No function

MOD2: Leading light barrier (MFZ)

MOD 1

MOD 2

MOD 1

9. Overview of functions

EN

CS 300 RM Gate Controls / Rev. B 1.0 – 19

Explanation of the relay modes:

A. Trafc light functions

MOD Description CLOSED end

position

OPEN end posi-

tion Forewarning Door moving

MOD 1 Red trafc light 1 ON / OFF * OFF Flashing Continuously lit

MOD 2 Red trafc light 2 ON / OFF * OFF Flashing Flashing

MOD 3 Red trafc light 3 ON / OFF * OFF Continuously lit Continuously lit

MOD 18 Red trafc light 4 OFF OFF Flashing OFF

MOD 23 Green trafc light OFF Continuously lit OFF OFF

* Depends on parameter MOD1-3 REST

B. Position messages

MOD Description Comments

MOD 6 OPEN end position The relay closes the contact when the door is in the OPEN end position.

MOD 7 CLOSED end position The relay closes the contact when the door is in the CLOSED end position.

MOD 8 Not OPEN end position The relay closes the contact when the door is not in the OPEN end position.

MOD 9 Not CLOSED end position The relay closes the contact when the door is not in the CLOSED end position.

MOD 11 Pre-limit position CLOSE The relay closes the contact when the door is in the pre-limit position CLOSE.

MOD 12 Pre-limit position CLOSE to CLOSED end position The relay closes the contact when the door is in the area between the CLOSED end

position and the pre-limit position CLOSE.*

* Only possible if an external pre-limit switch (MOD 1) is connected to the SU/WI input (X4 9+10).

20 – CS 300 RM Gate Controls / Rev. B 1.0

C. Impulse signals

MOD Description Comments

MOD 4 Impulse upon OPEN command The relay closes the contact for 1 second when the door receives an OPEN command.

This impulse can be used to control lights, for instance.

MOD 27 Impulse when OPEN end position is reached The relay closes the contact for 2 seconds when the door reaches the OPEN end

position.

This impulse can be used, for instance, to open a second barrier.

D. Brake functions

MOD Description Comments

MOD 14 Brake The switching contact of the brake rectier is activated via the relay to achieve a

faster brake function. The contact is closed, and the brake is therefore released, as

soon as the door moves (zero current brake).

MOD 15 Brake negated The switching contact of the brake rectier is activated via the relay to achieve a

faster brake function. The contact is opened, and the brake is therefore released, as

soon as the door moves (operating current brake).

MOD 16 Brake remains ON during open time The switching contact of the brake rectier is activated via the relay to achieve a

faster brake function. The contact is closed, and the brake is therefore released, as

soon as the door moves (zero current brake). In order to stop the door more smooth-

ly at the OPEN end position, the switching contact is not switched at the OPEN end

position (OPEN TIME).

9. Overview of functions

Table of contents

Other MFZ Ovitor Gate Opener manuals

Popular Gate Opener manuals by other brands

Mighty Mule

Mighty Mule MMS915 installation manual

Assa Abloy

Assa Abloy NORTON RIXSON 6200 Series Programming instructions

RIB

RIB NORMAL manual

CAME

CAME BKV Series installation manual

LIFE home integration

LIFE home integration ACER Instructions for installation, use and maintenance

BFT

BFT BOTTICELLI 800 U Installation and user manual