MFZ Ovitor E6L User manual

OVITOROY

SIENITIE24

FIN‐00760HELSINKI

FINLAND

Tel.+358‐207106600

Fax.+358‐207106601

CONTROLUNITE6L

FORONEDOORORGATEDRIVEUNIT

USER’SMANUAL

2‐ControlUnitE6L/Rev6.11

1.CONTENTS

1.Contents..................................................................................................................................2

2.Generalsafetyinstructions......................................................................................................4

3.Overviewofproduct................................................................................................................4

3.1.Productdescription...........................................................................................................4

3.2.Structure...........................................................................................................................5

3.3.PowersectionboardE6‐1LandterminalboardE6‐2L .......................................................5

3.4.Programversion ...............................................................................................................5

3.5.BoardsCON3andCON4....................................................................................................6

3.6.Protectionofthemotor ....................................................................................................6

4.Basicfunctions ........................................................................................................................7

4.1.Limitswitchesandadjustmentofdoorstoppinglocations ................................................7

4.2.Automaticclosing .............................................................................................................7

4.3.Runningtimelimiter .........................................................................................................8

4.4.Monitoringtheclosingtime..............................................................................................8

4.5.FunctionofThe‘STOP’buttoninautomaticclosing...........................................................9

4.6.Reversaldelay...................................................................................................................9

4.7.Selectionofradiocontrolforfullorreducedopening........................................................9

4.8.Single‐buttoncontrol(Impulsecontrol).............................................................................9

4.9.Loadguard .....................................................................................................................10

4.10.Introductionrun............................................................................................................11

5.SafetyEdge............................................................................................................................12

5.1.Functioningofthesafetyedge........................................................................................12

5.2.Testingthesafetyedge...................................................................................................12

5.3.Pneumatic/Electricsafetyedge.......................................................................................12

5.4.Foldingdoor....................................................................................................................14

6.Photocells..............................................................................................................................15

6.1.Theamplifierforatransmitter‐receivertypesafetyphotocellintegratedwiththe

electronicsboard...................................................................................................................15

6.2.Testingphotocells...........................................................................................................16

6.3.SeparatesafetyphotocellE6‐4,Single‐channel ...............................................................16

6.4.SeparatesafetyphotocellEU2‐4,1or2Channels ...........................................................17

6.5.UsingphotocellamplifiersE6‐4andEU2‐4asopeningphotocells ...................................19

7.Installationofanextradeviceboardequippedwithanedgeterminal...................................20

8.Warningandtrafficlights ......................................................................................................21

8.1.Warninglightcontrol......................................................................................................21

8.2.WarninglightcontrolboardE6‐5‐01...............................................................................21

8.3.WarninglightcontrolboardE6‐5‐05...............................................................................23

8.4.E6‐VLVControlcardforoncomingtrafficlight ................................................................26

9.Accessorycards .....................................................................................................................31

9.1.VPLVboardE6‐5‐06 ........................................................................................................31

9.2.SUTIboardE6‐5‐07 .........................................................................................................33

9.3.BoardE6‐5‐03forautomaticclosingwithquittance........................................................35

9.4.ProgramboardE6‐5‐04 ..................................................................................................37

9.5.SUPUboardE6‐5‐08 .......................................................................................................40

10.Firedooruse.........................................................................................................................41

12/10

ControlUnitE6L/Rev6.11‐3

11.Serviceandtroubleshooting ................................................................................................. 42

11.1.ServiceterminalE6‐6‐02/3E.......................................................................................... 42

11.2.FaultanderrormessagethroughserviceterminalE6‐6‐02/3E...................................... 43

11.3.Faulttrackinginstructions ............................................................................................ 45

11.4.LEDsindicatingtheoperatingmodeofthelimits .......................................................... 46

11.5.Service .......................................................................................................................... 46

12.Technicaldata ...................................................................................................................... 47

13.Declarationofincorporationofpartlycompletedmachinery................................................ 48

14.PowersectionboardE6‐1Lwiringdiagramdraw.no.:443..................................................... 49

15.Controlvoltagediagramforopeningandclosingdrivesdraw.no.:336L............................... 50

16.Internallay‐outofcontroldevicesinelectronicsdraw.no.:337L .......................................... 51

17.Regulatingdevices,wiringdiagramdraw.no.:340L............................................................... 52

18.ControlboardsCON3andCON4,exampleofconnectiondiagramdrawno.:385L................. 53

19.LogicboardE6‐2Ldrawno.:462V.......................................................................................... 54

4‐ControlUnitE6L/Rev6.11

2.GENERALSAFETYINSTRUCTIONS

Targetgroup

• Onlyqualifiedandtrainedelectriciansmayconnect,

programmeandservicethecontrols.Qualifiedand

skilledelectriciansmust:

• Haveknowledgeofthegeneralandspecificandacci‐

dentpreventionregulations.

• Haveknowledgeoftherelevantelectricalregula‐

tions.

• Betrainedintheuseandcareofappropriatesafety

equipmentandclothing.

• Becapableofrecognisingthedangersassociated

withelectricity.

Instructionsforinstallationandconnection

• Beforecommencingelectricalworks,thesystem

mustbedisconnectedfromtheelectricitysupply.

Measuresmustbetakenthattheelectricitysupply

remainsdisconnectedforthedurationoftheworks.

• Localsafetyregulationsmustbeobserved.

• Mainscablesmustbelaidseparatelyfromcontrol

cables.

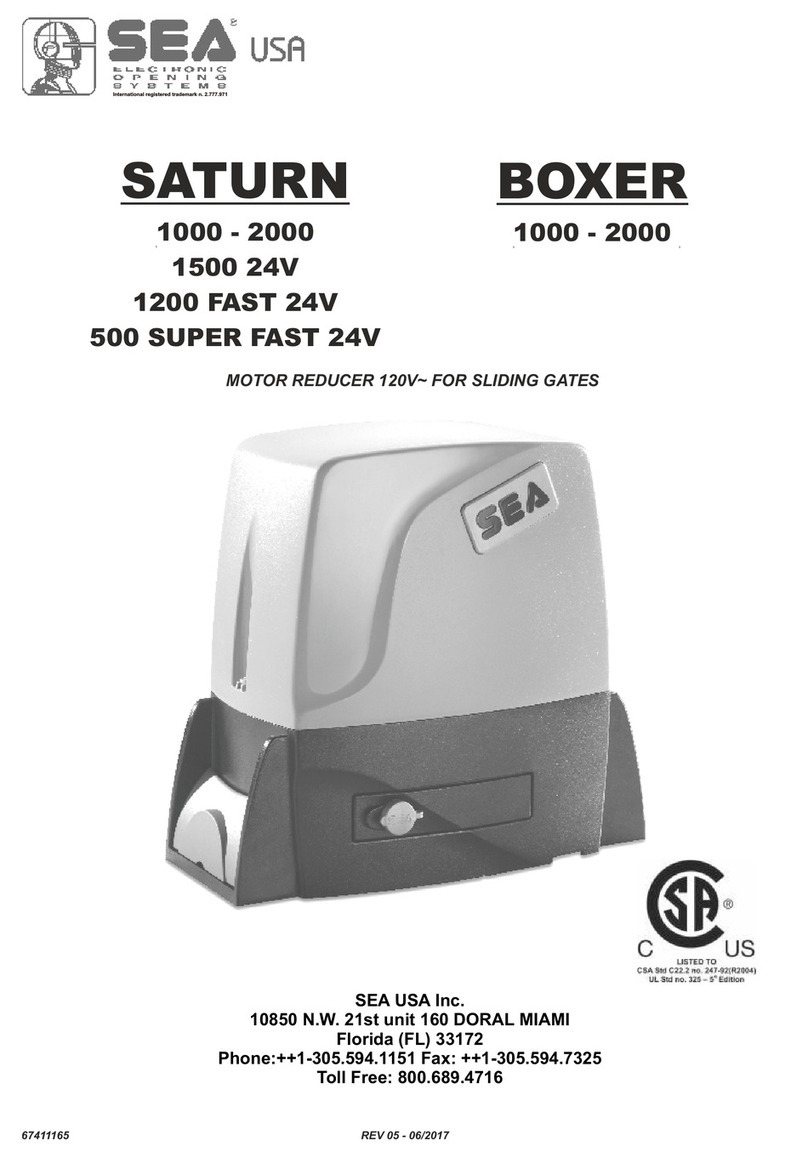

3.1.PRODUCTDESCRIPTION

ThecontrolunitE6LisOVITOR’sbasiccontrolunitforauto‐

maticdoorsandgates.ThecontrollogicoftheE6Lhas

beenimplementedbysoftware.Thesafetycircuitsare

connecteddirectlyinserieswiththemotorcontroltoen‐

surethatnofunctionrelatedtosafetydependsonthe

modeoftheprogramortheelectronics.Inthebasicver‐

sion,themotorcontroltakesplacebycontactors,butspe‐

cialarrangementsalsoenableotherkindsofmotorcon‐

trol,suchasinputthroughafrequencyinverter.Itispossi‐

bletoextendthebasicversionbyinstallingboardsforpe‐

ripheraldevicesorcomplementaryfunctionsontoprein‐

stalledplug‐insockets.Thereisasocketonthebasicboard

foraradioreceiveraswellasforanadditionalsafetypho‐

tocellboard.Otherextraboardsaretobeinstalledinto

threebusterminals.Ordinarybasicsettings,suchasthe

delayofautomaticclosingandthedurationoftherunning‐

timelimiter,aredonebymeansofrotaryswitchesonthe

board.Certainbasicmattersrelatedtothemodeofopera‐

tioncanbesetwithaDIP‐typeselectorswitchandshort‐

circuitplugsontheboard.

Thelight‐emittingdiodes(LED)indicatingtheoperating

modeoftheperipheraldevicesaresituatedabovetheter‐

minalblock;theoperatingmodesoftheprogramandof

theprocessorcanbeobservedontheLED’softheboard.

Thecontrolsystemcanbeusedforcheckingthecondition

oftheusedequipmentandthedooritself,testingthe

safetyedgeandsafetyphotocellandcheckingthecondi‐

tionofthedoorbalancewiththeloadcontrol.

Thecontrolsystemalsotakesaccountofoperations

neededduringafirealarmifthedoorisusedasafire

door.

3.OVERVIEWOFPRODUCT

12/10

ControlUnitE6L/Rev6.11‐5

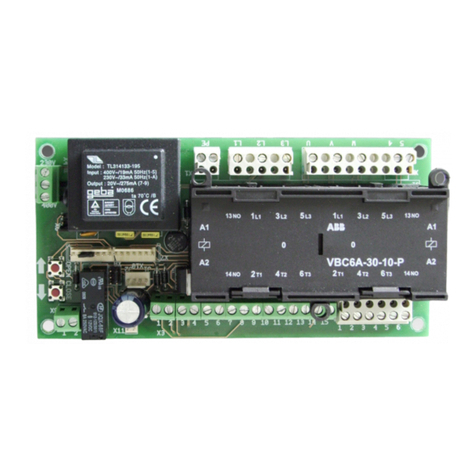

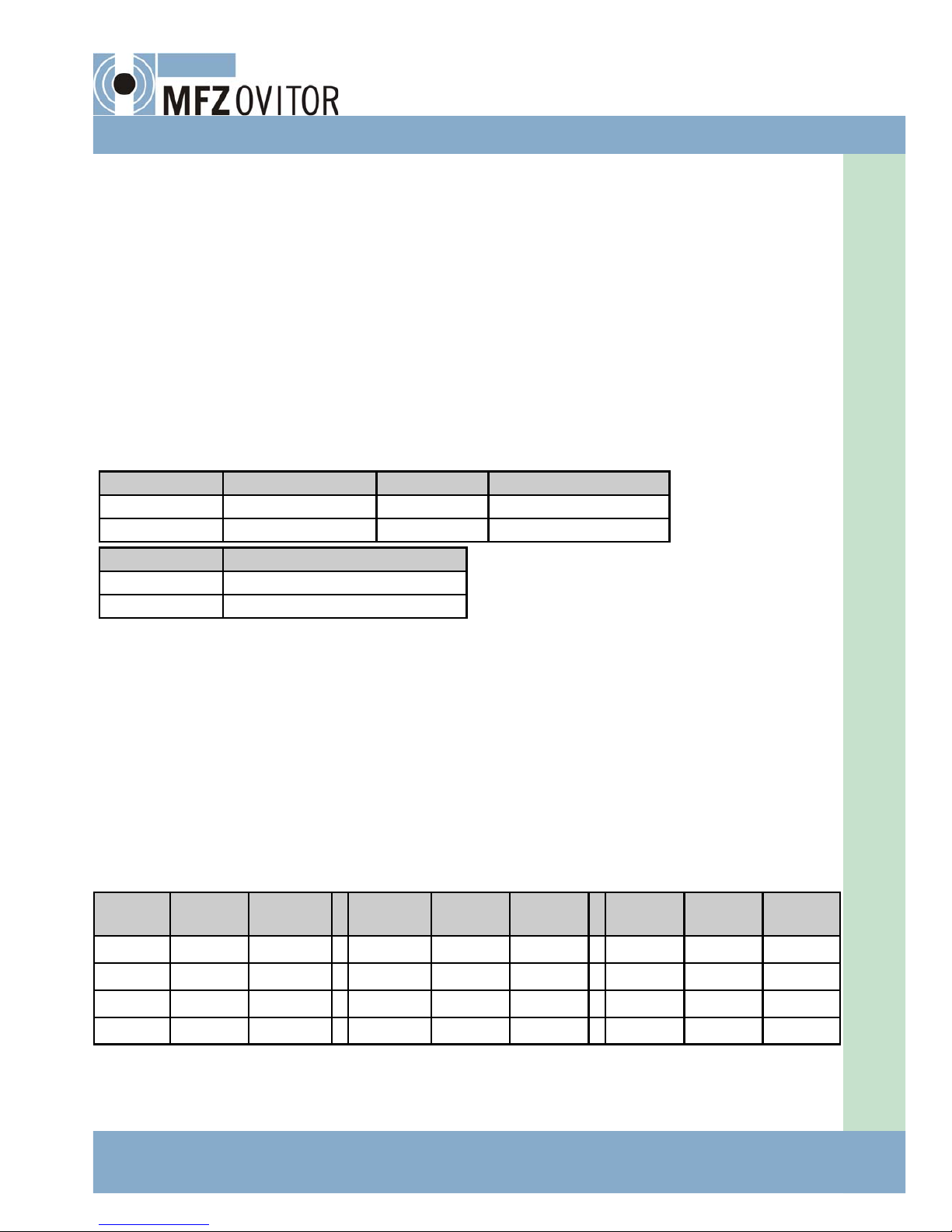

Figure1.ControlUnitE6L

1.BoardE6‐2L

2.Terminalforintegratedphotocell

transmitterandreceiver

3.Terminalforbuttonsonthecover

4.Busterminalsforextradevice

boards:

warninglightb.E6‐5‐01

warninglightb.E6‐5‐05

VPLVboardE6‐5‐06

SUTIboardE6‐5‐07

boardE6‐5‐03forautoclosingwith

quittance

programboardE6‐5‐04

SUPUboardE6‐5‐08

VLVboardE6‐VLV

serviceterminal

5.Rotaryswitchesfortimesettings

6.Programcircuit

7.DIP‐switchesforselectingcontrol

mode

8.Socketfotseparatesafetyphoto‐

cellamplifierboard

9.Terminalsforperipheralcontrol

devices

10.Directionalcontactorsofmotor

11.Mainswitch

12.ControlVoltageTransformer

13.AuxiliaryRelays

14.BoardE6‐1L

3.2.STRUCTURE

Whenthedriveunithasanormalsingle‐speedthree‐phasecurrentmotorwhichhasanominalmaximumcurrentvalueof

6A,thecontrolunitiscomposedoftwoboards(E6‐1LandE6‐2L)connectedwithterminalstogether,asshowninadjacent

Figure1.

3.3.POWERSECTIONBOARDE6‐1LANDTERMINALBOARDE6‐2L

OnthepowersectionboardE6‐1Larethedirectionalcontactorsofthemotor,controlvoltagetransformer,auxiliaryrelays

forperipheraldevicesandthemainswitchifrequired.Fordriveunitshavinganelectricmotorwithahighernominalcurrent

than6A,oraspecialmotor,thepowersectionofthecontrolunitwillbebuiltbywiringandtheboardE6‐1Lwillnotbe

used.TheE6‐2Lboardisaterminalboard/electronicsboard.Terminalsforthecontroldevices,abayonetsocketforthebut‐

tononthecover,anintegratedsafetyphotocellamplifier,aseparatesafetyphotocellsocket,anelectronicsafetyedgecon‐

trolunitsocket,aone‐channelradioreceiversocket,DIPswitches/shortcircuitplugsforcontrolmethodselectionandtime‐

settingrotaryswitchesarelocatedontheboard.Theboardalsoincludesbusterminalsforadditionalfunctionboards,pre‐

sentedbelow,thatcanbeusedtomaketheunitevenmoreversatile.

3.4.PROGRAMVERSION

Whentheunitisswitchedonandtheserviceterminalisconnectedtothebusterminal,theserviceterminalwilldisplaya

programversionnumber,e.g.6.00.Also,theuser’smanualhasaversionnumber,e.g.6.00.Iftheprogramversion’snumber

differsfromtheusermanual’snumbertheunit’sprogramwillnotnecessaryperformalloftheoperationspresentedinthe

manual.Theunit’sprogramcanbeupdatedwithamemoryboardorcomputer.

1

2

3

5

6

7

9

11

12

13

14

4

10

8

6‐ControlUnitE6L/Rev6.11

Thesimplestmethodistouseamemoryboard,placingitinthesocket,X14,nexttotheprocessorwhendisconnectedfrom

thepowersupply.Whentheunitisswitchedon,theprogramwillautomaticallyupdate.Updatingtakesawhileandthe

LEDs,H101...H104,willblink.Oncetheupdatingisfinished,theLEDswillstopblinking.Switchtheunitoff,removethe

memoryboardandtheunitwillbereadyforoperationwhenyouswitchitonagain.

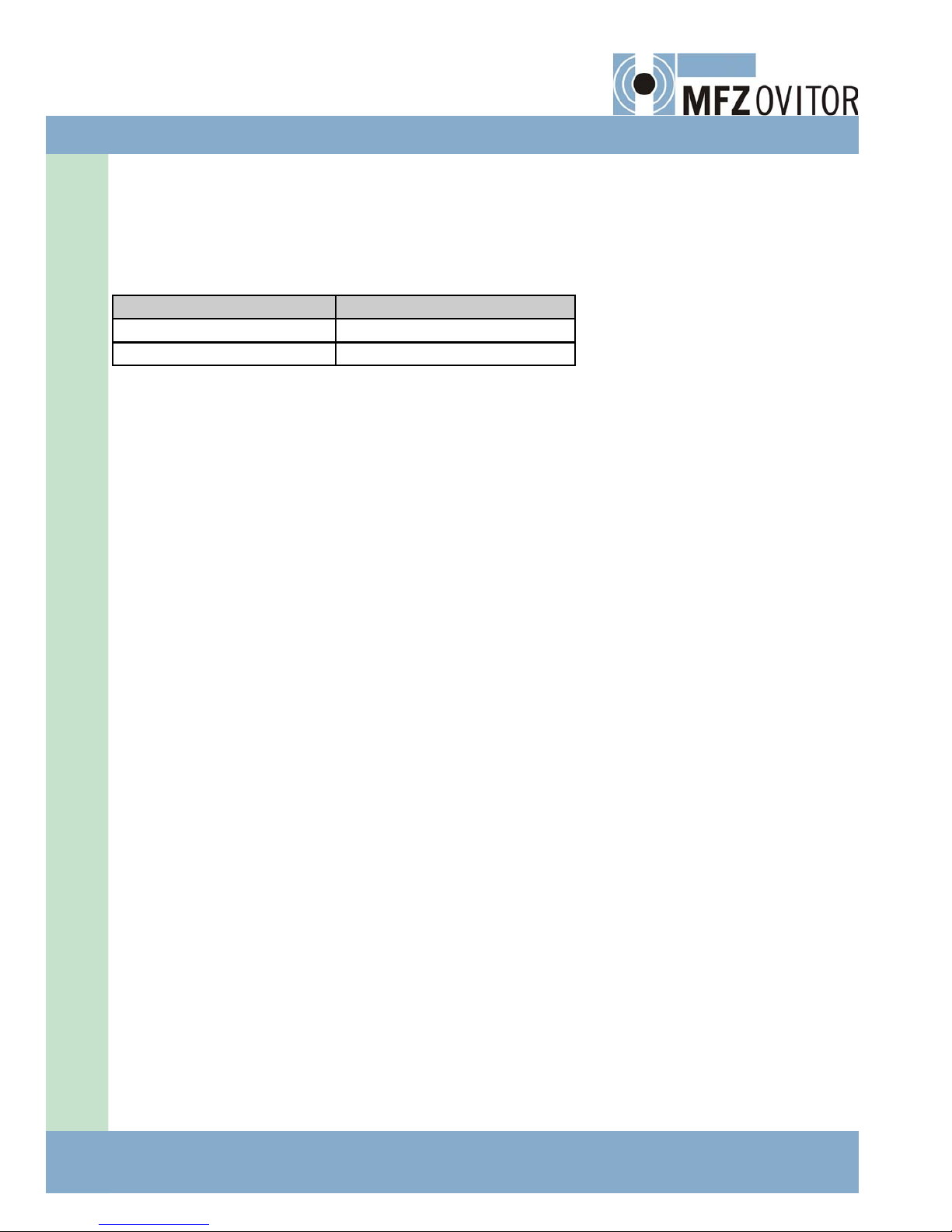

3.5.BOARDSCON3ANDCON4

InspecialcontrolunitswithoutpowersectionboardE6‐1L,therelaysK3andK4neededforperipheralfunctionswillbesub‐

stitutedwithaseparateboardCON3orCON4.Similarly,iftherelaysonthepowersectionboardarealreadyinuseandaux‐

iliaryfunctionsareneeded,theboardCON3orCON4shouldbeattached.

CON4‐boardisequippedwithtworelaysK3andK4functioninginthesamewayasanadditionalfunctioncardcontrolling

themshouldcontroltherelaysK3andK4ontheeffectboardE6‐1LorontheboardCON3.

CON3‐boardisequippedwithfiverelaysK3,K4,K5,K6andK7.RelaysK3andK4functionasmentionedabove.Thefunction

ofrelaysK5,K6andK7isdefinedbytheadditionalcardcontrollingthem.Thefunctionofadditionalcardsisdescribedlater

inthismanual.ThecontrolcircuitdiagramsfortheboardsCON3andCON4areattheendofthismanual(drawing385L).

DependingofmountingtherearetwoversionsofCON4‐board,AandB.InE6applicationstheonlyoptionisA.

Figure2.BoardsCON3andCON4

3.OVERVIEWOFPRODUCT

3.6.PROTECTIONOFTHEMOTOR

WiththecontrolunitE6L,theprotectionofthemotorisintendedtobecarriedoutbyathermaltripinthewindingofthe

motor.Thecontactofthetripopensasthemotorheatsduetoafaultoranoverload.Thecontactofthenormallyusedtrip

opensatthetemperatureof+130oCandclosesaftercoolingdownto+80oC.Theconnectingcapabilityofthetripis250Vac

1,6Acosφ=0,6and2,5Acosφ=1.Thetripisnormallyconnectedtoterminals101and102onboardE6‐1L;cf.drawingno.

443andthecase‐by‐casewiringdiagram.Ifthevoltageismorethan230Vac,thetripmustbeconnectedforinstancetoa

STOP‐circuitonthe24Vsideincontrol.Inthiscasetheterminals101and102shouldbeshort‐circuitedwithaloop.

MostofthedriveunitssuppliedbyOVITOROyhaveaready‐installedtripinthewinding.Driveunitswithaspecialmotor

and/orwithoutthetripmustbeprotectedwithaseparatethermalrelayoraprotectiveswitchforamotor.Themotorof

thedriveunitmaynotbeleftunprotected.

12/10

ControlUnitE6L/Rev6.11‐7

4.1.LIMITSWITCHESANDADJUSTMENTOFDOORSTOPPINGLOCATIONS

Stoppinglocationsofthedoorarefixedwithmechanicallimitswitches.ThecontrolunitE6Lcontrolsdriveunitwiththese

limitswitches.Innormaluse,threelimitswitchesareneeded:openlimit,closedlimitandthesafetydevicelimit.Thecon‐

tactsoftheopenandclosedlimitsopenwhenthedoorreachesitsextremeposition.Thecontactsofthesafetydevicelimit

close5...50mmbeforetheclosedpositionofthedoor.Thesafetydevicelimiteliminatestheopeningfunctionfromthe

control,butstopsthedooratanimpulsefromthesafetydevice.Thisfunctionpreventsthedoorfromopeninganewwhen

thesafetyedgehitsthefloorortheframe.Thestoppingfunctioncanbeeliminatedincasesofafoldingdoorequippedwith

safetyedgeinboththecollidingfrontedgesofthedoor,wherethesafetyedgestoucheachotherbeforethefullyclosed

positionofthedoor.Forthehalf‐openfunction,ahalf‐openlimitisalsorequired,withitscontactsclosinginthehalf‐open

position.LED’sH49...H51andH53indicatethemodeofoperationofthelimits,cf.drawingno.336L.Inthedrawing,the

positionofthecontactscorrespondstothemechanicalandelectricpositionofthelimitswitchcontactswhenthedooris

closed.ThefunctioningoftheLED’salsodependsonthemodeoftheregulatingunitsconnectedinseriesbeforethem.

Itiseasiertoadjustthelimitswhenthecontrolissettohold‐to‐run.Thecontrolcanbeswitchedtohold‐to‐runintheopen

directionusingshortcircuitplugNo.2ofterminalJ6andinthecloseddirectionwithplugNo.3ofterminalJ6.Whenthe

shortcircuitplugisinplacethecontrolwillswitchtohold‐to‐run.Oncethelimitshavebeenset,theshortcircuitplugscan

beremovedandthecontrolwillchangetoimpulsedirected.

4.2.AUTOMATICCLOSING

Bymeansofaselectorswitchconnectedtoterminalblocks12and13ofthecontrolunit,adoororsimilarcanbemadeto

closeautomaticallyfromtheopenorhalf‐openposition,whenthecontactsoftheswitchareclosed.Whenthecontactsof

theswitchareopen,noautomaticclosingwilltakeplace;cf.drawingno.337L.WithjumpersNo.2and3ofterminalJ7auto‐

maticclosingcanbechosenfromeitherhalf‐openorfully‐openpositionorboth.IfbothjumpersNo.2and3areofforon,

automaticclosingworksfromeitherposition.IfjumperNo.2isonand3isoff,automaticclosingworksfromfully‐openposi‐

tion.IfjumperNo.3isonand2isoff,automaticclosingworksfromhalf‐openposition.Operationwithautomaticclosingis

notpermittedwithoutsufficientsafetydevices.

Thedelaybeforeautomaticclosing,thatis,thetimethedoorstaysopen,issetwithrotaryswitchS133intheupperright

cornerofboardE6‐2LandwithterminalJ4jumperNo.8.NOTE!Whentherotaryswitchisinposition0andthejumpernot

inplace,theautomaticclosingfunctiondoesnotwork.Thetimeisdeterminedaccordingtothetablebelowbytheposition

oftherotaryswitch.IfthecontrollerisequippedwiththeserviceterminalE6‐6‐02/3E,thedisplayshows,whentheposition

oftherotaryswitchischanged,foramomentthetext‘A80‘andafterthatthesettime.

4.BASICFUNCTIONS

S133positionStayopentime[s]

J4jumperno.8OFF

Stayopentime[s]

J4jumperno.8ON

S133positionStayopentime[s]

J4jumperno.8OFF

Stayopentime[s]

J4jumperno.8ON

0noautoclose90815500

11120917600

23180A20800

35240B251000

46280C301500

58320D402000

610360E503000

712400F603600

4.3.MONITORINGTHECLOSINGDRIVE

Fortheeventualitythattheclosebuttongetsstuck,thecontrolhasbeenequippedwithclosingdrivemonitoring.Ifthe

closebuttonsendsaconstantclosingimpulsewhilethedoorisopening,thedoorwillnotcloseimmediatelyfromtheopen

position,butthecontrolwillrequireeitheranewclosingimpulseinordertocloseoritonlyclosesafterthestayopentime

setforautomaticclosing.

8‐ControlUnitE6L/Rev6.11

4.4.RUNNINGTIMELIMITER

ThecontrolunitE6Lhas,asasafetydevice,arunningtimelimiterthatstopsthemotoraftertheexpiryoftherunningtime

requiredforanormalopeningandclosingmotion.Thepermittedrunningtimeissetatthestageofintroductionofthe

door,bytherotaryswitchS132intheupperrightcornerofboardE6‐2L;cf.drawingno.340L.Therunningtimeisdeter‐

minedaccordingtothefollowingtable,bythepositionoftherotaryswitch.Thepermittedrunningtimeissetat2...10s

longerthantherunningtimerequiredforthenormaltravelofthedoor.Ifthecontrollerisequippedwithserviceterminal

E6‐6‐02/3E,thedisplayshows,whenthepositionoftherotaryswitchischanged,foramomentthetext‘A130‘andafterthat

thesettime.

Ifthesetcontinuousrunningtimeofthemotorisexceeded,theredLEDH103islitandthedoorstops.Ifthecontrolleris

equippedwithserviceterminalE6‐6‐02/3E,thenwhiletheLEDH103islit,thedisplayshowsthetext‘E9‘.Thiscanhappen,

forexample,whentheslippingclutchofthedriveunitslipsaftertheforcerequiredbythedoorhassurpassedthesetvalue.

TheredLEDissituatedontheCPUboardE6‐2L,cf.drawingno.340L.Thefaultindicationdisappears,andtheLEDturnsoff,

whenthedoorisagaindrivenintheopeningorclosingdirection.Iftherunningtimelimiterstopsthedooragain,checkBE‐

FOREdrivingthedoorineitherdirectionthat:

• thedoorcanfreelymoveinitsguidetracksfromoneextremepositiontotheother;

• therearenoforeignobjectsbetweenthehinges,sections,etc.ofthedoor;

• thedoorhasnotfrozenimmobile;

• nothingelseispreventingthenormalmovementofthedoor;

• thedoorhasnotbeensetonmanualusewiththereleaseleverofthedriveunit.

Ifeverythingisinorder,drivethedoorintheopeningorclosingdirectionfromoneextremepositiontotheother,observing

thedoormovementthroughoutthetravel.Ifthefaultindicationisrepeated,theresistanceagainstmotionofthedoorhas

forsomereasonincreased,and/ortheslippingclutchworkingassafetydeviceofthedriveunitisslipping.Thetimecanbe

setalittlelonger,butitisalsoimportanttofindoutthereasonwhythetravellingtimesetatintroductionhasincreased.

4.BASICFUNCTIONS

S132positionMaxrunningtime[s]S132positionMaxrunningtime[s]

05860

17970

210A80

315B90

420C100

530D120

640E180

750F300

4.5.FUNCTIONOFTHE‘STOP’BUTTONINAUTOMATICCLOSING

IfautomaticclosingissetinthecontrolandiftheSTOPbutton,connectedtoterminals38‐39or40‐41or42‐43or44‐

45,isbeingpressedwhilethedoorstandsinitsopenposition,thiswillproducetheresettingofthesequenceforautomatic

closing.Asthebuttonisreleased,thetimecountrecommences,andthedoorclosesautomaticallyafterthesettime.Ifthe

stopbuttonconnectedtotheseconnectorsorthecover’sstopbuttonispressedformorethan5secondswhenthedooris

open,thedoorwillnotcloseautomaticallybutstayopen.Thedoorcanbeclosedagainwiththeclosebutton,whichresets

theautomaticclosingfunction.

12/10

ControlUnitE6L/Rev6.11‐9

IftheSTOPbuttonconnectedtoterminals34‐35or36‐37isbeingpressed,thesequenceforautomaticclosingdoesnot

start,butthedoorstaysopen.Thesituationisclearedbypressingtheclosebutton,uponwhichthedoorclosesandfunc‐

tionsnormallyagain,sothatthenexttimeitclosesautomaticallyfromtheopenposition.Normally,thesafetymicro‐switch

ofthemanualusedisengagementlever,theslackcableswitchorasimilarsafetydeviceisconnectedtoterminals34‐35

and36‐37.Whenthefunctionofsuchasafetydevicereturns,automaticclosingcouldcauseadangersituation.Whenus‐

ingaprogramboardasanextradevice,thefunctioningofallstopbuttonscanbesettostopautomaticclosing.

4.6.REVERSALDELAY

Ifthedoorreceivesanopenimpulsewhileitisclosing,itstopsandopensafterashortdelaybeforereversal.Thereversal

delayaimsatreducingstrainsonthedoor,driveunitandfixations.If,however,theopenimpulsecomesfromthesafety

edgeasthedoorcollideswithanobstacle,thedooropensimmediatelywithoutdelay.Forsafetyreasons,nodelaycanbe

permittedinacollisionsituation.

4.7.SELECTIONOFRADIOCONTROLFORFULLORREDUCEDOPENING

TheradiocontrolontheterminalboardE6‐2LofthecontrolunitE6Lcanbeselectedtoopenthedooreithertofullopening,

ortoreducedopening.Theselectionisdonebyplacingthejumpersituatednexttotheradiosocketintothepositioncorre‐

spondingtothedesiredfunction.InthepositionX1theradiocontrolwillopenthedoorintofullopeningandintheposition

X2intoreducedopening,seedrawingsno.340Land337Lattheendpartofthismanual.Thepositionofthejumperistobe

changedonlywhentheboardisfreefromvoltage.Thechangingispracticallydonewiththinpointedpliers.

4.8.SINGLE‐BUTTONCONTROL(IMPULSECONTROL)

Thecontroldevicesofsingle‐buttoncontrolareconnectedtoterminals22...33accordingtodrawing337L.Theprogram‐

mingofsingle‐buttoncontrolisdonewiththeDIPswitchS131situatedintheupperrightcornerofboardE6‐2Landusing

shortcircuitplugno.1ofterminalJ7,cf.drawingno.340L.

Single‐buttonclosingissetbyturningswitchno.1ofS131intothepositionON.Nowthesingle‐buttoncontrolclosesthe

doorfromtheopenpositionandopensthedoorfromallotherpositions.Ifswitchno.1isturnedintothepositionOFF,sin‐

gle‐buttoncontrolsimplyopensthedoor.Ifavehicledetectoramplifier,forinstance,isconnectedtothesingle‐buttoncon‐

trol,theswitchiskeptinthepositionOFF.Single‐buttonstoppingissetwithswitchno.2ofS131.InthepositionONof

switchno.2,single‐buttoncontrolalwaysstopsamovingdooratthefirstpulseandopensitatthesecond,thatis,aclosing

doorstopsatthefirstpulseandopensatthesecond.Anopeningdoorstopsatthefirstpulseandreopensatthesecond.By

selectingthepositionOFFforswitchno.2,apulsefromthesingle‐buttoncontrolopensaclosingdoorimmediately,without

astoppingfunctionintheopeningdirection.TheswitchiskeptinthepositionOFFif,forinstance,avehicledetectorampli‐

fierisconnectedtothesingle‐buttoncontrol.

Single‐buttonclosingfromotherthantheopenpositionwillbedefinedbytheshortcircuitplugno.1interminalJ7.Inthat

casetheDIPswitches1and2mustbeinONposition.Theshortcircuitplugno.1beinginplacethedoor,stoppedwhen

movinginopendirection,startstocloseatthefirstimpulse.Thenextimpulsestopsthedoorandthenextoneopensit

again.Theoperationisnotallowedifitcancauseasafetyrisk.

4.9.LOADGUARD

ThecontrolunitE6Lisequippedwithaloadguard.Duringtheimplementationandservicingofthedoor,thecontrolsystem

isintroducedwiththepowerneededtomovethedoor.If,duringnormaluseofthedoor,thepowerdeviatesfromthein‐

troducedvalue,thecontrolwillreacttothechangedload.Anopeningdoorwillstopand,ifsorequired,closeafteraset

timeandaclosingdoorstopandre‐openiftheloaddeviatesfromtheenteredvalue.TheloadismeasuredwithaPNPtype

pulsesensorinthegear,whichmonitorstherotationspeed.Thesensorisconnectedtoterminals60(+24Vdc),61

(electronicszeropotential)and62(signal)ofboardE6‐2L.

10‐ControlUnitE6L/Rev6.11

Thecontrolsystemcontinuouslymeasuresthepowerneededtomovethedoor.Thesystemalsocontinuouslyupdatesthe

requiredpower,whichincreasesinnormalconditionsasthedoorwearsandthebalancechangesetc.Oncethepowerhas

increasedsothattherotationspeedhaschangedtomatchthegapbetweenthesetvalueandtheoriginalmeasuredvalue,

thecontrolautomaticallychangestohold‐to‐runandtheunitnotifiesaservicingrequest.Atthesametime,theredLED,

H103,blinksrapidlyapproximatelythreetimesasecondandiftheserviceterminalisconnecteditdisplaystheerrorcode,

“E 31”.Insuchacase,thepowerdiagramsmaynotbere‐runbutTHEDOORMUSTBESERVICED.Afterthedoorhasbeen

servicedandchecked,themotionpowerismeasuredaccordingtotheinstructionsbelow.

AloadguardoperationisselectedwithjumperNo.1ofterminalJ6.Iftheloadguardisinuse,jumperNo.1isdisconnected.

Iftheloadguardisnotinuse,jumperNo.1mustbeinstalled.

Astart‐updelayisdefinedfortheloadguard.Itsoperationistestedduringthestart‐updelay.Iftheguarddoesnotpassthe

testthedoorcontrolwillchangetohold‐to‐runinbothdirections.Onthesameboard,E6‐2L,theredLEDH103,willblinkat

arateof2secondsONand2secondsOFF.

Thesystemisalsosuitedtoinverteruse.InverteroperationisdefinedusingjumperNo.1ofterminalJ4.Duringinverteruse,

theshortcircuitplugisinplace.

4.BASICFUNCTIONS

JumperJ6/1LoadControlJumperJ4/1InverterUse

OFFControlONOFFDoornotininverteruse

ONControlOFFONDoorininverteruse

JumperJ4/4Start‐upDelay

OFF0,8seconds

ON1second

Jumper

J4/6

Jumper

J4/7

ClosingTime

OFFOFF0s

OFFON1s

JumperJ4/2

OFF

ON

Jumper

J7/4

OFF

OFF

Sensitivity

open

5%

8%

Jumper

J4/3

OFF

ON

Jumper

J7/4

OFF

OFF

Sensitivity

close

3%

6%

ONOFF2sOFFON12%OFFON10%

ONON6sONON16% ONON16%

Theloadguardstopstheopeningdooriftheloaddeviatesfromtheintroducedvalue.Toeasetheremovalofanobstacle,

thedoorcanbeclosedforasettimeaccordingtotheattachedtable.ThetimeisdefinedwithshortcircuitplugsNo.6and

7ofterminalJ4.IftheloadguardhasstoppedtheopeningdoortheredLEDH102blinksatarateof2secondsONand2

secondsOFF.Theserviceterminalthendisplaystheerrorcode,“E 20”.Thefaultdisappearswhenthedoorisopenedor

closedandtheoverloadhasbeenremoved.Thesensitivityoftheloadguardintheopendirectionisadjustedwithjumper

No.2ofterminalJ4andwithjumperNo.4ofterminalJ7,inaccordancewiththeattachedtable.Sensitivityisdefinedasa

percentageofthemeasuredvalues.

Theloadguardstopsandopenstheclosingdoorwithoutareversaldelayiftheloaddeviatesfromtheintroducedvalue.If

theloadguardhasstoppedandopenedaclosingdoor,theredLEDH102blinksatarateof2secondsONand2seconds

OFF.Theserviceterminalthendisplaystheerrorcode,“E 4”. Thefaultdisappearswhenthedoorisopenedorclosedand

theoverloadhasbeenremoved.ThesensitivityoftheloadguardinthecloseddirectionisadjustedwithjumperNo.3of

terminalJ4andwithjumperNo.4ofterminalJ7,inaccordancewiththeattachedtable.Sensitivityisdefinedasapercent‐

ageofthemeasuredvalues.

12/10

ControlUnitE6L/Rev6.11‐11

ThesizeoftheloadchangeintheoriginalmeasuredvaluesisdefinedusingjumperNo.5ofterminalJ4,inaccordancewith

attachedtable.Sensitivityisdefinedasapercentageofthemeasuredvalues.Iftheloadthedoorplacesonthegear

changesfromtheoriginal,introducedvaluebysomuchthattheset,permittedchangevaluesaresurpassed,theservice

terminaldisplaydisplaystheerrorcode,“E 31”.Simultaneously,theredLEDH103blinksquicklyontheE6‐2Lboard,repre‐

sentingadoorservicerequest.Atthesametime,thedoorcontrolswitchestohold‐to‐runintheopenandcloseddirection.

Inasituationlikethis,theloaddiagramsmustnotbere‐runbutTHEDOORMUSTBESERVICED.Afterthedoorhasbeen

servicedandchecked,anewintroductionrunisperformedwhichremovestheerrormessage.

JumperJ4/5LoadChange

OFF6%

ON10%

4.10.INTRODUCTIONRUN

Anintroductionrunisperformedduringdoorimplementationandservicing.Theintroductionrunisstartedbypressingthe

introductionrunstart‐upbutton,S5,betweenterminalsJ4andJ6orbysettingjumperNo.1ofterminalJ6inplacefora

whileandthenremovingitorcontinuouslypressingtheclosebuttonwhilethedoorisclosingandcontinuingtopressitfor

10secondsafterthedoorhasstoppedmoving.Ifpressingcontinuesformorethan22seconds–ifthebuttonjams,forex‐

ample–thecontrolwillnotswitchtointroductionrunmode.LEDsH103andH104blinkontheboardinturnandtheservice

terminaldisplayshowsthetext,“Lear”untiltheintroductionrunisfinished.While“LEAr”isdisplayed,the“OPEn”and

“CLOS”textsflashonthedisplaywhenthebuttonsareused.Thecontrolswitchestoautomatichold‐to‐run.Theintroduction

runproceedsinhold‐to‐runmodeinthefollowingmanner:

• Firstopenthedoortotheopenlimit.

• Nextcloseittotheclosedlimit.

• Re‐openthedoortotheopenlimit.

• Re‐closethedoortotheclosedlimit.

Openingandclosingmustbeperformedwithoutstopping,fromlimittolimitinhold‐to‐runmode.Makesurethatthesafety

photocellbeamisnotbrokenandthatthesafetyedgegivesapulseduringtheintroductionrun.Makesurebylookingthe

LEDsofthesafetyedgeandtheclosedlimitthatthedoorstopsinclosedpositionthroughthelimitswitch,notthroughthe

safetyedge:theLEDofclosedlimitgoesoutfirst.Whenneededshort‐circuitthesafetyedgeanddisablethesafetyedge

testingtemporarily.

Afterasuccessfulintroductionrun,theLEDsstopblinkingandthe“LEAr”textdisappearsfromtheserviceterminaldisplay.

Theintroductionrunisfinishedandthecontrolchangestoautomaticallyimpulsedirected.

12‐ControlUnitE6L/Rev6.11

5.SAFETYEDGE

5.1.FUNCTIONINGOFTHESAFETYEDGE

Ifapulseisreceivedfromthesafetyedgewhilethedoorisinclosingmovementbetweentheopenlimitandthesafetyde‐

vicelimit,theredLEDH102onboardE6‐2Llightsup;cf.drawingno.340L.Immediatelyafterthesafetyedgepulsethedoor

willopen.Ifautomaticclosinghasbeensetinthecontrol,thelatterprobeswiththesafetyedgefortheremovaloftheob‐

stacleinfrontofthedooredge.Thecontrollertriestoclosethedoor,andifapulsecomesindicatingcollisionagainstthe

safetyedge,thedoorwillreopen.Thecontroltriestentimesfortheremovaloftheobstacle,andiftheobstaclehasnot

disappearedfrominfrontofthedoor,thedoorwillremainopen.Thefirsttestingwilltakeplaceafterthetimesetfordelay

beforeself‐clearancedelay,andifthatisnotinuse,after60s.Thesecondtestingtakesplaceafterdoublethattime,the

thirdaftertriple,etc.Whenusingtheprogramboardasanextradevice,thetestingfunctioncanbeeliminated,sothatthe

doorremainsopenafterthesafetyedgepulseandwillnotcloseautomatically.InthiscasetheredLEDH102remainson.

TheLEDgoesoutandthedoorcloseswhenitisdrivenwiththeclosebutton.

5.2.TESTINGTHESAFETYEDGE

Themostimportantsafetydeviceofmovingdoorsisasafetyedgeinthecollidingedgeofthedoor.Apneumaticsafety

edgeistheonemostcommonlyused.ThecontrolunitE6Lisequippedwithasafetyedgetestingfunction.Thecontroller

teststhefunctioningofthesafetyedgeeverytimethedoorclosestightlyagainstthefloor,theframeorasimilarobstacle.If

nopulsecomesfromthesafetyedgeatthatmoment,thecontrolchangestohold‐to‐runintheclosingdirection.Theinfor‐

mationonthenon‐functioningofthesafetyedgeremainsinpermanentstorage,andthefaultindicationcanonlybecleared

withapulsefromthesafetyedge.

Iftherehasbeennopulsefromthesafetyedgeatthemomentthedoorreachedtheclosedposition,thered

LEDH104onboardE6‐2Llightsup,andthecontrolswitchesovertohold‐to‐runintheclosingdirection,cf.drawingno.

340L.IfthecontrolisequippedwithserviceterminalE6‐6‐02/3E,thedisplayshowsthetext‘E5‘whileH104ison.TheLED

H104goesoff,whenapulsecomesfromthesafetyedge.

Thefunctioningofthesafetyedgetestingcanbeobservedbydetachingthepressurehosecomingfromthesafetyedgeto

thepressureswitchandafterthisdrivingthedoorintotheclosedposition.Afterthedoorstopsintheclosedposition,the

redLEDH104mustlightup.IftheLEDdoesnotlightup,eitherthetestingofthesafetyedgehasbeenprogrammedoff,or

themembraneofthepressureswitchhasgotaconcussion,sothatthepressureswitchstillgivesapulse.Thepulsefromthe

safetyedgecanbeobservedfromthegreenLEDH47goingout,cf.drawingno.336L.Theeyedoesnotcatchtheveryshort

pulsewhichthelogic,however,recognises.Inaddition,wheneverapulsecomesfromthesafetyedgewhilethedoorisclos‐

ingbetweentheopenlimitandsafetydevicelimit,theredLEDH102ontheboardE6‐2Llightsupaccordingtosection

FUNCTIONINGOFTHESAFETYEDGE,cf.drawingno.340L.Ifnecessary,terminals46and47ofthesafetyedgecanbeshort‐

circuitedduringcontrolofthetesting,cf.drawingno.336L.Thecontrolofthistestfunctionmustbedonewithgreatcare,

asthedoorisatthattimebeingdrivenwithoutanysafetyfunction.

Incaseswheretherearenosafetyedgesortheydonothitanything,e.g.withtrafficbarriers,thesafetyedgetestingfunc‐

tioncanbeprogrammedoff.TheeliminationofthesafetyedgetestingisdonewiththeDIPswitchS131situatedintheup‐

perrightcornerofboardE6‐2L,cf.drawingno.340L.Turningswitchno.3ofS131intothepositionOFFcancelsthesafety

edgetesting.InthepositionONofswitch3,thesafetyedgetestingisinfunction.Ifthecontrollerisequippedwithservice

terminalE6‐6‐02/3E,thedisplayshows,whenthepositionoftheswitchischanged,forashortmomentthetext‘L60‘and

afterthat‘OFF‘or‘ON‘accordingtothepositionoftheswitch.

5.3.PNEUMATIC/ELECTRONICSAFETYEDGE

ControlunitE6Lcanbeequippedwithapneumaticand/orelectronicsafetyedge.Thepneumaticsafetyedgeisusedwhen

itsconditioncanbemonitoredinaccordancewiththesection,“SAFETYEDGETESTING.”Thepneumaticsafetyedgeiscon‐

nectedtoterminals46and47.Ifthesafetyedgeisnotused,theconnectorsmustbeshortcircuitedwitheachother.

12/10

ControlUnitE6L/Rev6.11‐13

Theelectronicsafetyedgeisusedwhenthereisnotestpulsefromthesafetyedgewhenthedoorisclosed,e.g.slidingand

foldingdoors.Tocontrolthecondition,theelectronicsafetyedgerequiresaseparatemonitoringunitSEM2whichisin‐

stalledusingconnectorX18ontheleftedgeoftheE6‐2Lboard.Inadditiontothemonitoringunit,thecontrolsystem’sown

safetyedgetestingcanbeused.Iftheelectronicsafetyedgeemitsapulsewhenittouchesthefloorortheequivalent,the

door’scontrolsystemwilltestthepulsefromthesafetyedge.Inthisway,thesafetyedgeoperationisdouble‐monitored.If

theelectronicsafetyedgeisnotused,thepinsoftheterminal,J3,nexttothesocketmustbeshortcircuitedwithaplug.

8,2kΩ1%

Whenthereisonly

oneelectronic

safetyedgeinuse,

theothermustbe

replacedwith

8.2kΩ1%resistor

SafetyEdge

X18

Figure3.SEM2.Connectionofelectronicsafetyedge.

SinceSEM2has2channels,itcanbeusedfortheindicationofoneortwoelectronicsafetyedges’obstaclerecognitionand

themalfunctionindicationforthesafetyedgeoritscabling.ThesensorsconnectedtoSEM2musthavean8.2kΩterminal

resistor.Withthehelpoftheidlecurrentthatrunsthroughtheterminalresistor,theSEM2canindicateapossiblesensor

circuitdisconnectionormalfunction.Alwaysmakesurethattheterminalresistorisinstalledonthefinalendofthesafety

edge.Youcanalsoconnectseveralsafetyedgesinseriesbutthelastsafetyedgeintheseriesmustbeconnectedwithan

8.2kΩterminalresistor.Whenconnectingsafetyedges,pleasenotethatthecircuitresistanceoftheusedcablesmustbe

nomorethan100Ω.

SEM2hastwoseparate,identicalsupervisingcircuitsformonitoringsafetyedgestatus.Bothcircuitsmonitorbothsafety

edges.Ifonesupervisingcircuitbreaksasingleorseveralcomponents,theothercircuitcanindicatetheobstaclerecogni‐

tionormalfunctionofbothsafetyedges.

WhentheSEM2monitoringunitisusedforonlyoneelectronicsafetyedge,theothersafetyedgemustbeconnectedwith

an8.2kΩ1%resistor.Innormaldeliveries,theresistorisready‐connectedwithbothconnectorsandthesinglesafetyedge

isconnectedinaccordancewiththefigure.Ifthereisonlyonesafetyedge,SEM2monitorsitusingbothsupervisingcircuits.

Whentheamplifierunitisconnectedtothesupplyvoltageandsafetyedgesandtheircablingisundamaged,noLEDswillbe

oninthemonitoringunitandthecircuitofthecontrolunitwillbeunbroken.OnlytheH47LED,indicatinganunbrokencir‐

cuit,willbeswitchedoninthedoor’sboard,E6‐2L.Whenthesafetyedgemeetsanobstacleortheresistanceoftheedge

circuitdrops,theyellowLEDs,H1andH3,willturnoninthemonitoringunit,thecontrolsystem’scircuitwilldisconnectand

theLED,H47,willswitchoff.Ifthesafetyedgecircuitisdisconnectedoritsresistanceincreases,theredLEDs,H2andH4,

willswitchoninthemonitoringunit,thecontrolsystem’scircuitwilldisconnectandtheLED,H47,willswitchoff.

IfonlyoneoftheLEDs,H1,H2,H3orH4,isswitchedonthismeansthatthereisamonitoringunitmalfunction,thecontrol

system’scircuitwilldisconnectandtheLED,H47,willswitchoff.Insuchacase,themonitoringunitmustbereplaced.

14‐ControlUnitE6L/Rev6.11

5.SAFETYEDGE

Theoperationofthesafetyedgesystemandthemonitoringunitmustbecheckedregularly,forexamplewheneverthe

doorisserviced.Whenthesafetyedgegivesapulsee.g.duetocontactwithahand,thedoor’scontrolsystemmustreact

accordingtotheselectedoperatingmode.Whentheothersafetyedgecableisdisconnected,thedoor’scontrolsystem

mustreactaccordingtotheselectedoperatingmode.Thedoorandmonitoringunitmayonlybeservicedbyanauthorised

servicetechnician.

5.4.FOLDINGDOOR

Ifthecontrolleddoorisafoldingdoorwithsafetyedgesinthecollidingedgeshittingeachotherbeforethefoldsofthe

doorhavestraightenedoutintothefullclosedposition,thestoppingeffectofthesafetyedgemustbeprogrammedoff.

TheeliminationisdonewiththeDIPswitchS131situatedintheupperrightcornerofboardE6‐2L,cf.drawingno.340L.

Turningswitchno.4ofS131intothepositionONby‐passesthesafetyedgeselectricallyatthefunctioningzoneofthe

safetydevicelimitswitch.Ifthesafetyedgesdonothiteachother,theswitchisleftinthepositionOFF.Ifthecontrolleris

equippedwithserviceterminalE6‐6‐02/3E,thedisplayshows,whenthepositionoftheswitchischanged,foramoment

thetext‘L50‘andafterthat‘OFF‘or‘ON‘accordingtothepositionoftheswitch

12/10

ControlUnitE6L/Rev6.11‐15

6.PHOTOCELLS

6.1.THEAMPLIFIERFORATRANSMITTER‐RECEIVERTYPESAFETYPHOTOCELLINTEGRATEDWITHTHE

ELECTRONICSBOARD

Anamplifierforatransmitter‐receivertypesafetyphotocellisintegratedwithelectronicsboardE6‐2L.Theamplifier,atrim‐

merforamplifieradjustmentandtransmitterandreceiverterminalsarelocatedontheleft,uppercorneroftheboard.The

transmitterandreceiverareconnectedaccordingtothefollowingfigure4.

Leftconnectors1and2oftheconnectorareinstalledwiththetransmitter(LT),theredsignalcabletoconnector1andthe

blacksignalcabletoconnector2.Therightsideconnectorsoftheconnectorareconnectedwiththereceiver(LR),the

sheathorblackcabletoconnector3andtheyellowsignalcabletoconnector4.NOTE!Theconnectorhasfiveconnectors

andthemiddleoneisleftempty.

Thephotocellamplifieristunedasfollows:

S301ON(pinsshortcircuitedwithaplug):widedoorway(greateramplifica‐

tion)

S301OFF(withoutashortcircuitplug):narrowdoorway(smalleramplifica‐

tion)

R308:adjustmentofamplification.

H300(green):lightsupwhentheamplificationisadjustedtosufficientmagni‐

tudewiththeR308andwhenthelightbeamisintact.

H301(green):lightsupwhenthephotocellamplifierhasoperatingvoltage.

H302(green):goesoutwhenthephotocellamplifiercontactopens.

TheLEDsarelocatedabovetheextradeviceterminalsontheleftedgeoftheconnector.

Thecorrectadjustmentofthephotocellamplifierisperformedattheinstallationsitebytestingwhetherthephotocellfunc‐

tionsreliably.Theamplificationmaynotbesettooweaknortoostrong.Thereceivershouldbeinstalledontheshadier

side,outofdirectsunlight.

Ifitisnecessarytolengthenthecablesofthetransmitterorthephotocellreceiver,thetransmittercableshouldgenerally

belengthened.Thetransmitterandreceiverconductorsshouldnotruninsidethesamecablesheath.Ifthismustbedone,

thecablemustbeofthedouble‐protectedtype.Fromtheoperationalpointofview,themostreliablewayistoinstallapro‐

tectedcableforeach.

ThesimplestwaytoalignthetransmitterandthereceiveristoconnectamicroammeterinserieswiththereceiverintheAC

band.Thetransmitterandthereceivershouldbeadjustedsothatthecurrentshownbythemeterisasgreataspossible,

thusindicatingtheoptimumalignment.

Ifanintegratedphotocellisnotused,shortcircuitplugNo.4ofterminalJ6mustbeconnected.

6.2.TESTINGPHOTOCELLS

OneofthefeaturesofcontrolunitE6Lcomprisesthetestingoftheclosingsafetyphotocelloperation.Thesafetyphotocell

istestedwheneverthedooropens.Withanintegratedphotocell,photocelltestingisperformedbydisconnectingthetrans‐

mittervoltagethatcorrespondstothedisconnectionofthephotocellbeam.Thetestingoperationisvisiblewhenthedoor

opensafterthegreenH56LEDhasgoneoff.IftheLEDdoesnotgooffbecauseofamalfunctionorthesafetycircuitinthe

closeddirectiondoesnotdisconnect,thecontrolchangestohold‐to‐runinthecloseddirection.Simultaneously,thered

LED,H104,blinksrapidly.Ifthecontrolhasaserviceterminal,itdisplaystheerrorcode“E 30”.Theerroralarmdisappears

whenthephotocelltestingissuccessful.Ifnophotocelltestisperformed,shortcircuitplugNo.6ofterminalJ6mustbe

connected.Safetyphotocelloperationmustbecheckedduringeachservicingoratleastonceayear.

Figure4.

LRLT

S301

R308

43

2

1

LT LR

red

black

sheath

yellow

16‐ControlUnitE6L/Rev6.11

Inadditiontotheintegratedphotocell,theE6‐2Lboardhasaseparatesocket,X103,whichcanbeconnectedinserieswith

otheroutsidephotocells,forexampleaseparatesinglechannelE6‐4oraseparatetwo‐channelEU2‐4oraseparatemirror

photocell.Whenconnectingamirrorphotocell,youneedaseparatescrewterminalpushedintoconnectors55and56of

connectorX103.Theelectronicszeroforthemirrorphotocellcanbeacquiredfromconnector58.Ifaseparatephotocellis

notused,connectors55and56ofconnectorX103mustbeinstalledwithatwo‐partscrewterminalwhoseconnectorsmust

beshortcircuitedwitheachother.

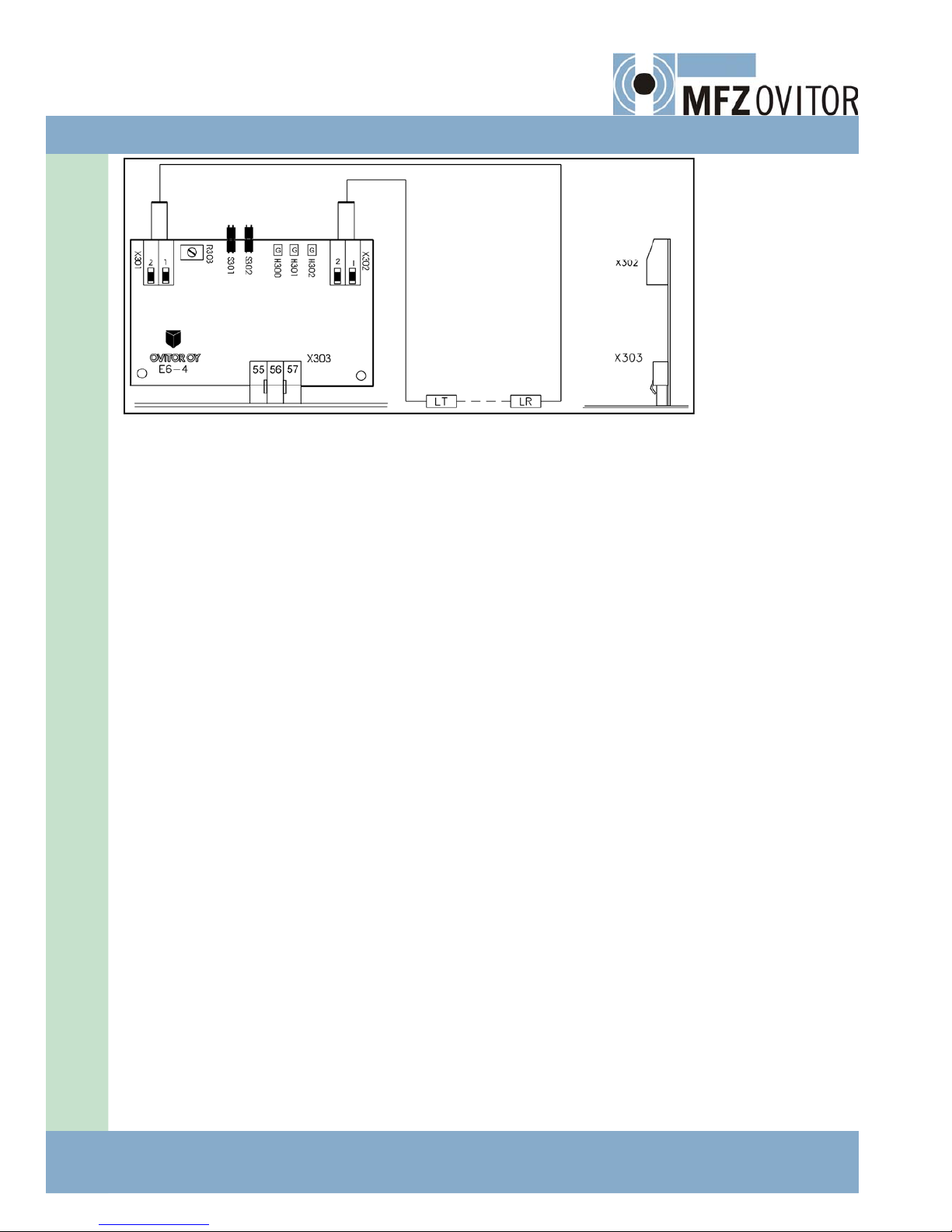

6.3.SEPARATESAFETYPHOTOCELLE6‐4,SINGLE‐CHANNEL

TheseparatesafetyphotocellamplifierboardE6‐4isinstalledintotheplug‐insocketX103intherightedgeofboardE6‐2L,

cf.drawingno.340L.IfaterminalblockwithajumperhasbeeninstalledinsocketX103,theterminalblockisfirstremoved

bypullingout,andthenterminalX303ofthephotocellamplifierboardispushedintosocketX103sodeepthatitsclawsget

intoperfectgripwiththecorrespondingclampstepoftheX103.Installedinanormalway,theboardonlyfitsinoneposi‐

tion.ThecomponentsideoftheboardfacestheE6‐2LsideoftheCPUboard.Thetransmitterandthereceiverareinstalled

ontheamplifierboardaccordingtothewiringdiagram.Thereceiver(LR)ismountedonterminalX301,thesheathontopin

1andthesignalconductor(yellow)ontopin2.

Thetransmitter(LT)isconnectedtotheterminalX302,thesignalconductor(red)ontopin1andthesheathortheblack

conductorontopin2.NOTE!Theorderofpinsisfromrighttoleft.Ifanothertypeofphotocellisused,itisinstalledaccord‐

ingtothewiringdiagramandtheinstructionofdrawingno.340L.

PhotocellamplifierE6‐4istunedupasfollows(cf.figure5):

• S301ON(pinsshort‐circuitedwithaplug):widedoorway(greateramplification);

• S301OFF(withoutashortcircuitplug):narrowdoorway(smalleramplification);

• S302ON(pinsshort‐circuitedwithaplug):thephotocellamplifierswitchedoffwhenthephotocellbeamisbroken,

so‐calledlightoperation.TheS302istobeswitchedintheONpositionincaseofasafetyphotocell;

• S302OFF(withoutshortcircuitplug):photocellamplifierisswitchedoffwhenthephotocellbeamisNOTbroken;

so‐calleddarkoperation.TheS302isconnectedintheOFFpositionwhentheamplifierisusede.g.asanopening

photocellinaseparatesocketFC2;

• R308:adjustmentofamplification;

• H300(green):lightsupwhentheamplificationisadjustedsufficientlygreatwiththeR308andwhenthelightbeam

isintact;

• H301(green):lightsupwhenthephotocellamplifierhasgotoperatingvoltage;

• H302(green):goesoutwhenthephotocellamplifiercontactopens

Thecorrectadjustmentofthephotocellamplifierisdoneattheplaceofinstallationbytestingareliablefunctioningforthe

photocell.

• Theamplificationmaynotbesettooweaknortoostrong.

• Thereceivershouldbeinstalledontheshadiersidesothatsunlightdoesnotshineonitdirectly.

• Ifitisnecessarytolengthenthecablesofthetransmitterorthereceiverofthephotocell,thecableofthetransmit‐

tershouldgenerallybelengthened.Thetransmitterandreceiverconductorsshouldnotruninsidethesamecable

sheath.Ifthismustbedone,thecablemustbeofdouble‐protectedtype.Fromthepointofviewofoperation,the

mostreliablewayistoinstallforboththeirownprotectedcable.

• Thealignmentofthetransmitterandthereceiverismostsimplydonesothatamicroampere‐meterisconnectedin

serieswiththereceiverintheACband.Thetransmitterandthereceiverareadjustedsothatthecurrentshownby

themeterisasgreataspossible,thusindicatingtheoptimumalignment.

6.PHOTOCELLS

12/10

ControlUnitE6L/Rev6.11‐17

INSTALLATION

POSITION

TRANSMIT‐

TER

RECEIVER

R308=ADJUSTMENTOFAMPLIFICATION

S301ON‐WIDEDOORWAY

OFF‐NARROWDOORWAY

S302ON‐LIGHTOPERATION

OFF‐DARKOPERATION

Figure5.PhotocellamplifierE6‐4

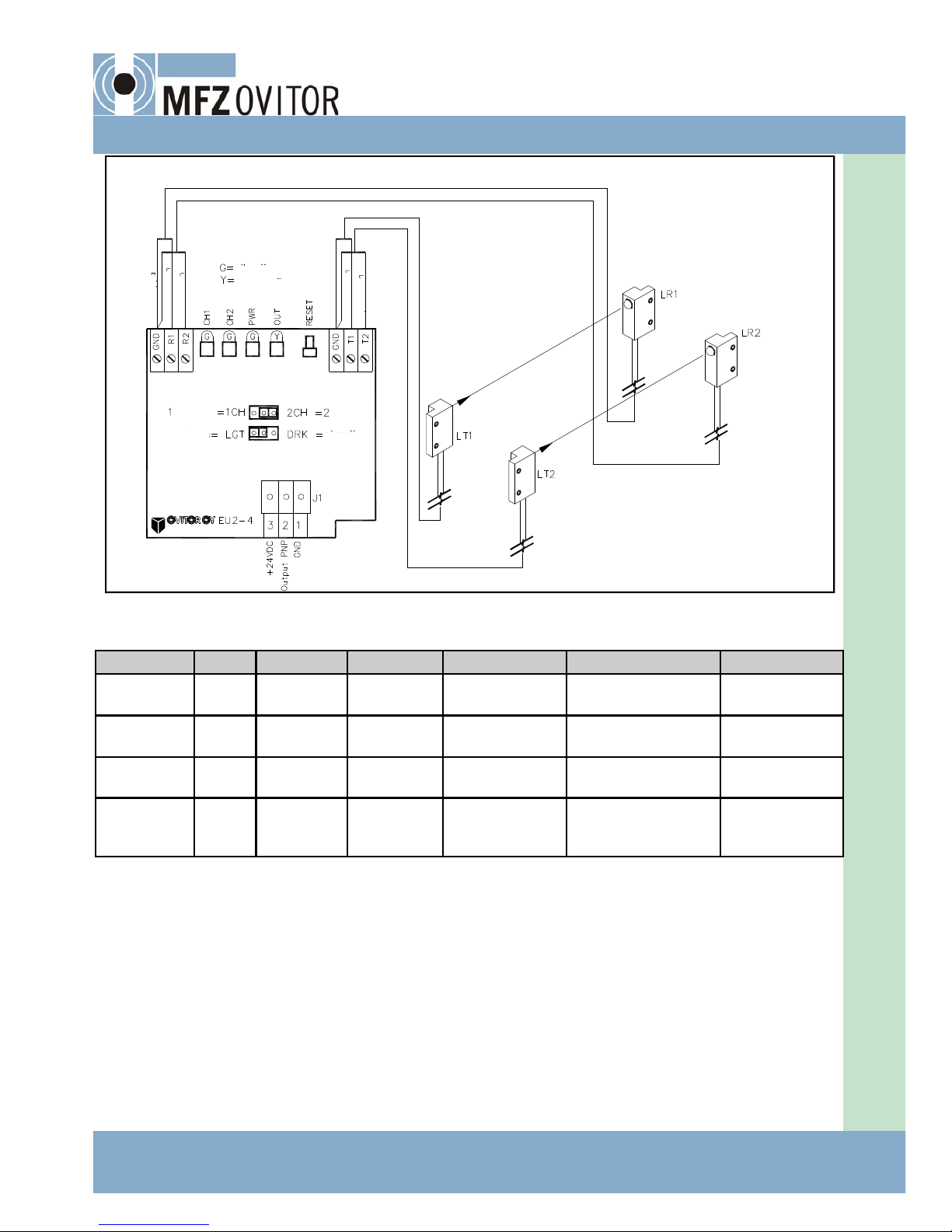

6.4.SEPARATESAFETYPHOTOCELLEU2‐4,1OR2CHANNELS

ThesafetyphotocellEU2‐4isdirectlysuitableforthecontrolunitE6L.Theamplifierboardwilloperatein1or2channel

modedependingofthepositionoftheshortcircuitplug1CH/2CH.Themiddlepinofthe3‐pinterminalisconnectedtopin

1CH(1channel)ortopin2CH(2channels).In1channelmodethetransmitterisconnectedtoterminalsT1andGND,the

receivertoterminalsR1andGND.In1channelmodethelevelindicatingLEDCH2isnoton.

TheselectionbetweenlightanddarkoperationmodeismadebytheshortcircuitplugDRK/LGT.Themiddlepinofthe3‐

pinterminalisconnectedtopinDRK(dark)ortopinLGT(light)accordingtotheoperationinuse.Incaseofsafetyphotocell

theconnectionislight.

ThetypeofthetransmitterofsafetyphotocellEU2‐4isLT01‐WS‐15M,thetypeofreceiverisLR02‐WS‐15M.Thetransmit‐

terLT‐WS‐15MandthereceiverLR‐WS‐15MofthepreviousphotocelltypesE6‐4,PA‐seriesandMPA‐series,arenotdirectly

suitabletousewithEU2‐4transmittersandreceivers,buttheymustalwaysbeusedastheirownpair.Whenusingtransmit‐

tersandreceiversofthepreviousphotocelltypesinthenewamplifierEU2‐4,inordertowork,theymustbeusedastheir

ownpair.Whenusingnewtransmittersandreceiverswithanamplifierofprevioustypes,pleasecontactOVITOROY.

ThesafetyphotocellamplifierboardEU2‐4isinstalledintotheplug‐insocketX103intherightedgeofboardE6‐2;see

illustration1.IfaterminalblockwithajumperhasbeeninstalledinsocketX103,theterminalblockisfirstremovedbypull‐

ingitout,andthenterminalJ1ofthephotocellamplifierboardispushedintosocketX103sodeepthatitsclawsgetinto

perfectgripwiththecorrespondingclampstepoftheX103.Installedinanormalway,theboardonlyfitsinoneposition.

ThecomponentsideofboardEU2‐4facesthecomponentsideoftheE6‐2Lboard.Thetransmitterandthereceiverofthe

photocellareconnectedontheamplifierboardaccordingtothewiringdiagramandillustration6.Theopeningphotocell

amplifierboardismountedonaseparatesocketFC2.

PhotocellamplifierEU2‐4istunedupautomaticallywhenthealignmentsoftransmittersandreceiversarecorrectandthe

amplifieroperatingvoltagewillbeswitchedon,ortheRESETbuttonontheboardwillbepushed.Whenswitchingpower

on,thegreenLEDPWRintheamplifierlightsup,andiftransmittersandreceiversarecorrectlyaligned,alsotheyellowLED

OUTlightsupindicatingbeamunity.SimultaneouslytheoperationlevelindicatinggreenLED’sCH1andCH2flashslowly

andafterawhilekeeponlightingconstantly.IfthelevelindicatinggreenLED’scontinuouslyflashslowly,thephotocellam‐

plificationisatmaximumrange.Thereasonforthatisnormallyawrongalignmentoftransmittersandreceiversanditmust

bechecked.IfthelevelindicatinggreenLED’sflashquickly,thereceiversareinfluencedbyasevereextraneousdisturbance.

InthatcasetheyellowLEDOUTgoesout.

18‐ControlUnitE6L/Rev6.11

6.PHOTOCELLS

LED’sFUNCTIONINGINLIGHTOPERATIONMODE

Figure6.PhotocellamplifierEU2‐4

LR=receiver

LT=transmitter

LEDColourOnOffFlashingslowlyFlashingcontinuouslyFlashingquickly

LevelLEDCH1GreenBeam1solidBeam1

broken

TuningAmplificationatmaxExtraneous

disturbance

LevelLEDCH2GreenBeam2solidBeam2

broken

TuningAmplificationatmaxExtraneous

disturbance

Operation

voltagePWR

GreenInorderMissingFaultyamplifierFaultyamplifierFaultyamplifier

OutputOUTYellowBeamssolidBeambroken

orextraneous

disturbance

Swingingobstacle

breaksthebeam

Swingingobstacle

breaksthebeam

Swingingobstacle

breaksthebeam

• Whenusingtwochannelsthebothtransmittersmustbeonthesameside,seefigure6.

• Thereceiversshouldbeinstalledontheshadiersidesothatsunlightdoesnotshineonthemdirectly.

• Ifitisnecessarytolengthenthecablesofthetransmitters/receiversofthephotocells,thecablesofthetransmitterare

tobelengthened.Thetransmitter/receiverconductorsshouldnotruninsidethesamecablesheath.Ifdone,thecable

mustbeofdouble‐protectedtype.Themostreliablewayistoinstallforallofthemtheirownprotectedcable.

• Thealignmentofthetransmitterandthereceiverismostsimplydonebyconnectingamicroammeterinserieswiththe

receiverintheACband.Thetransmitterandthereceiverareadjustedsothatthecurrentshownbythemeterisasgreat

aspossible,thusindicatingtheoptimumalignment.

• Thefunctioningofphotocellisbesttestedbybreakingforinstancewithahandthebeamandlookingatthesametimeif

thechannellevelLEDgoesout.Whenclosingthedoormuststopandopenwhenthephotocellworks.

Green

sheath

DARK

channel

LIGHT

Yellow

yellow

yellow

black

red

red

channels

12/10

ControlUnitE6L/Rev6.11‐19

6.5.USINGPHOTOCELLAMPLIFIERSE6‐4ANDEU2‐4ASOPENINGPHOTOCELLS

PhotocellamplifiersE6‐4andEU2‐4canalsobeusedasopeningphotocells,inwhichcasetheamplifierisintheso‐called

darkoperationmode.Theselectionofthedarkoperationmodeisdonewiththeshort‐circuitplugontheamplifierboards,

ashasbeenexplainedinthesafetyphotocellinstructionsabove.Theinstallationandwiringofthephotocelltransmitters

andreceiversarethesameasinsafetyphotocelloperation.Inopeningphotocelloperation,theamplifierisinstalledinthe

separateamplifierbaseFC2,installedwithDin‐rail,inaccordancewithfigure7,NOTinthesafetyphotocellbaseX103pre‐

installedonthecircuitboard.

Theterminalsontheamplifierbaseareconnectedtothedesiredopeningterminals.Whenmakingthewiring,remember

thecorrectdirectionofcurrentontheamplifierboard.Thevoltagetobecontrolledisinputontheamplifierbasetotermi‐

nal255,andthecontrollingvoltageisoutputfromterminal256.Thezeropotentialofelectronicsisconnectedtoterminal

257.Whenrequired,thedirectionofcurrentmustbecheckedinthediagramoftheinnergroupingofcontroldevices,in

thefinalsectionofthemanualconcerned.Below,thereisanoptionforthewiringoftheamplifierbaseoftheopeningpho‐

tocell(figure8).

Figure7.AmplifierbaseFC2Figure8.WiringoftheamplifierbaseFC2

DIN‐railincontrolunit

TheamplifierbaseFC2canalsobeutilisedwhenseparateidlecurrentsafetydevicesareconnectedinseries,suchasa

safetyphotocellandavehicledetector.Itmustberememberedinserialconnectionthatthephotocellamplifierisfirstinit

andtherelayoutputofthevehicledetectorafterit.Terminal255ofamplifierboardFC2isconnectedtoscrewterminal55

addedtothebaseofthesafetyphotocellofthecentralboard.Terminal256ofamplifierboardFC2isconnectedtoonepole

oftheopeningcontactoftherelayoutputofthevehicledetector.Theotherpoleoftheopeningcontactoftherelayoutput

ofthevehicledetectorisconnectedtoscrewterminal56addedtothebaseofthesafetyphotocellofthecentralboard.

Terminal257ofamplifierboardFC2isconnectedtoaterminalinzeropotentialofthecentralboard.

20‐ControlUnitE6L/Rev6.11

7.INSTALLATIONOFANEXTRADEVICEBOARDEQUIPPEDWITHANEDGETERMINAL

TheedgeterminaloftheextradeviceboardisconnectedtothefreeBUSterminalofboardE6‐2L.TheterminalsareBUS1,

BUS2andBUS3.Thedirectionofinstallationisshowninillustration9.Theextradeviceboardterminalmustfitcompletely

intotheBUSterminal.CheckthatthegreenLEDontheextradeviceboardlightsup.Thisshowsthattheprogramhasrecog‐

nisedtheboardtypeandthattheboardisreadyforoperation.

IftheLEDdoesnotlightupandthereareseveralextradeviceboardsinthecontroller,youcansearchforthedefective

boardasfollows:

1.Switchpoweroffofthecontroller.

2.RemoveallextradeviceboardsfromterminalsBUS1,BUS2andBUS3.

3.Reinstalloneboardatatime.

4.Switchpowerbackon.

5.IftheLEDlightsup,theboardinquestionisOK.

6.Repeatsteps1...5forallextradeviceboards.

7.IftheLEDdidnotlightupinanyextradeviceboard,thefaultisinthebasiccontroller.

TheserviceterminalequippedwithadisplaydoesnothaveaLED.Instead,afunctioningboardwillshowanumericseriesor

atextonthedisplay.Inadefectiveterminal,thedisplayisoutoritssegmentsarelitsporadically.

BOARD

E6‐2L

Installingtheboardbackwardsisnotpossiblebe‐

causeofthedoweledholeintheextradeviceboard

andacutpininthecorrespondingplaceoftheBUS

Extradeviceboardcompo‐

nentside

Figure9.Installationofanextradeviceboard

12/10

Table of contents

Other MFZ Ovitor Gate Opener manuals

Popular Gate Opener manuals by other brands

Comunello Automation

Comunello Automation ABACUS 220 Installation and user manual

Erreka

Erreka VIVO-M201M Quick installation and programming guide

Centsys

Centsys D3 user guide

Maximum Controls

Maximum Controls Max Megatron 1400 Installation and owner's manual

DoorKing

DoorKing 6004 manual

FAAC

FAAC 740 D manual