MG Energy Systems LFP Series User manual

MG Energy Systems B.V. | Foeke Sjoerdswei 3 | 8914 BH Leeuwarden | The Netherlands

Innovation in energy storage

Lithium-Ion LFP series battery module

- Manual -

MGLFP240280, MGLFP241280 (LFP 280Ah)

MG Energy Systems B.V.

Revision: 1.2

Date: 11-11-2020

MG Energy Systems B.V. | Foeke Sjoerdswei 3 | 8914 BH Leeuwarden | The Netherlands

Innovation in energy storage

Copyrights 2020 MG Energy Systems B.V.

All Rights Reserved

This publication or parts thereof, may not be reproduced in any form, by any method, for any purpose.

For conditions of use and permission to use this manual for publication in other than the English language,

contact MG Energy Systems B.V..

MG ENERGY SYSTEMS B.V. MAKES NO WARRANTY, EITHER EXPESSED OR IMPLIED, INCLUDING BUT NOT

LIMITED TO ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE,

REGARDING THESE MG ENERGY SYSTEMS B.V. PRODUCTS AND MAKES SUCH MG ENERGY SYSTEMS B.V.

PRODUCTS AVAILABLE SOLELY ON AN “AS IS” BASIS.

IN NO EVENT SHALL MG ENERGY SYSTEMS B.V. BE LIABLE TO ANYONE FOR SPECIAL, COLLATERAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES IN CONNECTION WITH OR ARISING OUT OF PURCHASE OR USE

OF THESE MG ENERGY SYSTEMS B.V. PRODUCTS. THE SOLE AND EXCLUSIVE LIABILITY TO MG ENERGY

SYSTEMS B.V.., REGARDLESS OF THE FORM OF ACTION, SHALL NOT EXCEED THE PURCHASE PRICE OF THE

MG ENERGY SYSTEMS B.V. PRODUCTS DESCRIBED HERE IN.

MG Energy Systems B.V. reserves the right to revise and improve its products as it sees fit. This publication

describes the state of this product at the time of its publication and may not reflect the product at all times

in the future.

MG Energy Systems B.V. | Foeke Sjoerdswei 3 | 8914 BH Leeuwarden | The Netherlands

Innovation in energy storage

TABLE OF CONTENTS

1 GENERAL ...................................................................................................................................................... 6

1.1 Document history ................................................................................................................................ 6

1.2 Terms, abbreviations, and definition................................................................................................... 6

2 SAFETY INSTRUCTIONS................................................................................................................................. 7

2.1 Safety message level definition ........................................................................................................... 7

2.2 User health and safety ......................................................................................................................... 7

General precautions..................................................................................................................... 7

Qualifications and training........................................................................................................... 8

Non-compliance risks................................................................................................................... 8

Unacceptable modes of operation .............................................................................................. 8

3 TRANSPORT, STORAGE AND UNPACKING.................................................................................................... 9

3.1 Transport.............................................................................................................................................. 9

3.2 Storage................................................................................................................................................. 9

3.3 Unpacking .......................................................................................................................................... 10

Scope of delivery........................................................................................................................ 10

4 GENERAL DESCRIPTION.............................................................................................................................. 11

4.1 Battery system components .............................................................................................................. 11

4.2 Functional description ....................................................................................................................... 11

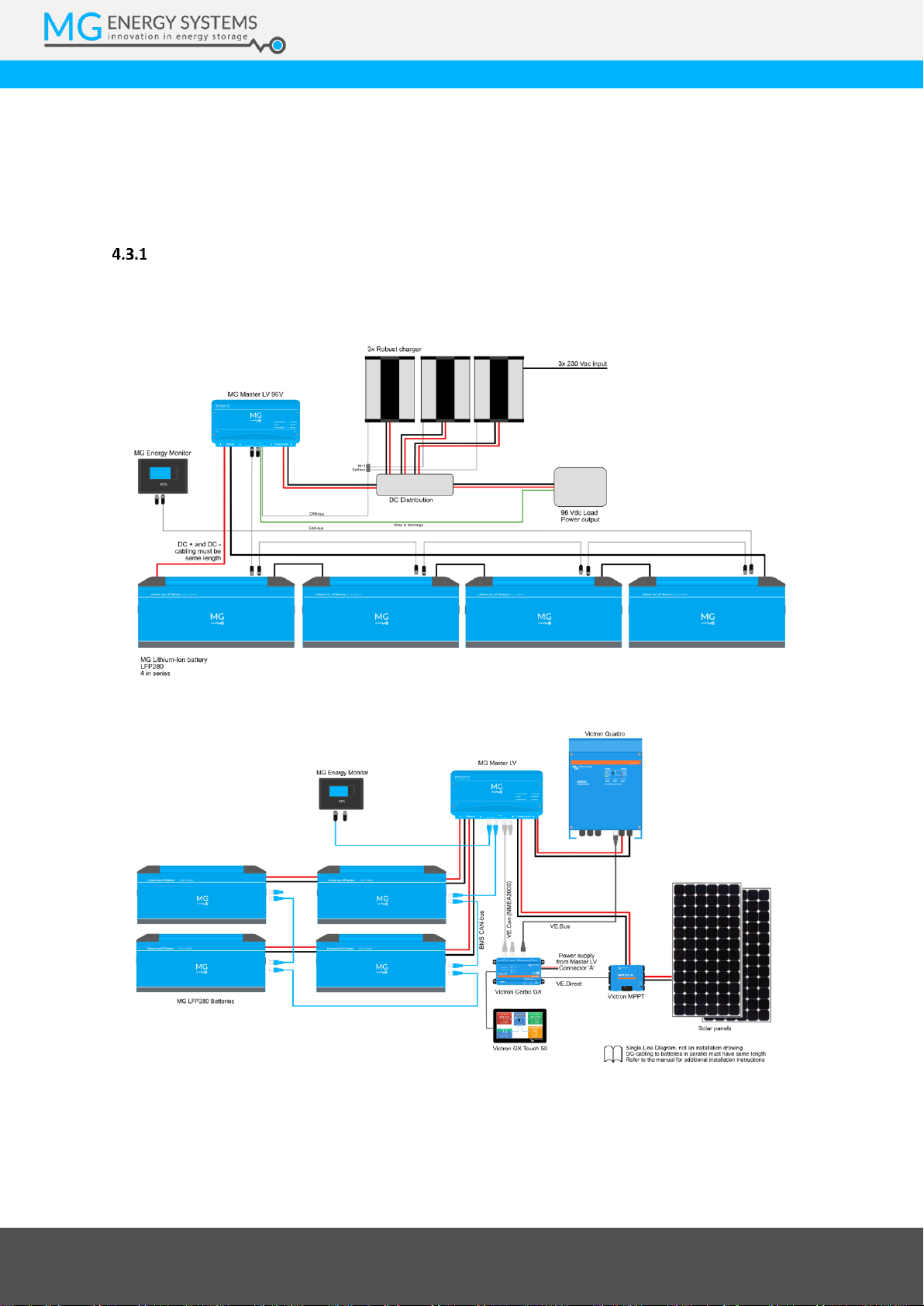

4.3 Example systems................................................................................................................................ 12

Low voltage systems .................................................................................................................. 12

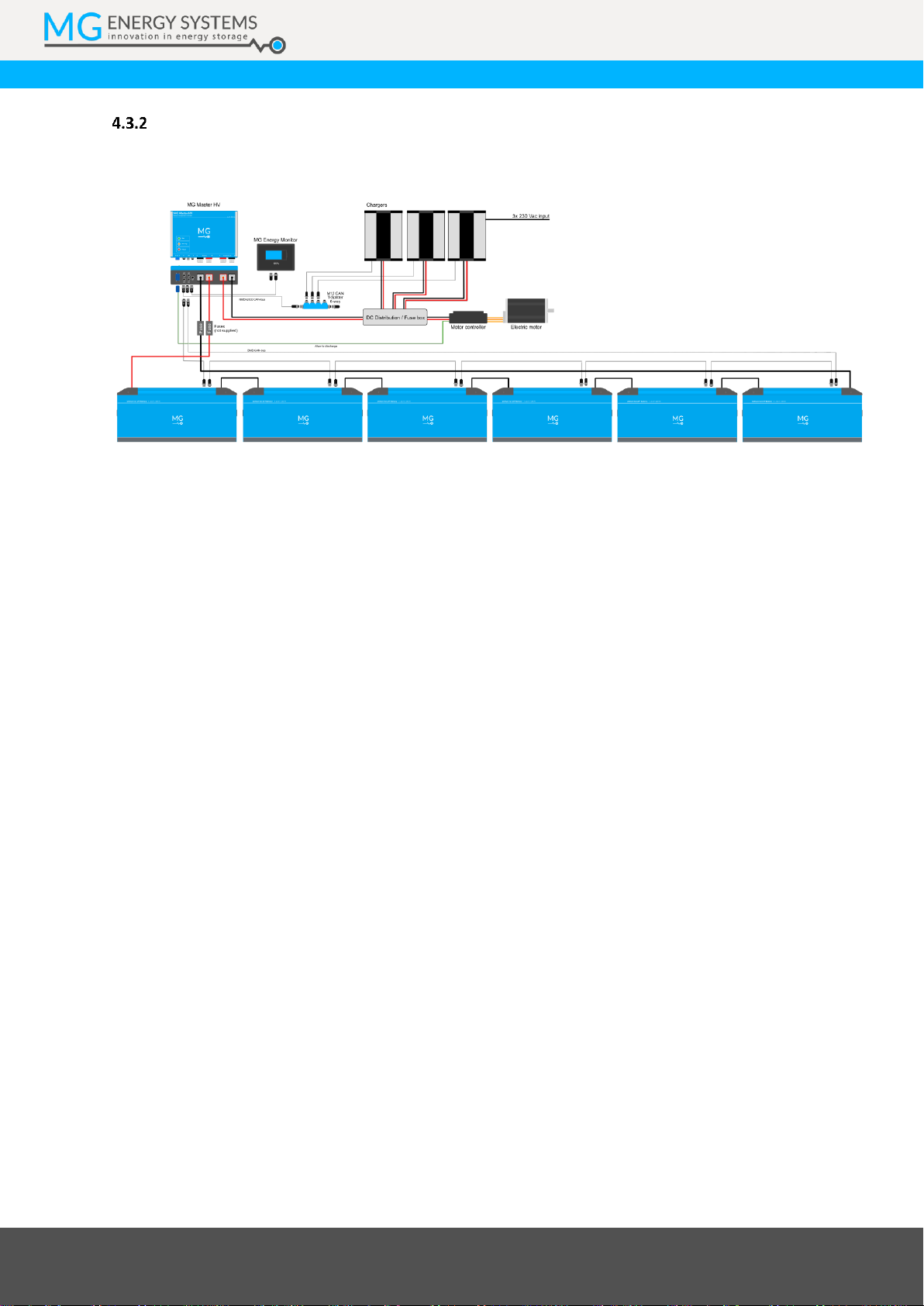

High voltage systems ................................................................................................................. 13

5 MODELS ..................................................................................................................................................... 14

5.1 Models and configurations ................................................................................................................ 14

Battery designation.................................................................................................................... 14

5.2 Identification label ............................................................................................................................. 15

6 OVERVIEW.................................................................................................................................................. 16

6.1 Connection overview ......................................................................................................................... 16

6.2 Connections details............................................................................................................................ 17

RJ45 CAN-bus connector details ................................................................................................ 17

M12 CAN-bus connector details ................................................................................................ 18

Power connections..................................................................................................................... 19

6.3 Status indication ................................................................................................................................ 21

Indication ................................................................................................................................... 21

MG Energy Systems B.V. | Foeke Sjoerdswei 3 | 8914 BH Leeuwarden | The Netherlands

Innovation in energy storage

7 INTEGRATION REQUIREMENTS AND INSTRUCTIONS ................................................................................ 22

7.1 Risk assessment ................................................................................................................................. 22

7.2 Location.............................................................................................................................................. 22

Environment............................................................................................................................... 22

Thermal management................................................................................................................ 22

7.3 Placement .......................................................................................................................................... 23

Positioning the battery .............................................................................................................. 23

Mounting considerations........................................................................................................... 24

Battery module spacing requirements ...................................................................................... 25

Placement in sealed spaces or compartments .......................................................................... 25

7.4 Electrical............................................................................................................................................. 26

Power cables .............................................................................................................................. 26

Parallel configuration................................................................................................................. 27

Paralleling using the Distributor LV............................................................................................ 30

Series configuration ................................................................................................................... 31

Charger....................................................................................................................................... 32

8 INSTALLATION............................................................................................................................................ 33

8.1 Installation procedures ...................................................................................................................... 33

8.2 Mounting procedure.......................................................................................................................... 34

8.3 Equipotential bonding connection procedure................................................................................... 34

8.4 Electrical connection procedure ........................................................................................................ 35

Power connection procedure .................................................................................................... 35

CAN-bus connection procedure................................................................................................. 37

8.5 Fuse replacing procedure................................................................................................................... 38

Dummy fuse............................................................................................................................... 38

Replacement instructions .......................................................................................................... 38

9 COMMISSIONING....................................................................................................................................... 40

10 SERVICE .................................................................................................................................................. 41

10.1 Maintenance ...................................................................................................................................... 41

Connections ............................................................................................................................... 41

Cleaning...................................................................................................................................... 41

10.2 End-of-life........................................................................................................................................... 41

10.3 Disposal.............................................................................................................................................. 41

11 BOUNDARY LIMITS................................................................................................................................. 42

MG Energy Systems B.V. | Foeke Sjoerdswei 3 | 8914 BH Leeuwarden | The Netherlands

Innovation in energy storage

11.1 Limits.................................................................................................................................................. 42

Cell voltage................................................................................................................................. 42

Cell temperature charging ......................................................................................................... 43

Cell temperature discharging..................................................................................................... 43

Power terminal temperature..................................................................................................... 43

Current ....................................................................................................................................... 44

Balancing.................................................................................................................................... 44

12 TECHNICAL SPECIFICATIONS .................................................................................................................. 45

12.1 Dimensions......................................................................................................................................... 46

13 ORDERING INFORMATION ..................................................................................................................... 47

14 CONTACT DETAILS.................................................................................................................................. 48

MG Energy Systems B.V. | Foeke Sjoerdswei 3 | 8914 BH Leeuwarden | The Netherlands

Innovation in energy storage

1GENERAL

Before continuing read the instructions in this chapter carefully and be sure the instructions are fully

understood. If there are questions after reading the instructions please consult MG Energy Systems.

1.1 Document history

Table 1 - Document history

Rev.

Date

Changes

Revision author

0.1

18-08-2020

Initial document

Ane Tjitze Rienstra

1.0

20-09-2020

Added schematics, detailed connector information

etc.

Mark Scholten

1.1

20-10-2020

Minor changes and typo fixes.

Mark Scholten

1.2

11-11-2020

Fixed typos.

Mark Scholten

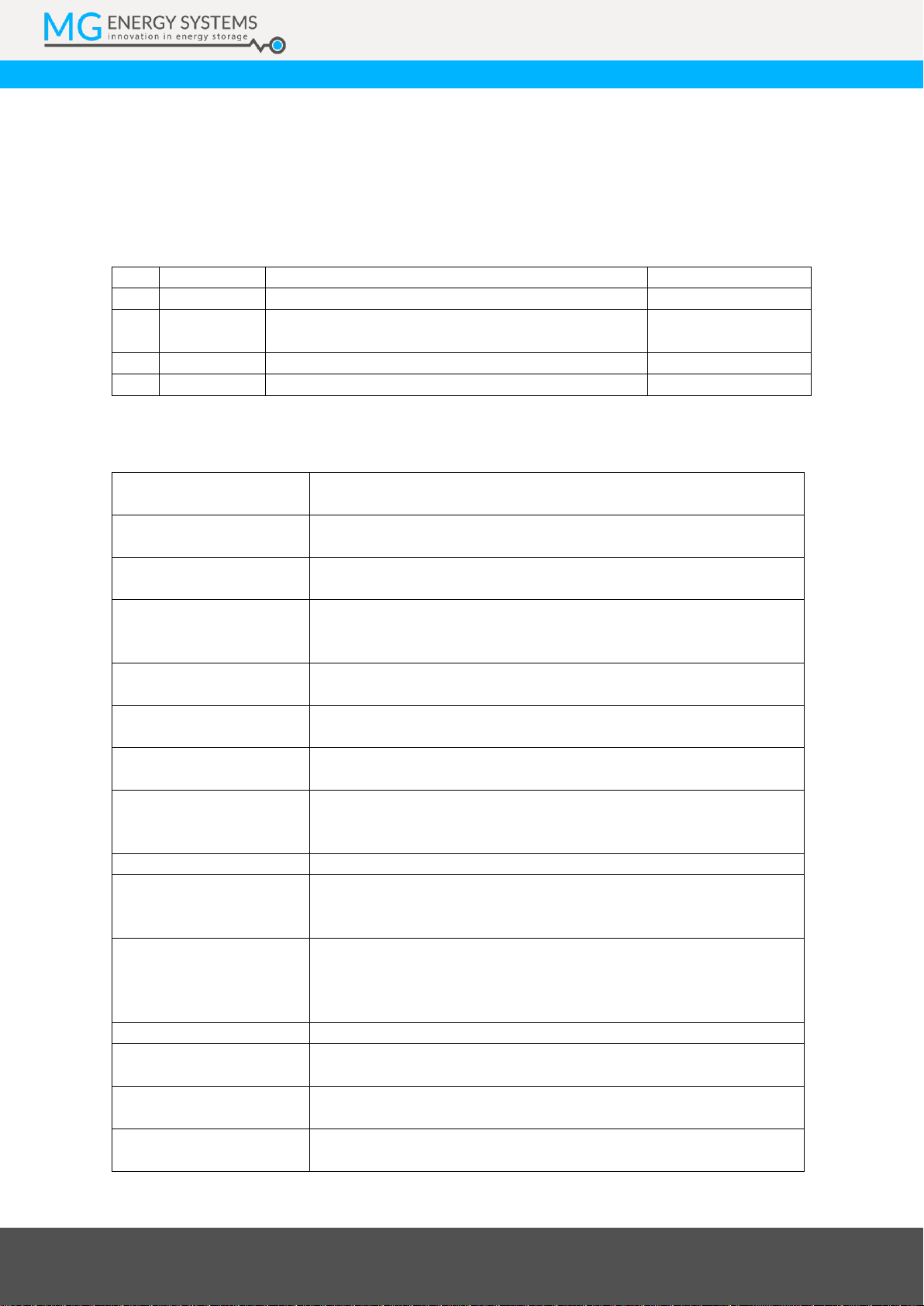

1.2 Terms, abbreviations, and definition

Table 2 - Terms, abbreviations, and definitions

Battery cell

Battery cell; the smallest building block in a battery, a chemical unit.

Cell is the bare Lithium-Ion battery cell.

Battery module

Battery module; is an assembly of submodules, BMS, fluid cooling

and outer enclosure.

Battery stack

Battery stack; is a set of multiple cells in cell cassettes constructed as

one.

BMS

Battery Management System; The BMS is the electronics that

monitors the battery cell parameters to keep it within the operation

specifications.

CAN-bus

Controller Area Network bus; CAN-bus is a standard serial data-bus

that provides data communication between two or more devices.

C-rate

C-Rate; the current (A) used to charge/discharge the battery system

divided by the rated ampere-hours (Ah).

EMS

Energy Management System; The EMS controls all power sources

and consumers in a system.

HVIL

High Voltage Interlock Loop; is a wire loop which is created for

protection of pulling cables from the battery system while in

operation. It shuts down the system when loop is not closed.

IC

Integrated Circuit; is a chip containing an electronics circuit;

MSDS

Material Safety Data Sheet; is a document that lists information

relating to occupational safety and health for the use of various

substances and products.

NMEA 2000

National Marine Electronics Association’s NMEA 2000 is a plug-and-

play communications standard used for connecting marine sensors

and display units within ships and boats, standardised in the IEC

61162-1.

PCB

Printed Circuit Board; is a board containing an electronic circuit;

PCBA

Printed Circuit Board Assembly; is a board containing an electronic

circuit including passive and active components;

SoC

State-of-Charge; is the remaining capacity in a battery cell or module

in percent (%).

SoH

State-of-Health; is a figure of merit of the condition of a battery (or a

cell, or a battery pack), compared to its ideal conditions.

MG Energy Systems B.V. | Foeke Sjoerdswei 3 | 8914 BH Leeuwarden | The Netherlands

Innovation in energy storage

2SAFETY INSTRUCTIONS

2.1 Safety message level definition

Table 3 - Safety message levels overview

WARNING:

A hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION:

A hazardous situation which, if not avoided, could result in minor or moderate

injury.

LIMITATION:

A limitation to use which must be considered for safe use of the equipment.

ELECTRICAL HAZARD:

The possibility of electrical risks if instructions are not followed in a proper

manner.

NOTICE:

A potential situation which, if not avoided, could result in an undesirable

result or state.

A practice not related to personal injury.

2.2 User health and safety

General precautions

This product is designed and tested in accordance with international standards. The equipment should be

used according the intended use only.

WARNING:

A battery is a permanent energy source which cannot be turned off.

ELECTRICAL HAZARD:

Wear applicable personal protective equipment when working on a

battery system.

Use insulated tools when working on a battery system.

Make sure the locale health and safety regulations for working on battery

systems are followed.

There is a risk of electrocution and burns when working on higher voltage

systems without proper protective gear and special training.

MG Energy Systems B.V. | Foeke Sjoerdswei 3 | 8914 BH Leeuwarden | The Netherlands

Innovation in energy storage

Qualifications and training

The personnel responsible for the assembly, operation, inspection, and maintenance of the battery system

must be appropriately qualified. The user company must do the following tasks:

Define the responsibilities and competency of all personnel working on the battery system.

Provide instruction and training.

Ensure that the contents of the operating and safety instructions have been fully understood by the

personnel.

Check the local safety rules and guidelines they have higher preference over the manufacturers

specification in case of regulatory conflicts.

Working on higher voltages requires specific training and certification.

Instructions and training can be carried out by MG Energy Systems B.V. by order of the user company.

Non-compliance risks

Failure to comply with all safety precautions can result in the following conditions:

Death or serious injury due to electrical, mechanical, and chemical influences.

Environmental damage due to the leakage of dangerous materials.

Product damage.

Property damage.

Loss of all claims for damages.

Unacceptable modes of operation

The operational reliability of this product is only guaranteed when it is used as intended. The operating limits

on the identification tag and in the data sheet may not be exceeded under any circumstances. If the

identification tag is missing or worn, contact MG Energy Systems B.V. for specific instructions.

WARNING:

The battery modules may only be used in combination with a master BMS.

(MG Master LV or MG Master HV)

MG Energy Systems B.V. | Foeke Sjoerdswei 3 | 8914 BH Leeuwarden | The Netherlands

Innovation in energy storage

3TRANSPORT, STORAGE AND UNPACKING

3.1 Transport

The package and transport instructions provided by the manufacturer must be followed under all

circumstances.

Notes on transport:

Use original packaging materials.

Lithium-Ion batteries are dangerous goods and must be

transported according to the applicable rules.

Transportation company and shipper must be qualified to

transport and package dangerous goods.

The SoC during transport must be ≤30%.

For details on transport of this battery module see the MSDS.

CAUTION:

It is not allowed to transport, connect or operate a damaged battery.

NOTICE:

No liability can be accepted for damage during transport if the equipment is not

transported in its original packaging or if the original packaging is opened before

the destination is reached.

NOTICE:

The SoC of the battery as delivered from factory is ≤30%.

3.2 Storage

The storage instructions provided by the manufacturer must be followed in all circumstances.

Notes on storage:

Battery module must be stored in its original packaging.

Store in a dry, clean, and conditioned location.

Local regulations for storage of dangerous goods may be applicable.

Recommended storage temperature of the battery module is between +10°C to +25°C.

It is recommended to limit the battery charge between 50% and 70% SoC. This will limit calendric

aging.

The battery module’s SoC is decreasing 1% per year. Recharging is required when the voltage is in the range

of the cut-off voltage.

NOTICE:

Check the MG Master LV or MG Master HV manual for storage of a connected

system.

MG Energy Systems B.V. | Foeke Sjoerdswei 3 | 8914 BH Leeuwarden | The Netherlands

Innovation in energy storage

NOTICE:

Check the voltage of the stored battery module every year.

When the battery module voltage is < 24 VDC, recharging is required. Contact MG

Energy Systems for specific instructions and tools.

3.3 Unpacking

Follow these handling guidelines when handling the product to prevent damage during unpacking:

Use care when handling the product.

Leave protective caps and covers on the product until installation.

CAUTION:

Always take the local applicable standards and regulations regarding the

prevention of accidents into account when handling the product. Be aware of the

total mass of the product and do not lift heavy objects unassisted.

Scope of delivery

The scope of delivery is as following:

MG LFP battery module of type as described in chapter 5.

Quick instruction guide.

NOTICE:

Not within the scope of delivery:

Power cables and connectors (details can be found in chapter 6.2.3).

Communication cables and connectors (details can be found in chapter

6.2).

MG Energy Systems B.V. | Foeke Sjoerdswei 3 | 8914 BH Leeuwarden | The Netherlands

Innovation in energy storage

4GENERAL DESCRIPTION

The LFP battery series is based on LiFePO4 chemistry. The next generation battery cells of this chemistry

gives this battery module a high energy density and long cycle life. A modular and compact design makes

system integration more flexible, especially in refit applications. The passive cooling concept keeps

integration simple and straight forward.

These features make this battery suitable for large energy storage applications as well as small peak power

packs in hybrid solutions.

4.1 Battery system components

MG Energy Systems Lithium-Ion battery system consists of the following components:

One or more MG LFP battery modules of the same type;

One or more MG Master HV or MG Master LV battery management systems; Details of these

battery management controllers can be found in their separate description documents;

4.2 Functional description

MG’s system philosophy is to have one master BMS, e.g. a MG Master LV or MG Master HV, per bank of

battery modules which communicates with one or more slave BMSs integrated in the Lithium-Ion battery

module(s). The slave BMSs are monitoring the battery cell parameters like cell voltage and cell temperature.

Besides monitoring, the slave BMS also controls balancing of cells based on the input of the master BMS.

All these parameters are send to the MG Master LV or MG Master HV via a dedicated CAN-bus which collects

all the data and monitors these parameters with different thresholds. When a parameter exceeds the

threshold this will first be communicated to the user via the, separated, auxiliary CAN-bus or the I/O

connections. If the exceeded threshold stays, the master BMS has the possibility to disconnect the batteries

from the system by opening the main contactors.

Functional and safety features of the MG LFP battery module are:

Robust chemistry;

Modular design;

High energy density;

Plug and Play installation: Automatic configuration;

Low voltage solutions: 24 V up to 96 V;

High voltage solutions: Up to 460 V;

RJ45 or M12 CAN-Bus connector options;

MG Energy Systems B.V. | Foeke Sjoerdswei 3 | 8914 BH Leeuwarden | The Netherlands

Innovation in energy storage

4.3 Example systems

Different kind of battery system configurations can be created because of the modular design. Battery

modules can be placed in series and parallel to create higher voltages and larger capacities.

Contact MG Energy Systems B.V. for more information about possible configurations.

Low voltage systems

Low voltage systems up to 96 VDC are setup with the MG Master LV series. For more information about the

MG Master LV, please refer to the data sheet and manual.

Figure 1 - 96 VDC propulsion system

Figure 2 - 48 V small ESS

MG Energy Systems B.V. | Foeke Sjoerdswei 3 | 8914 BH Leeuwarden | The Netherlands

Innovation in energy storage

High voltage systems

High voltage systems up to 460 VDC are setup with the MG Master HV series. For more information about

the MG Master HV, please refer to the data sheet and manual.

Figure 3 - 144 VDC propulsion system

MG Energy Systems B.V. | Foeke Sjoerdswei 3 | 8914 BH Leeuwarden | The Netherlands

Innovation in energy storage

5MODELS

5.1 Models and configurations

The LFP series lithium-ion battery features 2 models. One model suitable for systems voltages up to 96 VDC

and one for systems voltage up to 460 VDC please refer to chapter 12.

Article number

Description

Remarks

MGLFP240280

MG LFP Battery 25.6V/280Ah/7200Wh

24 V up to 96 V,

RJ45 connectors

MGLFP241280

MG LFP Battery 25.6V/280Ah/7200Wh

(M12, HV)

24 V up to 460 V,

M12 connectors

Battery designation

As per IEC 62620 it is required to state a standard designation per battery module configuration. For the LFP

series lithium-ion battery these are given in table 4.

Table 4 - Battery module designation as per IEC 62620

Article number

Designation

MGLFP24x280

IFpP/652/294/193/[1P8S]M/-10+40/90

MG Energy Systems B.V. | Foeke Sjoerdswei 3 | 8914 BH Leeuwarden | The Netherlands

Innovation in energy storage

5.2 Identification label

The identification label of the MG LFP battery module is located at the front of the enclosure.

Example identification label:

Figure 4 - Example identifications label

The identifications label shown in figure 4 contains written information about the product. The explanation

of the symbols used on the identification label is stated in table 5.

Table 5 - Identification lable logo explaination

Declaration of conformity with health, safety, and environmental protection standards

for products sold within the European Economic Area as per directive 2014/35/EU.

Symbol indication the manual must be red before installation and use of the device.

Device is treated according the Waste Electrical and Electronic Equipment (WEEE)

Directive 2012/19/EU.

GS1 data matrix type barcode containing detailed product information.

MG Energy Systems B.V. | Foeke Sjoerdswei 3 | 8914 BH Leeuwarden | The Netherlands

Innovation in energy storage

6OVERVIEW

This chapter shows an overview of the LFP battery.

Each battery module contains the following common parts:

Negative battery pole connection;

Positive battery pole connection;

BMS CAN-bus connection, either RJ45 or M12;

Status LEDs;

6.1 Connection overview

Figure 5 –LFP 280 Ah module overview

Table 6 - Module connection overview

Part

Description

A

Positive power connection (including fuse). M8 bolt connection.

B

Equipotential bonding connection (only available on the (M12, HV) option).

C

CAN-Bus communication, either RJ45 or M12.

D

Negative power connection. M8 bolt connection.

MG Energy Systems B.V. | Foeke Sjoerdswei 3 | 8914 BH Leeuwarden | The Netherlands

Innovation in energy storage

6.2 Connections details

Each battery module contains two CAN-Bus connectors to connect to one of the master BMSs.

This CAN-Bus connection is used for several functions:

Data communication between battery module(s) and master BMS;

The battery module uses the V+ to enable the power of the internal BMS;

The HE Series have the option to have RJ45 or M12 CAN-Bus connectors.

RJ45 CAN-bus connector details

The standard connectors in the LFP Series are the RJ45 CAN-Bus connectors.

Connector details

Typical cables that are used for the RJ45 CAN-Bus connections are standard CAT 5 Ethernet network patch

cables.

Table 7 –RJ45 connector details

Pin

Description

Connector view

1

2

3

GND

4

5

6

V+

7

CAN-H

8

CAN-L

NOTICE:

Always use standard prefabricated Ethernet network patch cables (straight).

MG Energy Systems B.V. | Foeke Sjoerdswei 3 | 8914 BH Leeuwarden | The Netherlands

Innovation in energy storage

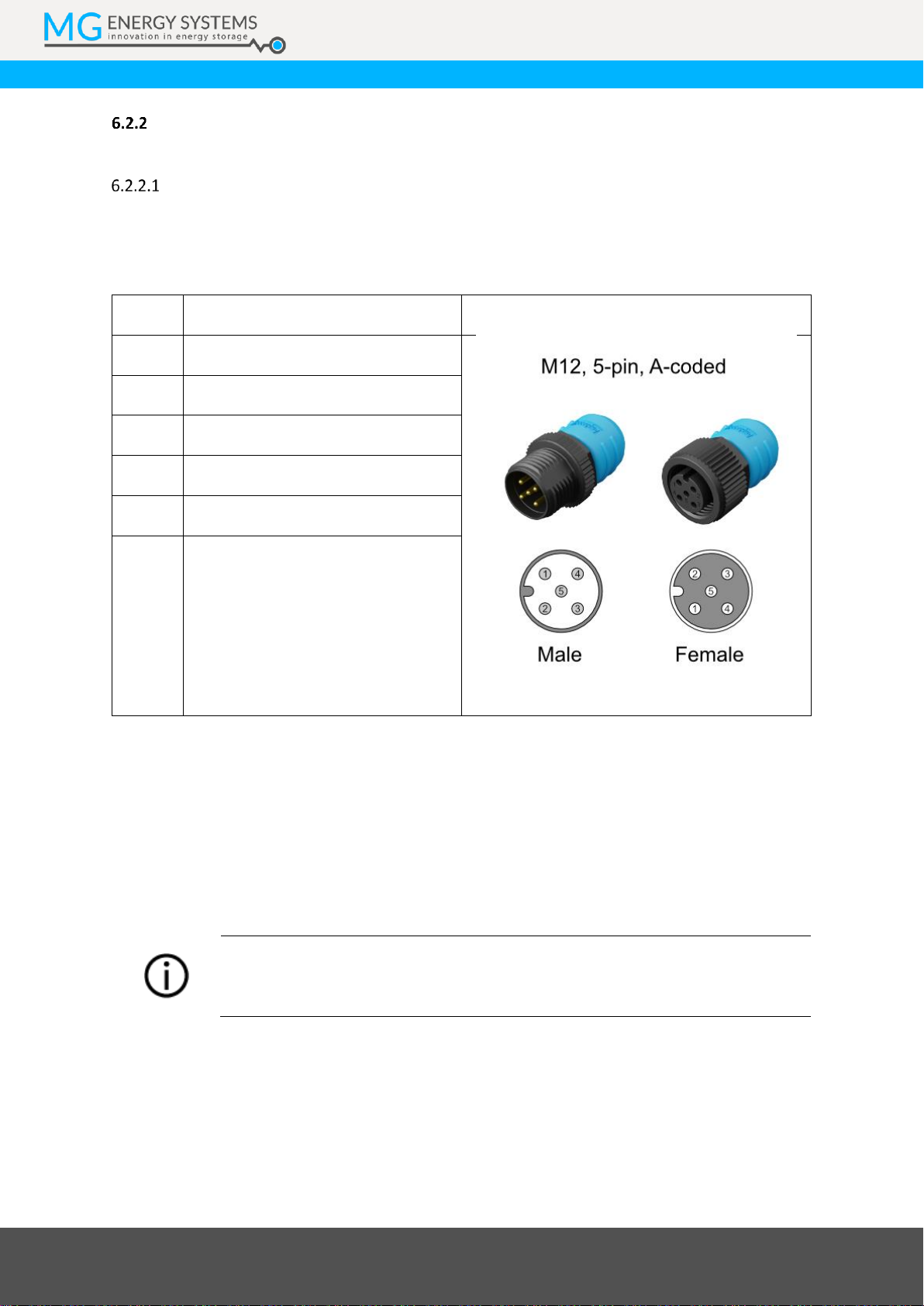

M12 CAN-bus connector details

The LFP Series have the option to contain M12 CAN-Bus connectors.

Connector details

The connectors used for connecting the CAN-bus are all of the same type, namely a circular M12 connector

with 5 positions and A-coded keying.

Table 8 - Circular M12 connector with 5 positions A-coded details

Pin

Description

Connector view

1

Shield

2

V+

3

GND

4

CAN-H

5

CAN-L

Cables to be used for the battery system are typically referred to as NMEA 2000 or DeviceNet compatible

cables. The minimum requirements for cables are:

Twisted pair connected to pins 4 and 5 for communication with a minimum wire cross sectional area

of 0.2 mm2(24 AWG).

Pair of conductors connected to pin 2 and 3 for power and HVIL with a minimum wire cross sectional

area of 0.34 mm2(22 AWG).

Cable with braided shielding connected to pin 1.

NOTICE:

Do not use sensor/actor cables. They often don’t have any twisted pairs and are

therefore not suitable for this application.

MG Energy Systems B.V. | Foeke Sjoerdswei 3 | 8914 BH Leeuwarden | The Netherlands

Innovation in energy storage

Power connections

The power connections on the battery module consists of two M8 bolt connections. One is the positive

battery pole and one is the negative battery pole.

Figure 6 - Battery pole connection overview

Part

Description

A

Nut

B

Spring washer

C

Washer

D

Battery pole

E

Fuse

Fuse

The positive battery pole contains a protection fuse. This fuse is a CF8 fuse. The default value is 300 A. See

chapter 8.5 for the replacement procedure.

MG Energy Systems B.V. | Foeke Sjoerdswei 3 | 8914 BH Leeuwarden | The Netherlands

Innovation in energy storage

Fuse types to use:

MG Fuse article

number

Fuse current

Fuse manufacturer article number

MGFUSE1580150

150 A

Little fuse CF8 - 155.0892.6151

MGFUSE1580200

200 A

Little fuse CF8 - 155.0892.6201

MGFUSE1580225

225 A

Little fuse CF8 - 155.2892.6221

MGFUSE1580250

250 A

Little fuse CF8 - 155.0892.6251

MGFUSE1580300

300 A

Little fuse CF8 - 155.0892.6301

MG000034A

-

MG dummy fuse CF8

NOTICE:

A broken fuse is indicated by measuring no voltage on the battery terminals.

WARNING:

For systems with a voltage above 58 VDC, a dummy fuse is required. See chapter

6.2.3.2 and 8.5.1 for more information.

WARNING:

In some cases it is required to replace the fuse for a smaller one according to the

cable size.

Dummy fuse

Replacing the fuse by a dummy fuse is needed in case the battery module is used in series

above 58 V. This dummy fuse is actually a complete battery pole that replaces the battery pole with fuse

holder. See chapter 8.5 for the replacement procedure.

This manual suits for next models

5

Table of contents