MH THYROMAT-BDC User manual

U

Us

se

er

r

M

Ma

an

nu

ua

al

l

Revision 8.6 INDEX 1

THYROMAT BD DIGITAL CRANE CONTROLLER

TABLE OF CONTENTS

SECTION PAGE

1. GENERAL

1.1. CONTROL SYSTEM..................................................................................................................... 6

1.1.1. Basic System Diagram............................................................................................................. 8

1.1.2. Thyromat Components Identification ....................................................................................... 9

2. SYSTEM DESIGN

2.1. GENERAL ................................................................................................................................... 10

2.2. THYROMAT –BD DIGITAL CRANE CONTROLLER RANGE................................................... 10

2.3. PROTECTION............................................................................................................................. 12

2.4. THYROMAT –BD DIGITAL CRANE CONTROLLER SELECTION........................................... 12

2.4.1. Standard Duty ........................................................................................................................ 12

2.4.2. Severe Duty (Based on 40% of nominal load permanently on hook) .................................... 13

2.5. PRINCIPLE OF OPERATION ..................................................................................................... 14

2.5.1. Control Box............................................................................................................................. 15

2.5.2. Control Card........................................................................................................................... 15

2.5.3. Relay Card ............................................................................................................................. 16

2.5.4. Phase Shifter Card................................................................................................................. 16

2.5.5. Snubber Card......................................................................................................................... 16

2.5.6. Control Panel.......................................................................................................................... 16

2.6. CONTROL SYSTEM SPECIFICATIONS.................................................................................... 17

2.7. THYROMAT - BD DIGITAL CRANE CONTROLLER ENCLOSURES........................................ 18

2.8. SELECTION OF RESISTORS.................................................................................................... 19

2.9. SELECTION OF MAINS CIRCUIT BREAKERS......................................................................... 21

2.10. SELECTION OF INTERPOSING INPUT RELAYS..................................................................... 23

2.11. SELECTION OF INTERPOSING OUTPUT RELAYS................................................................. 23

2.12. SELECTION OF CABLES........................................................................................................... 24

2.12.1. Power Supply Cables............................................................................................................. 24

2.12.2. Control Supply Cables............................................................................................................ 24

2.13. SELECTION OF STATOR REVERSING CONTACTORS.......................................................... 24

2.13.1. Contactor Switching Times .................................................................................................... 25

2.13.2 Contactors Drop Out Times ................................................................................................... 25

2.14. SELECTION OF CURRENT TRANSFORMERS........................................................................ 25

U

Us

se

er

r

M

Ma

an

nu

ua

al

l

Revision 8.6

INDEX

2

SECTION PAGE

2.15. SELECTION OF ROTOR CONTACTORS.................................................................................. 26

2.15.1. Star Connections.................................................................................................................... 26

2.15.2. Delta Connections.................................................................................................................. 26

2.15.3. V Connections........................................................................................................................ 27

2.15.4 W Connections....................................................................................................................... 27

2.16. MOTOR THERMAL PROTECTION UNIT................................................................................... 27

2.17. SELECTION OF SPARE PARTS................................................................................................ 28

3. PARAMETERS

3.1. HOIST APPLICATION PARAMETER LIST ................................................................................ 29

3.2. PARAMETER DESCRIPTIONS - HOIST.................................................................................... 30

3.2.1. CT Ratio ................................................................................................................................. 30

3.2.2. Motor Current ......................................................................................................................... 31

3.2.3. Overload Class....................................................................................................................... 31

3.2.4. Notch 1................................................................................................................................... 32

3.2.5. Notch 2................................................................................................................................... 32

3.2.6. Notch 3................................................................................................................................... 32

3.2.7. Hoist Plugging........................................................................................................................ 32

3.2.8. Hoist Plugging V..................................................................................................................... 33

3.2.9. Lower Plugging V ................................................................................................................... 34

3.2.10. Brake Release I...................................................................................................................... 34

3.2.11. Hoist Start Volt ....................................................................................................................... 34

3.2.12. Stop Delay.............................................................................................................................. 35

3.2.13. Lower Plug Out....................................................................................................................... 35

3.2.14. Max Stall Volts........................................................................................................................ 35

3.2.15. Ph Shift On Time.................................................................................................................... 36

3.2.16. Ph Shift Off Time.................................................................................................................... 37

3.2.17. Separate Directional Signals.................................................................................................. 38

3.2.18. Load Defaults......................................................................................................................... 39

3.3. TRAVEL APPLICATION PARAMETER LIST ............................................................................. 40

3.4. PARAMETERS DESCRIPTIONS - TRAVEL.............................................................................. 41

3.4.1. Current Transformer Ratio ..................................................................................................... 41

3.4.2. Current Transformer Enable .................................................................................................. 41

3.4.3. Motor Current ......................................................................................................................... 42

3.4.4. Overload Class....................................................................................................................... 42

3.4.5. Notch Speed 1........................................................................................................................ 43

3.4.6. Notch Speed 2........................................................................................................................ 43

U

Us

se

er

r

M

Ma

an

nu

ua

al

l

Revision 8.6 INDEX 3

3.4.7. Notch Speed 3........................................................................................................................ 43

SECTION PAGE

3.4.8. Notch Plugging....................................................................................................................... 43

3.4.9. Notch Plugging V.................................................................................................................... 43

3.4.10. Neutral Plugging V ................................................................................................................. 44

3.4.11. Neutral Deceleration Profile ................................................................................................... 44

3.4.12. Brake Plugging Volts.............................................................................................................. 44

3.4.13. Brakes on Speed.................................................................................................................... 45

3.4.14. Max Stall V ............................................................................................................................. 45

3.4.15. Min Start V.............................................................................................................................. 45

3.4.16. Notch 1; 2 and 3 Acceleration Time....................................................................................... 46

3.4.17 Notch 4_Accel Profile............................................................................................................. 46

3.4.18. Phase Shifter Off Time........................................................................................................... 46

3.4.19 Notch 4 Accel Delay............................................................................................................... 47

3.4.20. Separate Directional Signals.................................................................................................. 47

3.4.21. Plug Reduced %SP................................................................................................................ 48

3.4.22. Notches1,2 & 3 Smooth Prfl................................................................................................... 48

3.4.23. Brake Plug Soft ...................................................................................................................... 49

3.4.24. Load Defaults......................................................................................................................... 49

3.5. TORQUE APPLICATION PARAMETER LIST.............................................................................50

3.6. PARAMETER DESCRIPTIONS –TORQUE................................................................................51

3.6.1. Current Transformer Ratio ..................................................................................................... 51

3.6.2. Current Transformer Enable .................................................................................................. 51

3.6.3. Motor Current ......................................................................................................................... 52

3.6.4. Overload Class....................................................................................................................... 52

3.6.5. Notch 1 Voltage...................................................................................................................... 53

3.6.6. Notch 2 Voltage...................................................................................................................... 53

3.6.7. Notch 3 Voltage...................................................................................................................... 53

3.6.8. Notch 4 Voltage...................................................................................................................... 53

3.6.9. Notch 1 Plugging.................................................................................................................... 53

3.6.10. Notch 2 Plug........................................................................................................................... 53

3.6.11. Notch 3 Plug........................................................................................................................... 53

3.6.12. Notch 4 Plug........................................................................................................................... 53

4. INSTALLATION

4.1. GENERAL INSTALLATION......................................................................................................... 54

4.2. THYROMAT - BD DIGITAL CRANE CONTROLLER MECHANICAL INSTALLATION.............. 54

4.2.1. General................................................................................................................................... 54

4.2.2. Mounting Instructions............................................................................................................. 54

U

Us

se

er

r

M

Ma

an

nu

ua

al

l

Revision 8.6

INDEX

4

4.2.3. Tools and Special Equipment ................................................................................................ 55

SECTION PAGE

4.2.4. Mounting Arrangements......................................................................................................... 56

4.2.5. Mounting Procedure............................................................................................................... 58

4.3. ELECTRICAL INSTALLATION.................................................................................................... 59

4.3.1. General................................................................................................................................... 59

4.3.2. Electrical Connection Instructions.......................................................................................... 60

4.3.3. Tools and Special Equipment ................................................................................................ 64

4.4. INSTALLATION DIAGRAMS....................................................................................................... 64

4.4.1 Digital Inputs –Main Board.................................................................................................... 65

4.4.2. Digital Inputs –Connectors on the Control Panel.................................................................. 66

4.4.3. Relay Outputs –Connectors on the Main Board .................................................................... 66

4.4.4. Triac Outputs –Control Panel Board..................................................................................... 67

4.4.5. Motor Current Inputs .............................................................................................................. 68

5. COMMISSIONING

5.1. GENERAL ................................................................................................................................... 69

5.2. PREPARATION........................................................................................................................... 69

5.3. COMMISSIONING PROCEDURES............................................................................................ 70

5.4. HOIST OPERATIONS................................................................................................................. 75

5.4.1. Hoisting .................................................................................................................................. 75

5.4.2. Lowering With an Overhauling Load...................................................................................... 75

5.4.3. Regeneration.......................................................................................................................... 75

5.4.4. Lowering With a Light Load.................................................................................................... 75

5.5. TRAVEL OPERATIONS.............................................................................................................. 76

5.5.1. Travel in All Directions............................................................................................................ 76

6. OPERATION OF CONTROL PANEL

6.1. GENERAL ................................................................................................................................... 77

6.2. SUPPLEMENTRY DISPLAY PAGES “SCROLL MENU”............................................................ 78

6.2.1. Parameters............................................................................................................................. 78

6.2.2. Set Time................................................................................................................................. 79

6.2.3. Fault History ........................................................................................................................... 79

6.3. KEY PAD PUSH BUTTONS........................................................................................................ 79

6.4. CONTROL PANEL OPERATION................................................................................................ 80

6.5. PARAMETER LISTS PAGE........................................................................................................ 81

6.5.1. Accessing the Parameters Page............................................................................................ 81

6.6. SET TIME PAGE......................................................................................................................... 82

6.7. FAULT HISTORY........................................................................................................................ 83

U

Us

se

er

r

M

Ma

an

nu

ua

al

l

Revision 8.6 INDEX 5

SECTION PAGE

6.8. POSSIBLE CAUSES OF FAILURE............................................................................................. 85

6.8.1. Rotor Feedback...................................................................................................................... 86

6.8.2. Current Unbalance................................................................................................................. 87

6.8.3. Loss of Phase......................................................................................................................... 88

6.8.4. Current Feedback................................................................................................................... 88

6.8.5. Stack Temp ............................................................................................................................ 89

6.8.6. Overload Trip.......................................................................................................................... 89

6.8.7. Over Current........................................................................................................................... 89

6.8.8. H Loss of Torque.................................................................................................................... 90

6.8.9. Lower Overspeed................................................................................................................... 90

6.8.10. Motor Stall .............................................................................................................................. 91

6.8.11. Input Phases .......................................................................................................................... 91

6.8.12. Plugging Timeout ................................................................................................................... 91

6.8.13. Joystick Error.......................................................................................................................... 92

6.8.14. RFB & Current Loss............................................................................................................... 92

6.8.15. Not in Neutral ......................................................................................................................... 93

6.8.16. Drive Level ............................................................................................................................. 93

6.8.17. Power ON Test....................................................................................................................... 93

6.8.18. Break Release........................................................................................................................ 94

6.8.19-24. Error Codes.........................................................................................................................95

7. MAINTENANCE

7.1. GENERAL ................................................................................................................................... 96

7.2. PREVENTATIVE MAINTENANCE.............................................................................................. 96

7.2.1. Brakes .................................................................................................................................... 96

7.2.2. Ultimate Limit Switch.............................................................................................................. 97

7.3. SPARE PARTS LIST................................................................................................................... 97

8. SHIPPING AND STORAGE

8.1. GENERAL ................................................................................................................................. 100

8.1.1. Shipping ............................................................................................................................... 100

8.1.2. Storage................................................................................................................................. 100

9. ACRONYMS AND ABREVIATIONS

9.1. GENERAL ................................................................................................................................. 101

U

Us

se

er

r

M

Ma

an

nu

ua

al

l

Thyromat BDC User Manual - Summary of Changes 27.05.05

Page 1 of 5

LATEST REVISIONS ON SUMMARY DOCUMENT

Please note the following changes made to Thyromat BDC Digital Crane Controller User Manual:

Note: Please be aware that small or minor layout, grammatical, or format changes are not recorded.

THYROMAT BDC USER MANUAL REV 8.5 to REV 8.6 CHANGES

Section

Page

Item

From

To

Index

1-5

Table of Contents updated and page numbers changed.

2

24

Power cable selection explanation: changes to content and grammar.

3

31

Overload Class 2 removed and added O/C 10

3

29-39

Hoist Parameters edited for software versions CHV11.XX

3

50-53

Torque Parameters added for CTT01.xx software version.

3

36/37

Explanations for Ph Shift On and Off time updated after investigation/measurements

done

3

40/49

Travel Parameters edited for software versions CTT01.XX

4

All

Page numbering has been changed due to revision changes –Section 4 begins at page

54 through page 68.

5

All

Page numbering has been changed due to revision changes –Section 5 begins at page

69 through page 76.

6

85-95

Possible causes of failure section edited. Order Changed and added: Loss of Phase,

Current Feedback, Stack Temp, Overload Trip, H Loss of Torque, Plugging Timeout

6

All

Page numbering has been changed due to revision changes –Section 6 begins at page

76 through page 95.

7

All

Page numbering has been changed due to revision changes –Section 7 begins at page

96 through page 97.

8

All

Page numbering has been changed due to revision changes –Section 8 begins at page

100.

9

All

Page numbering has been changed due to revision changes –Section 9 begins at page

101.

THYROMAT BDC USER MANUAL REV 8.4 to REV 8.5 CHANGES

Section

Page

Item

From

To

7

Page numbering has been changed due to revision changes –Section 7 begins at page

88 through page 91.

7

90

7.3

Thyristor Phase Arm spares have been added to the Spare Parts List

8

All

Page numbering has been changed due to revision changes in Section 7 –Section 8 now

begins at page 92

9

All

Page numbering has been changed due to revision changes in Section 7 –Section 9 now

begins at page 93

THYROMAT BDC USER MANUAL REV 8.3 to REV 8.4 CHANGES

Section

Page

Item

From

To

3

29

Page numbering has been changed due to revision changes –Section 3 now begins at

page 29 through page 45.

6

All

All

Changed the word Thyromat to THYROMAT

6

78

6.8.3

“Input Phases”

“INPUT PHASES”

6

81

6.8.9

NOTE (figure)

CAUTION (figure)

6

83

6.8.14

Rfb and Currt Loss

RFB & CURRT LOSS

U

Us

se

er

r

M

Ma

an

nu

ua

al

l

Thyromat BDC User Manual - Summary of Changes 27.05.05 Page 2 of 5

6

67

Page numbering has been changed due to revision changes –Section 6 now begins at

page 69 through page 87.

THYROMAT BDC USER MANUAL REV 8.2 to REV 8.3 CHANGES

Section

Page

Item

From

To

3

29

Increment

2nd row

Minumum 10 A

Minimum 2 A

3

31

3.2.2

Minumum 10 A

Minimum 2 A

3

31

3.2.3

Overload class

Add: (This feature is not yet

implemented)

3

33

Caution

Moved text into Caution figure

3

34

3.2.10

Brake release current = No

load current / Motor current x

100

Brake release current % = (No load

current / Motor current) x 100

3

34

3.2.11

This parameter sets up the

minimum voltage applied to the

motor immediately at start of a

hoisting cycle.

This parameter sets up the minimum

voltage applied as a percentage of the

supply voltage to the motor

immediately at start of a hoisting

cycle.

3

35

3.2.13

“plugg out time”

“Plugging timeout”

3

35

3.2.14

(First paragraph))

Add: It is calculated as a percentage

of the supply volts.

6

67

6.1

…press the > key to de-

activate (switch-off) the back

lighting press the < key.

…press any key, the backlight will

automatically go off 20 seconds later.

6

67

Figure

6-1

Speed 000

O/L

Speed XXX

Removed O/L

6

68

Function 2nd

row

MAIN MENU

STATUS MONITORING PAGE

6

68

Remarks 2nd

row

To navigate through this page

press the menu key:-

To toggle between this page and the

motor currents page press the Menu

key.

6

68

Remarks 2nd

row

Each depression of the menu

key will display the next page;

the last page will loop back to

the first page.

Delete sentence completely.

U

Us

se

er

r

M

Ma

an

nu

ua

al

l

Thyromat BDC User Manual - Summary of Changes 27.05.05

Page 3 of 5

Section

Page

Item

From

To

6

68

Function 3rd

row

STATUS MONITORING PAGE

MOTOR 3 PHASE CURRENTS

MONITORING PAGE

6

68

Remarks 3rd

row

This….are also displayed.

Add: To return to status monitoring

page, press the Menu key.

Add: picture of Menu key

6

69

Function

3rd row

… have been rectified.

Add: Also clears the fault history when

in fault history page.

6

70

Figure

6-3

Top figure added %

Bottom three figures added XXX

6

71

Figure

6-3

Parameters

page Navig.

Added %

Step 7

6

73

Figure

6-5

Added XXX

6

74-

75

Table 6-5

Complete revision of table contents

6

75

Below Table

6-5

Add footnote: (1) these faults can not be reset in Neutral if they still

remain active.

6

76

6.8.1

(1

st

line)…as the motor loop

speed feedback that is

essential…

… as the motor loop speed feedback

and it is essential…

6

76

6.8.1 Possible

causes

Rfb and current loss

“RFB & CURRT LOSS”

6

76

6.8.1

(i.e. motorslip = 2)

(i.e. motorslip > 1)

6

78

6.8.3`

Ø Amps (1

st

line)

0 Amps

6

78

6.8.4

Ø Amps (1st line)

0 Amps

6

84

6.8.14 –6.8.24

Complete changes from 6.8.14 through 6.8.24

THYROMAT BDC USER MANUAL REV 8.1 to REV 8.2 CHANGES

Section

Page

Item

From

To

3

29

3.1.

1st parag.

10_00

10_XX

3

29

Increment

2nd row

Minimum 10 A

3

31

3.2.2 Table

Increment

1

Minimum 10 A

3

37

3.2.17

1st parag.

… selected

… programmed

3

37

3.2.17

Inserted drawings and text

3

37

3.2.17

All NO changed to “No”

All YES changed to “Yes”

6

74

Table 6-5

Added Drive Level and Power-on Test and Error Code 106

6

81

6.8.15

Inserted new paragraph Drive Level and Power-on Test.

6.8.15 Error Code 100 moved to 6.8.17

6

82

New item on

pg.83

Added: 6.8.22. –Error Code 106

U

Us

se

er

r

M

Ma

an

nu

ua

al

l

Thyromat BDC User Manual - Summary of Changes 27.05.05

Page 4 of 5

THYROMAT BDC USER MANUAL REV 8 to REV 8.1 CHANGES

Section

Page

Item

From

To

3

33

3.2.7

After, applies the mechanical

brake.

Caution Inserted.

3

32

3.2.7

Set the voltage level

Set the ceiling voltage level

3

32

3.2.7

Torque applied

Maximum torque applied

6

81

6.8.13

Possible causes:

‘failure’

Possible causes:

‘failed to energise’

6

80

6.8.13

Rotor Feedback & Current

Loss

Included 3 sub-categories:

RFB & CURRT LOSS S

RFB & CURRT LOSS R

RFB & CURRT LOSS I

6

74

Table 13th row

RFB & Current Loss

RFB & CURRT LOSS (S); (R); (I)

THYROMAT BD USER MANUAL REV 7 TO REV 8 CHANGES

Section

Page

Item

From

To

2

11

2.2

220 (last line)

B 220 Volts control voltage

2

15

2.5.1

Coding pings unique...

Delete sentence

2

18

Table 5th row

Output phases unbalanced

Change 33% to 50%

2

18

Table 5th row

Motor overload protection:

class...

Delete sentence and add “This feature

is not yet implemented”

2

22

Table M100

STR 22SE 63A

STR 22SE 100A

2

27

2.16

Motor Thermal …

Add “This feature is not yet

implemented”

2

28

2.17

Sec 7 Paragraph 7.2.3

Paragraph 7.3

3

29-

36

3.1

Version 9_00

Version 10_00

3

31

3.2.2

Note:

Add “This feature is not yet

implemented”

3

36

3.2.17

terminal 4

Terminals 4 and 5

3

42

3.2.18.

Terminal 4

Terminals 4 and 5

4

47

Table

M500 (520)

515

4

47

Table

M1000 (520)

515

5

61

Step 7

(i.e. < 70%...

(i.e. < 75%...

5

61

Step 7

bellow

below

5

65

5.4.4

four lowering speeds

Three lowering slow speeds

6

77

6.8.4

Overload Trip

Add “This feature is not yet

implemented”

7

83

7.3

(Row 2) BDH 252) to …

BDT 252) to BDT 20002)

7

83

7.3

2) Indicate Supply voltage

Change all voltages “A” to “F” and add

“G” to “J”

7

83

7.3

5 Indicates control panel…

Moved to inside table at the bottom

7

84

7.3

Thyristors 5)

Changed all the 5) to 6)

7

84

7.3

5) Indicates peak inverse…

6) Indicates peak inverse…

U

Us

se

er

r

M

Ma

an

nu

ua

al

l

Thyromat BDC User Manual - Summary of Changes 27.05.05

Page 5 of 5

THYROMAT BDC SHORT USER MANUAL REV 1 to REV 2 CHANGES

Section

Page

Item

From

To

2

10

2.2

220 (last line)

B 220 Volts control voltage

2

12

Table 4th row

Motor overload protection:

class...

Delete sentence and add “This feature

is not yet implemented”

3

14-

20

3.1

Version 9_00

Version 10_00

3

19

3.2.17

terminal 4

Terminals 4 and 5

3

21-

26

3.3

Version 7_00

Version 8_00

3

25

3.2.18

terminal 4

Terminals 4 and 5

6

35

6.8.4

Overload Trip

Add “This feature is not yet

implemented”

7

41

7.3

(Row 2) BDH 25

2)

to …

BDT 252) to BDT 20002)

7

41

7.3

2)

Indicate Supply voltage

Change all voltages “A” to “F” and add

“G” to “J”

7

41

7.3

5 Indicates control panel…

Moved to inside table at the bottom

7

42

7.3

Thyristors

5)

Changed all the 5) to 6)

7

42

7.3

5)

Indicates peak inverse…

6) Indicates peak inverse…

U

Us

se

er

r

M

Ma

an

nu

ua

al

l

Revision 8.6 SECTION 1 : GENERAL

6

SECTION 1 : GENERAL

1.1. CONTROL SYSTEM

The THYROMAT range of drives is used to control crane hoist and travel motions using slip-ring motors.

The controller is well suited to heavy duty and continuos operations in extreme environments.

THYROMAT digital crane control delivers leading thyristor control technology to a new generation of crane

drives. It is the natural successor to MH Automation’s very successful THYROMAT analogue crane drive.

Solid state electronics allows a compact design with enhanced reliability. Self-monitoring further improves

system safety and reliability. Software features and all hardware components are engineered to meet the

requirements for both new and existing cranes. THYROMAT digital crane control makes crane operation

simple, safe, precise and consequently more productive.

MH Automation’s experience and know-how of crane applications combined with digital technology and

thousands of man-hours of engineering and design has resulted in a unique, robust and reliable product.

Designed specifically to operate in the tough environments of steelworks THYROMAT digital is a robust

crane controller suitable for all types of steelworks cranes. Table 1-1 details the special features of the

THYROMAT.

Table 1-1 : Special Features.

SPECIAL FEATURES

FEATURE ADVANTAGES

Excellent reliability Increased production

Low maintenance

oReduced operation costs

Robust compact mechanical construction

oResistant to vibration

Operates in extreme ambient conditions

oRated for continuous duty at 60oC

oControl box sealed from dusty environment

oControl cards protected with silicon coating

High degree of safety Torque proving before operation commences (Hoist only)

Self diagnostics

oBuilt in watchdog timers

Built in electronic controller in neutral checking

Opto-isolation of inputs

User friendly Control panel

oKeyboard to enter parameters

oDisplay to show real time motor information

oDisplay faults and history

Reduced down time

Enables preventative maintenance

U

Us

se

er

r

M

Ma

an

nu

ua

al

l

Revision 8.6

SECTION 1 : GENERAL

7

SPECIAL FEATURES

FEATURE ADVANTAGES

Excellent control Load independent control

oExcellent repeatable placing of end load

oSafer working environment for personnel

Smooth steady control

oSafe efficient load handling

oGearbox and couplings not subjected to excessive stress

oReduced current peaks

Slip-ring maintenance reduced

Motor life extended

Safe brake control

oTorque proving before brake is opened (Hoist only)

oBrake is used only as a parking brake and in emergency

conditions

oNo more continual replacing of brake parts.

Rotor feedback speed measurement No tacho generator or pulse encoder required

oNo mechanical modifications needed on motor shaft

oNo additional installation costs, labour and equipment

oNo maintenance of a tacho required

oNo need for small control wires in cable loop system

oSimplifies the control system

Reversing contactors Reversing contactors are used to change torque direction on motor

oImproved reliability as compared with static bridge system

Contactors are switched during zero current conditions

oNo maintenance on contact tips

oContactor life extended

Simplicity Simple quick installation

Training easy to perform

Understood easily by maintenance staff

oFaults on crane easy to find

Loss of production eliminated

oRapid acceptance by maintenance staff

Large range Covers complete crane range

oControl system the same for any size motor

oIdeal for single motor use with emergency operation

requirement.

U

Us

se

er

r

M

Ma

an

nu

ua

al

l

Revision 8.6 SECTION 1 : GENERAL

8

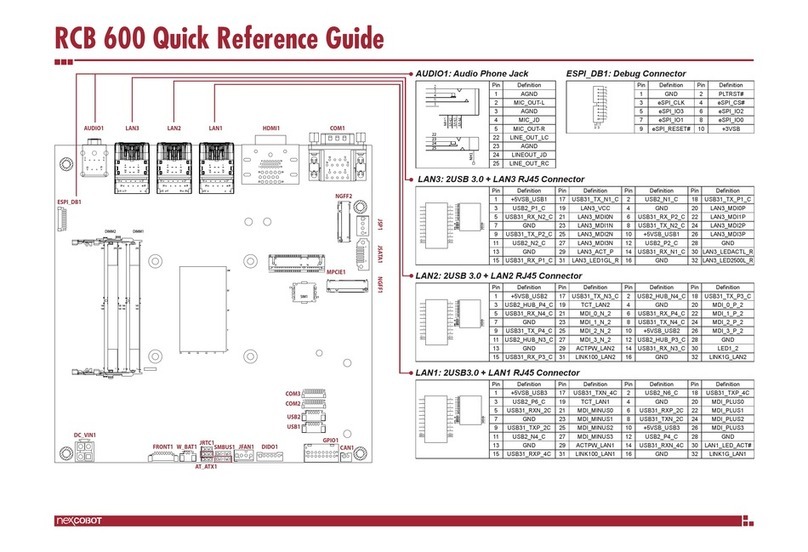

1.1.1. Basic System Diagram

The system’s simplicity is illustrated in the Basic System Diagram (refer to Figure 1-1). This diagram

is applicable to both hoist and travel operations.

Figure 1-1 : Basic System Operational Diagram

U

Us

se

er

r

M

Ma

an

nu

ua

al

l

Revision 8.6

SECTION 1 : GENERAL

9

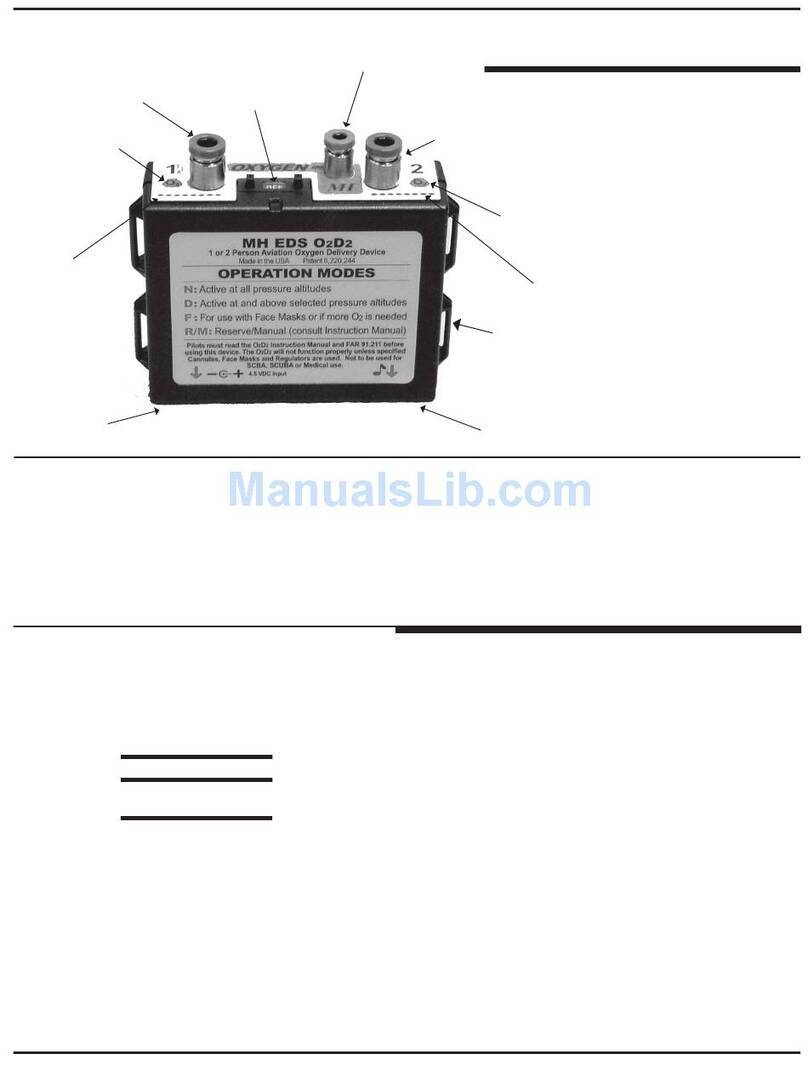

1.1.2. THYROMAT Components Identification

The following illustration details the components identification (refer to Figure 1-2). This diagram is

applicable to both hoist and travel motions.

Figure 1-2 : THYROMAT Components

1. Control box

2. Control panel

3. Keypad

4. Display

5. Snubber card

6. Phase shifter card

7. Relay card

8. Control card

9. Control connectors on control panel

10. Thyristor stack

11. Heat sink

12. Temperature switch

13. MOV’s

14. Supply connections

15. Fan

16. Thyristor pack

A Interior of control box

B Mother board

U

Us

se

er

r

M

Ma

an

nu

ua

al

l

Revision 8.6 SECTION 2 : SYSTEM DESIGN

10

SECTION 2 : SYSTEM DESIGN

2.1. GENERAL

The following paragraphs detail the selection of the Thyromat and associated equipment as well as the

details for the operation of the THYROMAT.

2.2. THYROMAT BD DIGITAL CRANE CONTROLLER RANGE

Table 2-1 details the THYROMAT range.

Table 2-1 : THYROMAT Range

THYROMAT

Abbreviated Code Ampere Rating

at 60°C Mechanical Size Dimensions

W x H x D in mm Weight

(Approx.)

THYROMAT –BD 25 25 A M100 237 x 180 x 202 6 kg

THYROMAT –BD 30 30 A M100 237 x 180 x 202 6 kg

THYROMAT –BD 60 60 A M100 237 x 180 x 202 6 kg

THYROMAT –BD 100 100 A M150 296 x 180 x 225 10 kg

THYROMAT –BD 150 150 A M150 296 x 180 x 225 10 kg

THYROMAT –BD 200 200 A M350 293 x 450 x 250 21 kg

THYROMAT –BD 350 350 A M350 293 x 450 x 250 23 kg

THYROMAT –BD 400 400 A M500 515 x 525 x 355 41 kg

THYROMAT –BD 500 500 A M1000 515 x 665 x 355 52 kg

THYROMAT –BD 700 700 A M1000 515 x 665 x 355 52 kg

THYROMAT –BD 1000 1000 A M1000 515 x 665 x 355 52 kg

THYROMAT –BD 1200 1200 A M2000 789 x 855 x 443 100 kg

THYROMAT –BD 1500 1500 A M2000 789 x 855 x 443 103 kg

THYROMAT –BD 2000 2000 A M2000 789 x 855 x 443 107 kg

THYROMAT –BD2500 2500 A M2500

U

Us

se

er

r

M

Ma

an

nu

ua

al

l

Revision 8.6

SECTION 2 : SYSTEM DESIGN

11

The product range is defined as detailed in Table 2-2.

Table 2-2 : Product Range Definition

Series Current Supply

Voltage Control

Voltage Explanation

Type Motion

BX X 025 380 X

B - Alternating current (ac) applications

BD - Digital applications

H - Hoist applications

T - Travel applications

025 A 200 A 1 000 A

030 A 350 A 1 200 A

060 A 400 A 1 500 A

100 A 500 A 2 000 A

150 A 700 A 2 500 A

380 volts

415 volts

525 volts

A - 110 volts

B - 220 volts

For example a product with the designated code:

BDH 025 380 B

This would be defined as a unit having the following characteristics:

BAlternating current (ac)

DDigital

HHoist

025 25 Ampere supply current

380 380 Volts supply voltage

B220 Volts control voltage

U

Us

se

er

r

M

Ma

an

nu

ua

al

l

Revision 8.6 SECTION 2 : SYSTEM DESIGN

12

2.3. PROTECTION

Table 2-3 lists the protection specifications for the THYROMAT.

Table 2-3 : THYROMAT Protection

Item Specification

Control enclosure IP51

Thyristor stack IP00

2.4. THYROMAT - BD DIGITAL CRANE CONTROLLER SELECTION

The selection of the THYROMAT for specific mechanical power requirements depends on the base stator

current rating on of the slip-ring motor to be used. In the event that the base stator current ratings are not

known then it is suggested that the same ratings S4or S5 for crane duty slip-ring motors be used.

Perform the following steps to calculate the mechanical power

Step 1. Calculate the mechanical power that will be generated by the motor using the speed, load and

efficiency of the motion.

Step 2. If this data is not available use the electrical power for the specific duty.

Step 3. Obtain the stator current for the specific power selected

Step 4. Refer to the table and select the THYROMAT.

The selection of the THYROMAT has been divided into two operational categories for both hoist and

travel namely, standard duty and severe duty.

The following paragraphs define standard and severe duty applications:

2.4.1 Standard Duty

The following defines standard duty:-

Characteristics

Rated starting class - 150 starts per hour.

Cyclic duration factor - 40%

Max. Ambient Temperature - 40ºC

Altitude above sea level - < 1 500 meters

The typical standard duty applications are as for BS 466:1984 cranes with a group mechanism in M3

and M4, the following lists typical standard duty applications:-

U

Us

se

er

r

M

Ma

an

nu

ua

al

l

Revision 8.6

SECTION 2 : SYSTEM DESIGN

13

Applications

Power station cranes.

Light workshop cranes.

Light stores duty cranes.

Light general load handling cranes

2.4.2 Severe Duty (Based on 40% of nominal load permanently on hook).

The following lists the severe duty parameters:-

Characteristics

Rated starting class - 150 to 600 starts per hour.

Cyclic duration factor - 40% or 60%

Max. Ambient Temperature - 60ºC

Altitude above sea level - < 1 500 meters

The typical severe duty applications are as for BS 466:1984 cranes with a group mechanism in M5 to

M8 heavy duty, workshop, warehouse and general hook service. The following lists typical severe duty

applications:-

Applications

Crane for grabbing work.

Ladle crane for foundry work.

Magnet crane for stockyard work.

Magnet crane for scrap yard work.

Process crane.

Shipyard crane.

Ladle crane.

Pig/scrap breaking crane.

Ingot stripper.

Stocking pit mould-handling crane.

Vertical ingot charger.

Furnace charging crane.

Forging crane.

Heavy mill service crane.

Heavy-duty service and maintenance crane.

U

Us

se

er

r

M

Ma

an

nu

ua

al

l

Revision 8.6 SECTION 2 : SYSTEM DESIGN

14

Table 2-4 details the selection of the maximum stator current ratings for both hoist and travel in

standard and severe duty applications of the various THYROMAT units.

Table 2-4 : Maximum Motor Stator Current Ratings

THYROMAT - BD Stator Current

Unit Sizes Continuos

Current

Ratings at

60°C

Hoist Travel

Standard

Duty Severe

Duty Standard

Duty Severe

Duty

M100

25 A 20.5 A 17.5 A 22.5 A 20.5 A

30 A 25 A 21 A 27 A 25 A

60 A 50 A 43A 55 A 50 A

M150 100 A 83 A 71 A 90 A 83 A

150 A 125 A 107 A 136 A 125 A

M350 200 A 166 A 143 A 181 A 166 A

350 A 291 A 250 A 318 A 291 A

M500 400 A 333 A 285 A 363 A 333 A

M1000

500 A 416 A 357 A 454 A 416 A

700 A 583 A 500 A 636 A 583 A

1000 A 833 A 714 A 909 A 833 A

M2000

1200 A 1 000 A 857 A 1 090 A 1 000 A

1500 A 1 250 A 1 071 A 1 363 A 1 250 A

2000 A 1 666 A 1 428 A 1 818 A 1 666 A

M2500 2500 A 2 080 A 1 780 A 2 270 A 2 080 A

2.5. PRINCIPLE OF OPERATION

The THYROMAT is connected in series with the stator supply voltage.

The control unit varies the stator voltage of the slip-ring motor by adjusting the firing angle of the

inversely connected (parallel) thyristors in each of the three phases. The motor torque is proportional to

the square of the stator voltage (T V2- where T is the motor torque and V is the stator voltage). The

speed of the motor is measured by the frequency of the rotor. Reversing the direction of motor rotation

is achieved by switching externally mounted reversing contactors at zero current.

Table of contents

Other MH Controllers manuals