Seko Pool Basic Pro Evo User manual

0000137188 Rev. 1.0

1

User Manual

0000137188 Rev. 1.0

2

CONTENTS

1. GENERAL INTRODUCTION ...............................................................................................................................3

2. INSTALLATION PRECAUTIONS........................................................................................................................3

3. IDENTIFICATION OF COMPONENTS................................................................................................................4

4. TECHNICAL SPECIFICATIONS..........................................................................................................................5

5. ASSEMBLY INSTRUCTIONS..............................................................................................................................6

5.1 APPLICATION EXAMPLE .................................................................................................................................7

6. DESCRIPTION OF THE CIRCUIT .......................................................................................................................8

7. CALIBRATION MENU .........................................................................................................................................8

7.1 CALIBRATION........................................................................................................................................................8

8. PROGRAMMING............................................................................................................................................... 10

9. DOSING METHOD............................................................................................................................................ 13

9.1 PHPROPORTIONAL DOSING ........................................................................................................................... 13

9.2 ON/OFF PHDOSING..................................................................................................................................... 13

9.3 ALARM FOR THE PHSET POINT ..................................................................................................................... 14

10. ACTIVATIONS ................................................................................................................................................ 15

11. ALARMS ......................................................................................................................................................... 15

12. PRE-DEFINED CONTROL PARAMETERS................................................................................................... 15

13. LIST OF POSSIBLE ANOMALIES AND RELATIVE SOLUTIONS............................................................... 16

14. HANDLING...................................................................................................................................................... 17

15. STORING THE PUMP AFTER USE............................................................................................................... 18

WARNINGS........................................................................................................................................................... 18

0000137188 Rev. 1.0

3

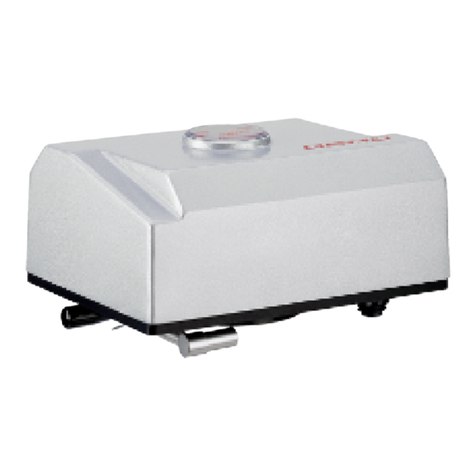

1. GENERAL INTRODUCTION

The Pool Basic Pro EVO control method belongs to a new line of instruments carefully

developed by the supplier for the innovative management of pools. This device is easy

to use and permits continuous control of the pH.

The peristaltic pumps have a 1,5 l/h flow rate for pH regulation and have a pressurised

injection flow rate up to 1.5 bar.

This easy-to-use instrument does not require special maintenance operations. It is

equipped with a self-regulation procedure and automatic control of the electrode’s state.

2. INSTALLATION PRECAUTIONS

WARNING!!!

Disconnect power before carrying out ANY operation inside the

control panel of the Pool Basic Pro EVO device.

NON-OBSERVANCE OF THE INSTRUCTIONS CONTAINED IN THE PRESENT

MANUAL COULD CAUSE INJURY TO PEOPLE AND/OR DAMAGE TO THE DEVICE.

WARNING

During installation of the Pool Basic Pro EVO device, proceed as follows:

Make sure that the supply voltage coincides with the one indicated on the label on

the side of the device.

Make sure that the injection pressure is below 1.5 bar.

Make sure that the pump’s protective cover is properly latched.

Make sure that the suction hose is immersed with the relative foot (PVC hose) in the

tank of the product which must be injected and that it is connected to the pump

(symbol on cover ▲). After carrying out the checks stated above, tighten the

connector nut.

Connect one end of the delivery hose (▼ symbol on cover) to the pump and connect

the other end to the pool through the injection valve.

NOTE: To insert the product which must be injected into the pump when starting for the

first time and every time the tank is changed, set the switch to forced running

using the button.

0000137188 Rev. 1.0

4

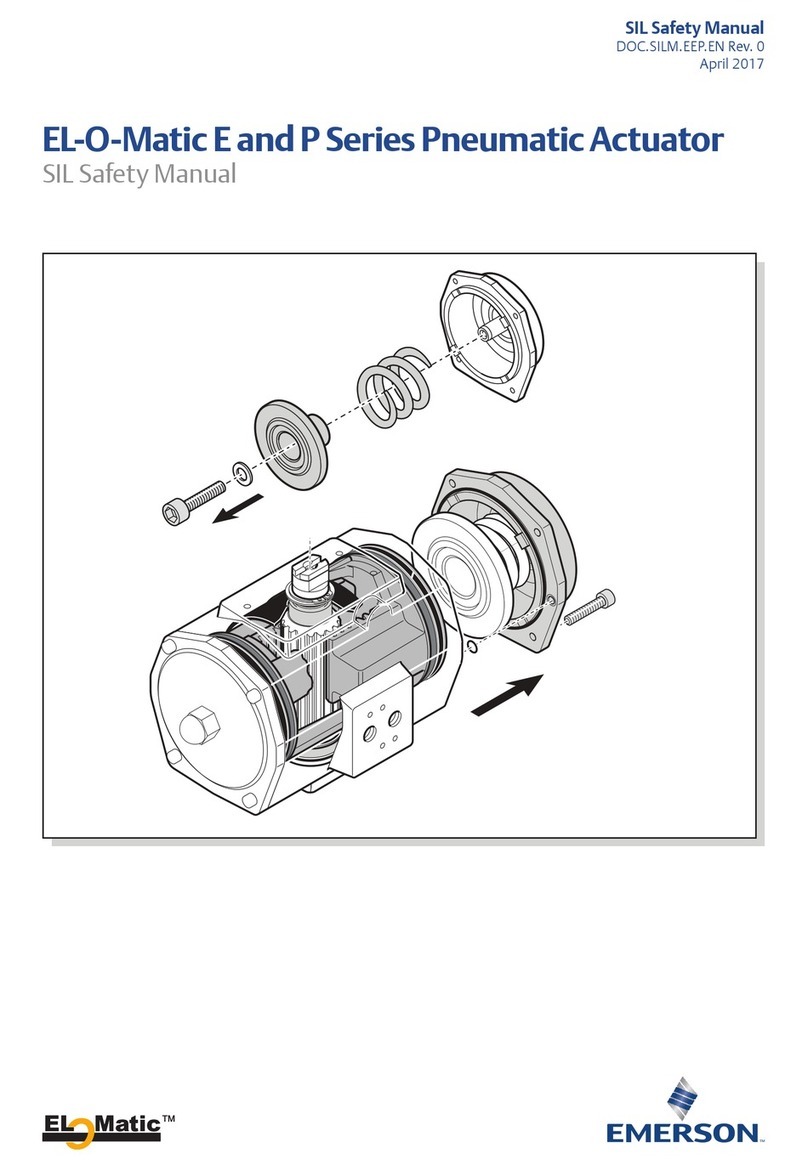

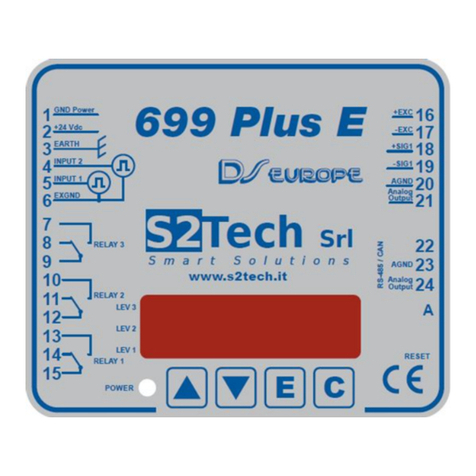

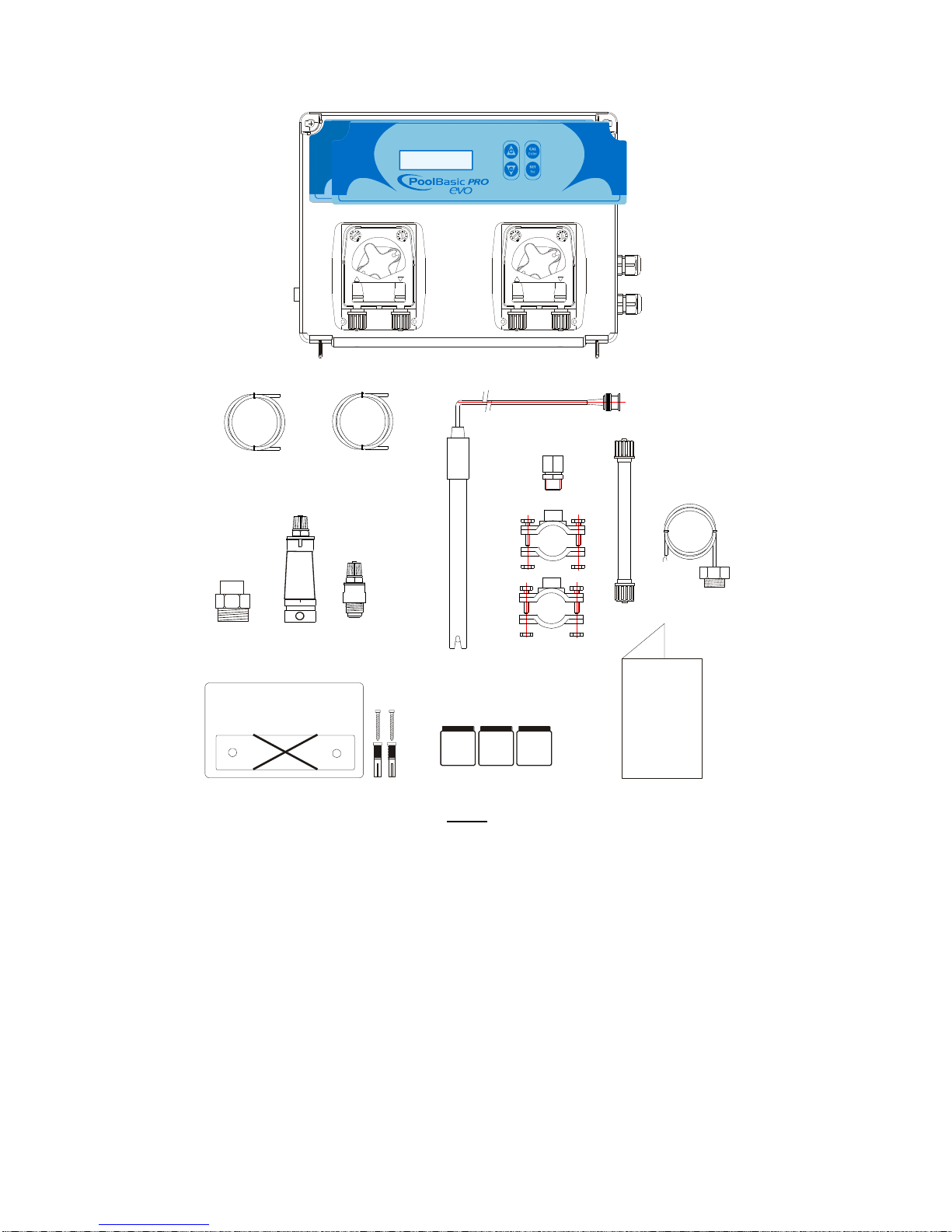

3. IDENTIFICATION OF COMPONENTS

PH 7 PH 4 H0

2

BCD

FG

M

E

Instructions manual

K

LN

H

I

JO

KEY

A. Pool Basic Pro EVO regulator

B. Suction hose in PVC Crystal 4x6 (4 m) x 2

C. Delivery hose in PE 4X6 (5 m) x 2

D. pH Electrode model SPH-1

E. Reducer for injection valve x 2

F. Duckbill valve in FPM (3/8” GAS) x 2

G. Suction foot (PVC hose) x 2

H. Tapping double-bolt clamp for fastening PSS3 probe holder onto 2” =50mm

hose

I. Tapping double-bolt clamp for fastening injection valve onto 2” =50mm hose x 2

J. Probe holder model PSS3 (1/2” GAS)

K. Hose 3x7

L. Fixing bracket kit

M. pH 4, pH 7, H2O Buffer solution kit

N. Instruction Manual

A

0000137188 Rev. 1.0

5

O. Temperature sensor

4. TECHNICAL SPECIFICATIONS

Power supply: 100÷240 Vac 50/60 Hz 30 watt

Switch: on side of box

Inlet measurements: pH, through BNC

opH scale: 0÷14.0 pH

opH precision: +/-0.1 pH

Temperature Scale: 0÷100 °C (PT100 sensor)

Pump flow rate with transaxle technology:

opH:1.5 l/h (hose 6X10) 1.5 bar

oH2O2:0.4 l/h (hose 3X7), 1.5 l/h (hose 6X10) 1.5 bar

Pump relay pH: 10 A 250 V (dry contact)

Relay for alarm: 10 A 250 V (dry contact)

Relay for H2O2:10 A 250 V (dry contact)

Dedicated power for pumps: 240 Vac 10 watt

Input signal: 100÷240 Vac

Level probe: pH, H2O2

Install the Pool Basic Pro EVO control device on a hard support (vertical wall) where it

can be easily accessed by the operator. Attach the Pool Basic Pro EVO control device

using the provided fixing bracket (distance between centre of holes: 95mm. Hole Ø 6).

Before carrying out any operation inside the equipment, make sure that the switches are

on 0. Unscrew the two screws on the upper part of the equipment by a quarter of a turn

and the front side will fold down on the hinges.

0000137188 Rev. 1.0

6

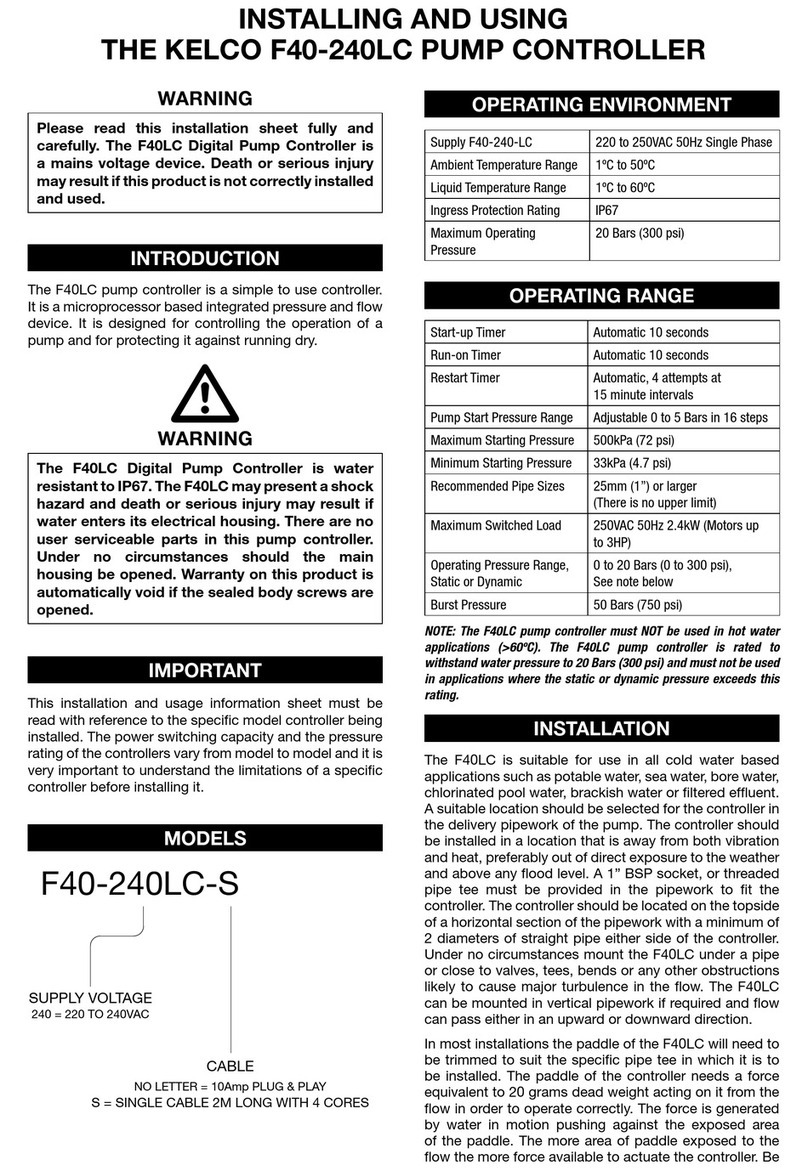

5. ASSEMBLY INSTRUCTIONS

NO

NO

* NOTA 2: LA PRESSIONE MAX. NON DEVE ESSERE SUPERIORE A 1,5 BAR.

PER AUMENTARE LA DURATA DEL TUBO, LA PRESSIONE NON DEVE SUPERARE 1 BAR.

* NOTA 1: IL CAVO DEVE PASSARE IN UNA ZONA DIVERSA DA QUELLA DI ALIMENTAZIONE

PER POMPE GROSSE, PER EVITARE DISTURBI DI CORRENTE.

3

1

25

4

6

0 7

Lunghezza massima de cavo: 6 mt

Pressione Massima: 1,5 bar

* NOTA 2

* NOTA 1

*NOTE 1: FOR LARGE PUMPS, THE CABLE MUST PASS THROUGH AN AREA OTHER THAN THE POWER

SUPPLY ZONE IN ORDER TO PREVENT CURRENT DISTURBANCES.

*NOTE 2: THE MAX. PRESSURE MUST NOT EXCEED 1.5 BAR.

TO INCREASE THE HOSE’S LIFETIME, THE PRESSURE MUST NOT EXCEED 1 BAR.

Max. length of cable: 6m

*NOTE 1

Maximum pressure

*NOTE 1

0000137188 Rev. 1.0

7

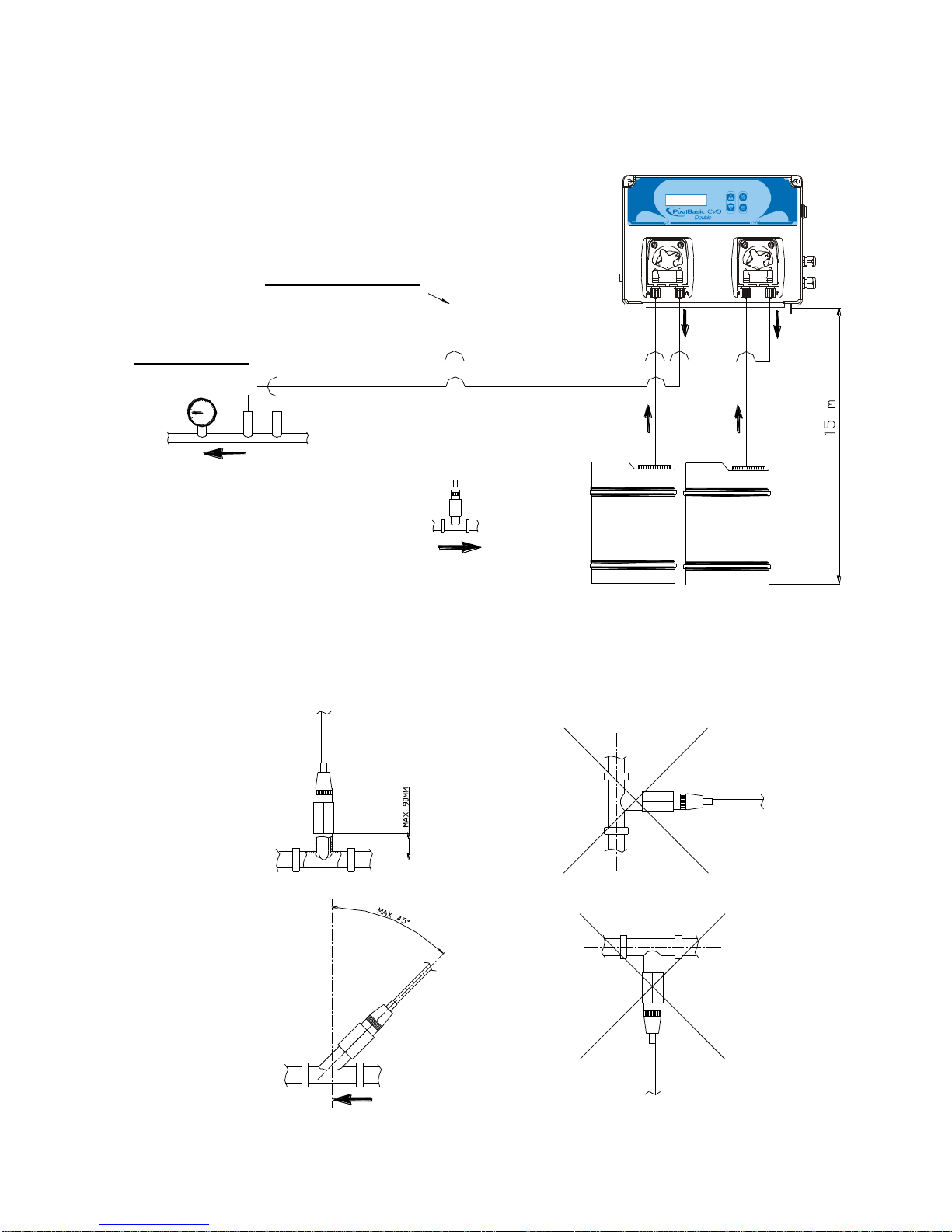

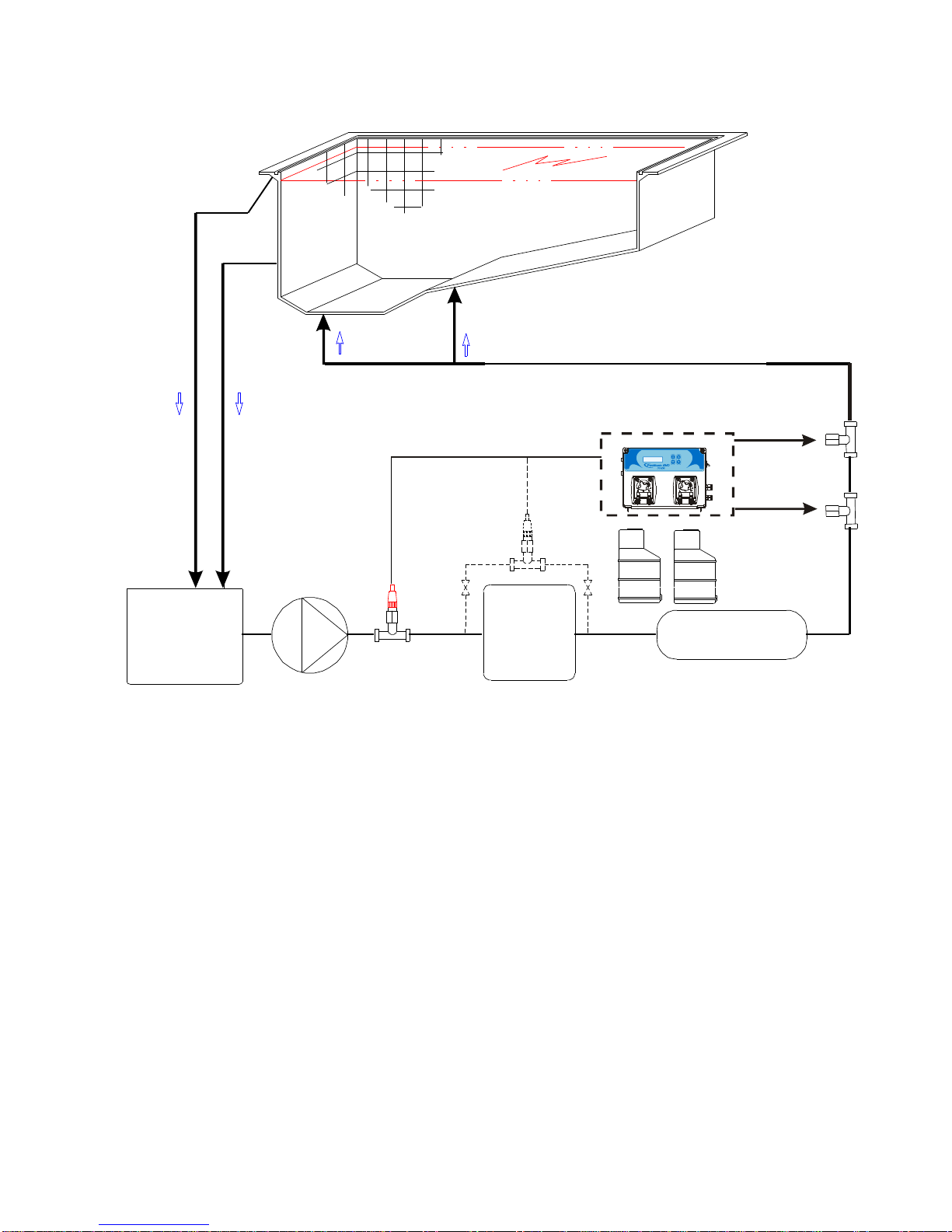

5.1 APPLICATION EXAMPLE

PH

Note:

The linear distance of the hose between the probe and the point of injection must

not be less than 60cm.

COMPENSATION

TANK

RECIRCULATION

PUMP

FILTER

HEAT

INTERCHANGER

0000137188 Rev. 1.0

8

6. DESCRIPTION OF THE CIRCUIT

1) Inlet pH measurement

2) Inlet temperature probe

3) Inlet probe level for product pH

4) Inlet probe level for product H2O2

5) Keyboard input

6) Flow (recirculation pump)

7) Relay for pH product, external pump.

8) Alarm relay

9) Relay for H2O2product, external pump.

10)Power supply input

11)Switch

12)Fuse

13)Power supply for pH pump

14)Power supply for H2O2pump

7. CALIBRATION MENU

7.1 Calibration

Before proceeding, the calibration must be enabled. Scroll down the menu

AdvancedCal, the display will show:

Exit the menu and return to the normal system status.

Calibration Menu Display

Settings

Advanced

Cal Off

Press ENTER to access the menu.

Advanced

Cal Full

Press ENTER and the + and –keys to

modify the calibration. Select Full and

confirm with ENTER.

Al arm

RL pH

Input

Flow

FN

Net

Fuse

µChip

Rel ay Rel ay Relay

156789

10

12

14

Lev

pH

Temp

Probe

Input

pH

234

11

PumppH

13

- +

Lev

HO

22

RLHO

22

H O Pump

2 2

Not Used

Not

Used

Not

Used

0000137188 Rev. 1.0

9

7.1.1 Calibrating the pH probe

Get some water

Remove the probe from the probe

holder

Wash the probe

Keep the probe in the buffer solution

pH 7

Press and hold down the Cal button

for 3 seconds

Tm 25°C 14pH

Press Cal to start calibration with a

buffer solution pH 7

Press CAL

B.Solution 7pH

The calibration takes 1 minute

Wait 59s

B.Solution 7pH

Probe quality

Quality

B.Solution 7pH

HO2

2

9

Wash the probe

4 pH

3

10

Keep the probe in the buffer solution

pH 4

Press Cal to start calibration with a

buffer solution pH 4

Press CAL

B.Solution 4pH

The calibration takes 1 minute

Wiat 59s

B.Solution 4pH

Probe quality

Quality

B.Solution 4pH

HO2

2

14

Wash the probe

15

Put the probe back in the probe holder

and press Cal to finish

0000137188 Rev. 1.0

10

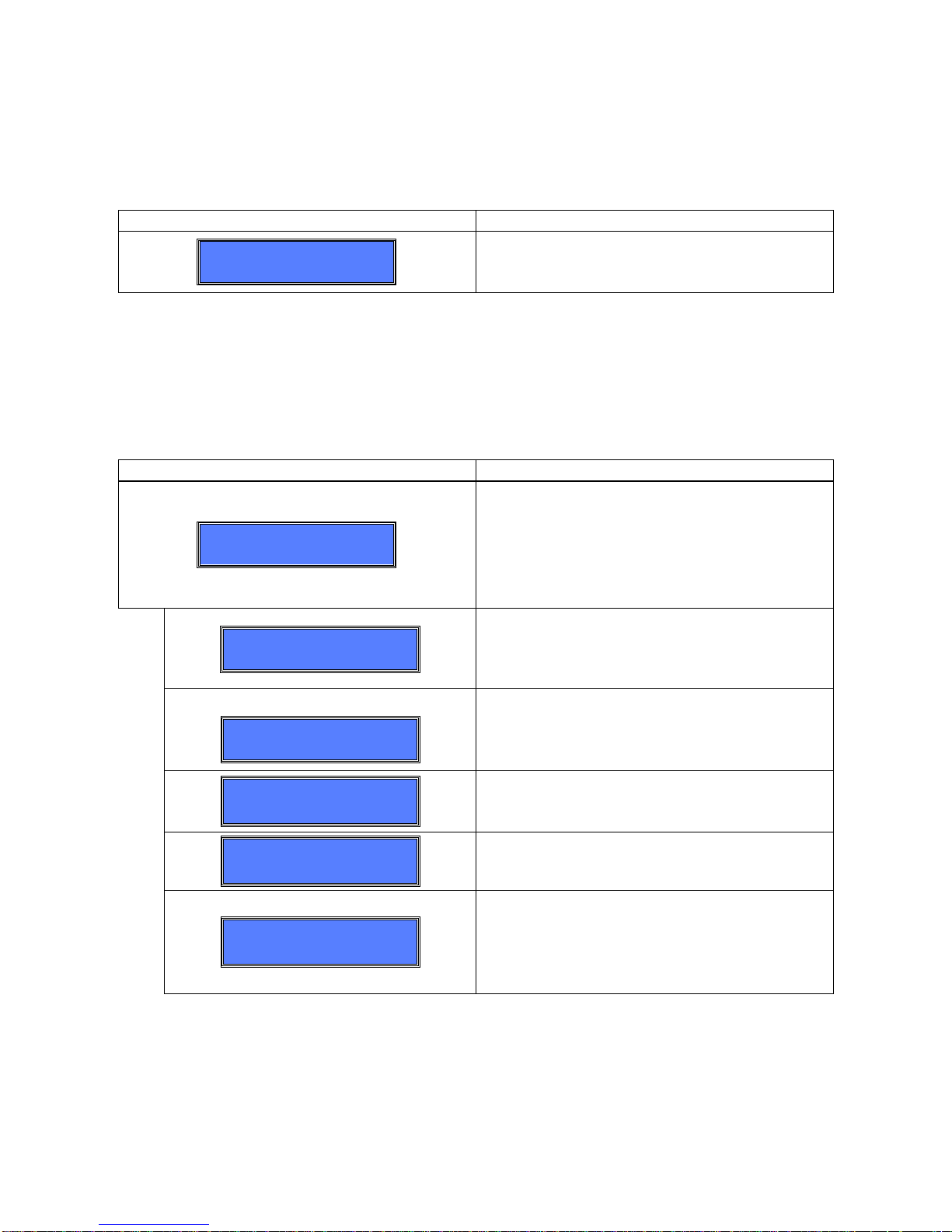

8. PROGRAMMING

The programming menu can be accessed by simultaneously pressing the Cal and Set

keys for at least 3 seconds.

Upon release of the keys the display will show:

To prime the pH pump, press the UP button for at least 3 seconds and release it to stop

the operation. To prime the H2O2pump repeat the same procedure pressing the DOWN

button for at least 3 seconds.

Progrma Menu

pH Measure

Use Enter to access the sub-menus:

Setpoint

Dos type

OFA time

Alr Band

Type

pH Measure

Setpoint 7.4 pH

Press Enter and the + and - keys to change

the Set Point value (0÷14 pH)

pH Measure

Sp Type Acid

Press Enter and the + and - keys to change

the Set Point type.

Acid

Alkaline

pH Measure

OFA Time Off

Press Enter and the + and - keys to set the

OFA time to OFF or from 1 to 240 min. (see

Paragraph 9.5)

pH Measure

Alr Band 3.0pH

Press Enter and the + and - keys to set the

band alarm from 1 to 3 pH.

pH Measure

Type PROP

Press Enter and the + and - keys to change

the dosing type.

PROP (see Paragraph 9.1).

ON/OFF (see Paragraph 9.2).

OFF (dosing disabled)

Language Display

Settings

Progrma Menu

Language EN

Press Enter and the + and –keys to change

the language:

FR, EN, IT, ES, DE

pH measurement display

Settings

0000137188 Rev. 1.0

11

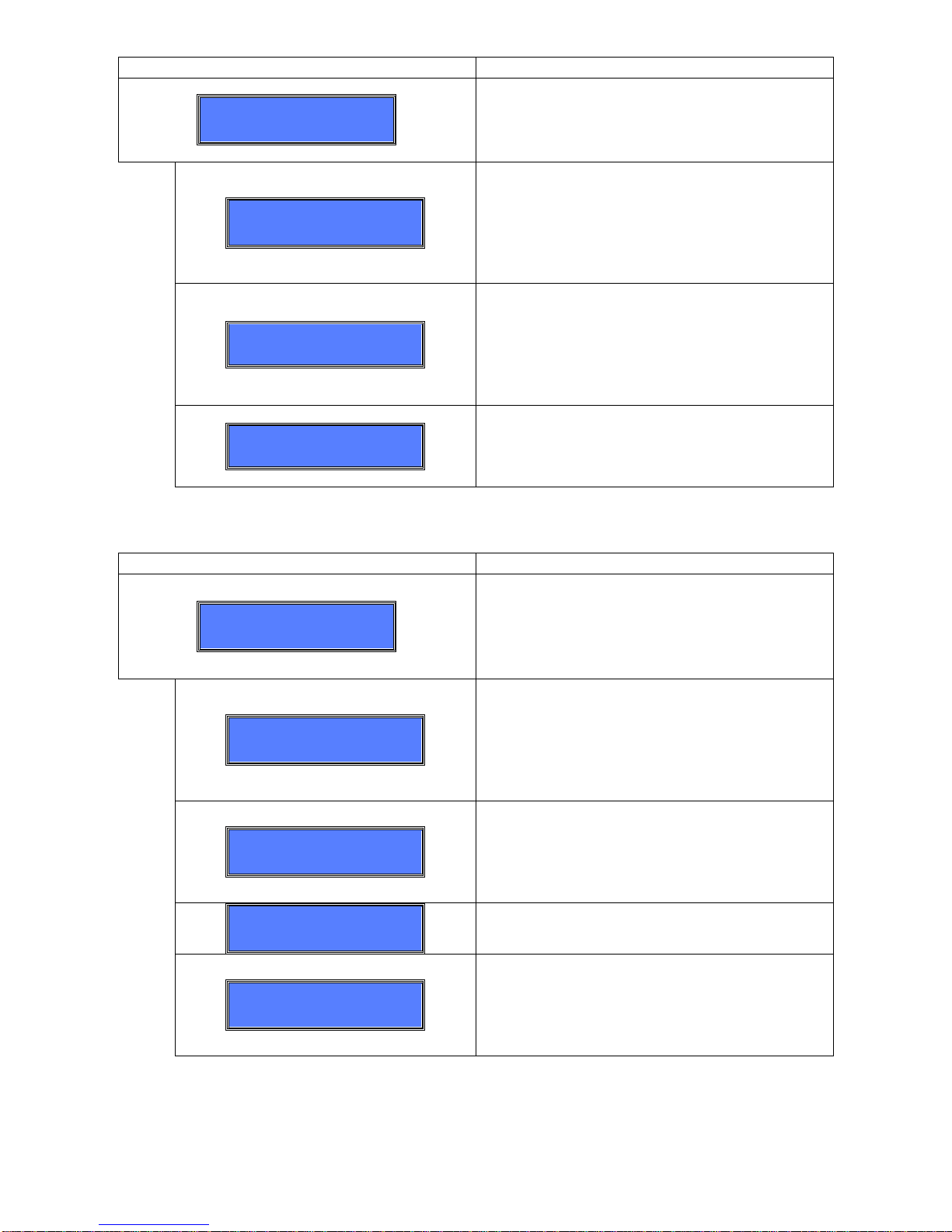

H2O2 measurement display

Settings

Progrma Menu

H2O2

Use Enter to access the sub-menus:

Hose

Conc.

Pump

H2O2

Tube 6x10

Use Enter to modify the dimensions of

the hose (3x7 or 6x10mm) and the

system automatically calculates the flow

rate with the other hose without changing

any parameters (the factory-set hose is

6x10).

H2O2

Conc 1.0 cc/m3

Enter the concentration value of the product

to be dosed with the 3x7 hose. This value

ranges from 1 to 4cc/m3. With the 6x10

hose the range is 1 to 15cc/m3.

H2O2

Pump 20 m3/h

Enter the value of the system recirculation

pump. It ranges from 2 to 100m³/h

Advanced Display

Settings

Progrma Menu

Avdvanced

Use Enter to access the sub-menus:

Temp.

Flow

Cal.

Password

Avdvanced

Temp. 25°C

Press Enter and the + and - keys to set the

compensation temperature from 1 to 100°C.

If a temperature probe is connected, the

menu item will not be displayed as the

system will compensate automatically with

the value read by the probe itself.

Avdvanced

Flow On

Press Enter and the + and - keys to set the

flow to OFF or ON. This item enables or

disables the Flow inlet (see. Paragraph

10.0).

Avdvanced

Cal Full

Press Enter and the + and –keys to set the

calibration to OFF or enable it to ON (Full)

Avdvanced

Password ****

Press Enter to set the system access and

modification password.

Use the + key to modify the figure and the –

key to scroll to the next figure and confirm

with Enter

0000137188 Rev. 1.0

12

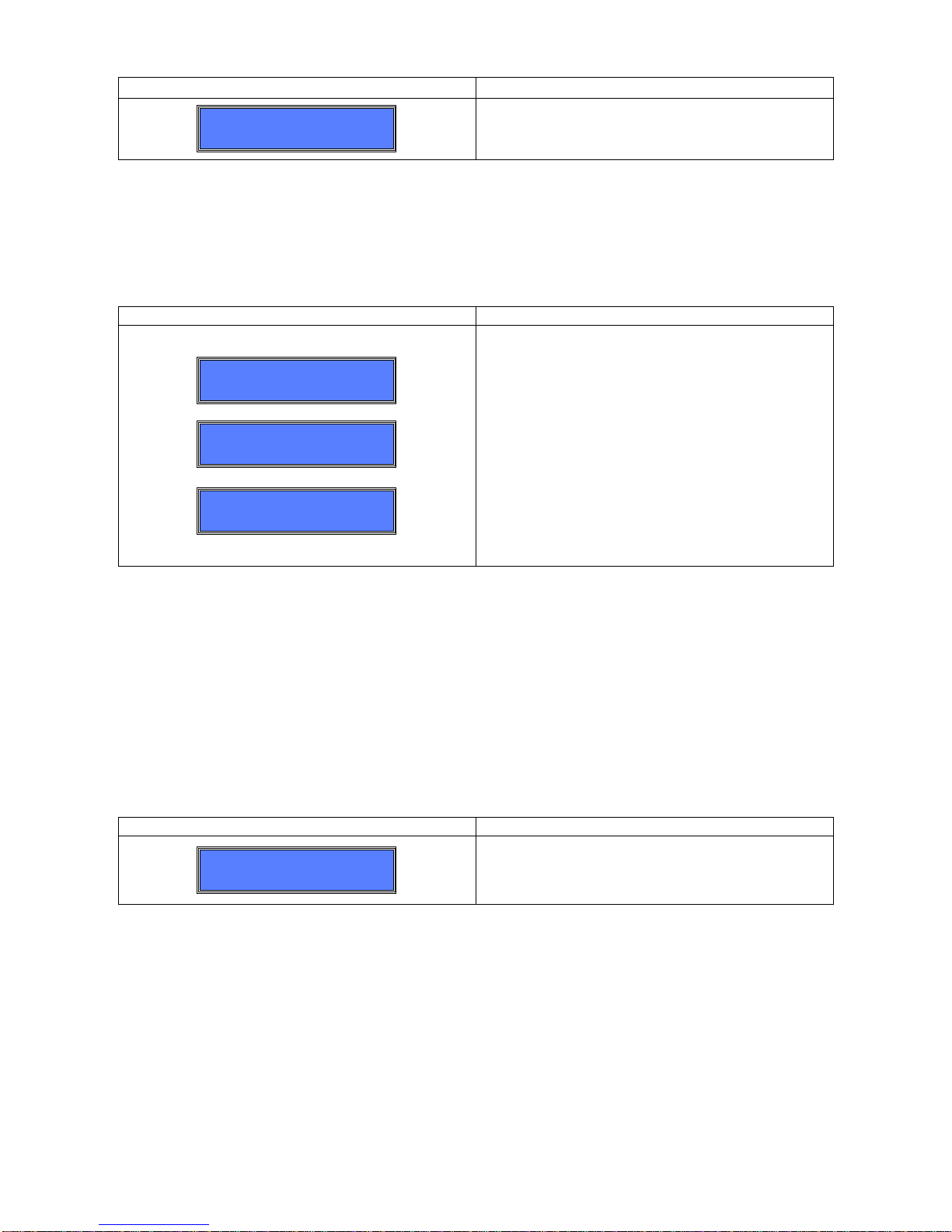

Press Esc to exit any menu and confirm the settings by pressing Enter.

DISPLAY VIEW WITH THE SYSTEM ON STAND-BY

*If AdvancedFlow=On and during H2O2 dosing, the recirculation pump stops and

blocks the system dosing, when the pump restarts, the H2O2 will restart the cc dosing

calculated from the start.

SHORTCUTS

To access the shortcut menu press the SET key for at least 3 seconds when the system is in stand-by.

Display

Settings

Progrma Menu

Exit Save

Press the + and –keys to choose Save or

NoSave, i.e. to save the settings or not and

press Enter to confirm.

Stand-by display

Operation

Alr

Tm 25°C 8.3pH

Alr 1200cc

Tm 25°C 8.3pH

Alr H2O2 37m

Tm 25°C 8.3pH

The display is divided into 4 parts:

On the upper left hand side the alarm is

shown, when present.

On the upper right hand side three views are

displayed:

oThe first is the stand-by system

oThe second shows the cc countdown

dosed by the pump

oThe third is the waiting time until the

next dosing with the message H2O2.

On the lower left hand side the temperature

read by PT100 or manually set is shown.

On the lower right hand side the value read

by the pH probe is shown

Display Set

Operation

pH = 7.2

H2O2= 10cc/m3

The pH- value flashes. It can be modified using the +

and –keys and confirmed using Enter. For the H2O2

value, repeat the same procedure, press Enter to

confirm and exit.

1

2

3

0000137188 Rev. 1.0

13

9. DOSING METHOD

The control of the pumps in the pH scale is carried out through the PWM function.

The proportional band is set to values pH= 0.8

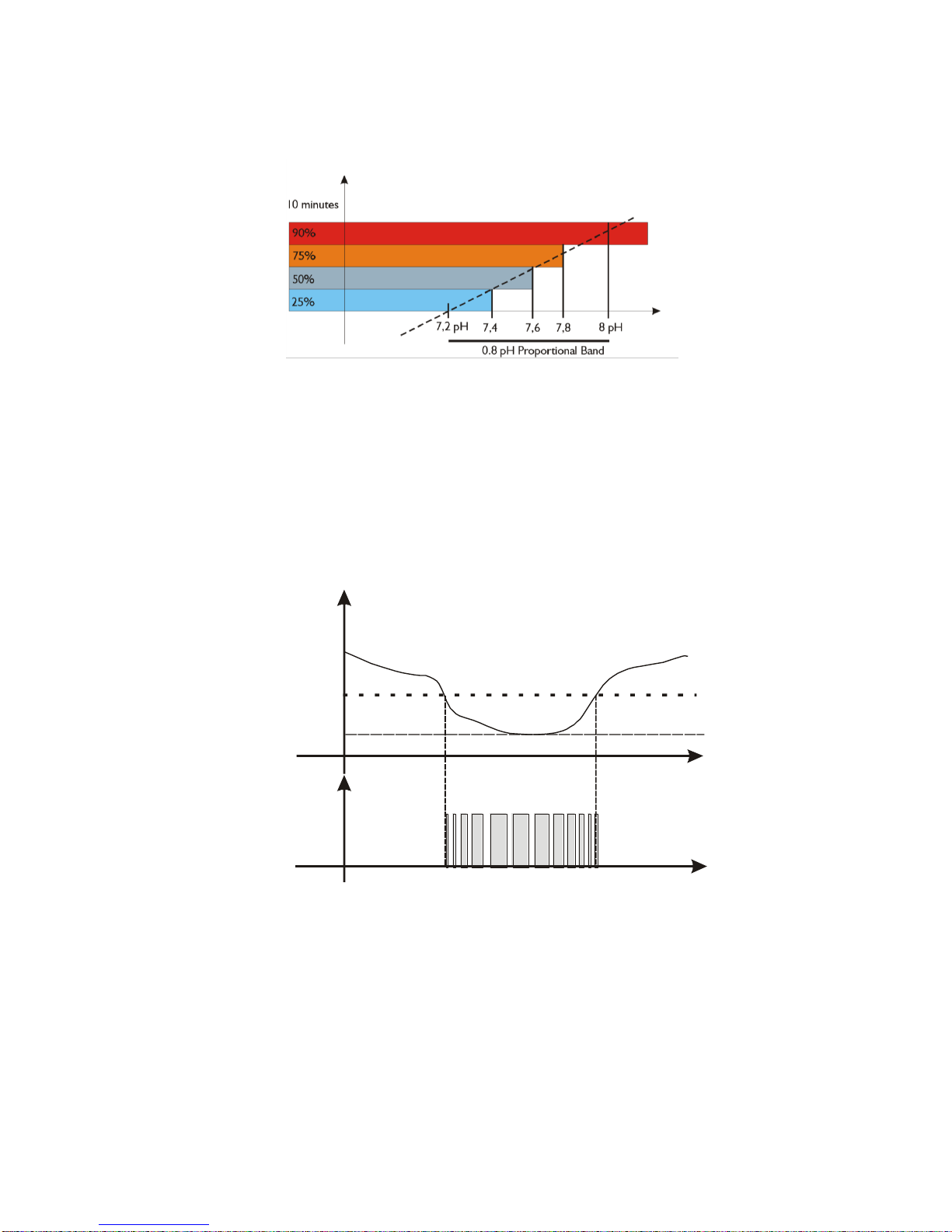

9.1 pH proportional dosing

The instrument allows the chemical measurement to be controlled and modified through

the pH Set Point automatically; adjusting the dosing though the pH motor controlled in

Proportional Time.

The dosing below is obtained by setting the following parameters:

Set point pH = 7.20 pH

Type of Dosing = Alkaline

Proportional Band = 0.80 pH

Set Point pH

Prop. Band

Motore pH

0000137188 Rev. 1.0

14

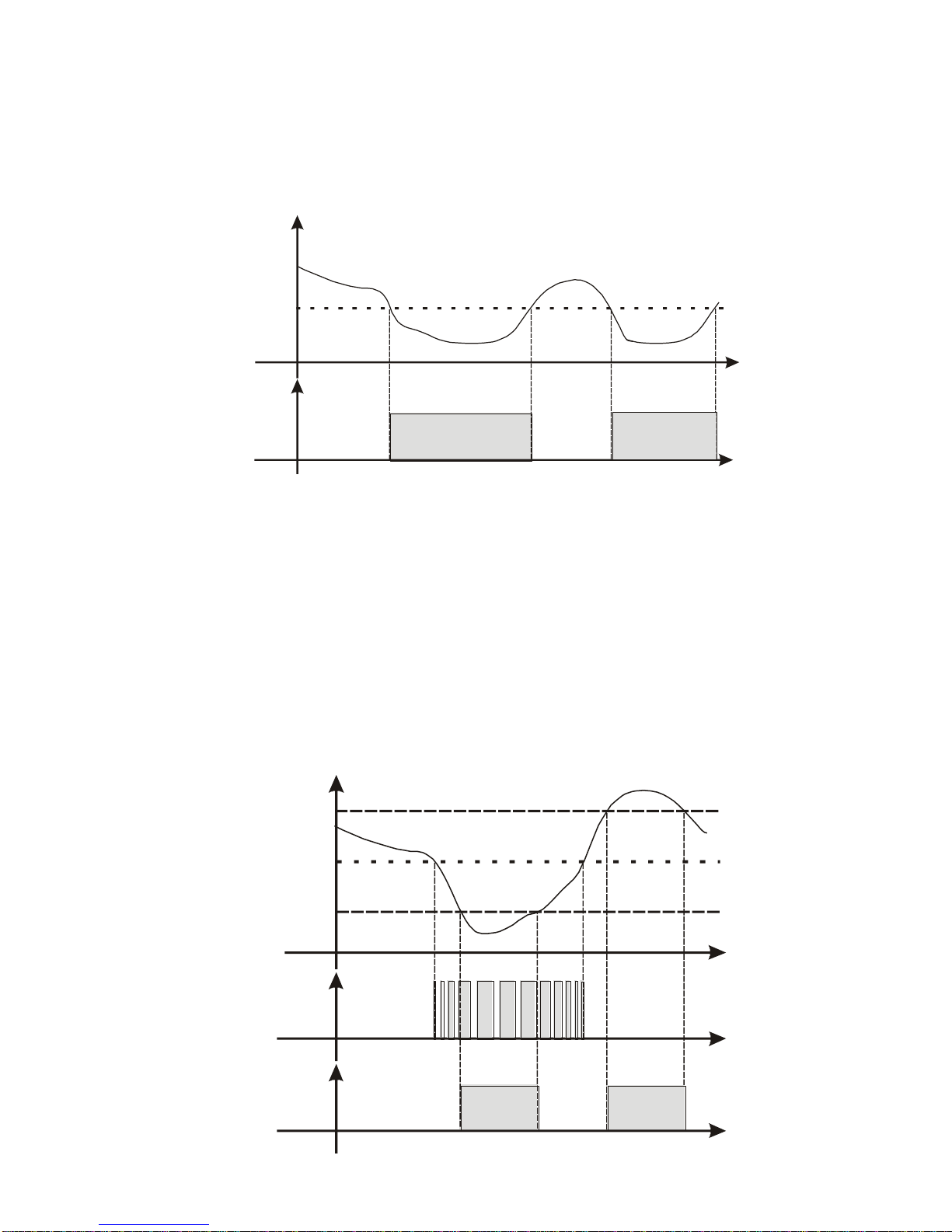

9.2 ON/OFF pH dosing

The instrument allows the chemical measurement to be controlled and modified through

the pH Set Point automatically; adjusting the dosing though the pH motor controlled in

ON/OFF.

The dosing below is obtained by setting the following parameters:

Set point pH = 7.20 pH

Type of Dosing = Alkaline

Set Point pH

Motore pH

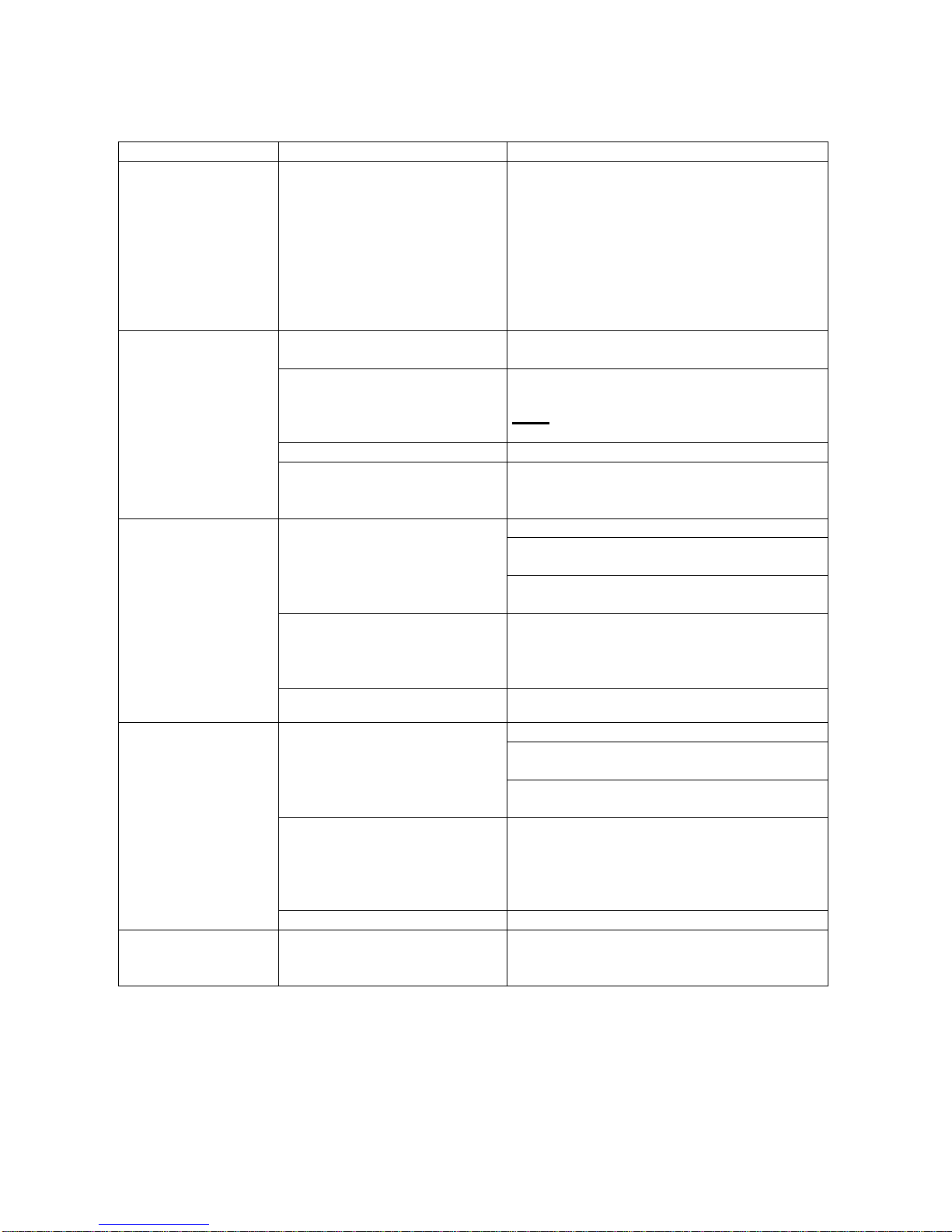

9.3 Alarm for the pH Set Point

When the alarm band is set, a work window is created. If the allowed limits are exceeded the alarm relay

closes and remains closed until the measurement is reset or the enter key is pressed to deactivate the

alarm.

When the OFA time (Over Feed Alarm) is set, the dosing time of Set Point pH in time is controlled with two

alarms:

First alarm at 70% of the time set is seen on the display, the alarm relay closes.

Second alarm at 100% of the time set is seen on the display and the alarm relay closes and the

pH motor is blocked.

Press the Enter key to eliminate the alarm and initialise the OFA time.

Motore pH

Set Point pH

ALR Relè

ALR Band

ALR Band

0000137188 Rev. 1.0

15

10. ACTIVATIONS

Flow Function

Through the recirculation pump.

High voltage input 100 ÷ 240 Vac, the dosing system is switched on.

High voltage input is off (the recirculation pump is switched off), the dosing system

shows FLOW flashing.

11. ALARMS

Lev pH= pH product level probe alarm.

Lev H2O2= Flocculant product level probe alarm.

OFA pH= Set Point not reached with the OFA time set*

pH Band= Shown when the value read is outside the SetPoint of +/- the band value

set.

*At 70% of the time set the system shows and activates the alarm relay, at 100% it

blocks the motor. Press the Enter key to reset the alarm.

Press the Enter key with the alarm active and its relay is deactivated only remaining

shown on the display.

12. PRE-DEFINED CONTROL PARAMETERS

To reset default values and settings:

Disconnect the device

Hold down the + and –keys simultaneously and connect the device

Confirm the choice to reset the default parameters

Default parameters:

Language = UK

Set Point = 7,4 pH; Acid; OFF; Alr Band 3,0 pH; PROP

H2O2= 6x10; 1cc/m3; 20m3/h

Temperature = 25°C

Calibration = FULL

Flow Input= OFF

Password = Disable

0000137188 Rev. 1.0

16

13. LIST OF POSSIBLE ANOMALIES AND RELATIVE SOLUTIONS

ANOMALY

CAUSE

SOLUTION

The instrument

always indicates pH

7.00

Problem with the cable and/or

connector.

1) Check for possible short circuits on the

electrode instrument connection cable

(between the cable’s core and the external

shielding).

2) Make sure that there are no traces of

humidity and/or condensation on the

connector of the probe or the device.

3) Make sure that 100 resistance is

present between terminals 11 and 12.

The instrument

always indicates a

high or continuously

unstable value

The electrode’s connection

cable is damaged.

Check the cable.

There is an air bubble in the

electrode’s membrane.

Place the electrode vertically and shake it

slightly until the air bubble rises.

N.B.: The electrode must be vertical or

tilted by a maximum of 45°.

Electrode worn.

Replace the electrode.

Connection cable too long or

too close to an electrical wire:

Disturbance.

Reduce the distance between the device

and the probe.

Impossible to

calibrate the pH 7

value

Error shown on the

display

Calibration quality of

pH probe < 20%

Unsuitable buffer solution.

Make sure that the solution used is pH 7.

Check the buffer solution pH using an

electronic pH-meter.

Use a new pH 7 buffer solution and restart

calibration.

Problem on probe’s porous

material, dirt deposits.

Make sure that the probe’s porous material

is in good condition; wash the electrode

using a diluted acid-based solution and dry

with a soft cloth.

Electrode worn.

Replace the electrode.

Impossible to

calibrate the pH 4

value

Error shown on the

display

Calibration quality of

pH probe < 20%

Unsuitable buffer solution.

Make sure that the solution used is pH 4.

Check the buffer solution pH using an

electronic pH-meter.

Use a new pH 4 buffer solution and restart

calibration.

Problem with the electrode

bulb.

Make sure that the electrode bulb is not

damaged. Make sure that it did not become

dry outside of the water. As a last resort,

clean the electrode and leave it immersed

in the water for a few hours.

Electrode worn.

Replace the electrode.

Slow electrode

response

Electrode electrostatically

charged.

During the calibration phase, the electrode

MUST NOT be dried with a cloth or paper;

let it drip.

0000137188 Rev. 1.0

17

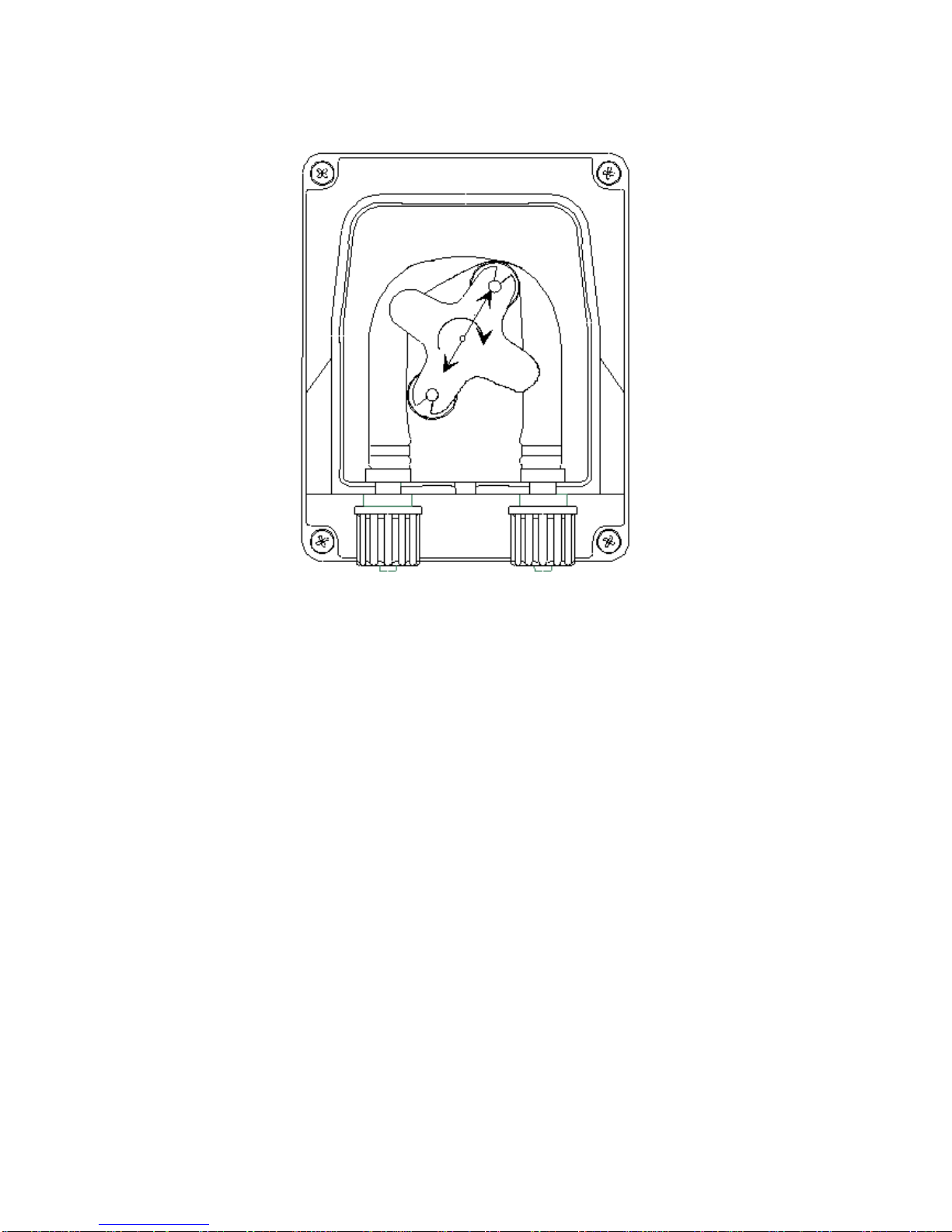

14. HANDLING

Hose replacement:

Release the cover by pulling the

left connector upward.

Position the roller at 20 past 10,

turning it in the direction of the

circular arrow.

Completely release the left

connector, holding it taut towards the

outside, and turn the roller in the

direction of the circular arrow so that

the hose is freed up to the right

connector.

Position the roller at 20 past 10,

turning it in the direction of the

circular arrow.

Insert the left connector into the

relative housing and pass the

hose under the roller’s guide.

Turn the probe holder in the

direction of the circular arrow,

simultaneously accompanying

the hose into the pump’s head,

until the right connector is

reached.

Arrows indicating the liquid’s

direction

Position the pump’s cap,

according to the direction of the

arrows (▲▼) and press its

surface hard so that it is

properly locked into place.

0000137188 Rev. 1.0

18

15. STORING THE PUMP AFTER USE

When the regulation device must be stored, clean water should be pumped through the

hose in order to rinse it.

Then position the probe holder at 7h05, turning in the direction indicated by the circular

arrow.

These two precautions will facilitate the subsequent reactivation of the unit.

0000137188 Rev. 1.0

19

WARNINGS

PRODUCTS TO BE USED:

pH Reduction: product with a sulphuric acid base, easily found on the market.

pH Increase: product with an alkaline acid base

PRODUCTS NOT RECOMMENDED

Do not use hydrochloric acid.

Ask the installer about all other products.

PROBE WARNINGS

Handle the probe with CARE.

DO NOT INSERT AN EXCESSIVE AMOUNT of chemical product prior to the probe.

Storing the probe: Extract the pH probe from the relative probe holder. Store it in the

original bottle filled with tap water. If necessary, close the probe holder using a plug

the size of a 5 euro cent coin.

Since the pH electrode consists of glass parts, handle it with care.

All of our electrodes are tested on the production line before being packaged.

Repairs of electrodes are not foreseen by the warranty unless they do not

function when they are activated for the first time. Packaging not included.

In this case, in order for the probe to be accepted for examination, it absolutely must be

sent in the original packaging with the relative bottle filled with water.

CAUTION: VAPOURS

SERBATOIO

TANK

RESERVOIR

TANK

2 mt

This manual suits for next models

1

Table of contents

Other Seko Controllers manuals