MHM SYNCHROPRINT 5000 User manual

Operating Instructions Synchroprint 5000

Operating instructions SP5000 V1-0.docx Page 1 of 52

OPERATING INSTRUCTIONS

(Translation of the original instructions)

MHM SCREEN PRINTING MACHINE

SYNCHROPRINT 5000

©2005-2016 Machines Highest Mechatronic GmbH, Erl, Austria

Operating Instructions Synchroprint 5000

Operating instructions SP5000 V1-0.docx Page 2 of 52

Preface

Dear Customer,

Congratulations and thank you for choosing the MHM Synchroprint 5000. This machine is

designed to provide the highest standards of performance and reliability throughout its normal

operating life. Highly innovative and precise MHM technology provides a combination of the finest

build quality along with optimal safety. We trust these Operating Instructions will assist you in

becoming familiar with the safe and efficient operation of the Synchroprint 5000.

Important note:

Due to our policy of continuous improvement we reserve the right to change specifications without

prior notice. Therefore certain individual fittings and components may differ slightly from the

model detailed in this document. For any further questions regarding your Synchroprint 5000,

please contact the MHM service team.

Wishing you every success with your future production…

Machines Highest Mechatronic GmbH

Important advice regarding these Operating Instructions

These Operating Instructions form an integral part of the Synchroprint 5000 and must be made

available to all authorized personnel at all times. No particular sections or pages should be removed

from these Operating Instructions, and any missing sections or pages should be replaced

immediately, particularly in relation to section “1. Safety Instructions”.

These Operating Instructions are subject to international copyright and may not be reproduced

and/or revised without our prior written approval.

©2005-2016 Machines Highest Mechatronic GmbH, Erl, Austria. (All rights reserved).

Published by: Machines Highest Mechatronic GmbH

Muehlgraben 43a

A-6343 Erl / AUSTRIA

Contact details: Telephone:+43 (0) 5373 –76080-18

Fax: +43 (0) 5373 –76080-20

Mobile: +43 (0) 664 –8151380

Erl, January 2016

Operating Instructions Synchroprint 5000

Operating instructions SP5000 V1-0.docx Page 3 of 52

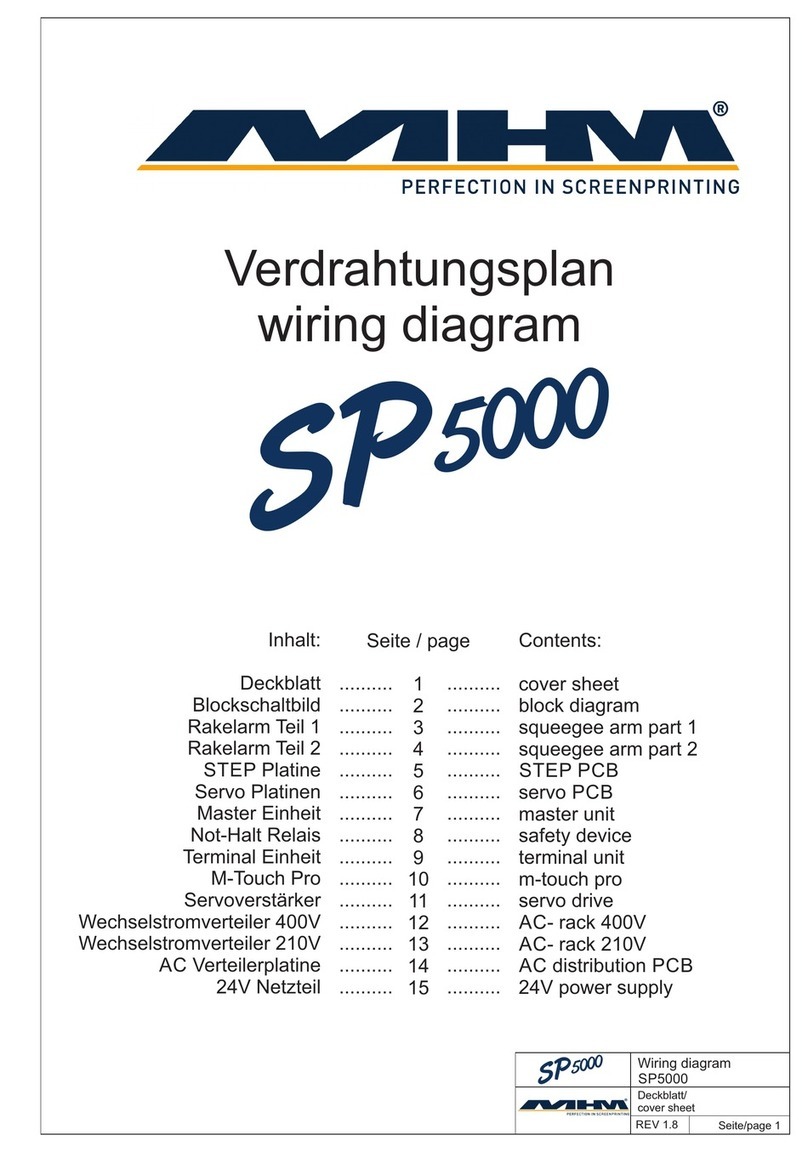

Content:

Preface..................................................................................................................................................2

Important advice regarding these Operating Instructions....................................................................2

1. Safety Instructions........................................................................................................................5

1.1. Description of Key Words and Symbols in the Operating Instructions................................5

1.2. General Information..............................................................................................................6

1.3. Qualification of Operating and Service Staff........................................................................6

1.4. Required qualification for operations....................................................................................7

1.5. Safety Instructions for the Operating Staff............................................................................8

1.6. Personal Protective Equipment .............................................................................................8

1.7. Additional Risks....................................................................................................................9

1.8. Safety Signs on the Machine...............................................................................................10

1.9. Other Valid Rules and Regulations:....................................................................................10

2. Intended usage of the machine...................................................................................................10

3. Data............................................................................................................................................11

3.1. Serial Number and Year of Manufacture ............................................................................11

3.2. Dimensions..........................................................................................................................11

3.3. Specifications ......................................................................................................................12

4. Transportation and packaging....................................................................................................13

4.1. General Notes with Regard to Transportation and Danger Warnings.................................13

4.2. Packaging ............................................................................................................................13

4.3. Unloading of the crates........................................................................................................13

4.4. Packaging material ..............................................................................................................13

5. Assembly....................................................................................................................................14

5.1. General Assembly Instructions ...........................................................................................14

5.2. Positioning of the Synchroprint...........................................................................................14

5.3. Ambient Conditions ............................................................................................................14

5.4. External supply/Connection ports.......................................................................................15

5.4.1. Electrical Connections .................................................................................................15

5.4.2. Compressed Air Requirements ....................................................................................15

6. Commissioning the Synchroprint...............................................................................................16

7. Design and Operation.................................................................................................................16

7.1. General Process Description ...............................................................................................16

7.2. Overview Machine Parts.....................................................................................................17

7.3. Control panel.......................................................................................................................17

7.4. Safety Devices.....................................................................................................................18

7.5. Pallets ..................................................................................................................................19

7.6. Foot switch ..........................................................................................................................19

7.7. Type Plate............................................................................................................................19

7.8. Main Power Switch.............................................................................................................19

7.9. Print Stations .......................................................................................................................20

7.9.1. Overview Manual Print Stations..................................................................................20

7.9.2. Part description Manual Print Station..........................................................................21

7.9.3. Submenu: .....................................................................................................................25

7.9.4. Squeegee Carriage........................................................................................................26

7.10. Additional equipment ......................................................................................................27

7.10.1. Flash Cure Units.......................................................................................................27

7.10.2. Flocking Devices......................................................................................................28

Operating Instructions Synchroprint 5000

Operating instructions SP5000 V1-0.docx Page 4 of 52

8. Danger Zones.............................................................................................................................29

9. Control of the Machine..............................................................................................................30

9.1. Stopping the Machine in the event of an Emergency..........................................................30

9.2. Stopping the Machine in the event of Malfunction.............................................................31

9.3. Putting the Machine into Operation ....................................................................................31

9.4. Configuration of the Control...............................................................................................31

9.5. Hybrid-Control....................................................................................................................31

9.6. Operating the machine with tablet „m-touch pro“ ..............................................................32

9.6.1. Adjust...........................................................................................................................32

9.6.2. Manually ......................................................................................................................35

9.6.3. Automatic.....................................................................................................................37

9.6.4. BasicSetup....................................................................................................................39

9.6.5. Help..............................................................................................................................40

9.7. Blocked operation................................................................................................................40

9.8. Operating the machine with the terminal............................................................................41

9.8.1. Adjust...........................................................................................................................43

9.8.2. Manual .........................................................................................................................44

9.8.3. Automatic.....................................................................................................................45

9.9. Error display........................................................................................................................45

9.9.1. Error messages terminal...............................................................................................45

9.9.2. Error messages tablet ...................................................................................................46

10. Trouble shooting .....................................................................................................................46

10.1. Basic errors (without error message)...............................................................................46

10.2. Error messages control system ........................................................................................47

11. Shutting Down the Synchroprint.............................................................................................49

11.1. Switching Off the Machine after Normal Operation.......................................................49

11.2. Long-term Shutdown.......................................................................................................49

11.3. Permanent Shutdown of the Machine..............................................................................49

12. Maintenance of the Synchroprint............................................................................................50

13. Terms of the Guarantee...........................................................................................................52

14. Limitation of liability..............................................................................................................52

15. Support, Customer Service and Hotline..................................................................................52

Operating Instructions Synchroprint 5000

Operating instructions SP5000 V1-0.docx Page 5 of 52

1. Safety Instructions

This section describes the safety instructions for the correct and safe operation of the Synchroprint

5000. In addition, this section also contains references to the European rules and regulations

concerning the guarantee of industrial safety along with safety at the workplace. These rules and

regulations provide the basis for these operating instructions.

These Operating Instructions include:

1. General safety instructions.

2. Special safety instructions, if they are relevant to a specific section, at the beginning of that

respective section.

3. Special safety instructions, if they are important for detailed sequences of operation, before

the description of that respective sequence of operation.

4. Indications to read such instructions included in the respective section.

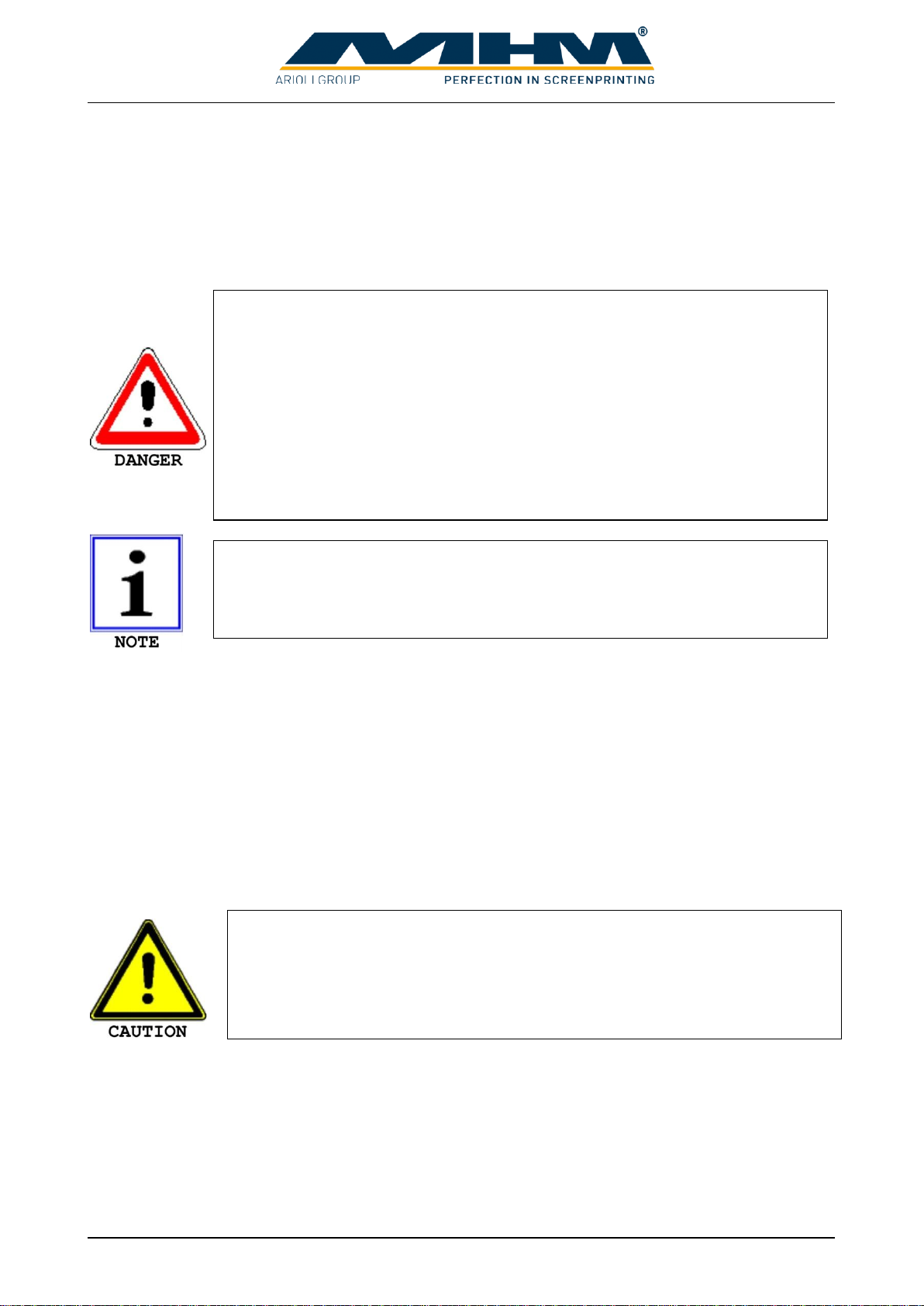

1.1. Description of Key Words and Symbols in the Operating Instructions

In these operating instructions classified key words and symbols are used to identify dangers and

items that require special attention. Particular attention is to be paid to the sections marked in this

manner, because they contribute to personal safety as well as the prevention of damage to the

Synchroprint.

Symbol

Key word

Meaning

DANGER

This symbol indicates possible risk to life.

CAUTION

This symbol indicates danger of damage to

property and/or environment.

NOTE

This symbol indicates useful additional information

and operating suggestions.

Operating Instructions Synchroprint 5000

Operating instructions SP5000 V1-0.docx Page 6 of 52

1.2. General Information

The Synchroprint 5000 (hereon named Synchroprint) is built in accordance to all appropriate safety

regulations. Owing to its complex design, the Synchroprint must only be operated and maintained

by suitably skilled staff.

Installation, operation or maintenance of the Synchroprint by persons who have not been suitably

trained, introduced or acquainted with the system and informed regarding the possible dangers may

result in:

1. Failure of essential functions of the Synchroprint.

2. Danger to persons through electrical or mechanical actions.

3. Material damage to the Synchroprint.

1.3. Qualification of Operating and Service Staff

‘Qualified personnel’ refers to people who are able to carry out the required procedures and be able

to recognize as well as prevent potential risks, as a result of their training and experience. Such

personnel should have a good knowledge of any relevant standards, regulations, rules of accident

prevention and internal conditions etc.

Every person instructed to perform any operation on the Synchroprint must:

1. Be physically and mentally capable of coping with the respective tasks.

2. Be suitably instructed in operating the Synchroprint.

3. Be familiar with the Operating Instructions, in particular the general safety instructions in

the individual sections, and have read and understood them.

4. Be aware of any additional general safety regulations of any local authorities/associations.

5. Be aware of the principles of industrial hygiene and be able to demonstrate them.

6. Be aware of the contents of suppliers’ safety instructions, should they affect his/her area of

responsibility.

7. Be aware of any relevant safety devices at the workplace and be able to use them.

8. Be informed regarding the prevention of environmental damage in respect of his/her area of

responsibility.

9. Be informed regarding the prevention of material damage in respect of his/her area of

responsibility.

If casual workers are employed for assistance work they must be particularly informed regarding

existing and potential dangers and instructed accordingly.

Operating Instructions Synchroprint 5000

Operating instructions SP5000 V1-0.docx Page 7 of 52

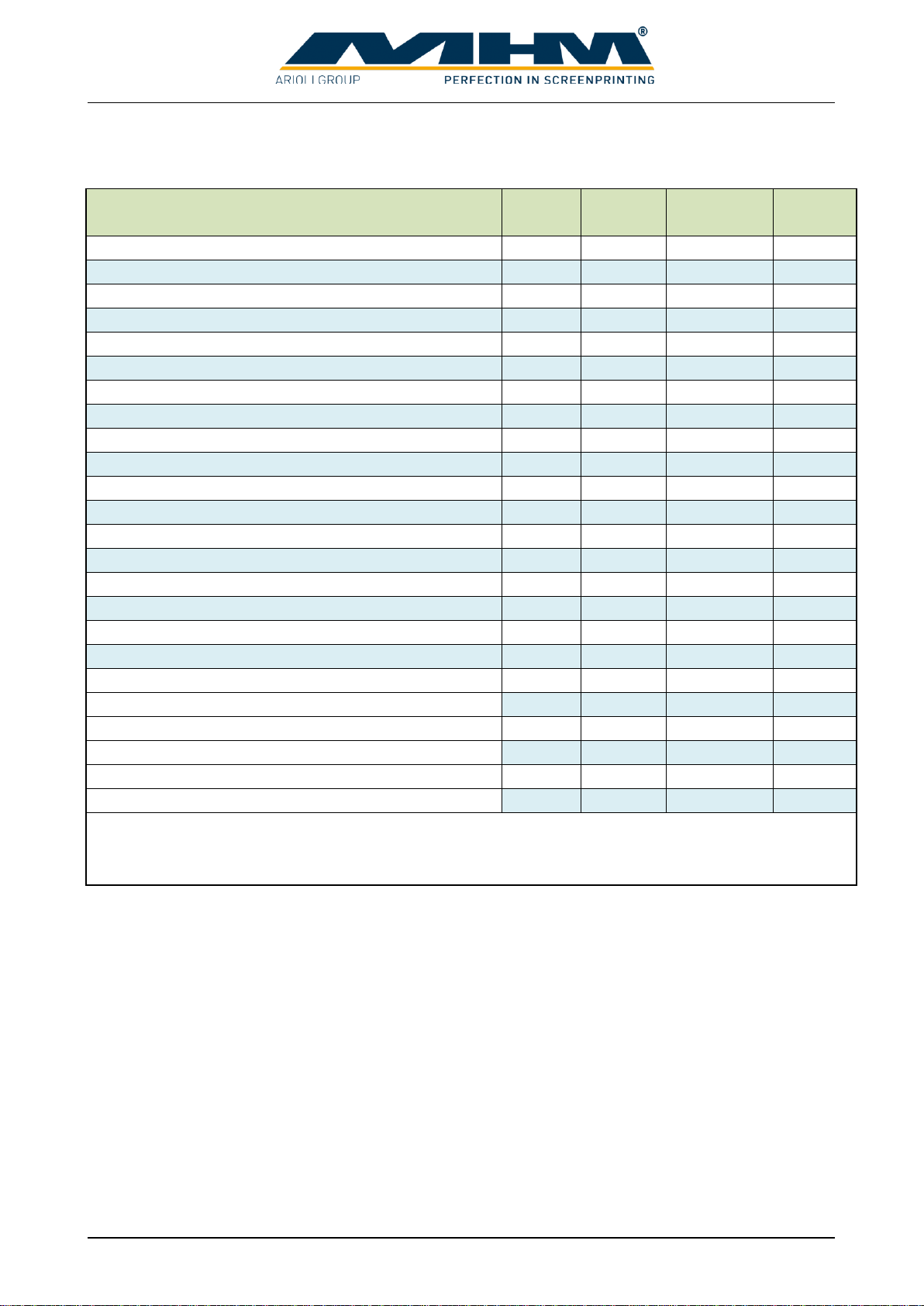

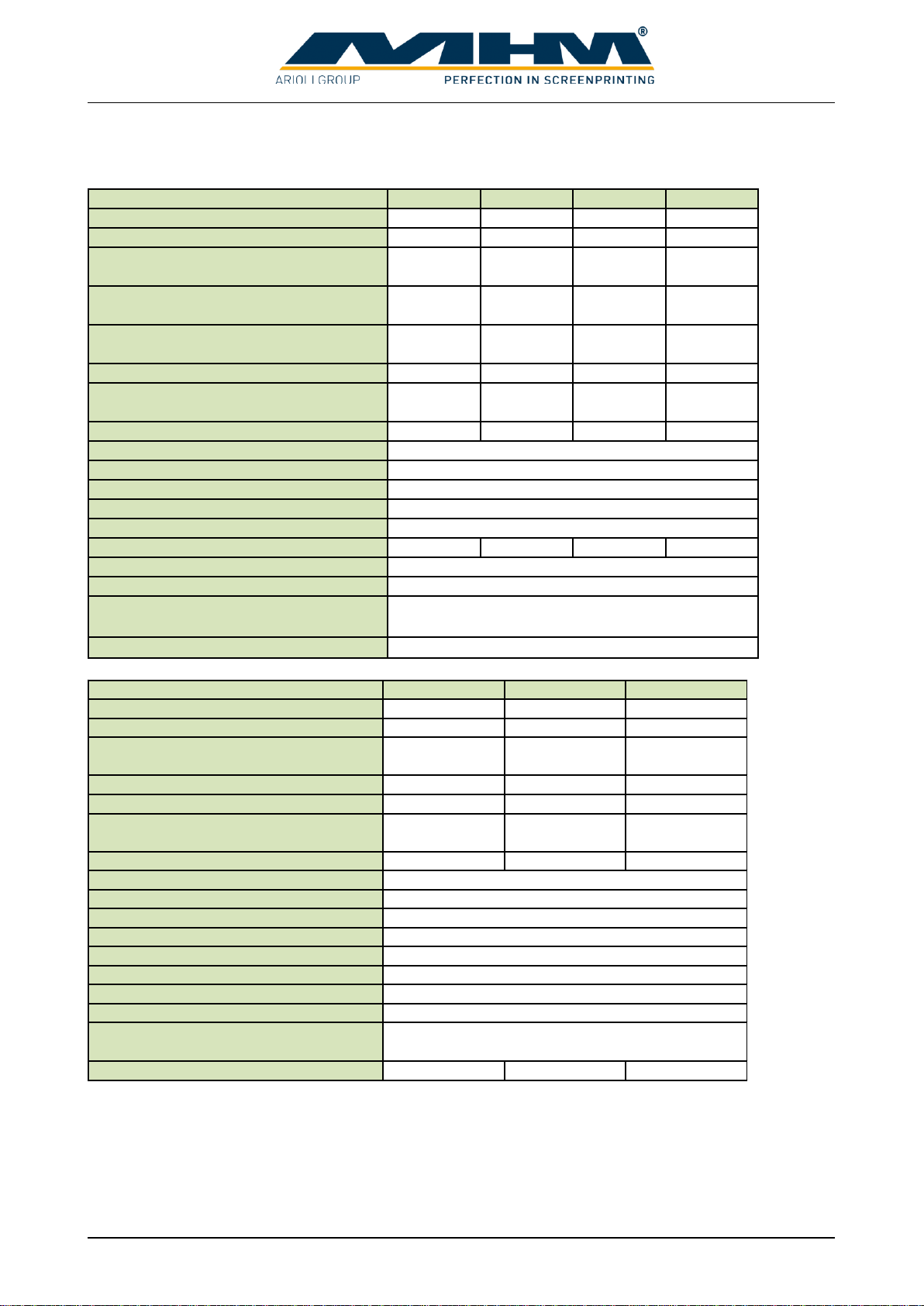

1.4. Required qualification for operations

Skill

Assistant

Operating

personnel

Maintenance

personnel

Service

personnel

Color refill (only at standstill)

x

x

x

x

Unloading substrates

x

x

x

x

Cleaning of the machine (only at standstill)

x

x

x

x

Setting screens

x**

x

x

x

Equip flood and print squeegees

x**

x

x

x

Equip the screens

x**

x

x

x

Adjust squeegees

x**

x

x

x

Clean of the screens in clean mode

x**

x

x

x

Equip machine with dryer or changing the position

x**

x

x

x

Applying substrates

x

x

x

Enable and disable printing heads

x

x

x

Enable and disable of dryer

x

x

x

Start of all printing processes and adjustment work

x

x

x

Activities at the maintenance unit

x

x

x

Lubricate of the machine

x

x

x

Shutting down the machine

x

x

x

Long-term shutdown

x

x

Permanent shutdown of the machine

x

x

Maintenance and repairs at the pneumatically system

x*

x

Maintenance and repairs at the electrical system

x*

x

Maintenance and repairs at the mechanical system

x*

x

Maintenance and repairs at additional units

x*

x

Maintenance and repairs at the electronically system

x

Maintenance and repairs at the safety system

x

* only with the required qualification

** only together with the operating personnel

Operating Instructions Synchroprint 5000

Operating instructions SP5000 V1-0.docx Page 8 of 52

1.5. Safety Instructions for the Operating Staff

All cabinets and covers on the Synchroprint must always be kept closed. Open

cabinets and covers are extremely dangerous as live electrical components are

accessible.

Mechanical or electrical failures must only be repaired by an MHM

authorized/approved technician.

On every occasion, the operator should check the correct functioning of the

safety devices (Emergency STOP), before commencing use of the Synchroprint.

No modifications to any part of the machine or its assembly system that may

adversely affect safety must be carried out without the prior approval of MHM.

Program modifications in the control program and changes of settings which

may affect the Synchroprint’s operation should only be carried out by an MHM

authorized/approved technician.

All working spaces, passageways, escape and emergency routes and exits must

be kept clear.

No tools or other objects must be kept or left in the area of the machine.

Any modifications or changes to the Synchroprint’s settings should only be

carried out by an MHM authorized/approved technician.

Always wear protective gloves and safety goggles during cleaning work, in

particular when using solvents!

Any remains of potentially harmful substances should be disposed of according

to the legal requirements of the country or state in which the Synchroprint is

operated.

All accessories for service and maintenance work (e.g. cleaning agents) must be

collected in suitable containers and disposed of according to any relevant

regulations.

1.6. Personal Protective Equipment

Personal protective equipment must be used at work. This equipment comprises close-fitting

working clothes with tight sleeves and high tearing resistance without any protruding parts. These

features prevent operators from getting caught by moving machine parts.

Operating Instructions Synchroprint 5000

Operating instructions SP5000 V1-0.docx Page 9 of 52

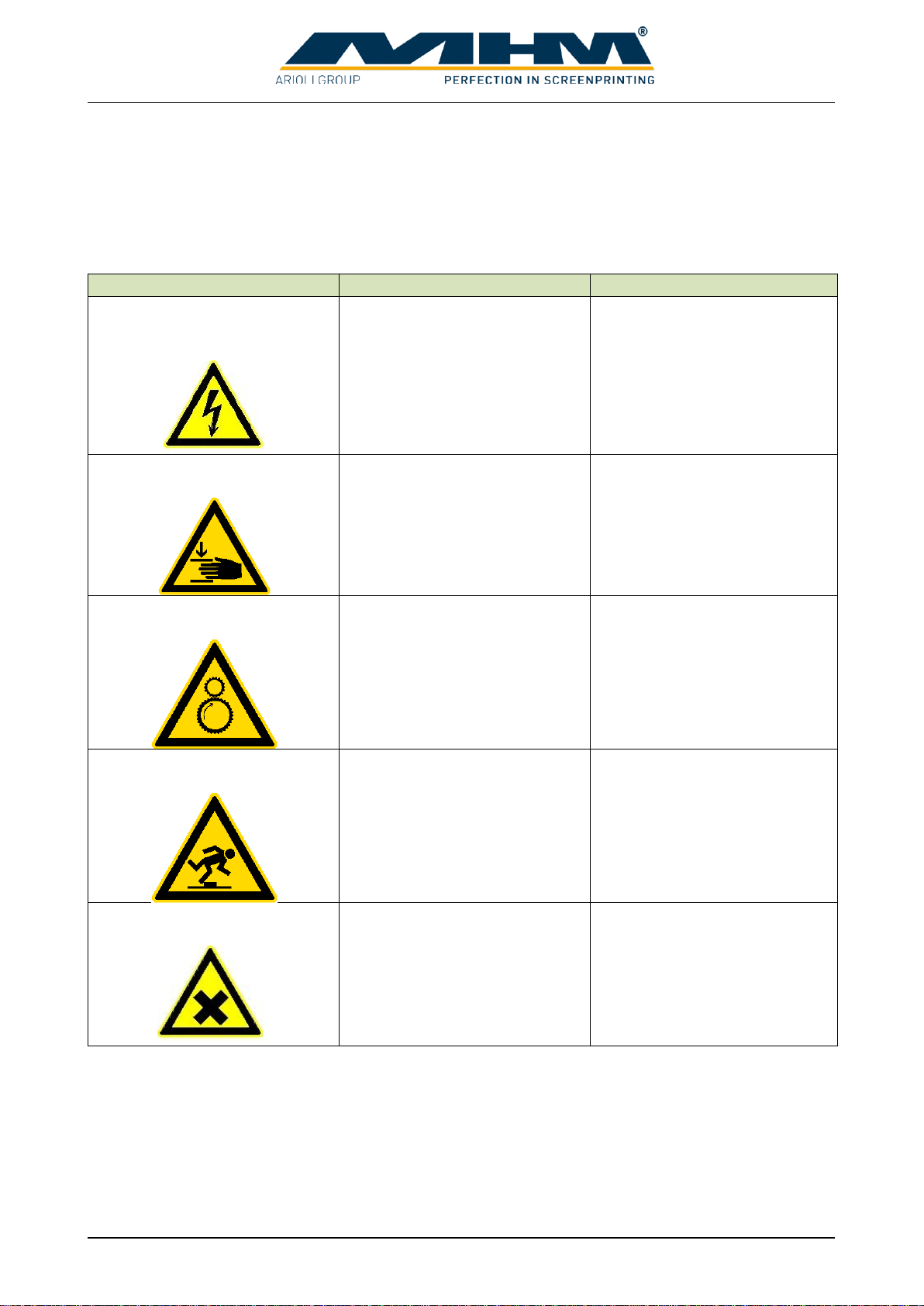

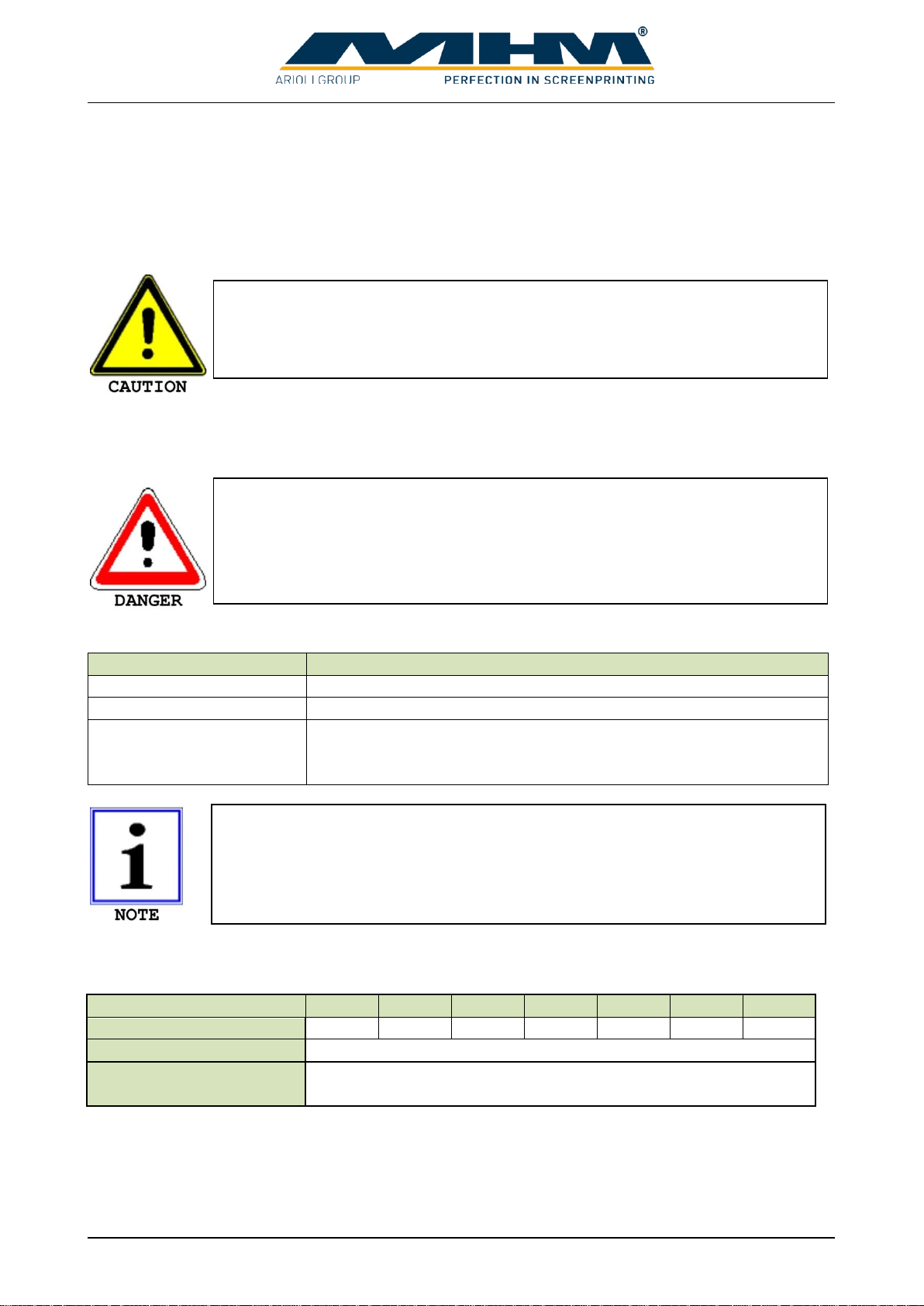

1.7. Additional Risks

Even though the Synchroprint has been designed and built according to the most stringent safety

criteria, as with all machinery we have to anticipate certain additional risks, which are detailed

below:

Danger

Description

Behaviour/Action

Electrical threats:

Indirect contact (in case of

defect)

Danger of life-threatening

electrical shock by indirect

contact with defective parts

carrying voltage (in particular

in case of defective insulation).

Disconnect the machine from

power supply by switching of

the “main power switch”.

Mechanical threats:

Crushing

Crushing of parts of the body -

in particular arms and hands.

Be aware of moving parts

whilst operating the machine.

Wear protective clothing at all

times.

Mechanical threats:

Getting caught or trapped

Danger through moving parts

(linear or rotary drive

systems).

Danger in reaching into, under

or over the machine. Only

reach into the machine from

the indicated points. Wear

suitably fitting clothing,

particularly in the area of the

arms.

Mechanical threats:

Slipping, stumbling and falling

Danger of falling (e.g.

obstacles on the floor).

The floor area around the

machine must be kept free

from any obstacles.

Danger through contact with or

inhaling of substances

Danger through contact with or

inhaling substances or

materials with harmful or toxic

effects.

Observe the safety instructions

for handling such substances.

Operating Instructions Synchroprint 5000

Operating instructions SP5000 V1-0.docx Page 10 of 52

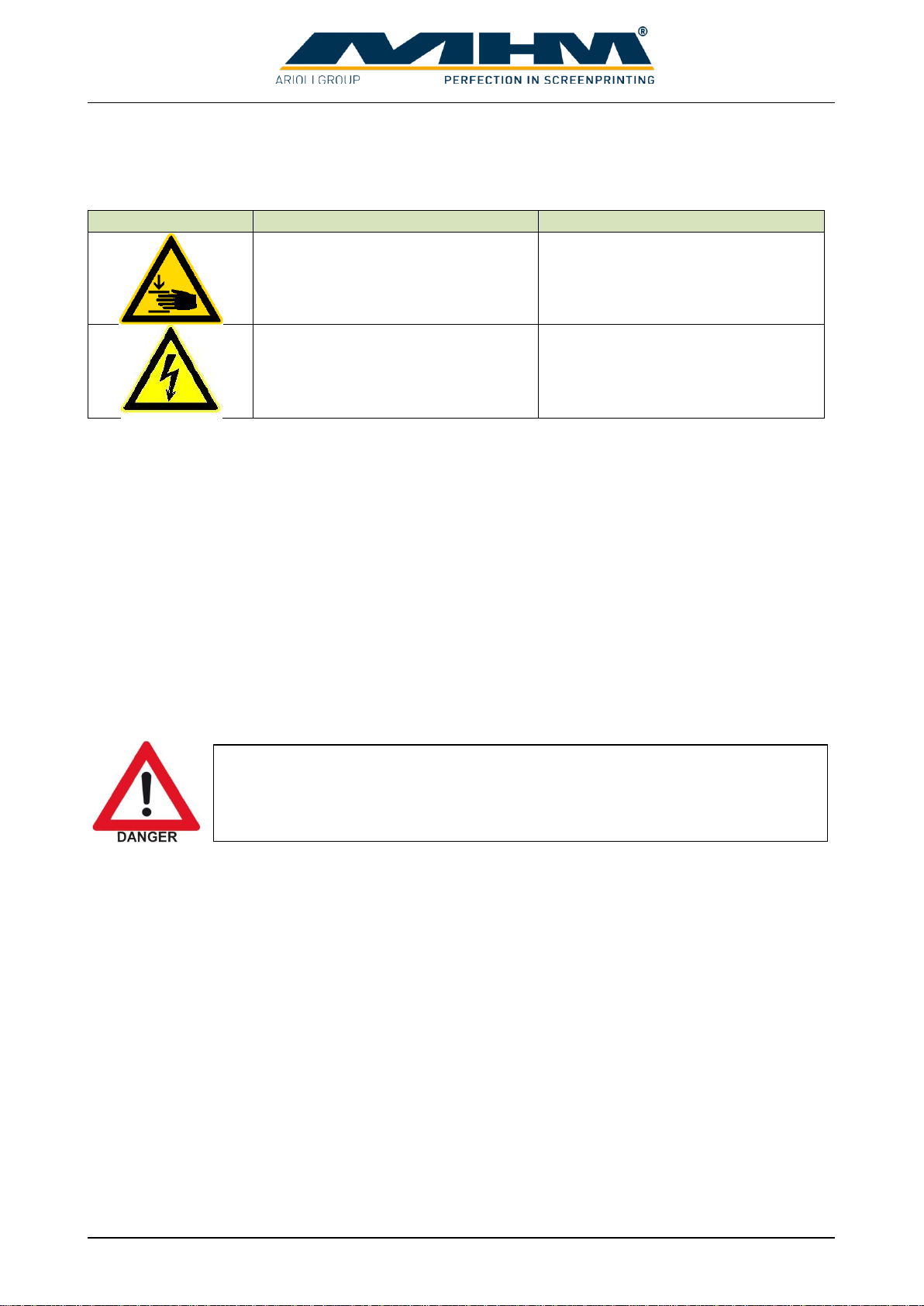

1.8. Safety Signs on the Machine

The following safety signs are attached to the corresponding points of the machine:

Danger

Description

Location

Warning against squashing of parts

of the body, in particular arms or

hands.

At squeegee carriages.

Warning of dangerous voltage.

At current-carrying parts of the

machine with 230/400VAC.

The adhesive labels must be replaced if illegible (due to dirt or damage).

1.9. Other Valid Rules and Regulations:

The customer must comply with all regulations applicable in the country where the machine is

located.

2. Intended usage of the machine

The machine is intended for the printing of substrates (usually textiles such as T-shirts, but also

paper or similar materials) by means of screen printing. The substrates are conveyed by means of

the “carrousel system”. With the use of optional accessories the substrate can also be dried or

treated with other finishing techniques (e.g. flocking).

Any other use of the machine than described above may result in danger to

persons or material damage and is therefore forbidden.

Operating Instructions Synchroprint 5000

Operating instructions SP5000 V1-0.docx Page 11 of 52

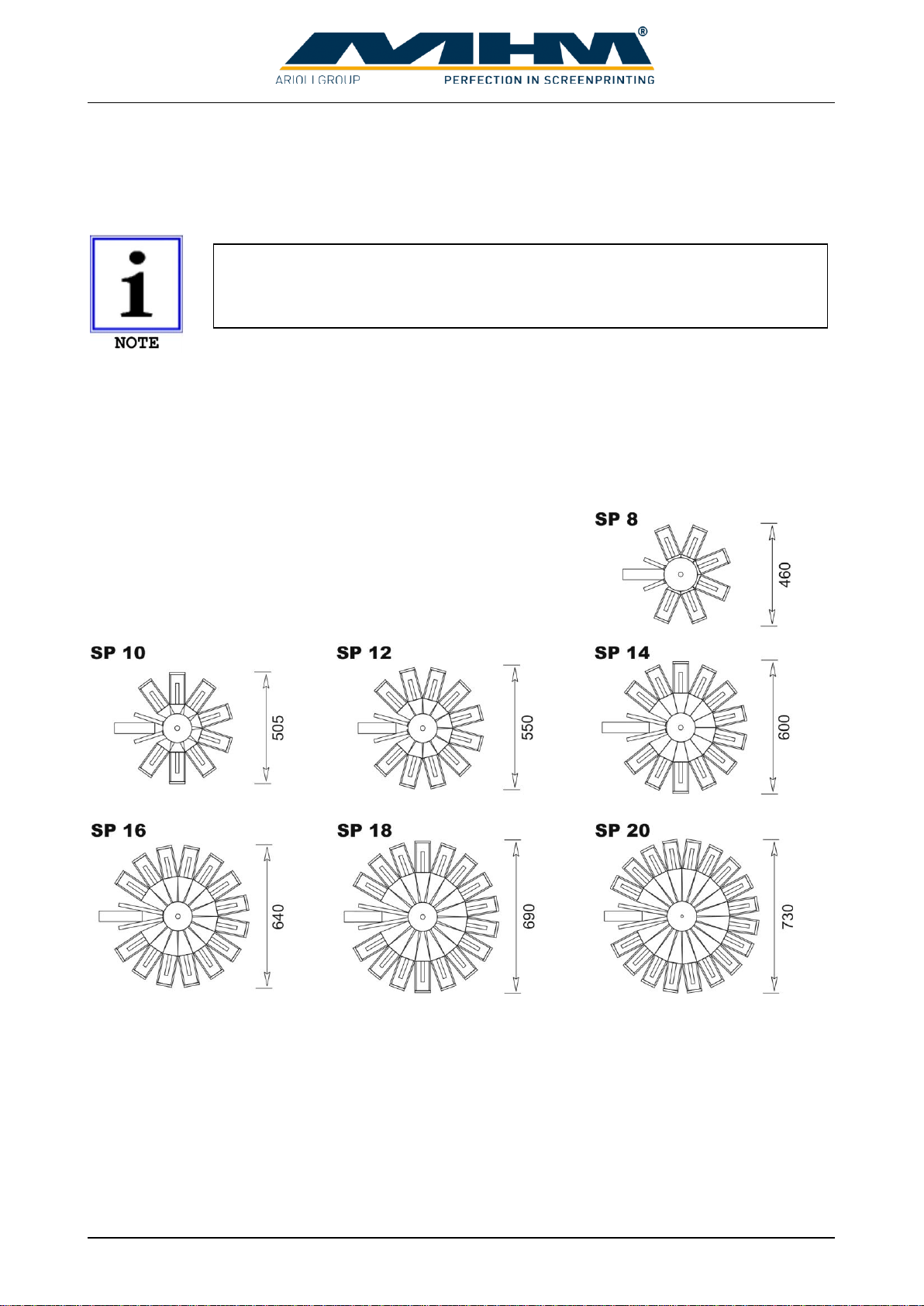

3. Data

This section details the Synchroprint technical specifications.

3.1. Serial Number and Year of Manufacture

Serial number and year of manufacture are indicated on the machine’s type plate.

3.2. Dimensions

NB: As our policy is one of continuous improvement, we reserve the right to

change specifications without prior notice.

Operating Instructions Synchroprint 5000

Operating instructions SP5000 V1-0.docx Page 12 of 52

3.3. Specifications

Model/Type SP 8 SP 10 SP 12 SP 14

Number of pallets 8 10 12 14

Max. No. of print stations 6 8 10 12

Max. print area (standard format)

50 x 70cm

20" x 28"

50 x 70cm

20" x 28"

50 x 70cm

20" x 28"

50 x 70cm

20" x 28"

Max. print area (large format)***

70 x 100cm

28" x 39"

70 x 100cm

28" x 39"

70 x 100cm

28" x 39"

70 x 100cm

28" x 39"

Max. diameter (std' format) [cm/inch]

(Lg' format) [cm/inch]

460/181"

575/226"

505/199"

620/244"

550/217"

680/268"

600/236"

735/289"

Machine height [cm/inch] 185/72,8" 185/72,8" 185/72,8" 185/72,8"

Machine weight*

1800 kg

3970 lbs

2150 kg

4740 lbs

2300 kg

5070 lbs

2650 kg

5840 lbs

Øair consumption [l/min.] 190 220 250 280

Minimum air pressure

Drive systems

Electrical Supply [V]

Connected load - machine base

Connected load - Squeegee drive

Øpower consumption [kWh] 0,9 1,05 1,2 1,35

Registration accuracy

Recommended frame/screen profile

Max. frame/screen size (O.D.)

Production capacity [pieces / h]**

75 x 110 cm / 30 x 42"

Large format 95 x 140 cm / 37 x 55"

40 x 40 mm / 1.57 x 1.57"

1000

8 bar / 116 p.s.i. (filtered, dry air only)

AC-Servo-Drive Index / Electric Squeegee Drive

3 x 210/400V, 50/60 Hz (+/- 5%)

2.5 kVA

0.4 kVA (each)

+/- 0.02 mm / +/- 0.00078"

Model/Type SP 16 SP 18 SP 20

Number of pallets 16 18 20

Max. No. of print stations 14 16 18

Max. print area (standard format only)

50 x 70cm

20" x 28"

50 x 70cm

20" x 28"

50 x 70cm

20" x 28"

Max. diameter [cm/inch] 640/252" 690/271" 730/287"

Machine height [cm/inch] 185/72,8" 185/72,8" 205/81"

Machine weight*

3000 kg

6615 lbs

3350 kg

7386 lbs

3650 kg

8047 lbs

Ø air consumption [l/min.] 310 340 370

Minimum air pressure

Drive systems

Electrical supply [V]

Connected load - machine base

Connected load - Squeegee drive

Ø power consumption [kWh] 1,5 1,65 1,8

Registration accuracy

Recommended frame/screen profile

Max. frame/screen size (O.D.)

Production capacity [pieces / h]** 900 800 700

75 x 110 cm / 30 x 42"

Large format 95 x 140 cm / 37 x 55"

8 bar / 116 p.s.i. (filtered, dry air only)

AC-Servo-Drive Index / Electric Squeegee Drive

3 x 210/400V, 50/60 Hz (+/- 5%)

0.4 kVA (each)

+/- 0.02 mm / +/- 0.00078"

40 x 40 mm / 1.57 x 1.57"

2.5 kVA

* …… Total weight (unpacked) with max. number of print stations

** ….. Single print stroke and medium length of stroke

*** … Special formats available upon request

Operating Instructions Synchroprint 5000

Operating instructions SP5000 V1-0.docx Page 13 of 52

4. Transportation and packaging

This section provides an overview of the proper transportation of the Synchroprint.

4.1. General Notes with Regard to Transportation and Danger Warnings

4.2. Packaging

The Synchroprint will be packed and delivered in wooden crates. The exact number, weight and

dimensions will vary slightly according to each model/type of machine. Contact customer service

for more information about individual orders.

4.3. Unloading of the crates

The Synchroprint is to be unloaded by the customer. A forklift truck with adequate fork length and

lifting capacity (see 4.2 Packaging) will be required.

4.4. Packaging material

After unpacking the machine, the packaging material must be disposed of according to local

regulations.

Upon delivery of the Synchroprint the consignment must be examined for

external damage immediately. In the case of any damages, they must be

documented and reported to MHM GmbH within 24 hours.

Danger of mechanical damage!

The Synchroprint must be lifted carefully and only at the dedicated lifting

points at the middle of the base unit. Lifting the Synchroprint at/by any other

point, especially the turntables, may result in serious damage. Be sure to

maintain an adequate and safe distance during lifting.

Danger of falling objects!

The following instructions must be observed

1. Never stand or walk under hanging loads!

2. Transportation must be carried out by qualified staff observing all safety

instructions.

3. The Synchroprint must only be lifted at the dedicated lifting points.

4. Only the lifting/handling devices and equipment indicated in this document

must be used for the movement of the Synchroprint. Non-compliance may

lead to serious damage of the Synchroprint and result in cancellation of the

warranty.

Operating Instructions Synchroprint 5000

Operating instructions SP5000 V1-0.docx Page 14 of 52

5. Assembly

This section describes the external supply/connection ports of the Synchroprint and the points to be

observed during assembly.

5.1. General Assembly Instructions

The customer should have a minimum of two persons available to assist the technician with the

installation and assembly of the machine.

5.2. Positioning of the Synchroprint

The machine must be mounted on a bed with sufficient load-bearing capacity. In case of doubt this

capacity is to be examined by a structural engineer.

In order to guarantee perfect installation and smooth operation of the Synchroprint, the machine

must be installed at a sufficient distance from adjacent elements of the building (walls, columns,

etc.) and/or other machines. The distance required in each case depends on the screen size, and must

be chosen so as to allow the operator to replace the screens without any problems. The dimensions

of the respective machine are indicated in Chapter “3 Data”.

5.3. Ambient Conditions

For the electrical equipment on the Synchroprint, ambient conditions according to standard IEC

60204 “Electrical Equipment of Industrial Machines” should be observed.

The following points should be observed in order to achieve efficient running and an optimum level

of production with the Synchroprint:

1. The premises, where the Synchroprint is to be operated, must be kept clean, dry and well-

aired.

2. The ambient temperature must not fall below +5° C or exceed +45° C.

3. Relative air humidity must not exceed 80 %.

4. The mains supply must not exceed or fall below a tolerance of +/- 5 % of the required

voltage for the Synchroprint. If this voltage stability cannot be guaranteed, the customer

must install a constant-voltage regulator to protect the Synchroprint against such

fluctuations.

5. The compressed air must be clean, filtered and dry (class 1:4:1 according ISO8573-1:2010).

6. Compressed air supply must be sufficient in terms of pressure, volume and consistency.

7. Electricity supply should be sufficient with adequate fuse protection.

8. Maximum installation altitude is 2000m above sea level.

The Synchroprint must only be installed / assembled by a service technician of

the machine manufacturer or by an authorized service technician from an

official MHM dealer/agent. Any assembly/installation by any third party not

listed above will result in immediate cancellation of the warranty.

Operating Instructions Synchroprint 5000

Operating instructions SP5000 V1-0.docx Page 15 of 52

5.4. External supply/Connection ports

Connections for compressed air and mains electricity are located on the base unit of the

Synchroprint as standard. Overhead supply connections may be ordered optionally but only at time

of order, to enable supplies to enter the machine from above, through the centre column.

5.4.1. Electrical Connections

The electrical requirements are as follows:

Description

Requirement/Value

Supply voltage

3x 210/400V

Supply frequency

50/60 Hz ± 5 %

Connected load

2.5 kVA + (0.4 kVA x “number of print heads”)

(= “power for indexer main drive” + “power per print head” x

“number of print heads”)

5.4.2. Compressed Air Requirements

Type of machine

SP 8

SP 10

SP 12

SP 14

SP 16

SP 18

SP 20

Air consumption (l/min.)

190

220

250

280

310

340

370

Minimum air pressure

8 bar / 116 PSI

Air quality

filtered, dry air supply only

(class 1:4:1 according ISO8573-1:2010)

Please observe the general safety regulations for electrical connections when

connecting the mains supply to the Synchroprint. Avoid any contact with live

components.

Danger of tripping over!

In case of laying supply lines on the floor, it is necessary to attach step covers.

All flash cure units must be supplied through a separate/independent

connection. Please observe the precise technical data from the flash cure unit

specification sheet.

Operating Instructions Synchroprint 5000

Operating instructions SP5000 V1-0.docx Page 16 of 52

6. Commissioning the Synchroprint

After the initial start-up of the machine, commissioning is to be completed in the presence of the

authorized technician along with any persons authorized on the part of the customer. During this

initial start-up and commissioning, all tasks carried out by the MHM service engineer or the

technicians of an authorized dealer are recorded.

This installation/job sheet must be clearly signed by both parties, stating the date and location of the

Synchroprint and will be legally binding hereon after.

7. Design and Operation

This section describes design and operation and indicates the individual assemblies.

7.1. General Process Description

The operator applies a substrate (usually a T-shirt or paper) to the pallets at the locating surface.

Textiles will be fixed in position by means of the spray adhesive applied to the pallets beforehand.

For paper a special vacuum model is necessary to hold the substrate on the pallet by means of

negative pressure. Subsequently, the carrousel moves the substrate to the first print station, where

the substrate is printed by means of screen printing or treated with optional accessories.

Subsequently, the substrate moves to the second station, where it is treated again, before the process

continues with all other stations. Finally, the substrate arrives at the unloading point, where an

operator takes it from the machine for further processing.

Any defects or complaints must be brought to the attention of the authorized

technician, documented in writing and recorded immediately on the service

technician’s installation/jobsheet.

Before starting the machine, mains connection and compressed-air supply

must be checked and, if necessary, established according to the instructions.

Initial start-up of the Synchroprint should only be carried out by an authorised

MHM service engineer or by an approved technician from an official MHM

dealer/agent.

Operating Instructions Synchroprint 5000

Operating instructions SP5000 V1-0.docx Page 17 of 52

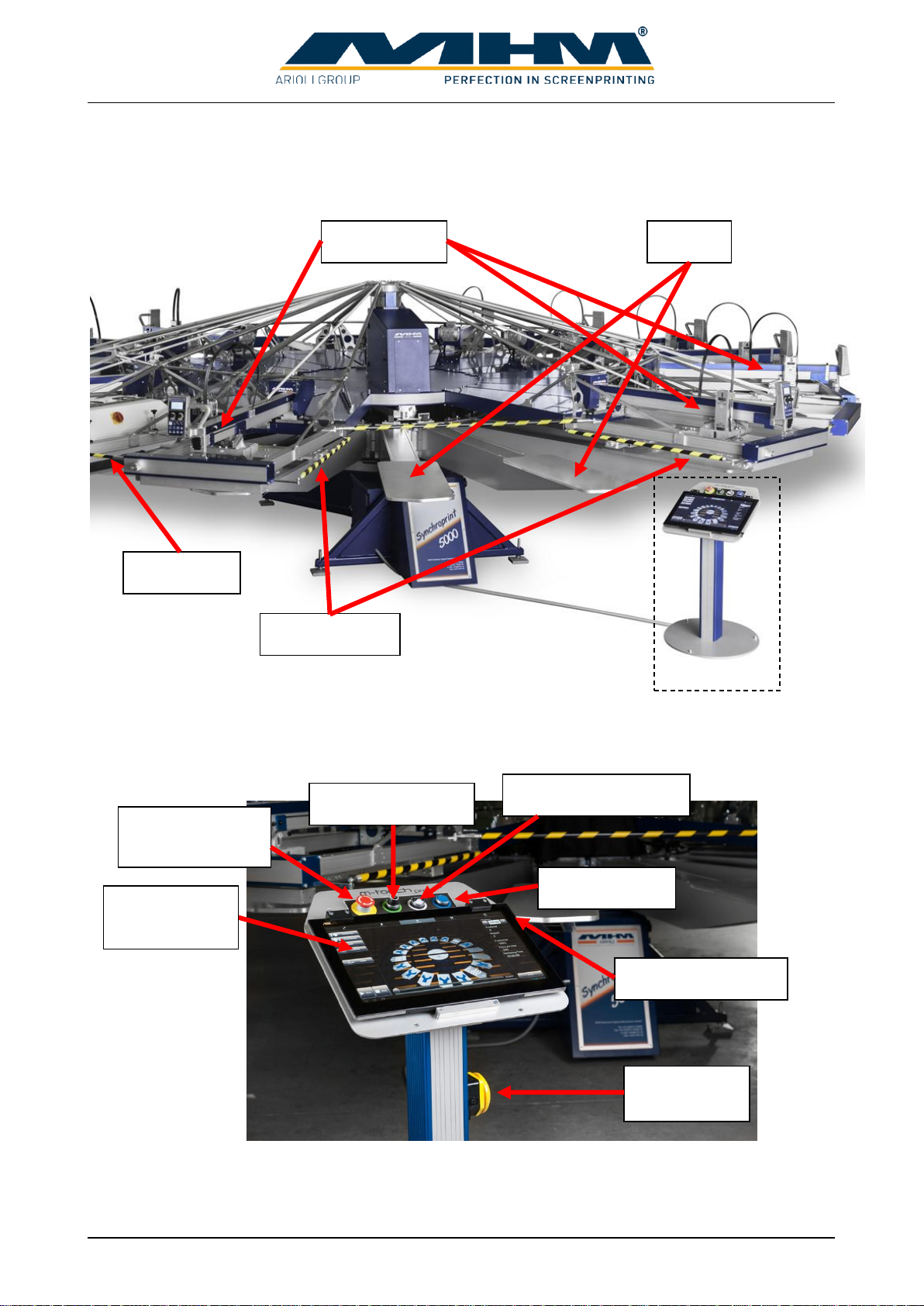

7.2. Overview Machine Parts

7.3. Control panel

Safety barrier

‘No shirt’/skip

pallet buttons

Pallets

Print station

Safety bars

Main switch tablet

EMERGENCY

STOP

Control ON/OFF

Control panel

Safety level key

Reset button

Tablet

m-touch pro

Operating Instructions Synchroprint 5000

Operating instructions SP5000 V1-0.docx Page 18 of 52

The control panel includes the following features:

Machine feature

Description

Tablet

m-touch pro

The tablet PC is used to control the main operating features of the

Synchroprint. Touching (tapping) the command buttons displayed on

the screen will operate various individual functions of the machine.

You will find a detailed description of all the functions in section 9

Control of the Machine.

Main switch tablet

Use “Main switch tablet” to switch the tablet on, off or to put it into

idle state. When the unit is on, push shortly to change into idle state.

After a longer push a menu will be displayed where the unit can be

switched off completely. To start the tablet a short push is enough.

The handling is similar to modern Smartphones.

Control ON/OFF

“Control ON/OFF” is used to switch the control power supply which

supplies all control components including the tablet. To switch off

the main power use the main power switch.

EMERGENCY STOP

(push button)

The EMERGENCY STOP push button is part of the safety facility.

See section 7.4. Safety Devices.

‘No shirt’/skip pallet

buttons

Press the Skip-Button when substrate is not applied in a correct way.

In this case the respective print station will not start to work and the

substrate will not be printed. The print process at other stations and

pallets will not be interrupted.

Safety level key

In operating mode ADJUST an automatic error resetting can be

activated; this is needed for adjusting the machine. This can be done

by switching the safety level key to 1-position, in normal operation

the key must be on 0-position. Only properly trained and suitably

qualified personnel should use this function. The quick stop function

of the turn table is active all the time. Print and Flood strokes can also

be made at active error situations. Active error resetting is displayed

with the safety level signal lamp.

7.4. Safety Devices

The safety devices serve as emergency stop facilities to avoid accidents and to guarantee safe

operation of the machine. The Synchroprint has the following safety devices:

Safety device

Description

EMERGENCY STOP

(push button)

Push button located at the main control panel. In case of emergency,

pressing the EMERGENCY STOP will stop all movements of the

machine. The function of the push button is cancelled by unlocking

the switch (turning it to the right).

Safety bars

Yellow/black bars located at the right and the left of the ‘load/unload’

area. Pressing any one of these bars will result in an immediate

EMERGENCY STOP of the machine. The location of these bars

ensures that the EMERGENCY STOP function is activated

automatically should a person become trapped between print station

and pallet.

Safety barrier

Yellow/black barriers located between the print stations which serve

to cordon off the danger zone. As soon as they are opened by a

person passing through, an immediate EMERGENCY STOP is

activated.

Operating Instructions Synchroprint 5000

Operating instructions SP5000 V1-0.docx Page 19 of 52

7.5. Pallets

The substrates must be applied on the pallets. Depending on the substrate size, different pallets must

be used. By default pallets with format 52x100cm or 75x120cm made of aluminum in honeycomb

structure and a thickness of 17mm are used. The maximum allowed pallet weight is 10kg.

7.6. Foot switch

The foot switch is used to start an index movement when machine runs in manual mode. In

automatic mode the index movement can be blocked.

7.7. Type Plate

The type plate with type, serial number, year of manufacture, mains voltage, mains frequency,

connected load and CE symbol is located on the left side of the machine base.

7.8. Main Power Switch

The main power switch is mounted at the machine’s basic frame. It disconnects the machine from

the main supply voltage immediately.

These safety devices must not be used to switch off the machine under normal

operation. Any EMERGENCY STOP presents an exceptional loading to the

servo-motor and transmission etc. Excessive use will result in damage to the

machine along with subsequent cancellation of the warranty.

Exceeding the maximum allowed weight of the pallets would increase the

dynamic load to the machine and can cause material damage. The maximum

weight of the pallets must be observed.

Only pallets provided by MHM must be used for production.

Operating Instructions Synchroprint 5000

Operating instructions SP5000 V1-0.docx Page 20 of 52

7.9. Print Stations

The print stations are used for printing individual colours on to textiles/garments. The Synchroprint

may be ordered with a maximum of up to 18 print stations. Two different types of print stations are

possible:

Manual Version: The screen positioning is manually made by hand wheel.

Automatic Version: The screen positioning is made automatic by stepping motors. Different

positions can be saved and reloaded.

The following sections include a detailed description of the individual components.

7.9.1. Overview Manual Print Stations

Screen adjustment

Left/right - rear

X-axis

Y-axis

Dryer connector

Squeegee

drive motor

Frequency converter

Screen adjustment

Left/right - front

Squeegee/print arm

Squeegee carriage

Screen adjustment

Forward/backward

Control keypad

Squeegee/print arm

lock-down

Squeegee carriage speed

controls

Squeegee stroke

length adjustment

Pressure control

Other manuals for SYNCHROPRINT 5000

2

Table of contents

Other MHM Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Trane

Trane SCWM Series Installation, operation and maintenance

ABB

ABB TPS44-F Series Operation manual

Aventics

Aventics MSC Series Repair instruction

INOXPA

INOXPA NHS VERTICAL AGITATOR Ex Installation, service and maintenance instructions

Aventics

Aventics R412012728-BDL-001-AC operating instructions

Eaton

Eaton NZM1-XT Series Instruction leaflet

CKD

CKD HMF Series instruction manual

Minebea Intec

Minebea Intec PR 6202 installation manual

branatech

branatech PAC Series user manual

PDR

PDR X410 Operator's manual

PCB Piezotronics

PCB Piezotronics 8311-RS-10A Installation and operating manual

Aerovent

Aerovent IM-502 Installation, operation & maintenance manual