COPYRIGHT © NOVEMBER, 2021 BY GRIZZLY INDUSTRIAL, INC.

NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

(FOR MODELS MFD. SINCE 11/21) #CS22154 PRINTED IN TAIWAN V1.11.21

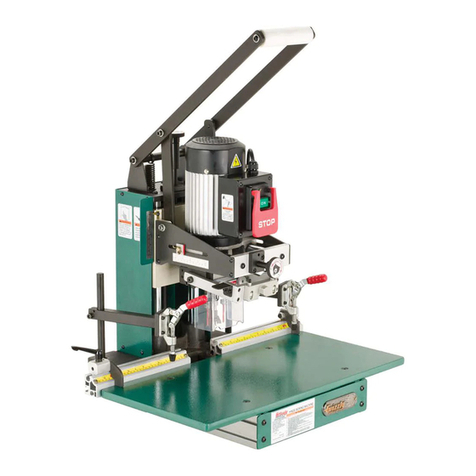

Introduction

The Model T32841 Sliding Log Milling Sled rip

cuts logs at least 173⁄4" long and up to 113⁄4"

in diameter on vertical wood-cutting bandsaws

when used with the T32838 Bandsaw Sled.

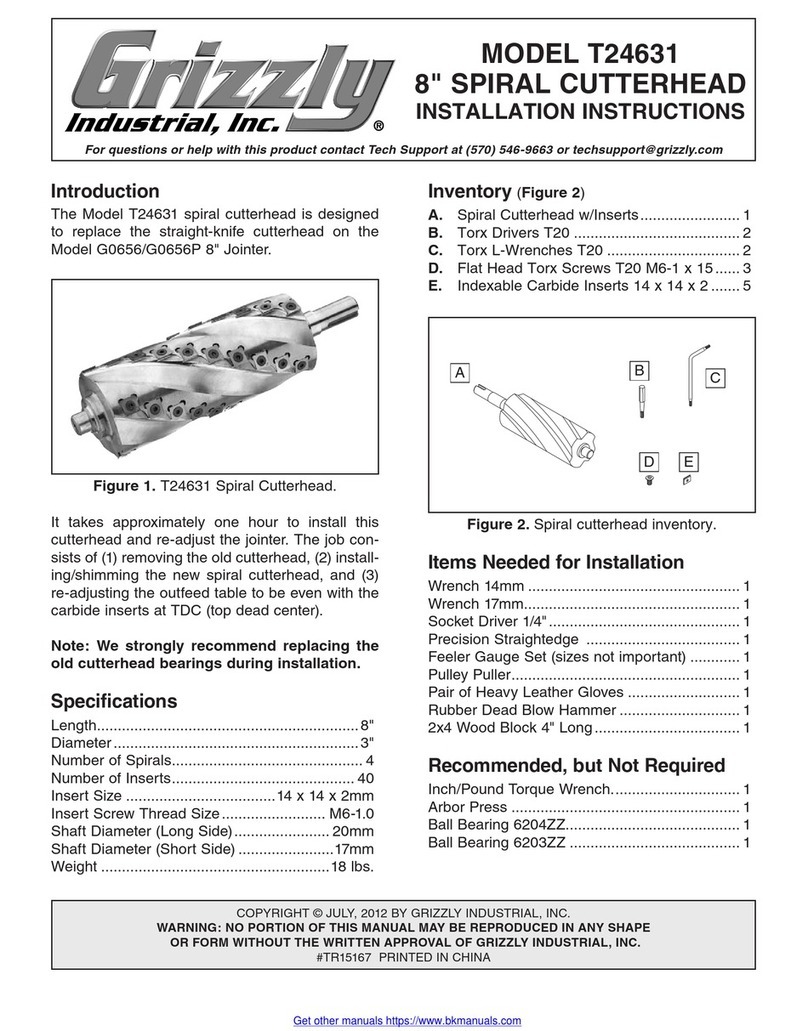

Inventory

Figure 1. T32841 inventory.

Description Qty

A. Milling Sled ................................................. 1

B. Hold-Down Weights .................................... 2

C. Knobs 3⁄8"-16 ............................................... 2

D. Hinge Rods................................................. 2

E. Open-End Wrenches 13mm ....................... 2

F. Hex Bolts M8-1.25 x 55 .............................. 2

G. Lock Nuts M8-1.25 ..................................... 2

H. Claw Hold-Downs ....................................... 2

NOTICE

If you cannot find item on list, check around/

inside packaging materials. Often, items

get lost in packaging while unpacking or

they are pre-installed at factory.

A

B

C

D

E

FGH

Assembly

Wear safety glasses during

the entire setup process!

The Model T32841 must be assembled before it

can be mounted on the bandsaw sled.

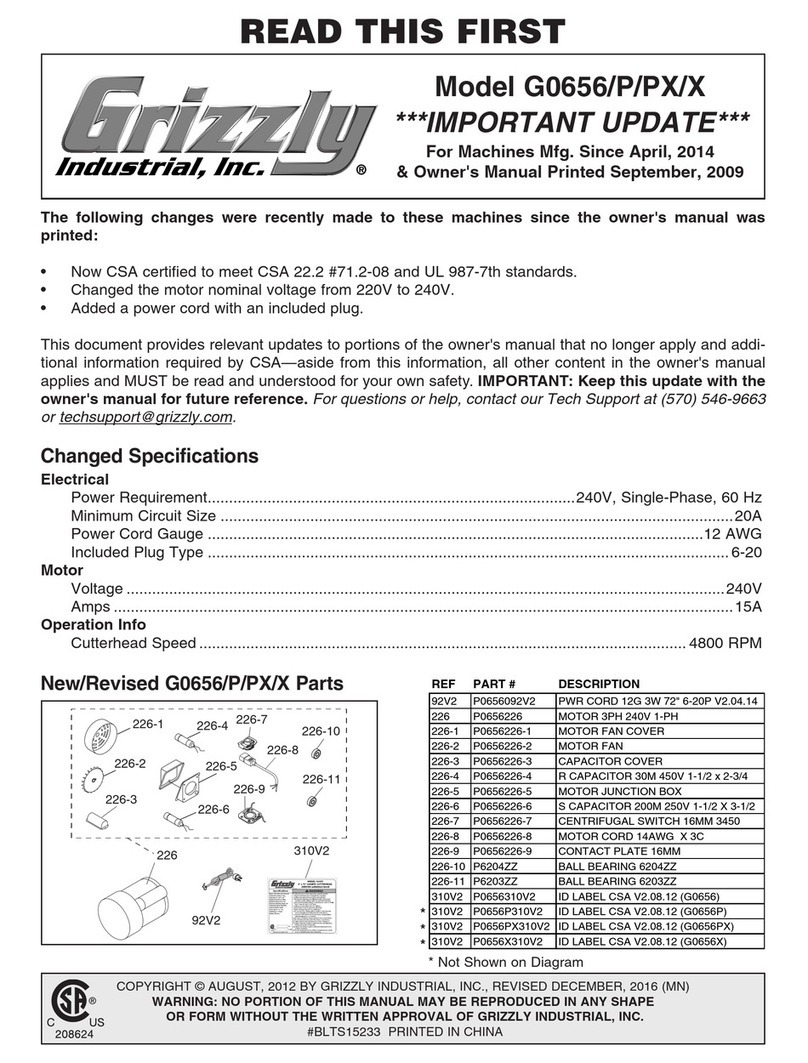

To assemble milling sled:

1. Attach (2) hinge rods to milling sled with (2)

M8-1.25 x 55 hex bolts and M8-1.25 lock

nuts, as shown in Figure 2.

Figure 2. Attaching hinge rods to milling sled.

x 2

Hinge

Rods

Milling

Sled

For questions or help with this product contact Tech Support at (570) 546-9663 or techsupport@grizzly.com

MODEL T32841

SLIDING LOG MILLING

SLED

INSTRUCTIONS