90‐90‐885 (Rev.B)

TOGA*3‐1

Section3TECHNICALDESCRIPTION

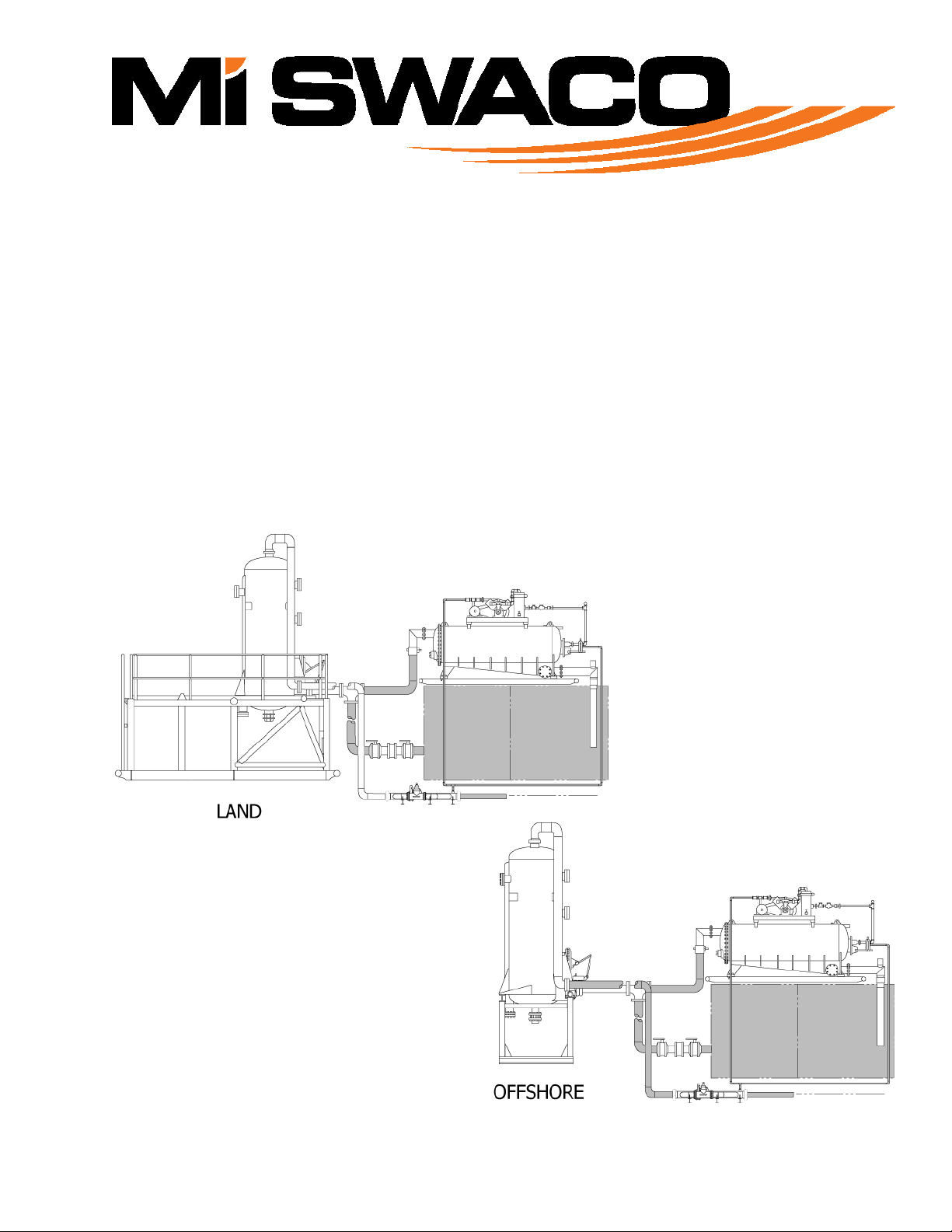

3‐1PRINCIPLESORTHEORYOFOPERATION

Thedrillingfluidcirculatedfromawellmayincludegasand/orformationliquidswhichhaveenteredthewell

bore.Asthefluidapproachesthesurfacethehydrostaticpressureisreduced,andthegasbubblesinthefluid

expandandformheadsormassivepocketsofgas.Theseheadsofgasorgascutmudarecirculatedfromthewell

borethroughtheflowlineorchokemanifoldintoasixinchinletlineontheMUD/GASSEPARATOR*.Thefree

gasisseparatedfromthefluidbyaseriesofbafflesinthevesselandventedintotheflarelinethroughaneight

inchlineonthetopoftheMUD/GASSEPARATOR*Vessel.

3‐1.1MUD/GASSEPARATOR*FloatValve

TheFloatoperatedcontrolvalveinsidetheMUD/GASSEPARATOR*vesselopenstopreventoverfillingofthe

VesselandclosestomaintainaliquidsealontheeightinchMudReturnLine.Theliquidsealpreventsthe

separatedgasfrombeingdischargedintothemudreturnline.

3‐1.2BackPressureManifold

TheBackPressureManifoldisinstalledintheMUD/GASSEPARATOR*VentLinetodampenthesurgeeffects

fromtheexpandinggasandpreventtheblowingofmudintotheVentLine.Abackpressuresettingof15‐50psi

(1.1–3.5kg/cmsquared)isrecommendedontheMUD/GASSEPARATOR*Vessel.

3‐1.3D‐GASSER*

ThegascutmuddischargedfromtheMUD/GASSEPARATOR*isdrawnintotheD‐GASSER*Vesselbya

vacuumforcecreatedbythedischargepipelowpressurejetassembly.Thefluidisdistributedoverabaffleina

thinevenlydispersedlayer.Thisthinlayeroffluidisexposedtoavacuumofatleasteightinchesofmercury

createdbythevacuumpump.Thevacuumforceremovestheentrainedgasesfromthefluidandthedegassed

fluidisdischargedintotheactivesystem.TheentrainedgasremovedfromthefluidbytheD‐GASSER*isvented

intotheclosedflaresystem,down‐streamoftheMUD/GASSEPARATOR*BackPressureManifold.

TheTOGA*systemutilizesM‐ISWACO’sstandardMUD/GASSEPARATOR*andD‐GASSER*whichhavebeen

specificallymodifiedtoassuretotalcontainmentandcontrolofthetoxicgascutmud.ThemodifiedD‐GASSER*

includestwocompletevacuumpumpsystems.Thevacuumpumpexhaustlinesareconnectedthrougha

manifoldcontainingaseriesofcheckvalvestopreventthepossibilityofblowbackfromtheflarelines.Plug

valveslocatedoneithersideofthecheckvalvesareusedtoprovideameanstoisolateandsafelyrepairorreplace

eithervacuumpumpsystemwhiletheotherisstilloperationalaswellastoconfigurethevacuumpumpsystems

foralternativemethodsofoperation.Thefirstalternativeistorunbothvacuumpumpsystemssimultaneouslyto

assuremaximumdegassingefficiencywhenlargevolumesofgasareencountered.Thesecondalternativeisto

provideameansforredundancyintheeventtheprimaryvacuumpumpsystemfailsduringkickconditions.