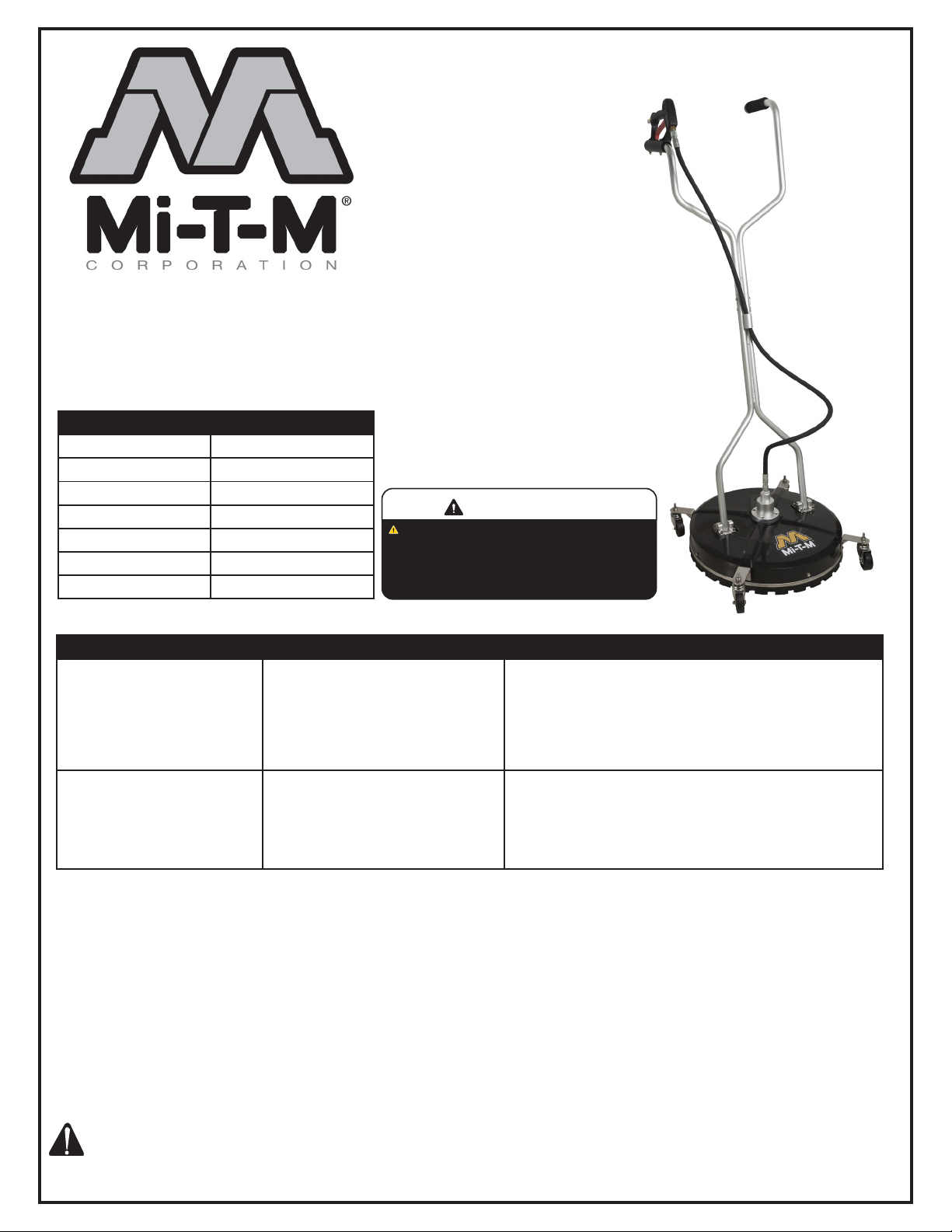

Professional 20 Inch Rotary Surface Cleaner

AW-7020-8010

HAZARD POTENTIAL CONSEQUENCE PREVENTION

RISK OF

BODILY INJURY

Serious injury or death could

occur. ALWAYS read, understand, and follow operation

instructions.

ALWAYS wear protective eye wear.

ALWAYS keep clear of rotating nozzles.

NEVER lock trigger gun open with any device.

RISK OF EQUIPMENT

DAMAGE

Risk of major repair. Drain water in cold weather to avoid freezing.

Use only genuine Mi-T-M replacement parts for

necessary repairs.

Tampering with any part of this machine will void all

warranties.

!SAVE THESE INSTRUCTIONS! Form #37-1472-090319

OPERATION:

Read, understand, and follow ALL safety guidelines and operation instructions prior to use.

1. Connect to pressure washer.

2. Turn water on and open valve. Open trigger gun for ow of water through nozzles. Nozzles must have owing spray.

If not, remove tips and clean; reassemble, making sure that groove of nozzle is parallel to spray bar. Use Teon tape

when installing nozzles.

3. Start pressure washer. The Rotary Surface Cleaner is ready for operation.

4. Walk slowly behind the Rotary Surface Cleaner cleaning as you go. If striping occurs, slow down your pace.

5. Check “weep holes” on bottom of swivel periodically. Water will seep slowly; if water shoots out, stop and replace

seals. Swivel assembly can be rebuilt.

6. For maximum effectiveness keep spray tips clean. If the machine vibrates, stop and clean spray tips.

DO NOT ALLOW MACHINE TO REMAIN STATIONARY ON SOFT SURFACES, SUCH AS WOOD.

CAUTION: Striking any raised obstacle during operation will damage machine. If contact does occur and results in

vibration when operating machine, STOP and replace spray bar. Continued operation could result in serious

injury or damage to machine.

WARNING: This product can expose you to

chemicals including Lead, which is known to

the State of California to cause cancer and birth

defects or other reproductive harm. For more

information go to www.P65Warnings.ca.gov

WARNING

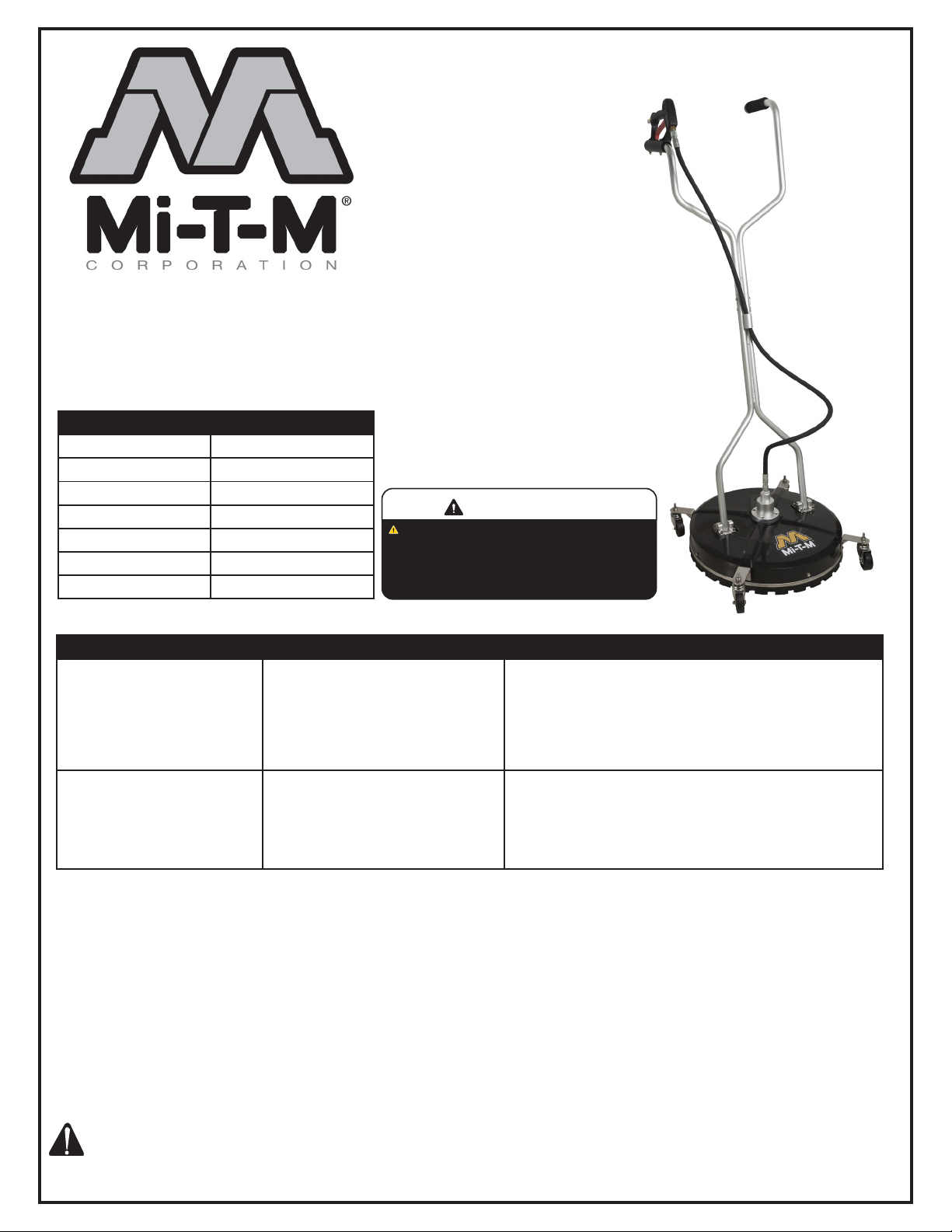

SPECIFICATIONS

Model AW-7020-8010

Operating Pressure 1,000 to 4,000 PSI

Maximum Flow 4.0 GPM

Maximum Temp. 180°F

Nozzles (2 per unit) 25020

Weight 18 lbs

Dimensions 70” x 22” x 22”

Mi-T-M Corporation

50 MI-T-M Drive Peosta, IA 52068

Ph: 800-553-9053 - Fax: 563-556-1235