CONTENTS

1

5700 331530 (10- 15)

CONTENTS

Page

SAFETY PRECAUTIONS 3.................

OPERATION 5............................

OPERATOR RESPONSIBILITY 5.........

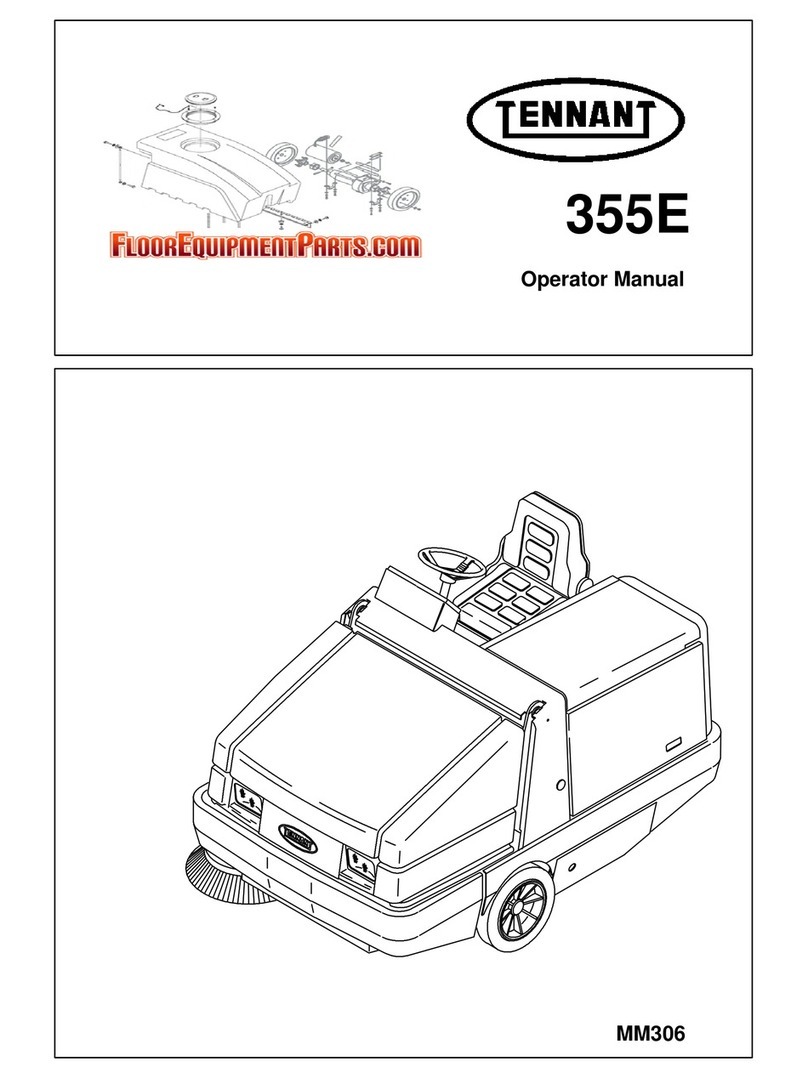

MACHINE COMPONENTS 6.............

CONTROL PANEL SYMBOLS 7..........

CONTROLS AND INSTRUMENTS 8......

STEERING HANDLES 9..............

SOLUTION FLOW LEVER 10...........

POWERWANDSWITCH(OPTION) 10..

RECOVERY TANK FULL LIGHT 11.....

ES SWITCH (OPTION) 11..............

BATTERY DISCHARGE INDICATOR 11.

BRUSH PRESSURE GAUGE 12........

SCRUB BRUSHES DOWN LIGHT 12....

SCRUB BRUSHES SWITCH 13.........

HOURMETER 13.....................

MACHINE ON LIGHT 13...............

ON-OFF KEY SWITCH 14..............

SQUEEGEE LEVER 14................

SOLUTION TANK LOCKING TAB 14....

SPEED REDUCTION KNOB (OPTION) 14

POWER KILL SWITCH (OPTION) 15....

CIRCUIT BREAKERS 15...............

SOLUTION TANK HOSE 16............

RECOVERY TANK DRAIN HOSE 16....

SUPPORT ARM 16....................

STOP ARM 16........................

SQUEEGEE DOWN PRESSURE

CAMS 17..........................

SQUEEGEE LEVELING KNOB 17......

PARKING BRAKE (OPTION) 17........

HOW THE MACHINE WORKS 18..........

BRUSH AND PAD INFORMATION 19......

PRE-OPERATION CHECKLIST 20.........

STARTING THE MACHINE 21.............

FILLING THE TANKS 21..................

WHILE OPERATING THE MACHINE 24....

SCRUBBING 24.........................

DOUBLE SCRUBBING 26.................

STOP SCRUBBING 27...................

DRAINING AND CLEANING THE TANKS 28

STOP THE MACHINE 33.................

OPERATION ON INCLINES 33............

POST-OPERATION CHECKLIST 34........

MACHINE TROUBLESHOOTING 35.......

OPTIONS 36............................

VACUUM WAND 36...................

POWER WAND 40....................

MAINTENANCE 45.........................

MAINTENANCE CHART 45...............

LUBRICATION 46........................

REAR CASTERS 46...................

TRANSAXLE 46......................

BATTERIES 46..........................

CHARGING THE BATTERIES 48.......

Page

ELECTRIC MOTORS 49..................

SCRUB HEAD 50........................

DISK BRUSH SCRUB HEAD SKIRT 50..

ADJUSTING THE SCRUB

HEAD SKIRT 50.................

REPLACING THE SCRUB

HEAD SKIRT 51.................

CYLINDRICAL BRUSH SCRUB HEAD

SKIRTS 52........................

ADJUSTING THE SCRUB HEAD

SKIRTS 52.....................

REPLACING THE SCRUB HEAD

SKIRTS 52.....................

REMOVING OR REPLACING THE

SCRUB HEAD 53..................

LEVELING THE SCRUB HEAD 55...

SCRUB BRUSHES 56....................

DISK BRUSHES 56...................

REPLACING THE DISK BRUSHES 56

CYLINDRICAL BRUSHES 59...........

REPLACING THE CYLINDRICAL

BRUSHES 59...................

CHECKING AND ADJUSTING

CYLINDRICAL BRUSH PATTERN 60.

SOLUTION SYSTEM 62..................

RECOVERY TANK 62.................

SOLUTION TANK 63..................

SQUEEGEE 64..........................

REMOVING THE SQUEEGEE

ASSEMBLY 64.....................

INSTALLING THE SQUEEGEE

ASSEMBLY 65.....................

LEVELING THE SQUEEGEE 65........

ADJUSTING SQUEEGEE BLADE

DEFLECTION 66...................

ADJUSTING THE SQUEEGEE GUIDE

ROLLERS 67......................

SQUEEGEE BLADES 67.................

REPLACING OR ROTATING THE

REAR SQUEEGEE BLADE 67.......

REPLACING OR ROTATING THE

FRONT SQUEEGEE BLADE 68......

BELTS AND CHAINS 70..................

BRUSH DRIVE BELT 70...............

STATIC DRAG CHAIN 70..............

TIRES 71...............................

PUSHING AND TRANSPORTING THE

MACHINE 71.........................

PUSHING THE MACHINE 71...........

TRANSPORTING THE MACHINE 72....

MACHINE JACKING 74...................

STORAGE INFORMATION 74.............

FREEZE PROTECTION 74.............