This machine is manufactured for

commercial use only.

This machine is designed and manufactured for indoor use

in burnishing wax coated hard floor surfaces. Amano

Pioneer Eclipse does not recommend use of this machine

in any environment other than an indoor environment.

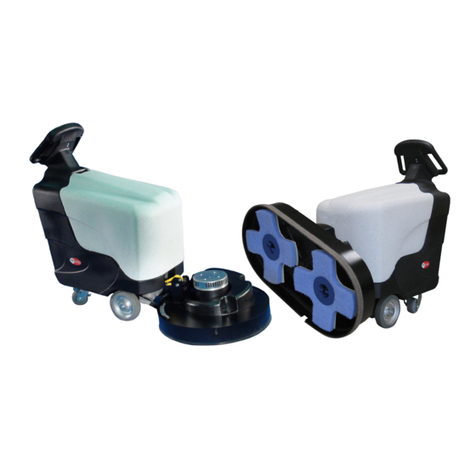

This propane powered floor machine is designed and

manufactured for commercial floor burnishing only. This

machine is designed to burnish most modern types of

floors including composition tile, stone, marble, terrazzo,

and resilient floor covering, and some coated wood floors.

Even though NFPA 11.13.2.3 says...”the use of floor

maintenance machines in buildings frequented by the

public, including the times when such buildings are

occupied by the public, shall require the approval of the

authority having jurisdiction.” Amano Pioneer Eclipse

suggests usage when occupancy of a given work area is

minimal.

These machines should not be used

In nursing homes, hospitals, day-care centers, etc.

that are occupied.

By unqualified or untrained personnel.

Unless properly maintained and adjusted.

On areas with obstructions such as thresholds,

floor outlet boxes, etc.

In areas where loose debris or other objects are

present.

In rooms and areas without proper ventilation.

Refueling and Storage of Fuel Cylinders

This machine uses a 20lb (9.1kg) capacity aluminum or

steel cylinder, which meets the DOT 4E240 standards.

These cylinders are also listed by UL. In addition, the

steel cylinder meets European TPED specifications and is

CE compliant. Filling should be done ONLY by a qualified

propane dealer. FILL THROUGH THE SERVICE VALVE

ONLY. A properly filled cylinder should not exceed 80% of

the rated capacity.

DO NOT attempt cylinder repair. Return the cylinder to

your propane dealer if repair is necessary. Please note

that DOT regulations prohibit shipping of cylinders after the

cylinder has been filled with propane.

When not in use, cylinders should always be stored

outside in an upright position in a secure, tamper-proof,

steel mesh storage cabinet. The cabinet may be located

next to the building, but with at least five feet (1.5 m) of

space between the cabinet and the nearest building

opening (door or window).

The cylinder to be used on this machine is a vapor

withdraw cylinder. A liquid withdraw cylinder is not to

be used with this machine. The use of a liquid withdraw

cylinder on a vapor withdraw system could freeze the

regulator and create a fire hazard. The National Fire

Protection Association (NFPA) Standard for Storage and

Handling of LP Gas is the appropriate authority for safe

propane use. A copy of this publication is available through

the National Fire Protection Association (1-800-344-3555)

or www.NFPA.org.

Canadian Safety Requirements

1. A sign indicating "NO SMOKING" shall be

permanently displayed at the storage area. The

sign shall be in accordance with the sign required

in Clause 10.12.3 of CAN/CGA-B149.2-M91,

Propane Installation Code.

2. When the cylinder is attached to the floor

maintenance machine for use, the operator shall

not leave the unit unattended except for short

periods of time such as rest stops, washroom, or

meal stops.

3. The requirements of 1.10.1 (e) and (g) do not

apply in industrial buildings.

4. A floor maintenance machine shall only be used in

buildings:

a. Provided with continuous mechanical

ventilation that removes products of

combustion to the outdoors of not less that

300 CFM for each 10,000 BTU-hr or

fraction thereof.

b. Provided with natural ventilation of not

less than 300 CFM for each 10,000

BTU-hr input or fraction thereof, based on

a maximum of one-quarter-air exchange

per hour for the net building volume.

5. The owner of a floor maintenance machine shall

ensure that the operator has participated in a

course authorized by the manufacturer of the unit

on the safe handling of propane and the safe

operation of the machine.

6. The owner of a floor maintenance machine shall

ensure that the unit is maintained in accordance

with the manufacturer's recommended

maintenance procedures in a safe operating

condition and the owner shall maintain a record of

the maintenance for a period of two years.

7. Before transporting a floor maintenance machine,

the cylinder shall be securely fastened with the

system valve closed, and the cylinder shall be

located in a well-ventilated space.

4