Micno KE600 Series User manual

Preface

Thank you for purchasing KE600 series inverters.

This manual describes how to use KE600 series inverter properly. Please read it carefully before

installation, operation, maintenance and inspection. Besides, please use the product after understanding

the safety precautions.

Precautions

In order to describe the product’s details, the drawings presented in this instruction are

sometimes shown without covers or protective guards. When using the product, please make

sure to install the cover or protective guard as specified firstly, and operate the products in

accordance with the instructions.

Since the drawings in this manual are represented examples, some are subject to differ from

delivered products.

This manual may be modified when necessary because of improvement of the product,

modification or changes in specifications. Such modifications are denoted by a revised manual

No.

If you want to order the manual due to loss or damage, please contact our company agents in

each region or our company customer service center directly.

If there is still any problem during using the products, please contact our company customer

service center directly.

Contents

Chapter 1 Safety and Precautions............................................................................... 1

1.1 Safety Precautions............................................................................................ 1

1.2 Precautions....................................................................................................... 3

Chapter 2 Product Information .................................................................................... 6

2.1 Product Inspection............................................................................................ 6

2.2 Model Description............................................................................................. 6

2.3 Description of Nameplate.................................................................................. 6

2.4 Selection Guide................................................................................................. 7

2.5 Technical Specifications.................................................................................... 8

2.6 External & Installation Dimensions.................................................................. 10

2.7 Routine Maintenance of Inverter..................................................................... 21

2.8 Instructions on Warranty of Inverter................................................................ 22

Chapter 3 Mechanical and Electric Installation ........................................................ 23

3.1 Mechanical Installation.................................................................................... 23

3.2 Electrical Installation....................................................................................... 24

Chapter 4 Operation and Display............................................................................... 35

4.1 Keypad Description......................................................................................... 35

4.2 Function Code Checking and Modification Methods Description.................... 37

4.3 Power-on Initialization..................................................................................... 37

4.4 Fault Protection............................................................................................... 37

4.5 Stand By ......................................................................................................... 38

4.6 Running .......................................................................................................... 38

4.7 Password Setting............................................................................................ 38

4.8 Motor Parameters Autotuning ......................................................................... 38

Chapter 5 Function Parameter List............................................................................ 40

5.1 Basic Function Parameter Table..................................................................... 41

5.2 Monitoring Parameter Table ........................................................................... 68

Chapter 6 Parameter Description .............................................................................. 71

Group P0 Basic Function...................................................................................... 71

Group P1 Motor 1 Parameters.............................................................................. 81

Group P2 Vector Control Parameters ................................................................... 84

Group P3 V/F Control Parameters........................................................................ 87

Group P4 Input Terminal....................................................................................... 90

Group P5 Output Terminal .................................................................................. 101

Group P6 Start and Stop Control ........................................................................ 106

Group P7 Keypad and Display.............................................................................111

Group P8 Enhanced Function..............................................................................117

Group P9 Fault and Protection ........................................................................... 126

Group PA PID Function....................................................................................... 134

Group PB Wobble Frequency, Fixed Length, Counting ...................................... 140

Group PC Multi-step Command and Simple PLC Function ................................ 143

Group PD Communication Parameters............................................................... 148

Group PP Function Code Management.............................................................. 148

Group A0 Torque Control Parameters................................................................. 150

Group A2 Motor 2 Parameters............................................................................ 152

Group U0 Monitoring Parameters....................................................................... 158

Chapter 7 EMC (Electromagnetic Compatibility).................................................... 165

7.1 Definition....................................................................................................... 165

7.2 EMC Standard Description............................................................................ 165

7.3 EMC Guide ................................................................................................... 165

Chapter 8 Trouble Shooting..................................................................................... 168

8.1 Fault and Trouble Shooting........................................................................... 168

8.2 Common Faults and Solutions...................................................................... 175

Chapter 9 MODBUS Communication Protocol ....................................................... 176

9.1 About Protocol .............................................................................................. 176

9.2 Application Method........................................................................................ 176

9.3 Bus Structure ................................................................................................ 176

9.4 Protocol Description...................................................................................... 176

9.5 Communication Data Structure..................................................................... 177

9.6 Command Code and Communication Data Description................................ 177

9.7 PD Group Communication Parameter Description........................................ 184

Chapter 10 Extension Card ...................................................................................... 186

10.1 Injection Card.............................................................................................. 186

10.2 PG Card...................................................................................................... 187

10.3 I/O Extension Card...................................................................................... 189

10.4 Communication Extension Card.................................................................. 190

KE600 Inverter Safety and Precautions

1

Chapter 1 Safety and Precautions

Safety definition:

In this manual, safety precautions are classified as follows:

Danger: Operations which are not performed according to requirements may cause serious

equipment loss or personnel injury.

Caution: Operations which are not performed according to requirements may cause medium hurt or

light hurt or material loss.

During the installation, commissioning and maintenance of the system, please make sure to follow the

safety and precautions of this chapter. In case of a result of illegal operations, caused any harm and losses

is nothing to do with the company.

1.1 Safety Precautions

1.1.1 Before Installation:

Danger

Do not use the water-logged inverter, damaged inverter or inverter with missing

parts. Otherwise, there may be risk of injury.

Use the motor with Class B or above insulation. Otherwise, there may be risk of

electric shock.

Caution

Carefully handled when loading, otherwise it may damage the inverter.

Please don’t use the damaged driver or inverter with missing parts, there may be

risk of injury.

Do not touch the electronic parts and components; otherwise it will cause static

electricity.

1.1.2 During Installation:

Danger

Install the inverter on incombustible surface such as metal, and keep away from

flammable substances. Otherwise it may cause fire.

Do not loose the set screw of the equipment, especially the screws marked in RED.

Caution

Do not drop the cable residual or screw in the inverter. Otherwise it may damage

the inverter.

Please install the driver in the place where there is no direct sunlight or less

vibratory.

When more than two inverters are to be installed in one cabinet, due attention

should be paid to the installation locations (refer to Chapter 3 Mechanical and

Electrical Installation) to ensure the heat sinking effect.

KE600 Inverter Safety and Precautions

2

1.1.3 During Wiring:

Danger

Operation should be performed by the professional engineering technician.

Otherwise there will be danger of electric shock!

There should be circuit breaker between the inverter and power supply. Otherwise,

there may be fire!

Make sure the power is disconnected prior to the connection. Otherwise there will

be danger of electric shock!

The ground terminal should be earthed reliably. Otherwise there may be danger of

electric shock.

Caution

Never connect AC power to output UVW terminals. Please note the remark of the

wiring terminals, connect them correctly. Otherwise may cause inverter damaged.

Ensure the wiring circuit can meet the requirement of EMC and the area safety

standard. Please follow the instructions in the manual before wiring. Otherwise may

cause injury or electric shock.

Never connect the braking resistor between DC bus (+), (-) terminals. Otherwise

may cause fire.

Encoder must be used together with shielded wire, and ensure the single terminal

of the shielded lay is connected with ground well.

1.1.4 Before Power-on:

Danger

Please confirm whether the power voltage class is consistent with the rated voltage

of the inverter and whether the I/O cable connecting positions are correct, and

check whether the external circuit is short circuited and whether the connecting line

is firm. Otherwise it may damage the inverter. The cover must be well closed prior

to the inverter power-on. Otherwise electric shock may be caused.

The inverter is free from dielectric test because this test is performed prior to the

delivery. Otherwise accident may occur.

Caution

The cover must be well closed prior to the inverter power-on. Otherwise electric

shock may be caused!

Whether all the external fittings are connected correctly in accordance with the

circuit provided in this manual. Otherwise accident may occur!

1.1.5 After Power-on:

Danger

Do not open the cover of the inverter upon power-on. Otherwise there will be

danger of electric shock!

Do not touch the inverter and its surrounding circuit with wet hand. Otherwise there

will be danger of electric shock!

Do not touch the inverter terminals (including control terminal). Otherwise there will

be danger of electric shock!

At power-on, the inverter will perform the security check of the external

heavy-current circuit automatically. Thus, at the moment please do not touch the

terminals U, V and W, or the terminals of motor, otherwise there will be danger of

electric shock.

KE600 Inverter Safety and Precautions

3

Caution

If parameter identification is required, due attention should be paid to the danger of

injury arising from the rotating motor. Otherwise accident may occur!

Do not change the factory settings at will. Otherwise it may damage the equipment!

1.1.6 During Operation:

Danger

Do not touch the fan or discharge resistor to sense the temperature. Otherwise,

you may get burnt!

Detection of signals during the operation should only be conducted by qualified

technician. Otherwise, personal injury or equipment damage may be caused!

Caution

During the operation of the inverter, keep items from falling into the equipment.

Otherwise, it may damage the equipment!

Do not start and shut down the inverter by connecting and disconnecting the

contactor. Otherwise, it may damage the equipment!

1.1.7 During Maintain:

Danger

Do not repair and maintain the equipment with power connection. Otherwise there

will be danger of electric shock!

Be sure to conduct repair and maintenance after the charge LED indictor of the

inverter is OFF. Otherwise, the residual charge on the capacitor may cause

personal injury!

The inverter should be repaired and maintained only by the qualified person who

has received professional training. Otherwise, it may cause personal injury or

equipment damage!

Carry out parameter setting after replacing the inverter, all the plug-ins must be

plug and play when power outage.

1.2 Precautions

1.2.1 Motor Insulation Inspection

When the motor is used for the first time, or when the motor is reused after being kept, or when periodical

inspection is performed, it should conduct motor insulation inspection so as to avoid damaging the inverter

because of the insulation failure of the motor windings. The motor wires must be disconnected from the

inverter during the insulation inspection. It is recommended to use the 500V megameter, and the insulating

resistance measured should be at least 5MΩ.

1.2.2 Thermal Protection of the Motor

If the ratings of the motor does not match those of the inverter, especially when the rated power of the

inverter is higher than the rated power of the motor, the relevant motor protection parameters in the in the

inverter should be adjusted, or thermal relay should be mounted to protect the motor.

1.2.3 Running with Frequency higher than Standard Frequency

This inverter can provide output frequency of 0Hz to 3000Hz. If the user needs to run the inverter with

frequency of more than 50Hz, please take the resistant pressure of the mechanical devices into

KE600 Inverter Safety and Precautions

4

consideration.

1.2.4 Vibration of Mechanical Device

The inverter may encounter the mechanical resonance point at certain output frequencies, which can be

avoided by setting the skip frequency parameters in the inverter.

1.2.5 Motor Heat and Noise

Since the output voltage of inverter is PWM wave and contains certain harmonics, the temperature rise,

noise and vibration of the motor will be higher than those at power frequency.

1.2.6 Voltage-sensitive Device or Capacitor Improving Power Factor at the Output Side

Since the inverter output is PWM wave, if the capacitor for improving the power factor or voltage-sensitive

resistor for lightning protection is mounted at the output side, it is easy to cause instantaneous over current

in the inverter, which may damage the inverter. It is recommended that such devices not be used.

1.2.7 Switching Devices like Contactors Used at the Input and Output terminal

If a contactor is installed between the power supply and the input terminal of the inverter, it is not allowed to

use the contactor to control the startup/stop of the inverter. If such contactor is unavoidable, it should be

used with interval of at least one hour. Frequent charge and discharge will reduce the service life of the

capacitor inside the inverter. If switching devices like contactor are installed between the output end of the

inverter and the motor, it should ensure that the on/off operation is conducted when the inverter has no

output. Otherwise the modules in the inverter may be damaged.

1.2.8 Use under voltage rather than rated voltage

If the KE series inverter is used outside the allowable working voltage range as specified in this manual, it

is easy to damage the devices in the inverter. When necessary, use the corresponding step-up or

step-down instruments to change the voltage.

1.2.9 Change Three-phase Input to Two-phase Input

It is not allowed to change the KE series three-phase inverter into two-phase one. Otherwise, it may cause

fault or damage to the inverter.

1.2.10 Lightning Impulse Protection

The series inverter has lightning over current protection device, and has certain self-protection capacity

against the lightning. In applications where lightning occurs frequently, the user should install additional

protection devices at the front-end of the inverter.

1.2.11 Altitude and Derating

In areas with altitude of more than 1,000 meters, the heat sinking effect of the inverter may turn poorer due

to rare air. Therefore, it needs to derate the inverter for use. Please contact our company for technical

consulting in case of such condition.

KE600 Inverter Safety and Precautions

5

1.2.12 Certain Special Use

If the user needs to use the inverter with the methods other than the recommended wiring diagram in this

manual, such as shared DC bus, please consult our company.

1.2.13 Note of Inverter Disposal

The electrolytic capacitors on the main circuit and the PCB may explode when they are burnt. Emission of

toxic gas may be generated when the plastic parts are burnt. Please dispose the inverter as industrial

wastes.

1.2.14 Adaptable Motor

1) The standard adaptable motor is four-pole squirrel-cage asynchronous induction motor. If such motor is

not available, be sure to select adaptable motors in according to the rated current of the motor. In

applications where drive permanent magnetic synchronous motor is required, please consult our company;

2) The cooling fan and the rotor shaft of the non-variable-frequency motor adopt coaxial connection. When

the rotating speed is reduced, the cooling effect will be poorer. Therefore, a powerful exhaust fan should be

installed, or the motor should be replaced with variable frequency motor to avoid the over heat of the

motor.

3) Since the inverter has built-in standard parameters of the adaptable motors, it is necessary to perform

motor parameter identification or modify the default values so as to comply with the actual values as much

as possible, or it may affect the running effect and protection performance;

4) The short circuit of the cable or motor may cause alarm or explosion of the inverter. Therefore, please

conduct insulation and short circuit test on the newly installed motor and cable. Such test should also be

conducted during routine maintenance. Please note that the inverter and the test part should be completely

disconnected during the test.

KE600 Inverter Product Information

6

Chapter 2 Product Information

2.1 Product Inspection

Checking the following items when receiving the inverter

Confirmation Items

Method

Confirm if the inverter is what you ordered

Check name plate

Damaged or not

Inspect the entire exterior of the inverter to see if

there are any scratches or other damage

resulting from shipping

Confirm if the fastening parts (screws, etc.)

are loose or not

Check with a screw driver if necessary

User’s manual, certification and other spares

User’s manual and the relative spares

Please contact the local agent or our company directly if there is any damage on the inverter.

2.2 Model Description

KE600 - 5R5G - T4

Close-loop vector

control inverter series

Power rating:

5R5: 5.5kW

G: Constant torque type

Input voltage:

S2: 1AC 220~240V

T2: 3AC 220~240V

T4: 3AC 380~440V

T6: 3AC 660~690V

Figure 2-1 Model description

2.3 Description of Nameplate

Figure 2-2 Nameplate

Model No.

Power rating

Input specification

Output specification

Bar code

KE600 Inverter Product Information

7

2.4 Selection Guide

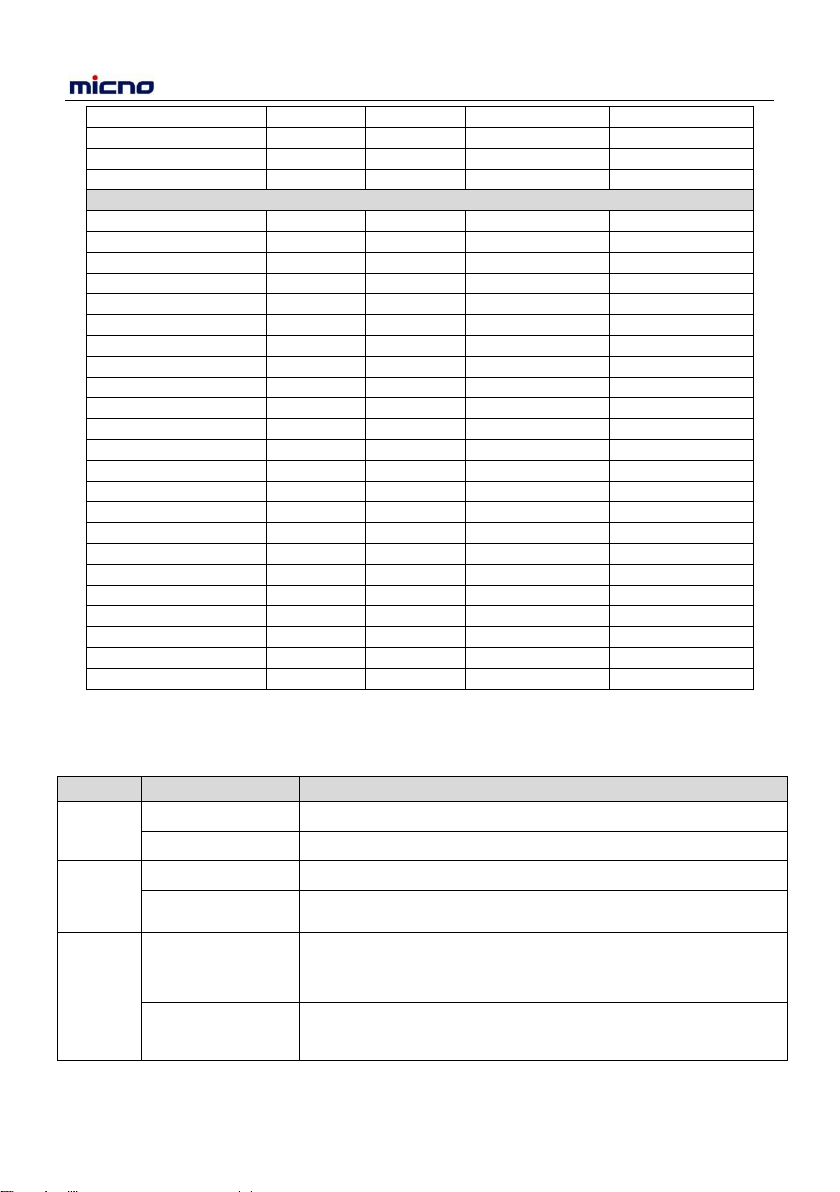

Table 2-1 KE600 Series Inverter Model and Technical Data

Inverter Model

Motor

Rated Input

Current (A)

Rated Output

Current (A)

kW

HP

3AC 220~240V±15%

KE600-1R5G-T2

1.5

2

7.7

7

KE600-2R2G-T2

2.2

3

10.5

9

KE600-004G-T2

4.0

5

14.6

13

KE600-5R5G-T2

5.5

7.5

26

25

KE600-7R5G-T2

7.5

10

35

32

KE600-011G-T2

11

15

46.5

45

KE600-015G-T2

15

20

62.5

60

KE600-018G-T2

18.5

25

76

75

KE600-022G-T2

22

30

92

91

KE600-030G-T2

30

40

113

112

KE600-037G-T2

37

50

157

150

KE600-045G-T2

45

60

180

176

KE600-055G-T2

55

75

214

210

KE600-075G-T2

75

100

307

304

3AC 380~440V±15%

KE600-1R5G-T4

1.5

2

5.0

3.8

KE600-2R2G-T4

2.2

3

6.8

6.0

KE600-004G-T4

4.

5

10

9

KE600-5R5G-T4

5.5

7.5

15

13

KE600-7R5G-T4

7.5

10

20

17

KE600-011G-T4

11

15

26

25

KE600-015G-T4

15

20

35

32

KE600-018G-T4

18.5

25

38

37

KE600-022G-T4

22

30

46

45

KE600-030G-T4

30

40

62

60

KE600-037G-T4

37

50

76

75

KE600-045G-T4

45

60

92

90

KE600-055G-T4

55

75

112

110

KE600-075G-T4

75

100

157

150

KE600-090G-T4

90

125

180

176

KE600-110G-T4

110

150

214

210

KE600-132G-T4

132

175

256

253

KE600-160G-T4

160

210

307

304

KE600-185G-T4

185

250

350

340

KE600-200G-T4

200

260

385

377

KE600-220G-T4

220

300

430

423

KE600-250G-T4

250

330

468

465

KE600-280G-T4

280

370

525

520

KE600-315G-T4

315

420

590

585

KE600-350G-T4

350

470

665

650

KE600 Inverter Product Information

8

KE600-400G-T4

400

530

785

725

KE600-500G-T4

500

660

880

860

KE600-560G-T4

560

750

980

950

KE600-630G-T4

630

840

1130

1100

3AC 660~690V±15%

KE600-015G-T6

15

20

21

19

KE600-018G-T6

18

25

28

22

KE600-022G-T6

22

30

35

28

KE600-030G-T6

37

40

40

35

KE600-037G-T6

37

50

47

45

KE600-045G-T6

45

60

55

52

KE600-055G-T6

55

75

65

63

KE600-075G-T6

75

100

90

86

KE600-090G-T6

90

105

100

98

KE600-110G-T6

110

130

130

121

KE600-132G-T6

132

175

170

150

KE600-160G-T6

160

210

200

175

KE600-185G-T6

185

250

210

195

KE600-200G-T6

200

260

235

215

KE600-220G-T6

220

300

257

245

KE600-250G-T6

250

330

265

260

KE600-280G-T6

280

370

305

300

KE600-315G-T6

315

420

350

330

KE600-350G-T6

350

470

382

374

KE600-400G-T6

400

530

435

410

KE600-450G-T6

450

600

490

465

KE600-500G-T6

500

660

595

550

KE600-630G-T6

630

840

700

680

2.5 Technical Specifications

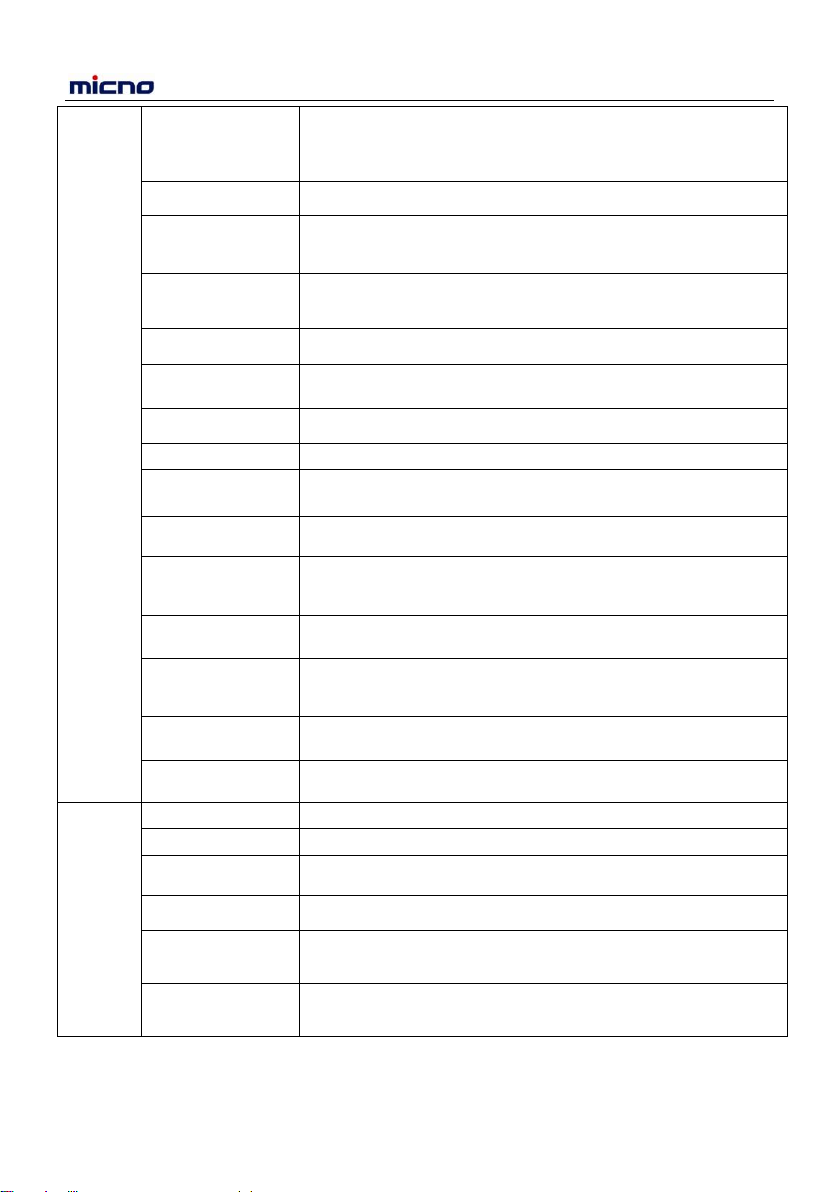

Table 2-2 KE600 Series Inverter Technical Specifications

Item

Technical Index

Specification

Input

Input voltage

3AC 220~240V±15%, 3AC 380~440V±15%, 3AC 660~690V±15%

Input frequency

47~63Hz

Output

Output voltage

0~rated input voltage

Output frequency

V/f control: 0~3000Hz

Sensorless vector control: 0~300Hz

Control

Features

Control mode

V/f control

Sensorless vector control (Open-loop)

Close-loop vector control

Torque control

Operation command

mode

Keypad control

Terminal control

Serial communication control

KE600 Inverter Product Information

9

Frequency setting

mode

Digital setting, analog setting, pulse frequency setting, serial

communication setting, multi-step speed setting & simple PLC, PID

setting, etc. These frequency settings can be combined & switched in

various modes.

Overload capacity

150% 60s, 180% 10s, 200% 3s.

Starting torque

0Hz/180% (Close-loop vector control);

0.5Hz/150% (SVC);

1Hz/150% (V/f)

Speed adjustment

range

1:1000 (Close-loop vector control);

1:100 (SVC),

1:50 (V/f)

Speed control

precision

±0.02% (Close-loop vector control); ±0.5% (SVC)

Carrier frequency

1.0--16.0kHz, automatically adjusted according to temperature and

load characteristics

Frequency accuracy

Digital setting: 0.01Hz

Analog setting: maximum frequency ×0.05%

Torque boost

Automatically torque boost; manually torque boost: 0.1%~30.0%

V/f curve

Three types: linear, multiple point and square type (1.2 power, 1.4

power, 1.6 power, 1.8 power, square)

Acceleration/decele

ration mode

Straight line/S curve; four kinds of acceleration/deceleration time,

range: 0.1s~3600.0s

DC braking

DC braking when starting and stopping

DC braking frequency: 0.0Hz~maximum frequency, braking time:

0.0s~100.0s

Jog operation

Jog operation frequency: 0.0Hz~maximum frequency

Jog acceleration/deceleration time: 0.1s~3600.0s

Simple PLC &

multi-step speed

operation

It can realize a maximum of 16 segments speed running via the built-in

PLC or control terminal.

Built-in PID

Built-in PID control to easily realize the close loop control of the

process parameters (such as pressure, temperature, flow, etc.)

Automatic voltage

regulation

Keep output voltage constant automatically when input voltage

fluctuating

Control

Function

Common DC bus

Common DC bus for several inverters, energy balanced automatically

Torque control

Torque control build-in

Torque limit

“Rooter” characteristics, limit the torque automatically and prevent

frequent over-current tripping during the running process

Wobble frequency

control

Multiple triangular-wave frequency control, special for textile

Timing/length/

counting control

Timing/length/counting control function

Over-voltage &

over-current stall

control

Limit current & voltage automatically during the running process,

prevent frequent over-current & over-voltage tripping

KE600 Inverter Product Information

10

Fault protection

function

Up to 30 fault protections including over-current, over-voltage,

under-voltage, overheating, default phase, overload, shortcut, etc., can

record the detailed running status during failure & has fault automatic

reset function

Input/out

put

terminals

Input terminals

Programmable DI (Digital Input):

7 inputs, 1 is optional for high-speed pulse input,

3 can be extended

Programmable AI (Analog Input):

AI1: 0~10V or 0/4~20mA

A12: 0~10V or 0/4~20mA

Output terminals

1 programmable open collector output: 1 analog output (open collector

output or high-speed pulse output), 2 can be extended.

1 relay output, 1 can be extended

2 analog output: 0/4~20mA or 0~10V

Communication

terminals

Offer RS485 communication interface, support MODBUS-RTU

communication protocol

Human

machine

interface

LED display

Display frequency setting, output frequency, output voltage, output

current, etc.

Multifunction key

QUICK/JOG key, can be used as multifunction key

Environ-

ment

Ambient

temperature

-10℃~40℃, derated 4% when the temperature rise by every 1℃

(40℃~50℃).

Humidity

90%RH or less (non-condensing)

Altitude

≤1000M: output rated power, >1000M: output derated

Storage

temperature

-20℃~60℃

2.6 External & Installation Dimensions

2.6.1 Parts Description

Operation keypad

Cover installation hole

Cables crossing

Inverter mounting hole

KE600 Inverter Product Information

11

Figure 2-3 Parts of inverter

Inverter

hoisting hole

Inverter

mounting hole

Keypad bracket

Control board

Main circuit wiring

When installing a

cabinet, can outlet

front, back, left

and right

KE600 Inverter Product Information

12

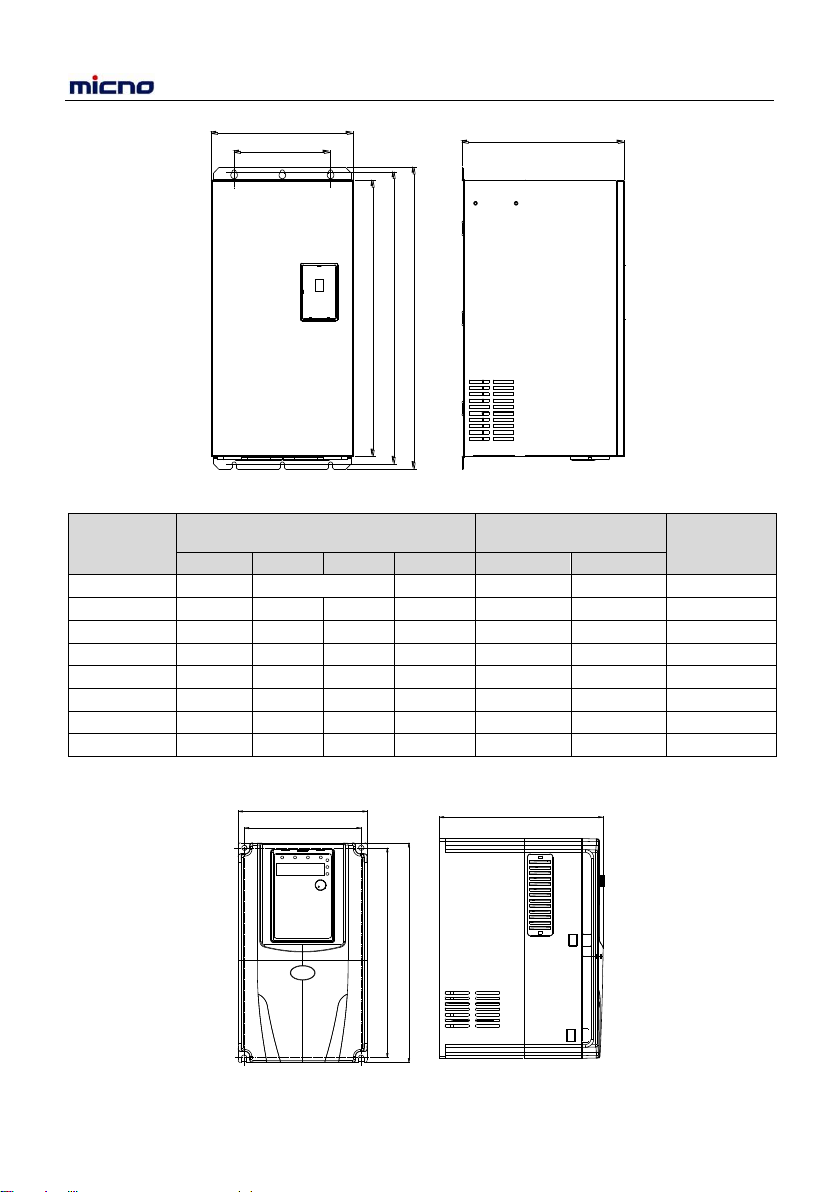

2.6.2 External & Installation Dimensions

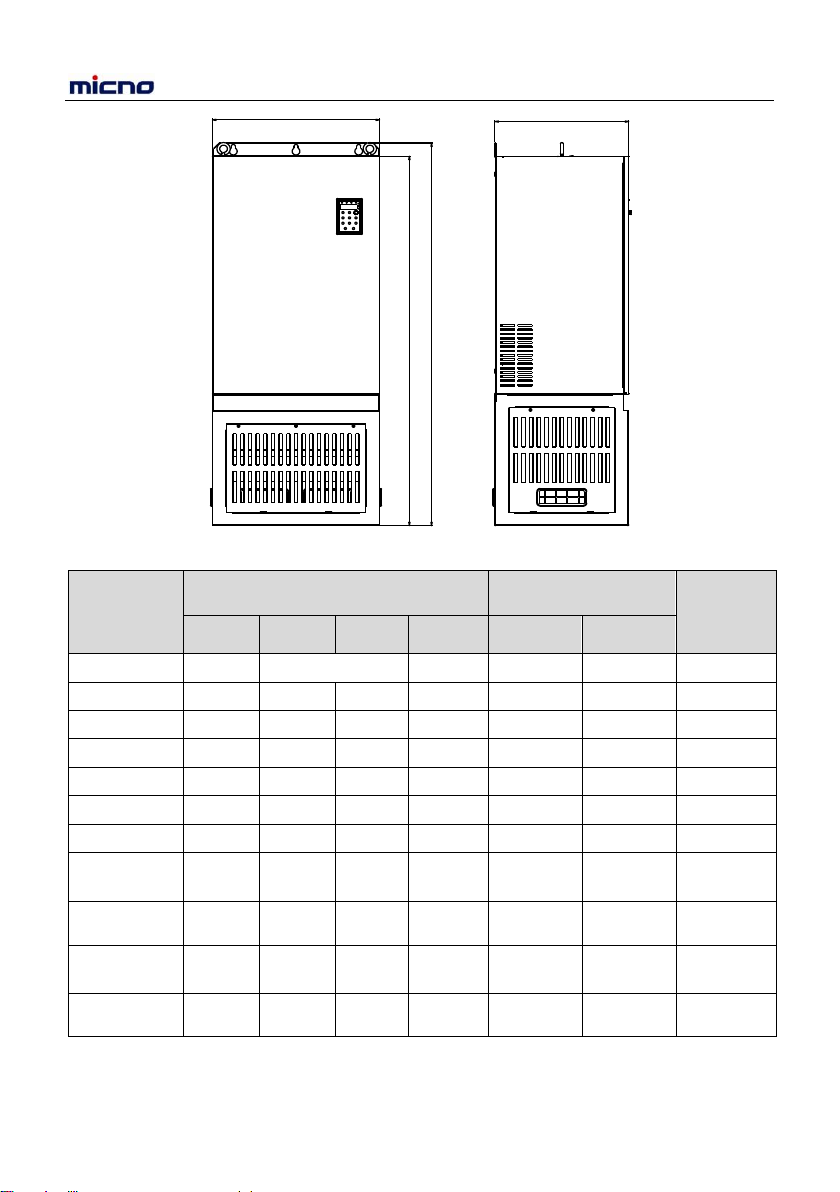

3AC 220~240V inverter dimension

5 0 .0 0

A

W

B

H

D

1.5~4kW

W

H1

D

A

B

H2

5.5~15kW

KE600 Inverter Product Information

13

W

A

H1

B

H2

D

18.5~75kW

Power

Range

External Dimension

( mm )

Installation Dimension

( mm )

Mounting

Bolt Model

W

H1

H2

D

A

B

1.5~4kW

135

240

173

122.6

229

M4

5.5kW

170

314

285

167

90

301.6

M4

7.5kW

200

329.1

300

177.2

90

316.6

M4

11~15kW

255

439.6

402.4

209.6

140

423.6

M5

18.5~22kW

280

570

521.2

258

190

552

M6

30~37kW

320

600

552

330

230

582

M8

45~55kW

320

715

662

330

230

695.5

M8

75kW

480

790

725

385

360

768

M10

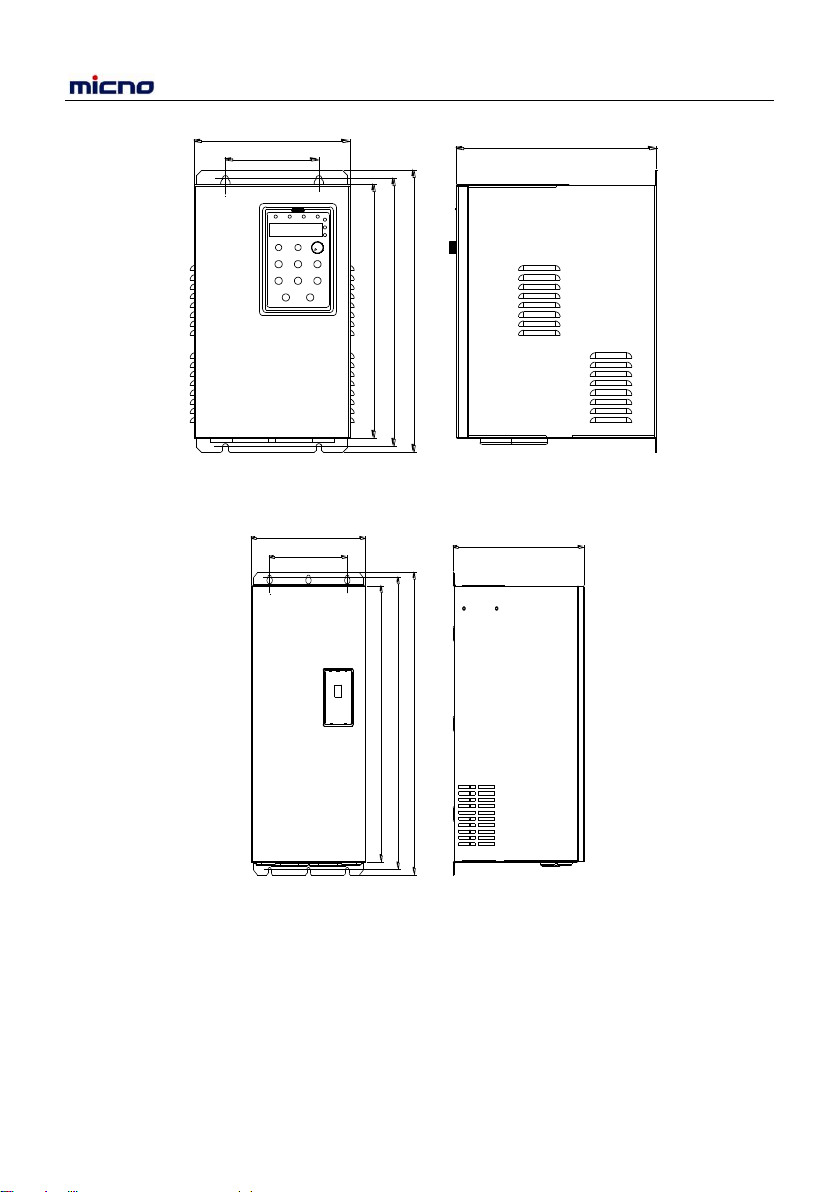

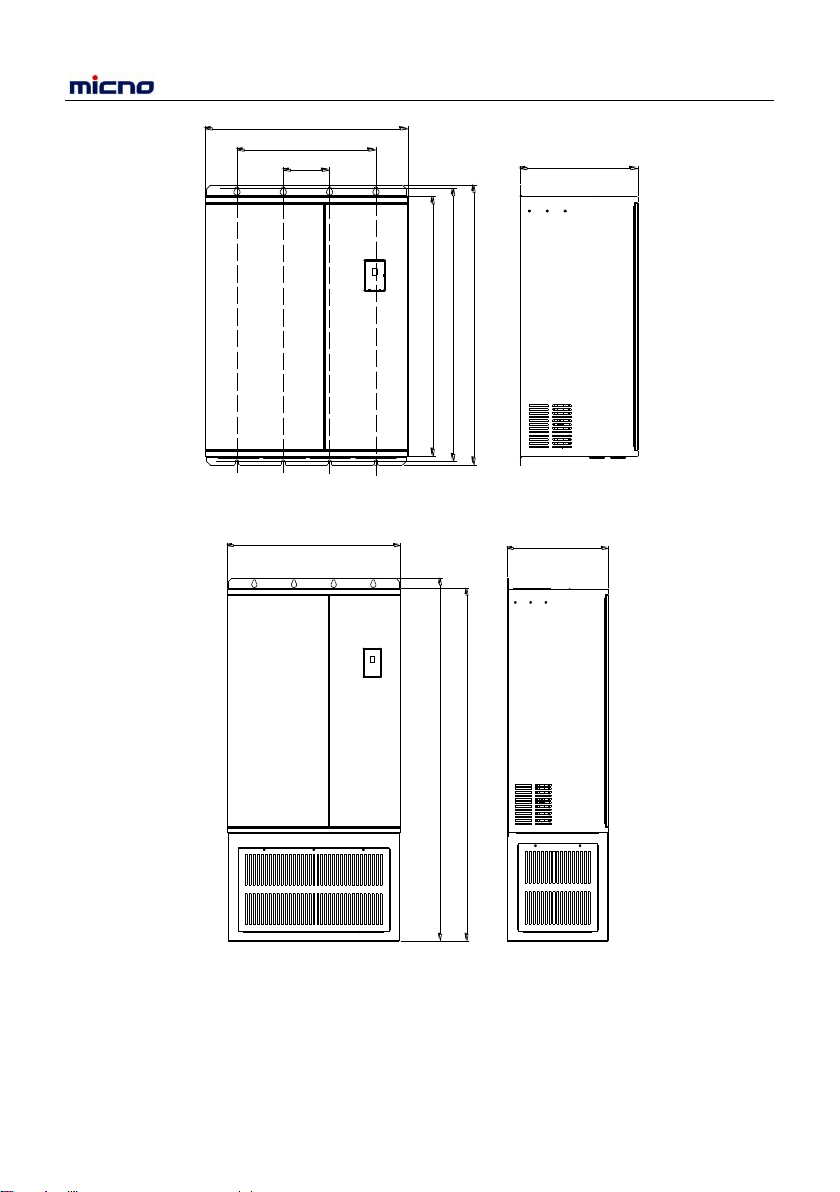

3AC 380~440V inverter dimension

5 0 .0 0

A

W

B

H

D

1.5~5.5kW

KE600 Inverter Product Information

14

W

H1

D

A

B

H2

7.5~30kW

W

A

H1

B

H2

D

37~200kW (including 90~200kW standard inverter (without base))

KE600 Inverter Product Information

15

50.00

W

H2

H1

D

90~200kW nonstandard inverter (with base)

Power

Range

External Dimension

( mm )

Installation Dimension

( mm )

Mounting

Bolt Model

W

H1

H2

D

A

B

1.5~5.5kW

135

240

173

122.6

229

M4

7.5kW

170

314

285

167

90

301.6

M4

11~15kW

200

329.1

300

177.2

90

316.6

M4

18.5kW

225

397.6

365

185.2

120

384.1

M5

22~30kW

255

439.6

402.4

209.6

140

423.6

M5

37~45kW

280

570

521.2

258

190

552

M6

55~75kW

320

600

552

330

230

582

M8

90~110kW

(without base)

320

715

662

330

230

695.5

M8

90~110kW

(with base)

320

992

962

330

132~200kW

(without base)

480

790

725

385

360

768

M10

132~200kW

(with base)

480

1165

1125

385

Note: Base is optional for 90~200kW inverters. Standard invertes are without base.

KE600 Inverter Product Information

16

D

A2

A1

W

H1

B

H2

220~630kW without base

W

H1

D

H2

220~630kW with base

KE600 Inverter Product Information

17

Power

Range

External Dimension

( mm )

Installation Dimension

( mm )

Mounting

Bolt Model

W

H1

H2

D

A1

A2

B

220~315kW

(without base)

700

970

900

408

160

480

946

M10

220~315kW

(with base)

700

1390

1350

408

350~630kW

(without base)

940

1140

1100

458

240

660

1146

M10

350~630kW

(with base)

940

1690

1650

458

3AC 660~690V Inverter Dimension

W

A

H1

B

H2

D

15~160kW (without base)

This manual suits for next models

66

Table of contents

Other Micno Inverter manuals

Popular Inverter manuals by other brands

EDECOA

EDECOA DPM10 user manual

Winco

Winco PSS8000 Installation and operator's manual

EINHELL

EINHELL BT-PG 4000 Original operating instructions

Parkside

Parkside PSE 2800 B2 original operation manual

Daihen

Daihen OTC CPTX-I 400 2W owner's manual

Mitsubishi Electric

Mitsubishi Electric FR-F800 instruction manual