Micom SW800 User manual

1

Micom Americas, Inc.

SW800 AUTOMATIC SWING DOOR OPERATOR

Operations & Installation Manual

These installation instructions detailed within are solely for professional installers

and are not intended to be handed over to the end user.

Ver. October 30, 2022

Micom Americas, Inc.

220 Viceroy Road, Unit 15

Concord, ON L4K 3C2, Canada

Tel: (905) 851-8688

Web: www.micomamericas.ca

Email: mailto:sales@micomamericas.ca

SW800 Installation Manual

2

WARNING

AVOIDANCE OF ELECTRIC SHOCK, INJURY, FIRE OR MALFUNCTIONS

Please read these instructions carefully before installing the door operator. We are not responsible for

any loss or damage if these precautions are not followed. These instructions should be followed to

avoid the possibility of injury and damage due to wrong installation or adjustment.

During maintenance and installation, the power to the control unit should be OFF.

Please use the correct power supply - Power Acceptance 90V-250V DC-50/60 Hz.

Make sure that the operator is grounded or connected to earth! The coating of the operator is made of

an electrically conductive metallic material which will easily induce electrical conduction. Make sure

the ground or earth wire is connected.

The operator housing is not completely sealed, therefore it should be noted that excessive moisture or

a corrosive atmosphere could destroy the electronic components contained within.

Do not remove screws and bolts from the structure of the Control Unit or Motor Gear Box. Do not

intend to open, repair, or alter any part of the operator unit. Failure to comply will result in loss of

warranty.

Installation and maintenance of this product can be performed by trained and authorized personnel

only.

Before switching ON the power supply, make sure that no objects obstruct the travel of the automatic

doors.

NATIONAL WIRING REGULATIONS AND STANDARDS MUST BE CONFORMED TO.

Follow all indicated instructions as improper installation could cause severe damage.

Correct equipment must be used in order to reach overhead area for installation and service.

KEEP FINGERS AND CLOTHING CLEAR OF ALL MOVING PARTS.

Please keep these instructions

WARRANTY

36 MONTHS FROM SHIPMENT. WARRANTY VOID IF REPAIR IS ATTEMPTED TO MOTOR GEAR OR

CONTROL ASSEMBLY.

Failure to observe the information in this manual may result in personal injury or damage to

the equipment. To reduce the risk of injury to persons, use this operator with single or

double pedestrian swinging doors only.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

SW800 Installation Manual

3

TABLE OF CONTENTS

SECTION 1.0 - PRODUCT SUMMARY ----------------------------------------------------------------------------------------------------------- 4

SECTION 2.0 - TECHNICAL SPECIFICATION---------------------------------------------------------------------------------------------------- 5

SECTION 3.0 - RECEIVING INSPECTION -------------------------------------------------------------------------------------------------------- 6

SECTION 4.0 - PRE-INSTALLATION INFORMATION ------------------------------------------------------------------------------------------ 7

SECTION 5.0 - OPERATOR INSTALLATION ----------------------------------------------------------------------------------------------------- 9

SECTION 6.0 - PUSH AND PULL ARMS INSTALLATION -------------------------------------------------------------------------------------14

SECTION 7.0 - LEARNING CYCLE AND START UP --------------------------------------------------------------------------------------------17

SECTION 8.0 - ELECTRONICS CONTROLLER PROGRAMMING ----------------------------------------------------------------------------18

BASIC SETTINGS TABLE DESCRIBING THE CONTROLS FUNCTIONS, SETTINGS, VALUES AND DEFAULTS-------------------------23

SECTION 9.0 - WIRING CONNECTIONS -------------------------------------------------------------------------------------------------------25

SECTION 10.0 - CHANGING HANDING OF OPERATOR -------------------------------------------------------------------------------------29

SECTION 11.0 - SAFETY SIGNAGE AND DECALS ---------------------------------------------------------------------------------------------33

SECTION 12.0 - TROUBLESHOOTING----------------------------------------------------------------------------------------------------------34

SECTION 13.0 - DAILY SAFETY CHECKLIST----------------------------------------------------------------------------------------------------36

SECTION 14.0 - ADDITIONAL INFORMATION------------------------------------------------------------------------------------------------37

SECTION 15.0 - PRELOAD SPRING TENSION -------------------------------------------------------------------------------------------------38

SECTION 16.0 - DROP SPINDLE INSTRUCTIONS ---------------------------------------------------------------------------------------------39

SECTION 17.0 - MISCELLANEOUS/FUTURE USE---------------------------------------------------------------------------------------------40

SECTION 18.0 - WARRANTY POLICY-----------------------------------------------------------------------------------------------------------41

SW800 Installation Manual

4

Section 1.0 - Product Summary

SW800 is a universal, non-handed, electro-mechanical swing door operator which provides powered door opening upon

activation. The unit is designed to facilitate barrier free access into and within building through swing doors.

When properly installed and programmed, this product complies with ANSI/BHMA A156.19 Standard for Power Assist

and Low Energy Power Operated Swinging Doors.

SW800 features enable the continuous automation of pedestrian doors while offering Low energy barrier-free access.

(THE SW800 IS) Designed to achieve the highest degree of safety while offering a long service life.

It is the responsibility of the installer and installation company to certify that the final completed operator is installed

in accordance with local building codes, applicable laws, and ANSI 156.19 standards governing this product.

Opening

When an open signal is received by the control unit, the door is opened at the factory set or pre-adjust opening speed.

Before the door is fully open, it will begin its back check, slowing automatically to low speed. The motor stops when the

selected full open angle has been reached. The open position is held by the motor.

In case the door encounters an obstruction during the opening cycle, once the maximum current limit is reached for at

least two (2) seconds, the door opening is then cancelled.

Closing

When the activation time has elapsed, the operator will close the door automatically using spring force and motor

power. The door will slow to latch speed before it reaches the full closed position. The door is kept closed by spring

power.

Power Failure

During power failure, the operator acts as a manual door closer with controlled closing speed.

SW800 can be surface mounted or overhead concealed mounted on either side of the door header for left, right, pull, or

push applications. It is suitable for either single or double door opening being either hinged or center hung mounted.

ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE

WITHOUT NOTICE TO IMPROVE RELIABILITY, FUNCTION OR DESIGN OR

OTHERWISE. ... It is the customer's responsibility to validate that a particular product with

the properties described in the product specification is suitable for use in a particular

application.

SW800 Installation Manual

5

Section 2.0 - Technical Specification

1.0

Model

SW800

2.0

Application

Low Energy Swing Door Operator

3.0

Power Supply

100V - 240V AC, 50/60 Hz

4.0

Consumption

100W Max

5.0

Motor

1/4 Hp, Low revolution 24 DC, 3A Max

6.0

Rated Operation

Continuous opening and closing cycles

7.0

Reduction Gear

Enclosed Reduction Gear system

8.0

Control System

Microprocessor Digital Control

9.0

Operating Environment

Ambient temperature: -18~ +50

(no condensation or icing)

Ambient humidity 30% to 85% RH

(no hazardous materials must be present in the

atmosphere)

10.0

Operation During Power Failure

Low manual resistance when opened by hand. Door

closing by spring.

11.0

Operator Net Weight

17 kg, approx. 38 lbs.

12.0

Operator Dimensions

5½" (h) (140 mm) x 4½" (D) (115 mm)

13.0

Door Weight (max)

700 lbs. (318 kg) per leaf

14.0

Door Width Limits

29" up to 60" (consult factory for special sizes)

15.0

Operator Width

29" to 102"

16.0

Installation Types

Push, Pull, Overhead Concealed, Center spindle

17.0

Adjustable Opening Angle

80to 180

18.0

Auxiliary Power

500mA @ 24 vdc for accessories AND

1,000mA @ 12 vdc for accessories

19.0

Closing Force

Adjustable pressure by spring tension and optional

motor close

20.0

Product Standards

UL 325 Listed by ETL #5012330

ANSI 156.19 Compliant

UL10C Fire Door Rated Operator - 2 hours

SW800 Installation Manual

6

Section 3.0 - Receiving Inspection

On receiving the package, please verify that the order was shipped complete and correct, including model number,

header width, door handing, arm and color.

•If any of the below items are not correct, do not attempt to install the unit until all conditions are correct.

•Report any incorrect items immediately.

NO CLAIMS FOR SHORTAGE WILL BE ACCEPTED UNLESS REPORTED WITHIN 24 HOURS OF RECEIPT OF SHIPMENT. THE

FOLLOWING ITEMS SHOULD BE SUPPLIED:

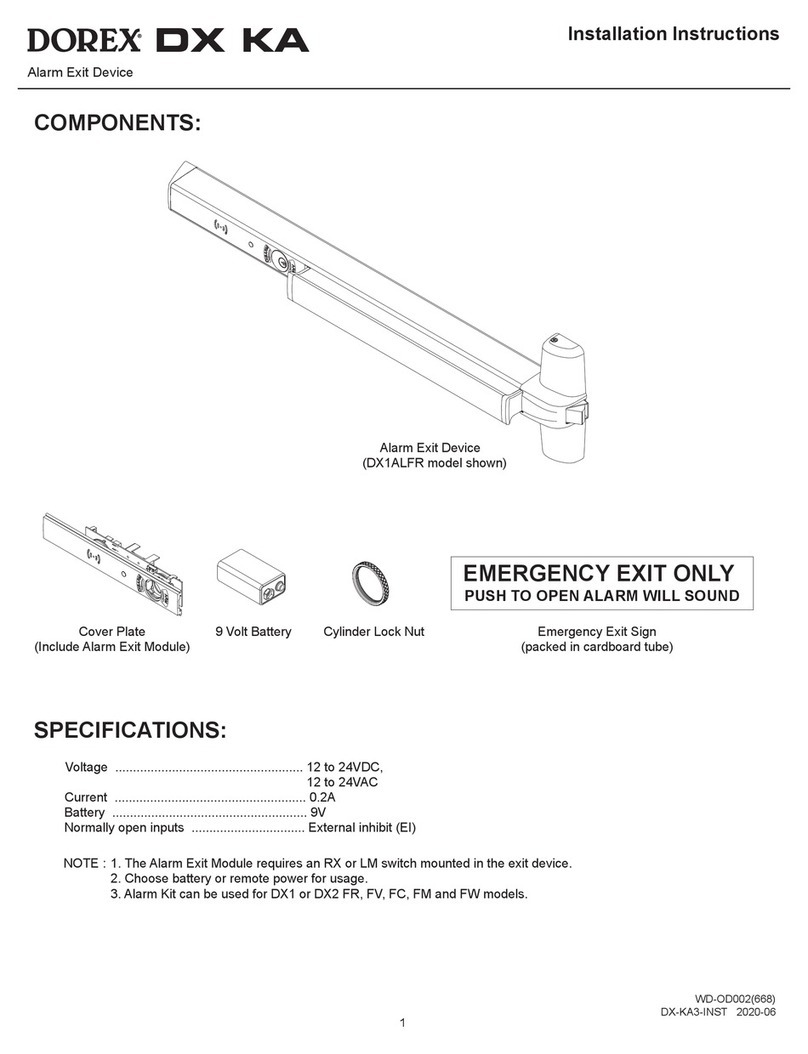

3.1 Exploded View

3.2 Parts List

No.

Description

Parts No.

1

SW800 Header/Housing

HDR

2

End cover plate

ECPL-800

3

Control Unit SW800

SW-CU-800

4

Motor

n/a

5

Gear Box/Motor Assembly

SW-MGB-800

6

Spindle

S-800

7

Mechanical door stop

MDS-800

8

Motor gear box end support bracket

MEB-800

9

Motor gear box mount bracket

MGBMB-800

10

Rev Counter/Encoder

SW-REV

1

2

3

4

5

6

7

8

9

10

2

SW800 Installation Manual

7

Section 4.0 - Pre-Installation Information

4.1 Safety Precautions

•Only trained technicians are authorized to carry out these operations.

•Ensure all power is OFF to the unit before performing any work or maintenance.

•Do not climb or put weight on any door or header parts.

•Do not let children play with the operator or the electrical board.

•Keep remote controls away from children.

To avoid bodily injury, material damage, and malfunction of the product, the instructions contained in this manual must

be strictly observed during installation, adjustment, repair, and service.

Training is needed to carry out these tasks safety.

4.2 Compliance Codes and Standards

It is the responsibility of the final installer and/or installation company to certify that the final completed operator is

installed in accordance with ANSI/BHMA A156.19 Standard for Power. Assist and Low Energy Power Operated Swing

Doors, local building codes and applicable laws.

Be sure to complete the site inspection and acceptance test before taking the door into operation.

•All wiring must conform to standard wiring practice in accordance with national and local wiring codes.

•Door must swing feely through the entire opening and closing cycle before beginning of installation.

•Incorrectly installed or improperly adjusted door operators can cause property damage or personal injury.

•All dimensions are given in inches (millimeters), unless otherwise noted.

•Before installation, verify door frame is properly reinforced and is well anchored in the wall.

•Concealed electrical conduit and concealed switch or sensor wires should be pulled to the frame before proceeding.

4.3 Electrical

The 115+/-5 VAC supply lines are connected into the Green Connector block located to the left hand side of the control

unit. Words clearly indicate its correct wiring. The ground wire is also connected into the Green Connector block.

The control board settings have been pre-set prior to shipment. It will be necessary for the door operator to be

functional while adjustments and settings are made. Please follow these instructions for a successful installation.

CAUTION

SW800 Installation Manual

8

A black push actuator button indicated by "TEST/LEARN" is mounted to the lower left corner of the visual display to ease

in the adjustment process.

Once the unit is powered up and before the arm is installed, push the "TEST/LEARN: button in order to check the spline

drive shaft rotates in the correct direction.

Keep all wires away from moving parts and sharp edges that may cut into the outer casing of the wires.

Installation of any extra wiring for controls or accessories into the header unit shall be secured and away from any

moving parts.

If the motor is not plugged into the circuit board, there is no resistance against the spring when manually opening the

door. The door or arm will close very quickly if opened.

If an electrical access hole is added or knocked out of the end plates, code approved electrical transfers must be used.

Hole cannot be knocked out and unfilled.

4.4 Required Tools for Installation

•Allen Wrench Set

•Power Drill and Drill Bits

•Level

•Tape Measure

•Wire Stripper

•Screwdrivers: Flat, Philips, 5/16" Hex. Nut

•Additional fasteners depending on surface

•Shims

•Hand Saw/Power Saw

4.5 Suggested Fasteners for Frame

•#14 x 2-2/3" (70mm) long sheet metal screws for wood.

4.6 Suggested Fasteners for Door

•#12, #14, Wood screws, Sheet Metal screws, Self-tapping screws of varying lengths depending on applications.

•Typically, doors are hung on 4 1/2" (114mm) butt hinges or 3/4" (19mm) offset pivots.

The fastener components listed above are merely suggestions. A technician should use their best discretion to

determine what components they will need to complete the job.

SW800 Installation Manual

9

Section 5.0 - Operator Installation

The following information gives a complete guidance to the correct installation on the SW800 operator.

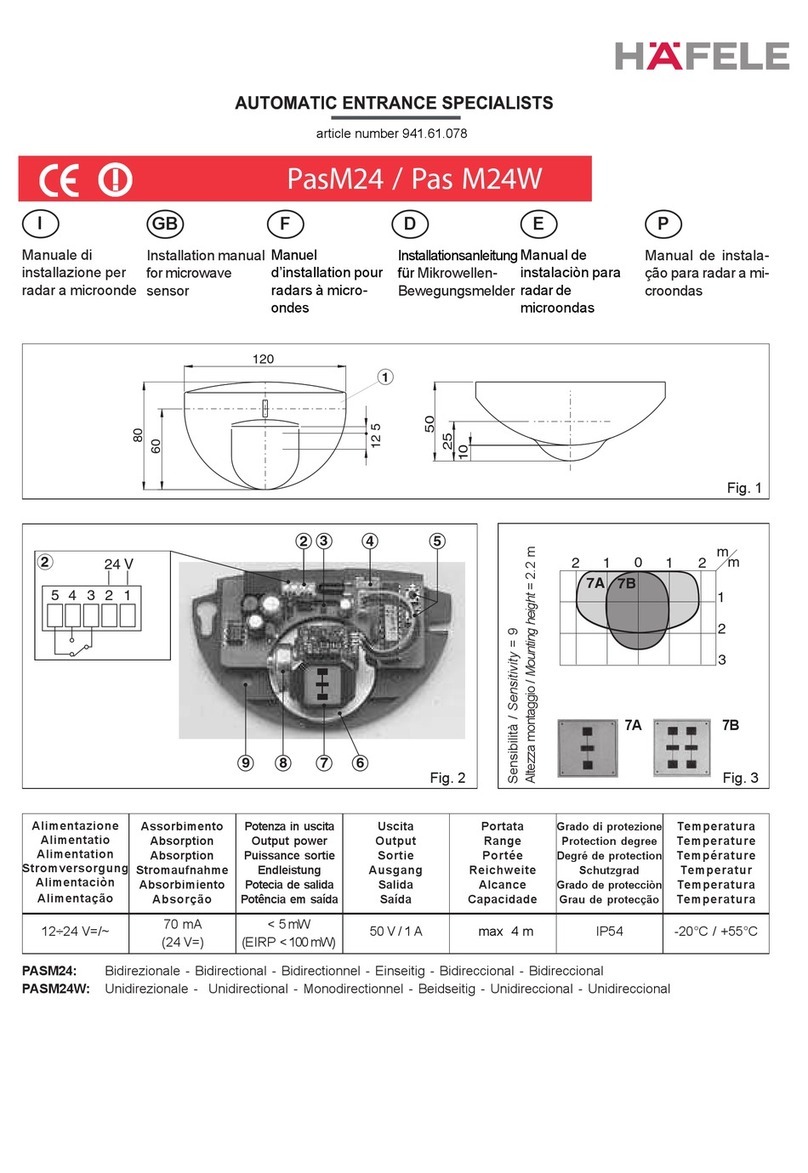

5.1 Control Unit

No.

Description

1

Power Unit (90-250VAC 50/60hz)

9

3 Position Switch Input Connector

2

Motor Connector Plug in

10

Enter Button

3

Motor Encoder Connector Plug in

11

Down Button

4

LED Display Screen

12

Up Button

5

Sync/Comm Connector Plug in (Double Operator)

13

Menu Button

6

24VDC/12VDC Power Output Connector

14

Test/Learn Button

7

Activation/Safety Accessories Connector

15

Fuse - Replaceable

8

E-Lock Signal Connector

16

Battery Back-up Connection

5.2 Operator Handing and Orientation

Verify that the operator is the correct orientation. Left Push, Right Push, Left Pull, or Right Pull.

Note:

•If the operator label is facing 'Down' to the floor, the handing is Left Hand Push/Pull.

•If the operator label is facing 'Up' to the ceiling, the handing is Right Hand Push/Pull.

SW800 Installation Manual

10

5.3 PUSH Arm Handing and Operator Orientation

RHR/LEFT Hand PUSH

LHR/RIGHT Hand PUSH

5.4 PULL Arm Handing and Operator Orientation

LEFT Hand PULL

RIGHT Hand PULL

SW800 Installation Manual

11

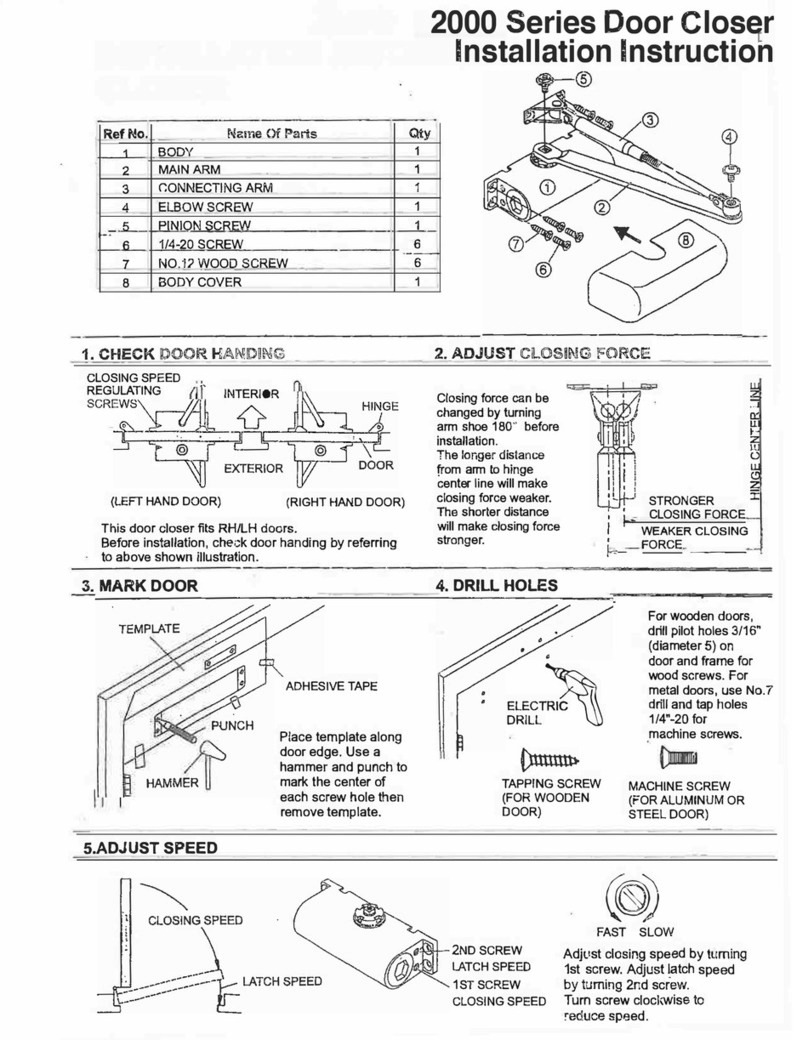

5.5 Operator Installation

Step 1. Remove the cover from the assembly by gently pulling the cover down with minimal effort. Carefully set the

cover in a location where it will not be damaged.

Step 2. Remove the motor/gear box and control board from the back plate, make through holes on the back plate for

mounting header where appropriate.

Note: Can be installed without removal of motor/gear box and control board if preferred.

SW800 Installation Manual

12

Step 3. Power Supply

Step 4. Fixing Operator in Place

Make sure all power is turned OFF before

handling the supply wires. This should be

done by a certified electrician and within

the guidelines of the enforced local

electrical codes.

Drill holes for the high voltage wires in

backing plate.

Pull the power supply into the header at the

same time as the header assembly is

positioned.

Be sure there is proper support in the wall

to secure the header at the vertical jambs

and behind the header at intervals between

the vertical jambs

A solid space material or filler may be

required to compensate for any gap

between the back of base rail and wall.

Ensure, before fixing base rail to the door

frame, that access holes for power supply

cables are in line, if required.

Secure the header box to the top of the

door frame with the appropriate

fasteners.

Holes can be made anywhere in header

to secure. All holes MUST be drilled

into substantial support (studs, blocks,

framing, etc.).

SW800 Installation Manual

13

Step 5. Once the header back plate is in place, install the motor/gearbox and control board to the header back plate.

Slide the nuts (supplied with the operator) to hold the motor/gearbox and control board along the 2 parallel tracks on

the back plate.

Fasten the bolt to hold the motor/gearbox and control board in place.

The motor/gearbox needs to be installed so that the center of the spindle is 6" (152mm) from the end of the plate, for

units produced after August 1, 2022. For units produced before August 1, 2022, the spindle was set at 4 ¾”.

6” (152mm)

SW800 Installation Manual

14

Section 6.0 - Push and Pull Arms Installation

Following these simple steps will allow the door to be set up quickly and correctly. Refer to installation drawings below.

6.1 Push Standard Scissors Arm for 0" - 14" Reveals

Note: Base rail to be mounted flush with the bottom of the door frame.

A solid spacer material or filler may be required to compensate for any gap between the back of base rail and wall.

Ensure, before fixing base rail to the door frame, that access holes for power supply cables are in line, if required.

Step 1: With door closed, attach shoe of the arm to

the door panel @ 13” from hinge edge. Fig. 1.

Step 2: Install power section of the arm to the

spindle on the operator @ 85°-90° from the hinge

side. Fig. 2.

Step 3: Rotate the attached arm from the above

85°-90° to about 110° from the hinge side. Fig. 3.

Step 4: Align and connect both the arms of the shoe

and power section. Slide the adjustable track

together and tighten the screws. Fig. 4.

Increase or decrease spring pre-load by rotating the

power section arm while attaching to the spindle.

Fig. 2.

Step 5: Press TEST/LEARN button to begin the

learning cycle. See Learning Door Cycle.

SW800 Installation Manual

15

6.2 Pull Standard Angle Arm With Track for 0" to 4" Reveals

Notes: Operator to be mounted so that base of drive shaft is clear above the door top. See Installation Drawings. A solid

spacer material or filler may be required to compensate for any gap between the back of base rail and wall. Ensure,

before fixing base rail to the door frame, that access holes for power supply cables are in line, if required.

Step 1. Without PULL arm fitted, set 3-position switch to Hold Open (II). The drive shaft will turn fully until hitting the

in-built fixed doorstop, so charging the spring.

Step 2. Manually open the door to

full Step 2. Manually open the door to

full open (approx. 100open position).

Fit PULL arm to the drive shaft at the full

open position so the roller touches the

door.

Mark the open position where roller

touches the door.

Step 3. Set 3-position switch to manual

(0) and allow the door to close under

spring power.

Mark the closed position where the

roller touches the door.

Step 4. Position slide track horizontally

within 1st and 2nd mark, then fix it to

the door.

Slide the roller along the channel,

followed by fitting end caps.

Step 5. Turn 3-position switch to automatic (I).

Press Test/Learn button to begin the learning cycle.

See Learning Door Cycle.

6”

SW800 Installation Manual

16

THIS PAGE INTENTIONALLY LEFT BLANK

SW800 Installation Manual

17

Section 7.0 - Learning Cycle and Start Up

"TEST/LEARN" button is currently used for two functions.

a. TEST - if the "TEST/LEARN" button is pressed for less than 3 seconds and released, an activation will be

generated.

b. LEARN - if the button is pressed for at least 4 seconds and released, a door re-learn is selected.

Re-learn is confirmed by pushing the "ENTER" button.

Re-learn can be cancelled by pushing the "TEST" or "MENU" or "UP" or "DOWN" button.

Step 1. Place a heavy item or your

foot at the desired full open position

at approx. 90open position.

Step 2. Press Test/Learn button for 3

seconds and release to begin the

learning cycle.

Step 3. Incorporating a unique

electronic stop, the door will learn the

full open position during a one-time

open/door cycle.

The door will open until it touches the

object at the desired full open

position.

Back-check and latching position are

automatically calculated and do not

need setting (unless adjustment is

required).

On the next activation, the door will

open, slow at back check, then stop at

the learnt opened position.

The door will not hit the in-built fixed

doorstop.

Note: The built-in mechanical doorstop should only act as a limiting device should the door be pushed past its pre-

set electronically selected open position.

micom

SW800 Installation Manual

18

Section 8.0 - Electronics Controller Programming

•Programming is quick and simple via the visual LED display.

•Each FUNCTION is clearly shown on the display in text, words, and symbols.

•The VALUE or APPLICATION can easily be adjusted using the buttons on the face of the controller.

•Changed menu values will automatically be saved during the next opening cycle.

SPECIAL WARNING

All Menu Values and Settings must comply with ANSI/BHMA A156.19 Standard

for Power Assist and Low Energy Power Operated Swing Doors.

8.1 Opening Speed (05-12 for Low energy) or (05-20 for Full Automatic)

•This setting is the door "Opening" speed from the fully closed position to the back-check position.

•Use the "UP" and "DOWN" buttons to select the desired door opening speed.

•Active the door to check the speed is correctly adjusted.

8.2 Back-check Speed (01-05)

•This setting is speed when the door reaches the back-check position to the full door opening.

•Use the "UP" and "DOWN" buttons to select the desired door back-check speed.

•Activate the door to check the speed is correctly adjusted.

8.3 Safety Speed (Hold/Crawl)

•This setting is door speed when "Safety 2" is active during the opening cycle.

•Use the "UP" and "DOWN" buttons to select either Hold or Crawl speed.

8.4 Closing Speed (01-15

•This setting is the door "closing" speed from the fully opened position to the Latch area.

•Use the "UP" and "DOWN" buttons to select the desired door "Closing" speed.

•Activate the door to check the speed is correctly adjusted.

8.5 Latch Speed (01-05)

•This setting is the door "Closing" speed in the Latch area until fully Closed.

•Use the "UP" and "DOWN buttons to select the desired door "Latching" speed.

•Activate the door to check the speed is correctly adjusted.

SW800 Installation Manual

19

8.6 Current Limit (01-20)

•In case the door encounters an obstruction during the Opening cycle, once the maximum Current limit is

reached for at least 2 seconds, the door Opening is then cancelled.

•Use the "UP" and "DOWN" buttons to select the desired "Current" limit strength.

•Activate the door to Open. During the Opening cycle, physically apply pressure to stall the door for at least 2

seconds.

•Check the force needed to reach the limit at which the door Opening is cancelled.

•Increase or Decrease this setting to achieve the correct strength needed.

•

Note: Setting of 10 is sufficient for most all applications.

8.7 Activation Time (01-60 seconds)

•This setting is the duration of the door Open cycle in seconds.

•The timer starts when the door starts to activate.

•Use the "UP" and "DOWN" buttons to select the desired "Opening" time.

8.8 Hold On Manual Open (No or 01-05 seconds)

•This setting is the length of time the door will be physically held Open, when the door is "Manually" pushed or

pulled open by a pedestrian.

•The door must be opened at least 60% of the door swing for this feature to activate.

•Use the "UP" and "DOWN" buttons to Enable or Disable this feature and set the timer value to keep open.

•Caution: Do not set timer for more than 1.0 seconds unless requested by the end user.

8.9 Electronic Door Stop (Yes/No)

•This feature is always Enabled even if you select Disabled.

8.10 Electric Lock (Yes/No)

•This setting is to Enable or disable the electric Lock/Strike through the Control unit.

•Select No when there is not an electric Lock.

•Use the "UP" and "DOWN" buttons to set the proper Electric Lock.

8.11 Electric Lock Delay (0.2-2.0 seconds)

•This setting is the length of time in seconds for the Delay between activating the Electric Lock and the Start of

the Opening cycle.

•Use the "UP" and "DOWN" buttons to Disable or Enable the electronic Delay/Output.

•Note: Setting of 0.2 seconds is sufficient for most applications.

8.12 Latch Position (2%-30%)

•This setting will adjust the door Latch position during the Closing cycle.

•Use the "UP" and "DOWN" buttons to set the starting point for the Latch position.

•Activate the door. During the Closing cycle, check the Latch starting position where the door begins to slow

down.

•Check this setting is correctly adjusted.

•If stack pressure is preventing the door from Fully Closing, set at 30% and activate the Power Close feature.

SW800 Installation Manual

20

8.13 Back-check Position (70%-98%)

•This setting is to adjust the door Back-check position of the Opening cycle.

•Use the "UP" and "DOWN" buttons to set the starting point for the Back-check position.

•Activate the door. During the Opening cycle, check the position where the Back-check begins and the door

starts to slow down.

•Check this setting is correctly adjusted.

•In windy conditions, set to 70%.

8.14 Push & Go (Yes/No)

•This setting is to Enable or Disable the Push & Go feature, also known as Manual Activation, when the door is

Manually pushed or pulled open by hand.

•Caution: Do not activate this feature without training and specifically requested by the end user.

•Use the "UP" and "DOWN" buttons to Disable or Enable this feature.

8.15 Push & Go Active Time (01-30 seconds)

•This setting is to adjust the duration of the door Open cycle in seconds from when the door is Manually pushed

Open to when the Push & Go feature is enabled.

•Use the "UP" and "DOWN" buttons to select the desired Opening time.

8.16 Power Close (Yes/No)

•WARNING: You should always install a Presence Safety sensor when Enabling this feature.

•This setting is to Enable or Disable the Power Close Assist feature.

•When Power Close is "ON", should the door reach the Latch position and cannot fully Close after 3 seconds,

the motor will assist the spring in order to fully Close the door.

This feature is used when the pressures on the door prevent the door from fully Closing

•Use the "UP" and "DOWN" buttons to Enable or Disable this feature.

8.17 Power Close Force (01-05)

•This setting will allow you to increase or decrease the amount of Closing Force needed to fully Close the door

at the Latch position.

•This feature is used to counter act Stack or Wind pressures.

•IMPORTANT: When using the Power Close Force feature, we strongly recommend to wire a Presence Safety

sensor into the input (PC Cancel" on the control board terminal that Cancels out this feature when a pedestrian

presence is detected. PC = Power Close.

•Use the "UP" and "DOWN" buttons to select the desired Closing Force. Use the lowest Force setting needed to

ensure positive Latching in these conditions.

•Check this setting is correctly adjusted.

8.18 Door Seal (Yes/No) Not an Active Function.

Table of contents

Other Micom Door Opening System manuals

Popular Door Opening System manuals by other brands

LCN

LCN 4050 Series installation instructions

Sesamo

Sesamo smart PRO operating instructions

Assa Abloy

Assa Abloy effeff ePED 1386Z1LB7 04S0 Series Brief instructions

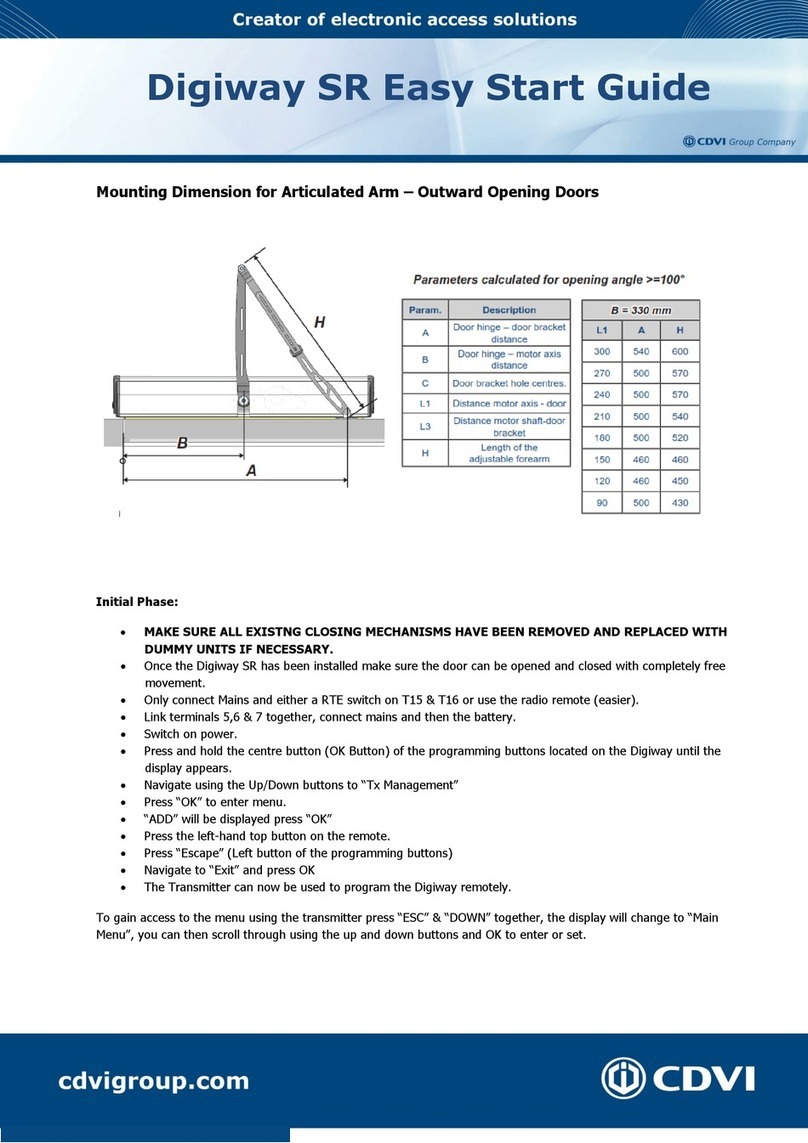

CDVI

CDVI Digiway SR Easy start guide

4Ddoors

4Ddoors 4DR2 Installation instructions and user guide

Assa Abloy

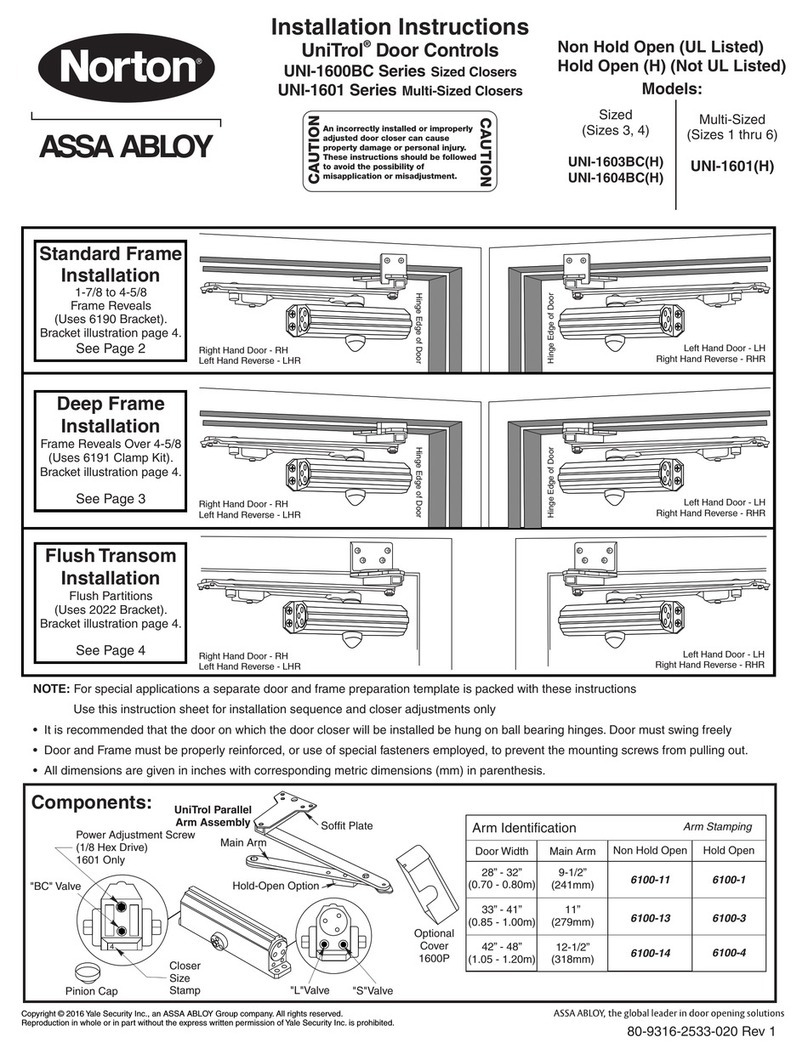

Assa Abloy Norton UniTrol UNI-1600BC Series installation instructions

BFT

BFT BOTTICELLI SMART BT A 850-1250 Installation and user manual

cinetto

cinetto PB15 Assembly instructions

Assa Abloy

Assa Abloy Sargent FIREGUARD 2408 Series Wiring instructions

Assa Abloy

Assa Abloy Corbin Russwin ED7400 Series installation instructions

Dorma

Dorma 7400 DS manual

WITTUR

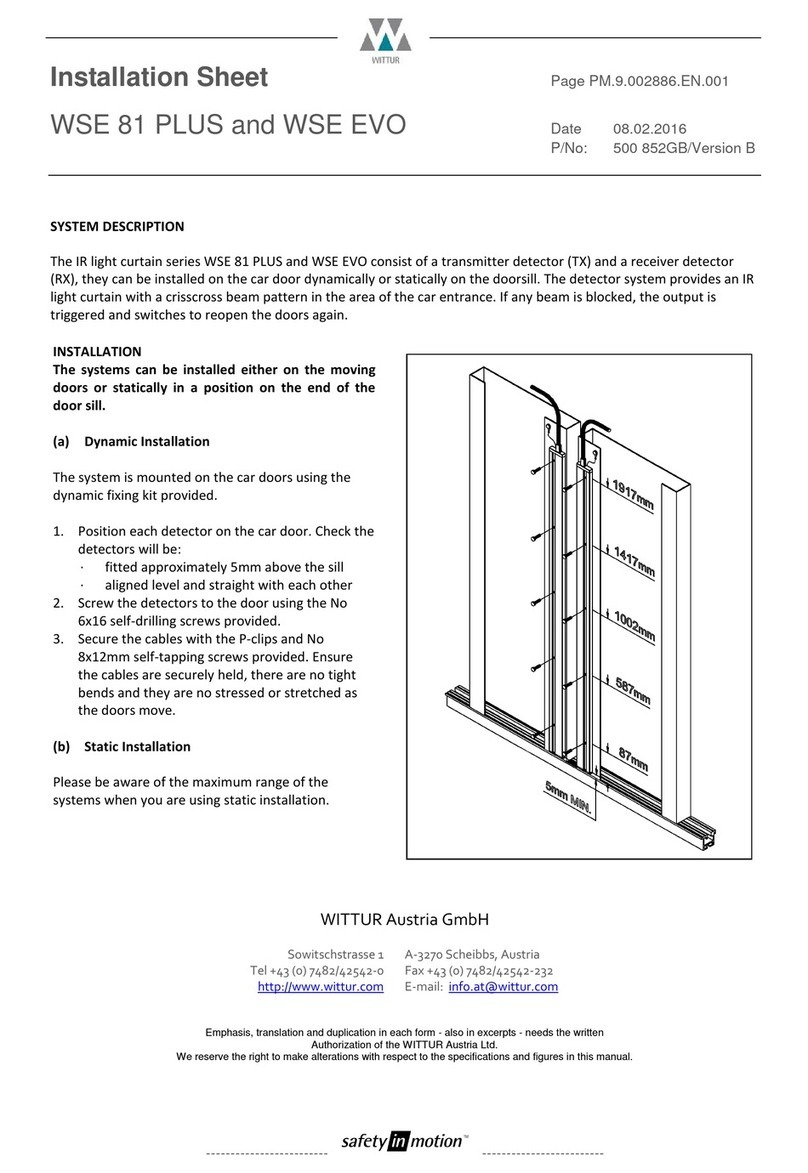

WITTUR WSE 81 PLUS Series Installation sheet