Micos ORM 96 Series Guide

1

Instructions for installation of distribution box, series ORM 96,

ORM 96 SIS ZK, ORM 96 SIS

Table of contents

1. Installation of ORM 96, ORM 96 SIS ZK, ORM 96 SIS 2

2. Equipment of the distribution box 4

2.1. Door removal/mounting 4

2.2. Roof removal/mounting 4

2.3. Equipping the tilting frame with accessories 4

2.3.1. Tilting frame removal/mounting 4

2.3.2. Connector panel removal/mounting 5

2.3.3. Plastic lug removal/mounting 5

2.3.4. Cassette module holder removal/mounting 6

2.4. Installation of SAFetNET modules and cassettes of SE type 6

2.4.1. Working with the module –cassette removal / installation 6

2.4.2. Working with the module –module installation / removal 7

2.5. Installation of cables 8

2.5.1. Working with the module - selection and installation of the fixing holder 10

2.6. Installation of pigtails 10

2.7. Installation of fibres in modules and cassettes 11

2.7.1. Conducting fibres in the modules 11

2.7.2. Conducting the fibres into cassettes 12

2.7.3. Conducting the fibres in the cassette 12

2.7.4. Preparation for fibre splicing 13

2.7.5. Placement of the unconnected fibre length reserve in the cassette 13

2.8. Installation of patchcords 14

2.9. Example of implementation 16

3. Optional Accessories 17

2

ORM 96

ORM 96 SIS ZK

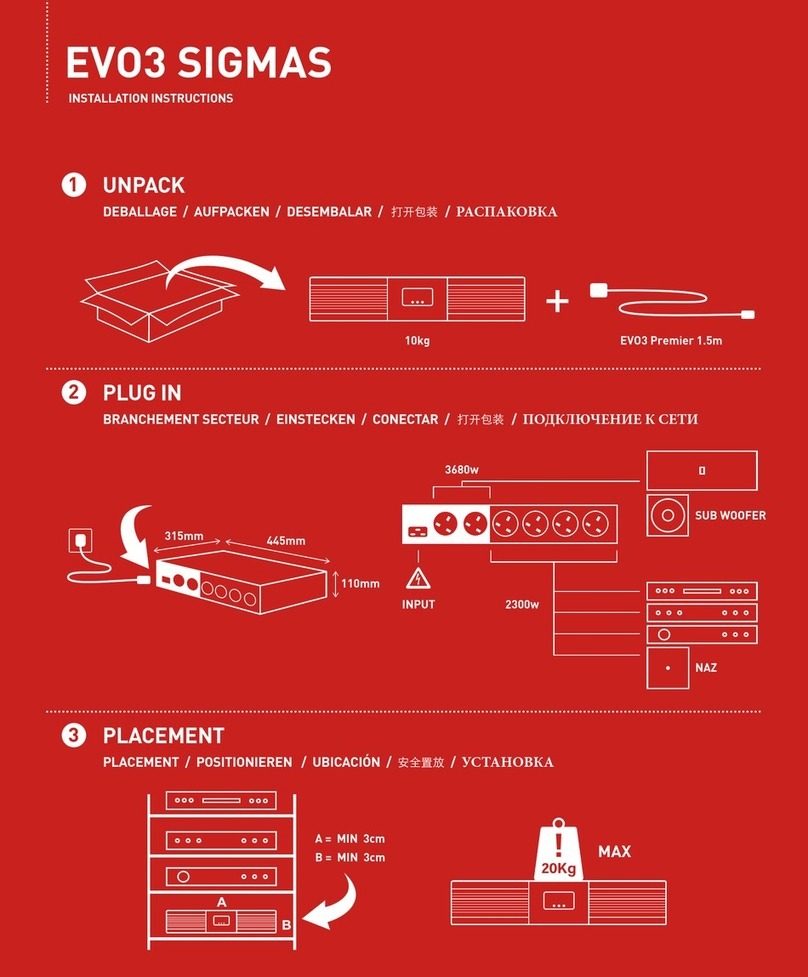

1. Installation of ORM 96, ORM 96 SIS ZK, ORM 96 SIS

ORM 96 SIS - Once unpacked, assemble the base.

Use two woodscrews to install the spacer bar.

3

Using four wood screws and washers, attach the

stand to the base, making use of the predrilled

holes.

The base must be buried in the ground all along

its height (it should not protrude above the ground

level) so that its upper part is at the level of the

surrounding terrain. If the terrain around the base

is uneven (e.g. ORU 5 SDF SIS is situated on a

sloping hillside), level the terrain surface to a

distance of 50 cm on each side of the base to

make it flat. Once the HDPE ducts are installed

and the soil is backfilled, compact the

surroundings thoroughly.

ORM 96 SIS ZK - The distribution box is fastened

to the floor using four bolts.

ORM 96 - Drill four holes, Ø 6.2mm, into the rear

panel of the distribution box. The holes should be

drilled in the centre of the holes in the rear

assembly panel. Attach the distribution box at the

desired position using four wood screws with Ø

6mm. Drill holes in the wall for Ø 10 mm dowels.

4

2. Equipment of the distribution box

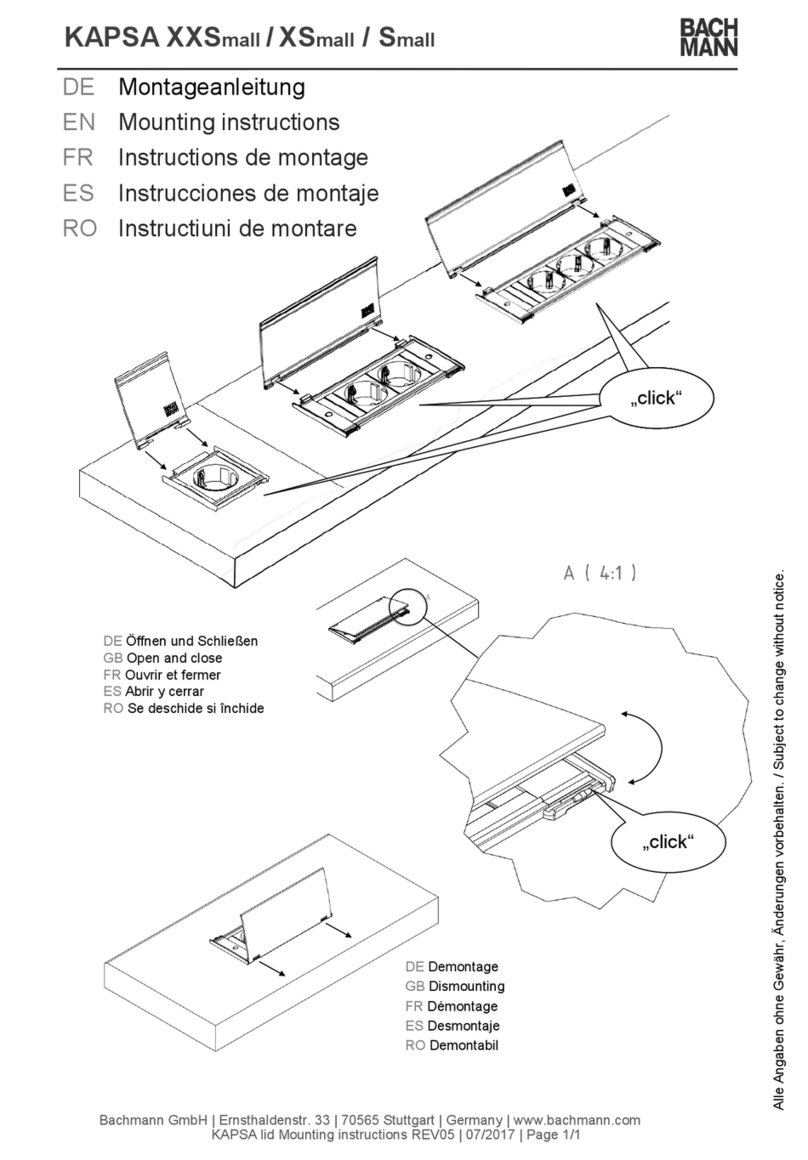

2.1. Door removal/mounting

The distribution box door can be easily removed by

releasing the lower hinge. The upper hinge is not

removable.

Loosen the lower hinge by sliding it upwards,

using a flat tip screwdriver. Once the hinge has

been released, slide the door out. The frame

shall be mounted following the steps above in the

reverse order.

2.2. Roof removal/mounting

Remove the roof by unscrewing the four wing nuts from the inside. The frame shall be mounted following

the steps above in the reverse order.

2.3. Equipping the tilting frame with accessories

2.3.1. Tilting frame removal/mounting

Unlock the tilting frame by turning the tabs in its

upper part in the direction of the arrows (left, right).

Once unlocked, tilt the frame.

5

Remove the tilting frame from the distribution box

by unhooking the securing straps.

Remove the frame by moving the frame up and

towards you. The frame shall be mounted

following the steps above in the reverse order.

2.3.2. Connector panel removal/mounting

Unlock the panel by partly pulling out the locking

pins.

Slide the panel upwards. The frame shall be

mounted following the steps above in the reverse

order.

2.3.3. Plastic lug removal/mounting

Squeeze the lugs.

Unlock the lugs by sliding

them in the direction of the

arrow and remove them

from the holes.

The frame shall be mounted

following the steps above in the

reverse order.

6

2.3.4. Cassette module holder removal/mounting

Remove the module holder by loosening the screw

with a knurled head.

Tilt the module holder and slide it out of the

groove in the frame.

2.4. Installation of SAFetNET modules and cassettes of SE type

The protective cover is hung on the module on

risers marked by arrows.

Release the cover by sliding it out.

2.4.1. Working with the module –cassette removal / installation

Push the tab (in the direction of the arrow) and slide

the cassette out to the right.

7

2.4.2. Working with the module –module installation / removal

Release the Velcro from the removed module

holder.

Remove the upper clip by sliding it out of the

module holder.

Slide in the cassette module from the upper part of

the module holder.

Install the modules from the bottom of the module

holders.

Push the module into the holder. Check the position

of the three tabs for correct installation.

Fasten a clip above the top module.

8

Number the cassettes, as required (see accessory

bag).

2.5. Installation of cables

Insert the cable to the distribution box through PG

13.5 or PG 21 bushing. Remove the cable jacket

and other protective features from the minicable

along the required length (see the table below) so

that the buffers with fibres and the central pulling

element remain free.

Cut off the central pulling element of the

minicable to the required length and fix with the

pulling element holder screwed to the rear panel

of the distribution box.

Cable or minicable length required for its termination in the distribution box.

Reserve required

for the removal

and tilting of the

frame

Access to the

module

Fibre reserve in

the module

Total required

length

2.0m

0.3-0.7m

2.0m

4.7m

9

In the ORM 96 SIS ZK version, fasten the cable

with a retainer of the corresponding size to the L

section in the pedestal.

Installation of buffers in ORM 96.

Place the cable or minicable reserve in the

management rings at the back of the distribution

box. Tie the buffers together so that they can be

unfolded and the tilting frame may be removed from

the distribution box.

Tie the buffers with PVC draw bands every

100mm to 150mm, or use a spiral tape as shown

in the picture.

Conduct the cable or minicable buffers from underneath the tilting frame and fix them with two PVC draw

bands, or terminate them in a standard way, see step 2.5.1.

reserve of 1.5

turns, approx. 2m

10

2.5.1. Working with the module - selection and installation of the fixing holder

The fixing holders of various sizes are delivered in

the module accessory bags. Select a holder of

appropriate size to fit the buffer duct firmly. Use the

measuring tool for the selection.

Install the fixing holders by sliding them into their

position as indicated by the arrows in the picture.

Each position can hold up to 3 fixing holders.

Remove the protection buffer duct from the buffers,

so that the duct ends at the mark on the module

body. Place the buffer duct to the fixing holder and

insert slide the holder to the module.

Push the fixing holder, until it stops.

2.6. Installation of pigtails

Remove the plexiglass covers from the connector panel. Attach adapters to the connector panel and connect

pigtails from the rear side. Conduct the pigtail fibres to the cassette modules through the management rings.

The mark of the end

of the protective

duct.

Měřící nástroj

Measuring instrument

Slide the plexi on and

snap the plastic pins.

11

Conducting pigtail fibres.

Tie the bundles of pigtail with tight secondary

protection fibres with a spiral tape and fix them

to the module body with a draw band, or

introduce the fibres to the protective duct and

use the fixing holder, see section 2.5.1. Max. 6

0.9 mm fibres may be conducted into a single SE

cassette.

Zvláken pigtails with free secondary protection

secondary protection to remove the required length.

12-fiber bundle, wrap bandage tape as shown.

Fiber bundle to fix the housing module fixation

holder see. Point 2.5.1. Max. 12 0.250 mm

fibres may be conducted into a single SE

cassette.

2.7. Installation of fibres in modules and cassettes

While working with modules and cassettes, it is recommended to remove the frame from the distribution box

and mount it onto the assembly stand (the stand is not provided).

0,9mm

0,25mm

12

2.7.1. Conducting fibres in the modules

In zone 1 fibres are distributed between the modules. Prior to commencing the assembly, all fibres must be

cleaned. The fibres may be conducted into any of the modules using the side access points. The primary rule

to adhere to is that fibres shall be taken into the module containing the cassettes where the fibres are placed.

2.7.2. Conducting the fibres into cassettes

Conducting the fibres into SE cassettes.

In zone 2 cassettes are selected and fibres are distributed into the corresponding cassettes. The fibres are

introduced into the SE cassette parallel with the edge of the cassette.

2.7.3. Conducting the fibres in the cassette

While working with cassettes, use the cassette

securing tool.

13

Place the fibre reserve into the cassette with the maximum possible bending radius.

2.7.4. Preparation for fibre splicing

Fibre length reserve in the cassette (for each side from the splice)

Cassette type

SE

min

650mm

Fibre diameter 250µm

max

2050mm

900µm

max

1500mm

mix 250/900µm

max

1500mm

Splice the fibres and place the splice protectors into the splice holder.

2.7.5. Placement of the unconnected fibre length reserve in the cassette

14

Fibre reserve length

Cassette type

SE

min

1000mm

Fibre diameter 250µm

max

2500mm

900µm

max

1500mm

mix 250/900µm

max

1900mm

Place the fibre ends into the centre of the cassette.

Close the upper cassette with the lid, place the cassette securing tool on the lid and fix it with Velcro.

2.8. Installation of patchcords

Conduct the patchcords to the distribution box through the bushings PG 29/24 (sealing included in the

accessory bag). Blind the vacant holes in the PG bushing with the pins supplied. Place the patchrecord

reserve in the plastic holders and management rings at the back of the distribution box. Tie the fibres together

so that they can be unfolded and the tilting frame may be removed from the distribution box. Connect the

patchcord connectors into the adapters from the front side of the panel.

15

Conducting patchcords taken in through the first

and second bushing.

Conducting patchcords taken in through the third

and fourth bushing.

Required patchcord reserve length.

Reserve required

for the removal

and tilting of the

frame

Access to the

module

Total required

length

2.0m

0.3-0.7m

2.7m

Conducting patchcords on the connector panel.

16

Conduct the patchcords into the tilting frame from the left-hand or right-hand side through the management

rings. After installation, group the patchcords with the Velcro in common bundles so that the tilting frame may

be removed if necessary.

reserve of 1.5

turns, approx. 2m

17

2.9. Example of implementation

Example of equipment.

18

3. Optional Accessories

SE module for 36 splices. - Subscriber unit kit.

SE module lid.

RECORDsplice holder.

Splice mechanical protector holder FIBRLOK II

2529 for 4 splices.

Betterman retainer 8 –12,

12 –16,

16 –22,

22 –28,

28 –34,

34 –40.

Assembly stand.

Contact:

MICOS spol. s r.o. divize TELCOM

Vápenice 17

796 01 Prostějov, Czech Republic

tel.: +420 582 307 111, fax.: +420 582 331 919

E-Mail: telcom@micos.cz; www.micos.cz

This manual suits for next models

2

Table of contents