3

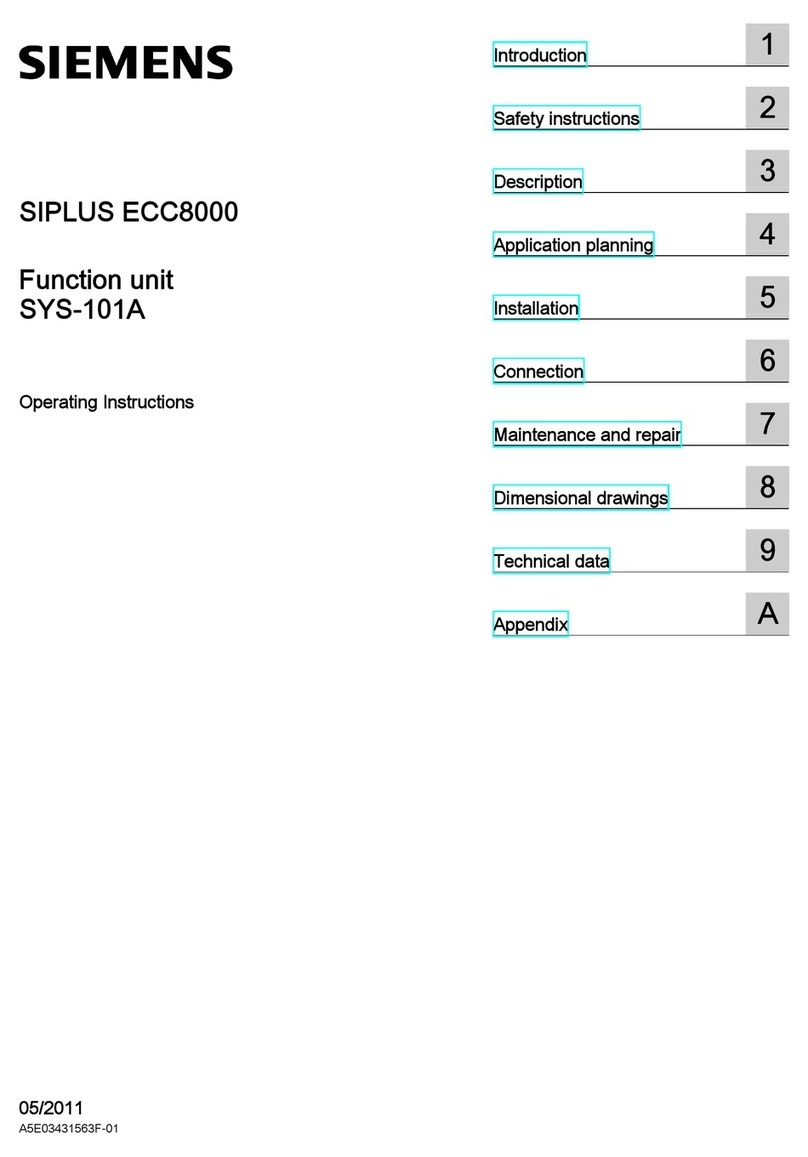

Table of Contents

Chapter - 1. MCS-BMS-GATEWAYS .......................................................................................................5

1.1. MCS-BMS-GATEWAY (Model with LonTalk) ...............................................................................................5

1.1.1 LONTALK Protocol..............................................................................................................................5

1.2. MCS-BMS-GATEWAY-NL (Model NO LonTalk) ...........................................................................................5

1.3. MCS-BMS-GATEWAY-N54 (Model NO LonTalk) .........................................................................................5

Chapter - 2. NETWORK PROTOCOLS ..................................................................................................6

2.1. MCS-MAGNUM BMS PROTOCOLS............................................................................................................6

2.1.1 BACnet OVER IP PROTOCOL...........................................................................................................6

2.1.2 ETHERNET NETWORK PROTOCOL ................................................................................................6

2.1.3 MODBUS RTU PROTOCOL...............................................................................................................7

2.1.4 MODBUS TCP/IP PROTOCOL...........................................................................................................7

2.2. PROTOCOLS USING MCS-BMS-GATEWAY ..............................................................................................7

2.3. Protocols MCS controllers support: ..............................................................................................................8

2.4. MCS-MAGNUM USING RS-485 ..................................................................................................................9

2.5. Wiring Multiple MCS Controllers.................................................................................................................10

2.6. EXAMPLE NETWORK ...............................................................................................................................11

2.6.1 Standalone MCS-Magnum ...............................................................................................................11

2.6.2 MULTIPLE MCS-MAGNUM ENCLOSURES ....................................................................................12

2.7. MULTIPLE MCS-MAGNUM BMS RS485 WIRING DIAGRAM..................................................................13

Chapter - 3. MCS-BMS-GATEWAY & NL FIELDSERVER TOOLBOX ................................14

Chapter - 4. Setup-MCS-BMS-GATEWAY & GATEWAY-NL .......................................................17

4.1. Record Identication Data ..........................................................................................................................17

4.2. Conguring Device Communications .........................................................................................................17

4.2.1 Set COM settings on all Devices Connected to the MCS-BMS-GATEWAY .....................................17

4.2.2 Set IP Address for each MCS-MAGNUM connected to the MCS-BMS-GATEWAY .........................17

4.3. BMS Network Settings: ..............................................................................................................................18

4.3.1 BACnet MS/TP, N2 and Modbus IP to RTU......................................................................................18

Figure 5 Protocol Selection Switch Tables........................................................................................................18

4.3.2 BACnet MS/TP: Setting the MAC Address for BMS Network ...........................................................18

4.3.3 BACnet MS/TP and BACnet/IP: Setting the Device Instance ..........................................................19

4.3.4 Metasys N2: Setting the Node-ID .....................................................................................................19

4.3.5 BACnet MS/TP: Setting the Serial Baud Rate for BMS Network......................................................19

4.3.5.1. Baud Rate DIP Switch Selection ..........................................................................................20

Chapter - 5. Interfacing MCS-BMS-GATEWAY to Devices .........................................................21

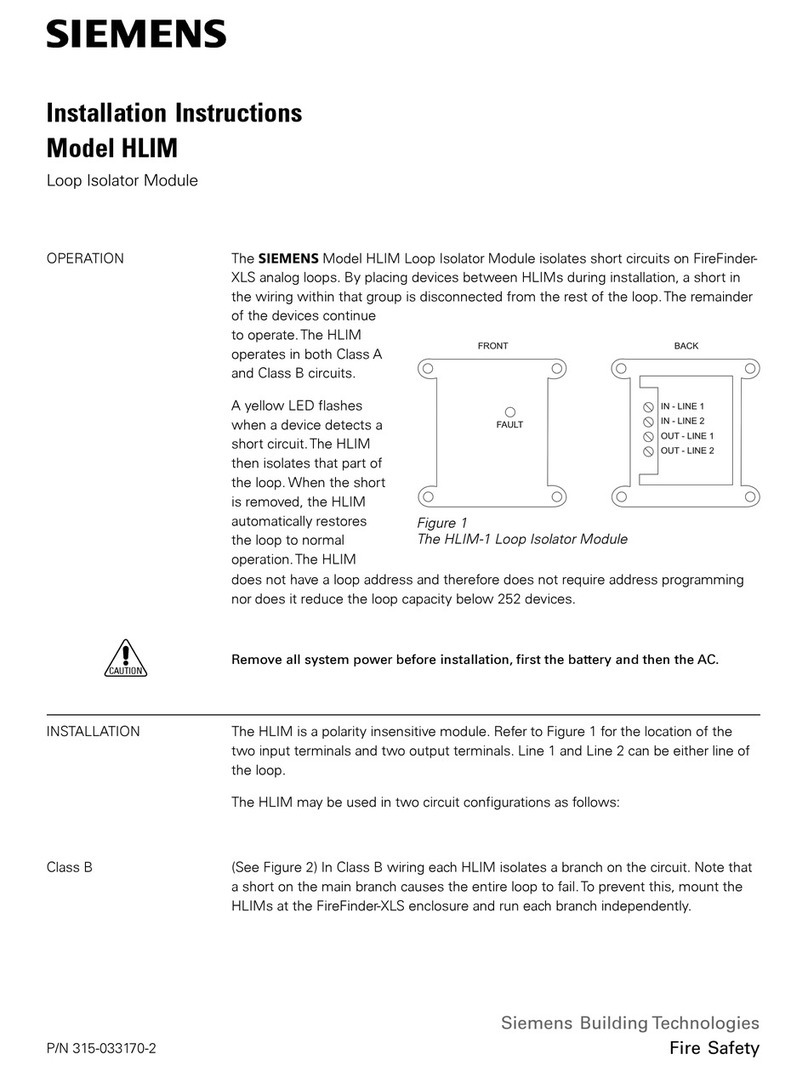

5.1. MCS-BMS-GATEWAY Connection Ports....................................................................................................21

5.2. Wiring diagram for connecting the MCS-Magnum......................................................................................22

5.3. Device Connections to MCS-BMS-GATEWAY ...........................................................................................23

5.4. MCS-MAGNUM Address Settings ..............................................................................................................23

5.5. Biasing the RS-485 Device Network ..........................................................................................................25

5.6. End of Line Termination Switch for the Modbus RS-485 Device Network..................................................25

5.7. Power-Up MCS-BMS-GATEWAY ...............................................................................................................26

Chapter - 6. MCS-BMS-GATEWAY-N54 START-UP GUIDE ........................................................27

Chapter - 7. BMS SWITCH SETTINGS ...............................................................................................54

7.1. BMS Address DIP Switch Settings .............................................................................................................54

Chapter - 8. APPENDIX - INPUT / OUTPUT POINTS / STATES ..............................................60

8.1. Sensor Input Points ....................................................................................................................................60

8.2. Relay Output Points....................................................................................................................................61

8.3. ANALOG Output Points..............................................................................................................................62

8.4. Setpoints.....................................................................................................................................................62

8.5. Chiller/Compressor States..........................................................................................................................62

8.6. Other Points................................................................................................................................................63

8.7. Network inputs to MCS-MAGNUM .............................................................................................................66

8.8. MCS Capacity Control State Chart.............................................................................................................67