4 Assembly, removal, and electrical installation..........................................................................4-1

4.1 Assembly and removal.......................................................................................4-1

4.1.1 Unpacking the module ........................................................................4-1

4.1.2 General ...............................................................................................4-1

4.1.3 Setting the DIP switches .....................................................................4-2

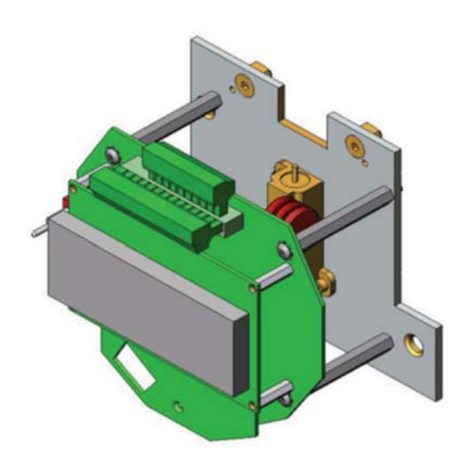

4.1.4 Assembly and removal of the safety module ......................................4-3

4.2 Electrical installation...........................................................................................4-5

4.2.1 Electrical installation of the VersaPoint station ...................................4-5

4.2.2 Electrical installation of the safety module ..........................................4-6

5 Parameterization of the safety module.....................................................................................5-1

5.1 Parameterization in a VersaSafe system...........................................................5-1

5.2 Parameterization in a PROFIsafe system..........................................................5-1

5.3 Parameterization of the safe relay outputs.........................................................5-2

5.4 Behavior of the relay outputs in the event of enabled switch-off delay for

stop category 1...................................................................................................5-4

5.5 Parameterization of clock outputs and alarm inputs...........................................5-5

6 Connection examples for the safe relay outputs and the safety-related segment circuit .........6-1

6.1 Explanation of the examples..............................................................................6-1

6.2 Notes on the protective circuit for external relays/contactors

(free running circuit) ...........................................................................................6-2

6.3 Measures required to achieve a specific safety integrity level ...........................6-3

6.4 Single-channel assignment of safe relay outputs...............................................6-5

6.5 Two-channel assignment of floating contacts ....................................................6-9

6.5.1 Monitoring via common readback .......................................................6-9

6.5.2 Monitoring via separate readback ....................................................6-13

6.5.3 External monitoring ...........................................................................6-16

6.6 Safety-related segment circuit..........................................................................6-17

6.6.1 Assignment with single-channel actuators .......................................6-19

6.6.2 Assignment with two-channel actuators: Use of DO terminals .........6-22

7 Determining PFH, PFD, and MTTFd...............................................................................................................7-1

7.1 Single-channel operation ...................................................................................7-1

7.1.1 Determining PFD for single-channel operation ...................................7-1

7.1.2 Determining PFH for single-channel operation ...................................7-1

7.1.3 Determining MTTFdfor single-channel operation ...............................7-2

7.2 Two-channel operation.......................................................................................7-3

7.2.1 Determining PFD for two-channel operation ......................................7-3

7.2.2 Determining PFH for two-channel operation ......................................7-3

7.2.3 Determining MTTFdfor two-channel operation ..................................7-5

7.3 Other marginal conditions ..................................................................................7-5

ii User manual IC220SDL840 - May 2018 GFK-2734