Micro Detectors SB400M User manual

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

SB400M

Safety Modules

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ESB1261501

1/19

!

!

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

SB400M

Safety Modules

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ESB1261501

2/19

!

!

CONTENTS

1.0 INTRODUCTION ..................................................................................................... 3

2.0 SB400M MODULE ................................................................................................... 4

2.1 OPERATING MODES DESCRIPTION .................................................................... 4

2.1.1 AUTOMATIC.................................................................................................. 4

2.1.2 MANUAL........................................................................................................ 5

2.1.3 CONNECTION OF K1 K2 EXTERNAL CONTACTORS....................................... 6

2.2 CONNECTION EXAMPLES.................................................................................... 7

2.2.1 CONNECTION OF AD SRM WITH AN LS BARRIER (MANUAL

MODE,WORKING RANGE=HI, K1K2 EXTERNAL CONTACTORS, TIMEOUT

MUTING=30s) ........................................................................................................... 7

2.3 MUTING FUNCTION ............................................................................................ 7

2.3.1 Muting sequence .......................................................................................... 8

2.3.2 MUTING OVERRIDE FUNCTION.................................................................... 9

2.3.3 Override with mantained action control .................................................... 10

2.3.4 Override with pulse control........................................................................ 10

2.4 INSTALLATION AND ELECTRICAL CONNECTIONS............................................ 11

2.5 INSTALLATION AND ELECTRICAL CONNECTIONS............................................ 11

2.5.1 Characteristics of the output circuit........................................................... 12

2.5.2 Use of K1 and K2 auxiliary contact elements............................................. 12

2.5.3 Warnings regarding the connection cables................................................ 12

2.6 SIGNALS DESCRIPTION.................................................................................... 13

2.7 The RESTART command.................................................................................... 14

2.8 K1K2 FEEDBACK input ...................................................................................... 14

2.9 SYSTEM STATUS output.................................................................................... 14

2.10 DIMENSIONS .................................................................................................... 14

2.11 TECHNICAL DATA SB400M ............................................................................... 15

2.12 STATUS INDICATORS / FAULT DIAGNOSIS ..................................................... 15

2.12.1 Status indicators (BASE MODULE) ............................................................. 16

2.12.2 Status indicators (BASE MODULE) ............................................................. 16

2.12.3 Status Fault diagnosis ................................................................................ 16

2.12.4 Status indicators (MUTING MODULE) ........................................................ 17

2.13 PERIODIC TESTS TO DO EVERY YEAR .............................................................. 18

2.14 GUARANTEE ...................................................................................................... 19

! !

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

SB400M

Safety Modules

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ESB1261501

3/19

!

!

!This symbol indicates an important personal safety warning. Failure to comply with the warning

may result in very high risk for exposed personnel.

1.0 INTRODUCTION

The SB400M interface, connected to an IEC 61496 – ½certified type 4 safety light curtain and

equipped with two autocontrolled PNP type solid-state outputs, is a type 4 ESPE (Electro sensitive

Protective Equipment).

The other characteristics indicated above remaining constant, if the light curtain is type 2, the

entire ESPE will be type 2.

The SB400M main features are the following:

•Inputs for the connection of one safety barrier with fail safe outputs

•Restart manual or automatic selectable

•2 N.O. outputs with guided contact safety relays

•1 system monitor PNP output

•1 external contactors feedback input

•Muting function with two sensors logic

•1 muting function enable input

•1 muting lamp output

•Muting override function integrated

•Selectable muting timeout

The safety modules also guarantees that:

•the output lines are open if the barrier is intercepted;

•the output lines are enabled only with correct response times;

•in manual mode, maintenance of the RESTART contact closed is not interpreted as AUTO

mode.

!For safe use of the device, it is essential to read and understand the contents of this handbook.

!Failure to comply with the prescriptions indicated in this handbook may result in very high risks

for the operating personnel of the machine protected.

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

SB400M

Safety Modules

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ESB1261501

4/19

!

!

2.0 SB400M MODULE

2.1 OPERATING MODES DESCRIPTION

OPERATING MODES SELECTION

TERMINAL 6

TERMINAL 15

OPERATION

0 Vdc

+24 Vdc

Automatic

+24 Vdc

+24 Vdc through a N.O. contact

Manual

0 Vdc

0 Vdc

Non-permissible

conditions

+24 Vdc

+24 Vdc

Table!1!

2.1.1 AUTOMATIC

In this operating mode, the outputs of the safety module follow the status of the photocell:

•with the protected area free (outputs of the barrier active), the relay outputs of the control

unit are active.

•with the protected area occupied (outputs of the barrier de-activated), the relay outputs of

the safety module are de-activated.

!

Figure!1

NOTE: refer to the "CONNECTON EXAMPLES" section to see the muting signals connection

! Use in manual mode (start/restart interlock activated) is mandatory in the case in which the

safety device controls an access protecting a danger zone and once a person has passed through

the opening, he/she may remain in the danger zone without being detected (use as trip device

according to IEC 61496). Failure to comply with this rule may result in very serious risks for the

persons exposed.

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

SB400M

Safety Modules

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ESB1261501

5/19

!

!

!Check correct functioning of the entire safety system (control unit+barrier) following each re-

installation. In particular, if the original operating mode was Manual, check that the unit has been

reconfigured in this mode.

2.1.2 MANUAL

In this operating mode, the outputs of the control unit are activated only if the protected area is

free and after sending the RESTART signal to the control unit using the push-button or by means

of a specific command on the RESTART input (terminal 15).

Once the protected area has been occupied, the relay outputs are deactivated.

The sequence described above must be repeated in order to re-activate these.

The RESTART command is active with with a 0 Vdc ---> +24 Vdc transition.

The minimum duration of the command is 100 ms.

!

Figure!2!

NOTE: refer to the "CONNECTON EXAMPLES" section to see the muting signals connection

!

!

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

SB400M

Safety Modules

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ESB1261501

6/19

!

!

2.1.3 CONNECTION OF K1 K2 EXTERNAL CONTACTORS

In this operating mode, the outputs of the control unit are activated only if the protected area is

free and after sending the RESTART signal to the control Control of external contactors K1K2 can

be activated in both operating modes. If this control is to be used, the set of normally closed

contacts of the external contactors must be connected to terminal 20 of the safety module (Figure

8 and Figure 9).

!

Figure!3

Automatic functioning with K1K2 relays

!

Figure!4

Manual operation with K1K2 relays

NOTE: refer to the "CONNECTON EXAMPLES" section to see the muting signals connection

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

SB400M

Safety Modules

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ESB1261501

7/19

!

!

2.2 CONNECTION EXAMPLES

2.2.1 CONNECTION OF AD SRM WITH AN LS BARRIER

(MANUAL MODE,WORKING RANGE=HI, K1K2 EXTERNAL

CONTACTORS, TIMEOUT MUTING=30s)

!

Figure!5!

!

2.3 MUTING FUNCTION

!The muting function is a temporary suspension of the safety light curtain’s protective function.

Carefully check your risk analysis in order to assess whether the muting function is compatible with

your application and what additional measures have to be taken.

The muting function generates a temporary, automatic interruption of the protective action of the

barrier in order to permit normal transit of material through the guarded opening.

The muting function is activated when the system detects the object that interrupts the opening

protected. In other words, when the system recognizes the material and distinguishes between

this and any operator (in a potentially dangerous situation), it is enabled to bypass the light curtain

temporarily, allowing the material to pass through the opening (Figure 11).

The muting sensors form the sensing system that decides whether the muting function is to be

activated (or not). Control of the dangerous opening can be de-activated only by a correct

sequence of interruption of the beams of the muting sensors.

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

SB400M

Safety Modules

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ESB1261501

8/19

!

!

!

Figure!6

Muting on palletizing system application example

2.3.1 Muting sequence

The timing diagrams in Figure 12 and Figure 13 show the correct signal sequence. The muting

function is initiated by the contemporary occurrence of two events :

•When the two beams of the muting sensors are activated within a time limit of 4 sec.

•When the muting enable signal (terminal 11) is high (+24 Vdc)

The muting function is terminated by one of the following events:

•As soon as one of the muting sensors is no longer activated whichever occurs first.

•When the muting time-out limit is expired; in this case the OSSDs are brought to the off-

state. The muting time-out limit can be selected at 30 s or ∞.

!The muting enable command will only enable the muting function and should be generated at

the appropriate time by the machine control system (e.g. When the muting function is needed); it

has no effect on the deactivation of the muting function. If not used, fix the terminal 11 at +24

Vdc.

!Remember that muting is a temporary automatic suspension of the safety function. This means

that a time limit is always mandatory. If a time out limit of 30 s is a too short time for a particular

machine cycle, the configuration without time monitoring (t = ∞) can be selected. In this case

alternative solutions or additional measures shall be implemented to detected the condition of a

muting function permananently active caused by accumulation of faults or by the muting sensors

activated all the time. For example for the application of guarding the openings of a conveyor

system (palletizers) by monitoring appropriate signals generated by the transport system to

determinate if and when a pallet is in the detection zone.

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

SB400M

Safety Modules

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ESB1261501

9/19

!

!

!

Figure!7

Muting Cycle

!

Figure!8

Muting cycle closed by a timeout

2.3.2 MUTING OVERRIDE FUNCTION

The OVERRIDE function must be used when the machine stops due to incorrect muting activation

sequences with the material obstructing the guarded opening.

In this situation, the OSSD outputs are not active as the barrier and/or at least one Muting sensor

is occupied. In this condition the OVERRIDE request LED blinks (ref. "Status Indicators").

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

SB400M

Safety Modules

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ESB1261501

10/19

!

!This function activates the OSSD outputs making it possible to remove the material that is

obstructing the protected field.

!Throughout the phase during which the OVERRIDE function is active, the OVERRIDE/MUTING

light blinks. Check efficiency of this light periodically (during the Muting or Override phases).

!Warning!! The Override with pulse command automatically activates the outputs of the light

curtain until both the light curtain and the muting sensors are free of obstacles again. During this

period, the light curtain is unable to protect access to the guarded opening. Therefore, all

operations must be carried out under the strict supervision of expert personnel.

!During the installation of the module be sure to avoid short circuits between the contacts 7 and

8.

The operator will use the Override mode previously selected.

1. Override with mantained action control.

2. Override with pulse control.

2.3.3 Override with mantained action control

This function is activated driving terminals 7 and 8 of the control unit to +24 Vdc at the same time

(maximum delay = 400 ms) using for example a 2-way key selector with spring return;

PIN 7

PIN 8

CONDITION

0

0

Normal operation

24 Vdc

24 Vdc

OVERRIDE request

The maximum override duration is 15 minutes; it can be stopped for two different causes.

@ When the selector is released or if the 15 minutes has been elapsed, override ends, de-

activating the OSSD outputs, turning off the muting lamp and showing normal condition on the

display. A new override condition can be started, releasing and rearming the selector.

@ Once the opening has been cleared and the sensors are free again, override ends and GUARD

condition (control unit in normal operation) is activated without necessity of further commands.

2.3.4 Override with pulse control

This function is activated inverting (maximum delay = 400 ms) the condition of pin 7 and 8 of the

receiver using for example a push button (switch). During the override the 7 and 8 are not

controlled.

PIN 7

PIN 8

CONDITION

0

24 Vdc

Normal operation

24 Vdc

0

OVERRIDE request

!The override condition can last a maximum of 15 minutes (repeatable).

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

SB400M

Safety Modules

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ESB1261501

11/19

!

!The function can only be re-started by pressing the pushbutton again (subject to the following

conditions):

1. Maximum total OVERRIDE time (after

n

consecutive requests) = 60 min

2. Maximum number of consecutive requests for OVERRIDE = 30.

!The override condition ends when the barrier and sensors are cleared (entrance clear) and the

GUARD condition is re-enabled (barrier fully operational) without sending any further commands.

!The timer (point 1) and counter (point 2) are reset when one of the following conditions occurs:

- A correct muting sequence.

- A system reset (switched off and then turned on).

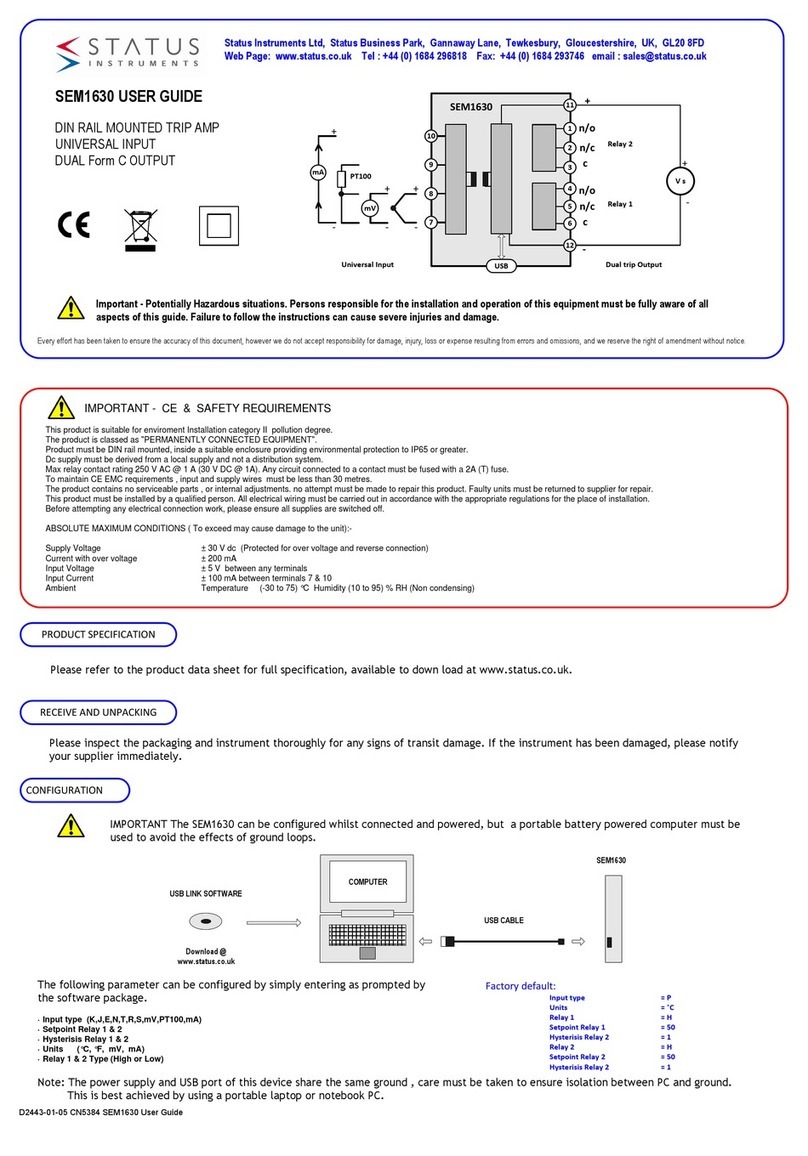

2.4 INSTALLATION AND ELECTRICAL CONNECTIONS

Figure 9

LED

COLOR

STATUS

CONDITION

S1

Green

OFF

Muting sensor 1 free

ON

Muting sensor 1 interrupted

S2

Red

OFF

Muting sensor 2 free

ON

Muting sensor 2 interrupted

MUT

Yellow

OFF

Correct operation

ON

Muting active

Blinking

Override request

Muting fail (only with FAIL

LED ON) *

IN

Green

OFF

Barrier interrupted

ON

Barrier free

FAIL

Red

OFF

No Failure

ON

Failure detected *

GUARD

BREAK

Green /

Red /

Yellow

RED

Output relays opened

RED blinking

The number of blinking shows

the kind of FAIL (only with

FAIL is ON) *

GREEN

Output relays closed

YELLOW

Barrier free – Output relays

opened (only in manual

mode)

Table 2

* M.D. MICRO DETECTORS TO THE “FAULT DIAGNOSI” SECTION

TO HAVE A DETAILED EXPLANATION OF THE POSSIBLE FAULT

2.5 INSTALLATION AND ELECTRICAL CONNECTIONS

!Install the SB400M safety module in an environment with a protection rating of at least IP54.

!If more modules SB400M must be installed in the same board panel, in order to avoid

overheatings, maintain between them one minimal distance of 2 cm.

!The SB400M control unit must be supplied with a 24 Vdc ±20%.

!The external power supply must comply with the standard EN 60204-1.

!During the installation of the SB400M control unit be sure to avoid short circuits between the

contacts 17 and 18.

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

SB400M

Safety Modules

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ESB1261501

12/19

!

2.5.1 Characteristics of the output circuit

For the output circuit, the control unit uses two guided contact safety relays.

These relays are rated by the manufacturer for voltage and current values above those indicated

in the technical data; however, to assure correct insulation and to avoid damage or premature

aging, protect each output line with a 4 A slow-blow fuse and check that load characteristics

comply with the indications given in the table below.

Minimum switching voltage

18 Vdc

Minimum switching current

20 mA

Maximum switching voltage

250 Vac

Maximum switching current

2 A

2.5.2 Use of K1 and K2 auxiliary contact elements

For loads with higher voltage and current characteristics than those indicated in the table above,

use of auxiliary external relays or contactors suitable for the load to be controlled is recommended.

•The K1 and K2 auxiliary contactors or relays must be of the guided contact safety type.

•Referring to the table below, pay particular attention to the configuration of the control

contacts on terminal 20 and that of the contacts of use.

Relay K1

Relay K2

Control contacts

K1-1 normally closed

K2-1 normally closed

Use contacts

K1-2 normally open

K2-2 normally open

•Control contacts K1-1 and K2-1 (terminal 20) must be able to switch a current of 20 mA

and a voltage of 24 Vdc.

•To increase the electrical life of internal relays A and B, it is advisable to use anti-

disturbance devices which must be connected across the coils of K1 and K2.

2.5.3 Warnings regarding the connection cables

•For light curtain/control unit connections of more than 50 m, cables with a cross-section of

at least 1 mm2must be used.

•It is good practice to separate the power supply of the control unit from that of other

electrical appliances (electrical motors, inverters, frequency variators) or other sources of

disturbance.

•The path of the connection cables between the control unit and the sensors, the

connection referring to the test command and feedback contacts connected to terminal 20

must be different from that of other power cables.

!

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

SB400M

Safety Modules

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ESB1261501

13/19

!

2.6 SIGNALS DESCRIPTION

TERMINAL

NUMBER

SIGNAL NAME

TYPE OF SIGNAL

DESCRIPTION

1

SENSOR 1

Input

Muting Sensor n°1

2

SENSOR 2

Input

Muting Sensor n°2

3

24 Vdc

Input

Power supply 24 Vdc

4

TIMEOUT 1

Input

Timeout selection n°1 *

5

TIMEOUT 2

Input

Timeout selection n°2 *

6

MAN / AUTO

Input

Manual/Automatic configuration

7

OVERRIDE 1

Input

Override selection n°1 **

8

OVERRIDE 2

Input

Override selection n°2 **

9

N.C.

-

-

10

MUTING LAMP

Output

Muting lamp output

11

MUTING ENABLE

Input

External muting enable input

12

Relay B NO 1

Output

Safety relay B, contact 1 (N.O.)

13

0 Vdc

Input

Power supply 0 Vdc

14

PE

-

Ground connection

15

RESTART

Input

Restart command Input

16

N.C.

-

-

17

INPUT1 BARR

Input

Barrier input 1

18

INPUT2 BARR

Input

Barrier input 2

19

N.C.

-

20

K1/K2 (Feedback)

Input

K1K2 external contactors feedback

21

SYSTEM STATUS

Output

Output safety relays status

22

Relay B NO 2

Output

Safety relay B, contact 2 (N.O.)

23

Relay A NO 1

Output

Safety relay A, contact 1 (N.O.)

24

Relay A NO 2

Output

Safety relay A, contact 2 (N.O.)

Table 3

* M.D. MICRO DETECTORS TO THE Table 4 FOR THE SELECTION OF THE MUTING TIMEOUT

Read carefully the "muting sequence" section to select the right timeout

SELECTION OF THE MUTING TIMEOUT

TERMINAL 4

TERMINAL 5

DURATA TIMEOUT

0 Vdc

+24 Vdc

30 s

+24 Vdc

0 Vdc

Infinite

0 Vdc

0 Vdc

Conditions

not allowed

+24 Vdc

+24 Vdc

Table 4

** REFER TO THE Table 5 FOR THE SELECTION OF THE OVERRIDE

SELECTION OF THE MUTING TIMEOUT

TERMINAL 7

TERMINAL 8

DURATA TIMEOUT

0 Vdc

0 Vdc

Spring return key

0 Vdc

+24 Vdc

Push button

+24 Vdc

0 Vdc

Conditions

not allowed

+24 Vdc

+24 Vdc

Table!5

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

SB400M

Safety Modules

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ESB1261501

14/19

!

2.7 The RESTART command

•The RESTART command must be sent to the control unit connecting terminal 15 to the +24

Vdc.

•The contact used for the RESTART command must be able to switch a voltage of 24 Vdc

and a current of 20 mA (guaranteeing a closing time > 100 ms). This data is particularly

important in the case of automatic management of sending of the RESTART command, for

example using a PLC.

•The SYSTEM RESET TIME is obtained adding the reset time of any external contactors

K1K2 to the reset time of the SB400M control unit (100 ms).

•In the case of manual activation, a normally open external button can be used, temporary

closing of which generates the RESTART command.

!The Restart command must be installed outside the danger area in a position where the danger

area and the entire work area concerned are clearly visible.

!It must not be possible to reach the RESTART control from inside the danger area.

2.8 K1K2 FEEDBACK input

Using the K1 and K2 auxiliary safety contactors with guided contact safety type, it is necessary to

connect the +24 Vdc to the K1K2 FEEDBACK through the series of the K1-1 e K2-1 N.O. control

contacts. The control of the correct switching of K1 and K2 is performed with a delay of 300ms

after the real command. When the K1-1 e K2-1 N.O. control contacts are not used (or no control is

provided) it is mandatory to connect the terminal 20 (K1K2 FEEDBACK) to the terminal 21

(SYSTEM STATUS).

2.9 SYSTEM STATUS output

The SYSTEM STATUS output reports exactly the output safety relays status :

•When the output relays are opened, the SYSTEM STATUS reports 0 Vdc.

•When the output relays are closed, the SYSTEM STATUS reports +24 Vdc.

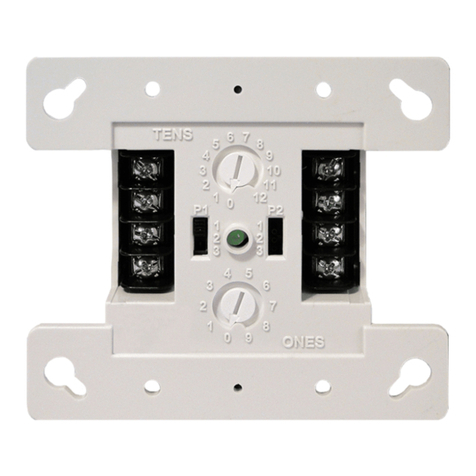

2.10 DIMENSIONS

!

Figure!10

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

SB400M

Safety Modules

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ESB1261501

15/19

!

2.11 TECHNICAL DATA SB400M

Safety category

Type 4

Power supply

Vdc

24 ± 20%

Power requirement

W

5 max

Output

Relay

2 N.O. contacts (2 A; 250 V)

Response time

ms

20 max

Operating modes

Manual or Automatic, selectable from terminal block

External Relay control

2 N.C. contacts (20 mA; 24 Vdc)

Number of connectable

barriers

1 (with 2 PNP safety static outputs)

Muting sensors input

2 sens. (24 Vdc; PNP; dark-on)

Muting enable input

24 Vdc, PNP

Time-out Override

min

15

System Status Output

100 mA; 24 Vdc

Muting lamp output

24 Vdc / 0,5 ÷ 5 W

Connections

Terminal block with protection against reversal of

polarity

Status indicator

LEDs

Power On – Barrier status – Fail

Max. length of connections

M

100

Operating temperature

°C

0 ÷ 55

Enclosure protection rating

IP 20

Terminal block protection

rating

IP 2X

Fastening

Fast attachment to rail according to EN 50022-35

Dimensions (h x w x d)

mm

99 x 22,5 x 114,5

Weight

g

150

B10d

800.000

Device lifetime

20 years

Safety level

Type 4

IEC 61496-1:2004

IEC 61496-2:2006

SIL 4

IEC 61508:1998

SILCL 4

IEC 62061:2005

Cat. 4

ISO 13849-1 : 2006

Load

Number of Commutations

PFHd *

DCavg #

MTTFd #

PL #

CCF #

2 A @

230Vac

1 every 30 s

2,80E-08

98,89%

25,97

d

80%

1 every min

1,71E-08

98,78%

49,92

e

80%

1 every hour

6,58E-09

98,78%

100,00

e

80%

1 every day

6,42E-09

96,25%

100,00

e

80%

0,5 A

@

24Vdc

1 every 30 s

5,03E-08

98,94%

13,25

d

80%

1 every min

2,80E-08

98,89%

25,97

d

80%

1 every hour

6,76E-09

97,01%

100,00

e

80%

1 every day

6,43E-09

96,28%

100,00

e

80%

Table!6

* IEC 61508

# ISO 13849-1

2.12 STATUS INDICATORS / FAULT DIAGNOSIS

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

SB400M

Safety Modules

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ESB1261501

16/19

!

2.12.1 Status indicators (BASE MODULE)

LED

MEANING

IN

FAIL

GUARD / BREAK

(GREEN)

(RED)

(RED/YELLOW/GREEN)

ON

ON

Red

Power up test

OFF

OFF

Red

Photocell interrupted

Output relays opened

ON

OFF

Yellow

Photocell free

Output relays opened

ON

OFF

Green

Photocell free

Output relays closed

Table!7

2.12.2 Status indicators (BASE MODULE)

LED

MEANING

SENSOR1

(YELLOW)

SENSOR2

(YELLOW)

MUTING (YELLOW)

ON

ON

ON

Power up test

OFF

OFF

OFF

Both the sensors are

free

ON

OFF

OFF

Sensor 1 interrupted

OFF

ON

OFF

Sensor 2 interrupted

ON

ON

ON

Muting active

Shows the

sensor_1 status

Shows the

sensor_2 status

Blinking

Override request

Table!8

2.12.3 Status Fault diagnosis

LED

MEANING

IN

FAIL

GUARD/BREAK

GREEN

RED

RED/GREEN (pulses LED Red)

OFF

ON

(2 pulses)

Internal fault

OFF

ON

(3 pulses)

Internal relays fault

OFF

ON

(4 pulses)

K1K2 external relays fault

OFF

ON

(5 pulses)

User configuration failure

OFF

ON

(6 pulses)

User configuration changed

without system restart: Switch

off and restart the module to

solve the problem. At the switch

on verify the new user

configuration

OFF

ON

(7 pulses)

Possible overload or

SYSTEM STATUS

connection error

Table!9

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

SB400M

Safety Modules

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ESB1261501

17/19

!

2.12.4 Status indicators (MUTING MODULE)

NOTE: The following status signals are present with the base module permanently light on.

LED

MEANING

SENSOR

1

SENSOR2

MUTING

YELLOW

YELLOW

YELLOW

OFF

OFF

(2 pulses)

Bad connection of the

muting lamp, lamp

not present or in

overload

OFF

OFF

(3 pulses)

Muting timeout

wrong configuration

OFF

OFF

(4 pulses)

Wrong override

configuration

at the power up

Shows the

sensor_1

status

Shows the

sensor_2

status

(5 pulses)

Instable Muting

Sensor

Blinking

Blinking

Blinking

Override with pulse

command expired

!If it is not possible to clearly identify the malfunction and to to remedy it, stop the machine and

contact the M.D. Micro Detectors's Assistence Service.

!

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

SB400M

Safety Modules

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ESB1261501

18/19

!

2.13 PERIODIC TESTS TO DO EVERY YEAR

!

!

!

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 253973

www.microdetectors.com

SB400M

Safety Modules

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors

CAT8ESB1261501

19/19

!

2.14 GUARANTEE

M.D. Micro Detectors warrants that each SB400M unit in new ex-factory condition, in conditions of

normal use, is free of defects in the materials and of manufacturing defects for a period of 24

months.

In this period, M.D. Micro Detectors undertakes to eliminate any faults in the product through

repair or replacement of the faulty parts, completely free of charge as regards material and labor.

However, M.D. Micro Detectors reserves the right to replace the entire faulty appliance with

another equivalent appliance or with the same characteristics instead of repairing this.

Validity of this warranty is regulated by the following conditions:

• The user must inform M.D. Micro Detectors of the fault within 24 months from the date of

delivery of the product.

• The appliance and its components must be in the conditions in which they were delivered by

M.D. Micro Detectors.

• The serial numbers must be clearly legible.

• The fault or defect has not been caused directly or indirectly by:

– Improper use;

– Non-compliance with instructions for use;

– Carelessness, inexperience, incorrect maintenance;

– Repairs, modifications, adaptations not carried out by M.D. Micro Detectors personnel,

tampering, etc.;

– Accidents or impacts (also due to transportation or causes of force majeure);

– Other causes not to be ascribed to M.D. Micro Detectors.

Repairs will be carried out at the M.D. Micro Detectors laboratories to which the material must be

delivered or dispatched: transport risks and the risks of any damage or loss of the material during

shipment are the responsibility of the user.

All products and components replaced become the property of M.D. Micro Detectors.

M.D. Micro Detectors does not recognize any other warranties or rights except for those

specifically described above; therefore, no claims for damages may be submitted for expenses,

interruption of business or other factors or circumstances in any way related to failure of the

product or of one of its parts.

Do not dispose of WEEE as mixed urban waste, arrange separate collection.

Contact the appropriate authorized collection points or the

manufacturer. (2012/19/UE)

Precise, complete compliance with all the rules, instructions and prohibitions indicated in this

handbook is an essential requirement for correct functioning of the safety interface.

M.D. Micro Detectors s.p.a. therefore declines any responsibility for all and anything resulting from

failure to comply, even partially, with such indications.

Characteristics subject to change without notice.

Total or partial reproduction is forbidden without the prior authorization of M.D. Micro Detectors.

Table of contents

Popular Control Unit manuals by other brands

Phoenix Mecano

Phoenix Mecano DewertOkin MC11 installation instructions

BENDIX

BENDIX SC-3 INLINE SINGLE CHECK VALVES manual

DF ROBOT

DF ROBOT SEN0521 user manual

DeZurik

DeZurik APCO CVS-6000 Installation, operation and maintenance manual

Sony

Sony HSCU300RF Service manual

Smarteh

Smarteh LPC-2.CX1 user manual