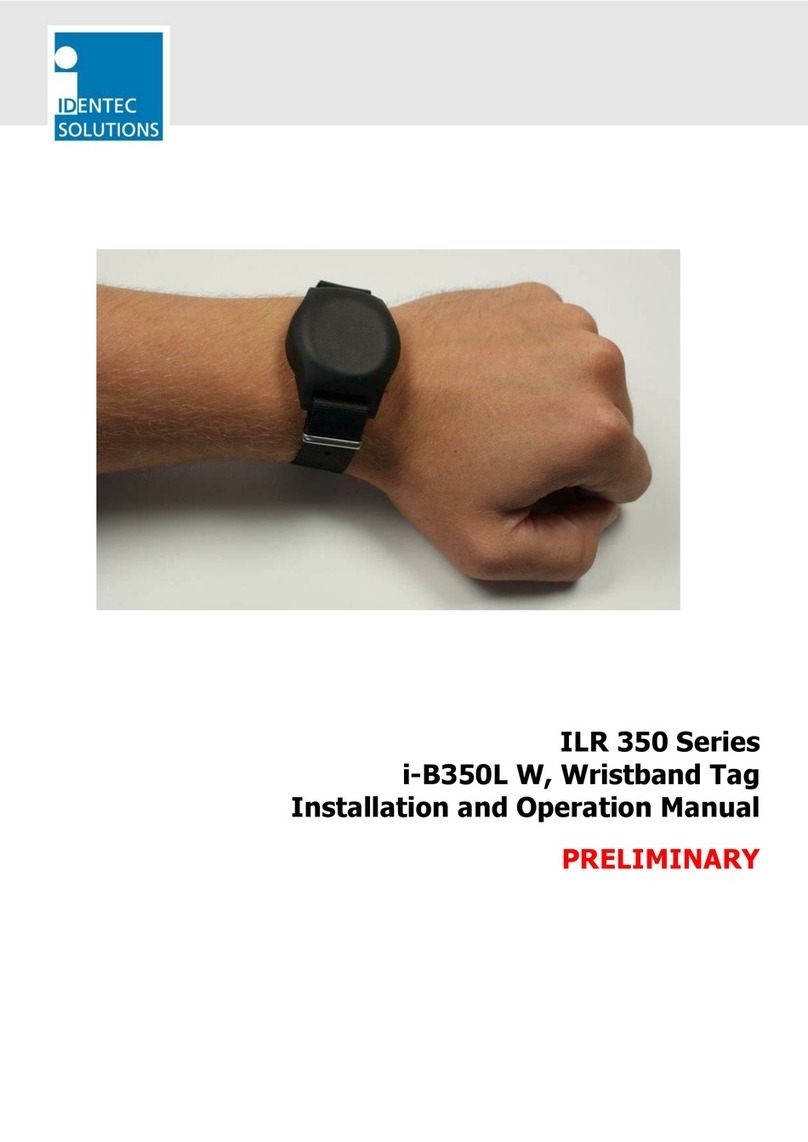

MicroAir Avionics T2000ADSB User manual

T2000ADSB TRANSPONDER

INSTALLATION MANUAL

Microair Avionics Pty Ltd

ACN 646 664 459

601 Curtin Ave East

Pinkenba QLD 4008

Australia

Phone: +61 7 4160 8200

Email: support@microair.aero

sales@microair.aero

Web: www.microair.aero

T2000ADSB Transponder

Installation Manual

T2000ADSB Installation Manual 01R2

Page 2 of 33

24th Mar 2023

About This Document

Microair Avionics has developed the T2000ADSB transponder to provide for aircraft surveillance requirements of ATCRBS

Mode 3A/C with ADS-B.

This is a controlled document, and may not be copied, amended, or distributed without the prior consent of Microair Avionics

Pty Ltd.

© Microair Avionics Pty Ltd

DOCUMENT REVISION STATUS

Revision

Date

Change

01R1

21/02/23

Initial Release

01R2

24/03/23

Minor correction. Programming moved from User manual. Extended test and

calibration section from user feedback.

T2000ADSB Transponder

Installation Manual

T2000ADSB Installation Manual 01R2

Page 3 of 33

24th Mar 2023

TABLE OF CONTENTS

1.0 INTRODUCTION 4

2.0 PANEL MOUNTING 5

3.0 ALTITUDE ENCODER 6

4.0 TRANSPONDER ANTENNA & COAX CABLE 7

4.1 MOUNTING 7

4.2 GROUND PLANE 7

4.3 COAXIAL CABLE 7

5.0 GPS ANTENNA 9

5.1 DASH MOUNTED ANTENNA 9

5.2 EXTERNAL MOUNTED ANTENNA 9

6.0 WIRING 10

6.1 GENERAL WIRING 10

6.2 AUDIO BEEP 11

6.3 SUPPRESSION IN 11

6.4 SUPPRESSION OUT 11

6.5 AIR/GND (PREVIOUSLY KNOWN AS EXTERNAL STANDBY) 11

6.6 EXTERNAL IDENT 11

7.0 INITIALISATION AND SETUP 12

7.1 PROGRAM MODE 12

7.2 VFR CODE 12

7.3 ICAO CODE 13

7.4 EMITTER CATEGORY 13

7.5 AIRCRAFT ID 14

7.6 ENCODER SOURCE 14

7.7 ALTITUDE UNIT 15

7.8 BAROMETER UNIT (MB OR INHG) 15

7.9 AIR GROUND LOGIC 15

7.10 ADSB VERSION 16

7.11 EXIT PROGRAM 16

8.0 CALIBRATION & TESTING OF INSTALLATION 17

8.1 IFR6000 TEST PROCEDURE 17

8.2 ADSB TEST PROCEDURE 18

8.3 BACKGROUND INFORMATION ON INTEGRITY 19

8.3.1 INTEGRITY NUC 19

8.3.2 ACCURACY NAC 20

8.3.3 INTEGRITY SIL 20

9.0 WIRING DIAGRAMS 21

10.0 INSTALLATION DIMENSIONS 29

11.0 PIN ASSIGNMENTS 30

12.0 PANEL TEMPLATE 31

13.0 SPECIFICATIONS 32

T2000ADSB Transponder

Installation Manual

T2000ADSB Installation Manual 01R2

Page 4 of 33

24th Mar 2023

1.0 INTRODUCTION

Microair recommends you familiarise yourself with this Installation Manual BEFORE you start installing

your Microair T2000ADSB Transponder.

IMPORTANT NOTE

The T2000ADSB must be installed and tested by a suitably qualified and

authorised Avionics mechanic and all structural changes, such as the GPS

antenna installation, must be approved by a suitably qualified and authorised

engineer or the aircrafts manufacturer.

The installer is responsible for ensuring that the installation meets all

functional and regulatory requirements. If the T2000ADSB is installed by an

aircraft owner, who has the appropriate authority to do so, they remain

responsible for the ensuring the installation meets all functional and

regulatory requirements.

Microair strongly recommends the use of an ADSB/Transponder test set such

as the IFR6000 to validate the installation. Microair had an IFR6000

available for lease on a day rate basis.

If ADSB test equipment is not available then Microair recommends that as a

minimum, a structured test flight is conducted with a detailed log maintained

during the flight which can then be compared to the Flight Track Log from an

ADSB tracking provider such as FlightAware or Flightradar24. We

recommend that the flight log, the downloaded flight track and the

comparison are filed in the aircrafts records as demonstration of a compliant

installation.

T2000ADSB Transponder

Installation Manual

T2000ADSB Installation Manual 01R2

Page 5 of 33

24th Mar 2023

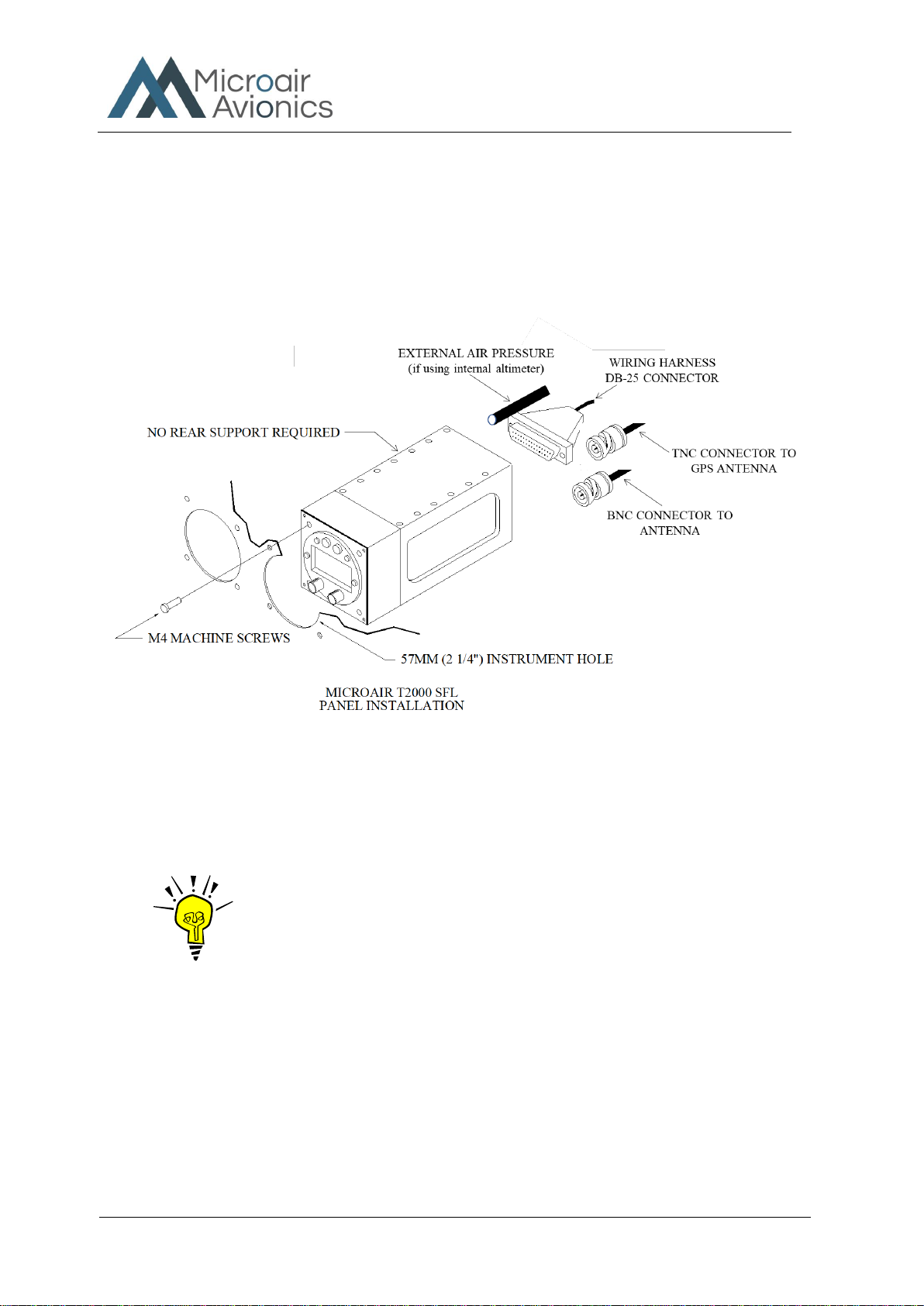

2.0 PANEL MOUNTING

Determine a suitable location in the instrument panel in full view of both pilots. Cut a 57mm diameter (2

¼ inch) hole with 4 x 4mm holes for the mounting screws. Dimensions for this are provided on the panel

template. Allow a minimum of 63mm (2 ½ inch) square behind the cut out, to allow clearance from other

instruments. A depth of 200mm (8 inches) is recommended to accommodate the transponder and

electrical connectors.

The T2000ADSB weighs only 685g (24oz). The four M4 x 12mm machine screws are sufficient to

support the transponder. No rear support is required unless the panel structure itself is too weak to

support the load.

IMPORTANT NOTE

Removal of the chassis screws for the purpose of attaching support

bracket is not permitted.

The drilling of holes in the chassis for any purpose is not permitted.

Filings from changing the thread of the M4 screw may cause electrical

faults. Faults of this type are NOT covered by warranty.

T2000ADSB Transponder

Installation Manual

T2000ADSB Installation Manual 01R2

Page 6 of 33

24th Mar 2023

3.0 ALTITUDE ENCODER

The T2000ADSB has three options for its altitude source:

1. An inbuilt altimeter that requires no connection to an external altimeter, mode C blind encoder

or other EFIS system for its altitude data input. If using the inbuilt altimeter, connect the

External Air Pressure static source directly to the 1/8” NPT male input on the rear side of the

transponder and select the appropriate Encoder Source from the Program Mode user menu.

2. A Gillham encoded external altimeter or mode C blind encoder.

3. A serial encoded external mode C blind encoder or EFIS system.

For customers intending to use an installed altimeter, mode C blind encoder or other EFIS altitude source

(either Gilham or serial) ensure installation is per the manufacturer’s instructions and select the

appropriate Encoder Source from the Program Mode user menu. An appropriate wiring harness is

connected to the T2000ADSB via a DB25 connector (refer wiring diagram). The power for blind mode C

encoders can be supplied from the T2000ADSB and is equal to the aircraft supply voltage. This power is

switched when the T2000ADSB is turned on.

If the encoder is to be powered separately, it is recommended that a ground wire is run between the

encoder and T2000ADSB to ensure correct switching of the data lines.

IMPORTANT NOTE

Most encoder manufacturers advise of a warm up period for their product

before altitude data is supplied. The period can typically be up to 10

minutes. For the Microair EC2002, the warm up time is only 10 seconds!

Refer to WIRING DIAGRAMS (section 9.0) for wiring details and pin assignments for commonly used

altitude encoders or EFIS, in both Gillham and serial data outputs.

IMPORTANT NOTE

If the aircraft voltage is 28V and the encoder is 14V only, a 28/14V

converter should be installed between the T2000ADSB and the encoder.

Please ensure that the voltage supply line to power the encoder is NOT

shorted to any data line or ground. The T2000ADSB will incur internal

faults if a short occurs. This type of damage is NOT covered by the

warranty.

T2000ADSB Transponder

Installation Manual

T2000ADSB Installation Manual 01R2

Page 7 of 33

24th Mar 2023

4.0 TRANSPONDER ANTENNA & COAX CABLE

The T2000ADSB requires an antenna tuned to 1090MHz.

4.1 Mounting

The transponder signal is primarily directed to ground stations (Radar sites), hence the antenna is

typically located on the underside of the fuselage. The position should give the antenna a full 360-degree

view of the horizon. The position should be away from other protrusions from the airframe, such as

footsteps, and undercarriage legs.

To avoid possible interference the antenna must be mounted a minimum of 0.3m (12 inches) away from

the T2000ADSB. The transponder antenna outputs high levels of RF energy and should be located at

least 1m (3ft) away from vulnerable part of the human body or be separated by a metal panel.

If the VHF comm antenna is already located on the underside of the fuselage, the transponder antenna

should be located at least 1 metre (3ft) away. The transponder antenna should be mounted 2 metres (78

inches) from a DME antenna, and 1.5 metres (58 inches) from the ADF sense antenna.

4.2 Ground Plane

In metal skin aircraft the skin forms the ground plane. To ensure a good electrical connection, it may be

necessary to remove paint/primer from the inside face of the skin, before attaching the antenna. This may

be resealed after the antenna is installed. On pressurised aircraft, the antenna should be sealed using RTV-

3145 or equivalent, to seal around the connector and mounting hardware. All antenna mounts should be

sealed around the outside for moisture protection, using RTV-3145 or equivalent.

In a composite aircraft the skin of the airframe cannot be used,

and a suitable ground plane must be fabricated. The ground

plane is typically an aluminium disc with a radius equal to the

height of the antenna (approx. 75mm or 3”). The antenna is

mounted in the centre of the ground plane.

The ground plane does not have to be circular however, but the

area should be approx the same size. Fibreglass aircraft can

mount the ground plane on the inside of the aircraft.

Although carbon fibre is a good reflector of RF, it is not a

suitable material for a ground plane. A metal ground plane is

ideal.

It is important to ensure that a good electrical contact is

established, as some antennas have sealing O-rings which can

isolate this connection.

4.3 Coaxial Cable

The T2000ADSB allows for 2dB cable loss from the unit to the antenna. The installer should consider

carefully what type of coaxial cable is to be used, so that this loss limit is not exceeded. The cable should

be terminated with a crimped BNC connector rated for 200Wpep and 2GHz such as the Amphenol

112514.

T2000ADSB Transponder

Installation Manual

T2000ADSB Installation Manual 01R2

Page 8 of 33

24th Mar 2023

Microair recommends the use of RG400 coax cable in accordance with the table below.

Cable

Bending

Radius

Loss @ 1Ghz

dB/m

Max Length

TX Power

RX

Sensitivity

RG400 (Mil Spec)

50mm

(2”)

0.485dB/m

3.9m

12.8ft

> 125W

< -69dBm

IMPORTANT NOTE

Do not exceed the minimum bending radius. Tight bends will introduce losses

in the cable, which may affect the performance of the transponder.

When fixing the coax cable in the airframe, do not “strangle” the cable with

tight cable ties. This can distort or damage the coax screen.

Avoid looping excess Coax cable. It is recommended that a coax cable correct

to within 300mm (1ft) be ordered (available at microair.aero). If shortening a

coax cable pay particular attention to the termination. A crimped connector

rated for operation up to 2GHz and 200W is required such as the 112514 BNC

Connector.

T2000ADSB Transponder

Installation Manual

T2000ADSB Installation Manual 01R2

Page 9 of 33

24th Mar 2023

5.0 GPS ANTENNA

The T2000ADSB requires the installation of a GPS Antenna to receive a satellite GPS signal required by

the unit. The GPS Antenna is connected to the T2000ADSB on the back of the unit via TNC connection.

Two types of GPS Antennas are recommended for operation with the T2000ADSB transponder.

5.1 Dash Mounted Antenna

For composite skinned aircraft, a dash-mounted GPS antenna can be connected to the unit and positioned

on the instrument dashboard in an unobstructed position. Maintain separation of the GPS antenna from

other antennas located on the dashboard should these be present.

The Microair dash mounted antenna uses an adhesive pad to secure the antenna to the dash. Peel the label

from the adhesive backing of the GPS antenna and firmly press the antenna into position on top of the

instrument panel.

Other GPS dash mounted antennas may require a physical fixture to be installed on the dash. Ensure to

follow the manufacturer’s instructions for the installation of your dash mounted GPS antenna in such

instances.

IMPORTANT NOTE

A magnetic fixing solution is not recommended for the GPS antenna as

this may interfere with other instrumentation present.

5.2 External Mounted Antenna

For metallic skinned aircraft, it is recommended that a TSO’d externally mounted antenna is used.

Position the GPS antenna on the upper side of the fuselage in an unobstructed position, preferably at the

highest point of the aircraft when in level flight. To the extent practicable, mount the antenna so that the

base is horizontal when the aircraft is in cruise attitude. Route the antenna cable in the most direct path

practicable and reduce the cable length to the minimum required.

Ensure to follow the manufacturer’s instructions for the installation of the Externally mounted antenna.

IMPORTANT NOTE

Avoid looping excess Coax cable. It is recommended that a coax cable

correct to within 300mm (1ft) be ordered (available at microair.aero). If

shortening a coax cable pay particular attention to the termination. A

crimped connector rated for operation up to 2GHz is required such as

the Amphenol 122372 (straight) or 122365 (right angle) TNC connector.

T2000ADSB Transponder

Installation Manual

T2000ADSB Installation Manual 01R2

Page 10 of 33

24th Mar 2023

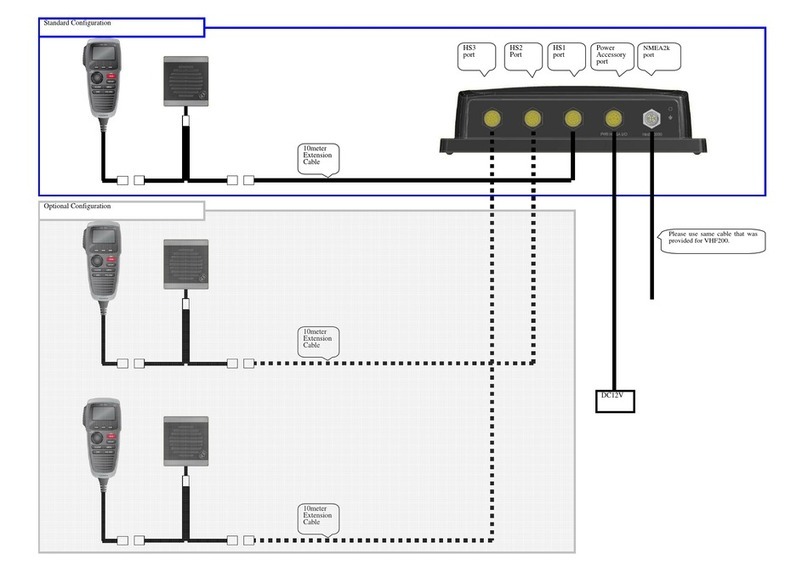

6.0 WIRING

The T2000ADSB must be installed with a wiring harness which meets the following requirements.

6.1 General Wiring

The T2000ADSB is to be powered from the aircraft supply, via the avionics master and fuse/circuit

breaker with a maximum 5 amp rating (3 amp minimum).

IMPORTANT NOTE

The aircraft’s electrical system may produce severe transient voltages

during engine start and stop

Microair recommends that the avionics master be turned off during

engine start and stop, to prevent damage occurring to the T2000ADSB.

Damage to the transponder as a result of transient voltages is NOT

covered by the warranty.

Microair recommends that if used, the external encoder be installed and wired in accordance with the

manufacturer’s installation instructions. The encoder can be powered directly from the T2000ADSB.

It is very important to secure all D series plugs via their security screws before operation. Aircraft

vibration may disconnect a D series plug if it not secured. Wiring is to be separated from the coaxial

cables.

Microair recommends the following wire types for connection of the T2000ADSB:

Power Input

18 AWG TEFZEL 22759/16-16

Red and Black Wire

External Connections

22 AWG TEFZEL 22759/16-22

Wire or

22 AWG TEFZEL 27500-22TG1T14

Single core shielded

Encoder Power

22 AWG TEFZEL 22759/16-22

Red and Black Wire

Encoder Data

22 AWG TEFZEL 22759/16-22

White Wire

To ensure correct installation and to make future service simple, Microair recommends that all wiring be

labelled for easy identification.

T2000ADSB Transponder

Installation Manual

T2000ADSB Installation Manual 01R2

Page 11 of 33

24th Mar 2023

6.2 Audio Beep

The T2000ADSB beep function when set to ON, will emit a beep tone on this line. Audio beep should be

taken to the Auxiliary input of the aircraft’s radio or Audio Panel.

When connecting the beep function to the Microair M760 transceiver, simply join the beep line directly

to any headphone line (orange wire in factory supplied harness).

6.3 Suppression IN

The suppression IN line is used in installations with multiple transponders or DME systems to “suppress”

the T2000ADSB, to prevent concurrent transmissions, and interference. When another system transmits,

it will send a positive voltage to the suppression IN, which prevents the T2000ADSB from transmitting.

The T2000ADSB requires a minimum signal voltage of 5V. The signal voltage may not exceed 20V.

In most installations the Suppression IN can be left unconnected.

6.4 Suppression OUT

Where the T2000ADSB is used in installations with multiple transponders or DME systems, the

suppression OUT line is used to “suppress” other transponder and DME equipment installed in the

aircraft, from interfering. When the T2000ADSB transmits, it raises a positive voltage on the suppression

OUT line, which prevents the other equipment from transmitting.

The signal voltage is 5V.

In most installations the Suppression IN can be left unconnected.

6.5 AIR/GND (previously known as External Standby)

The T2000ADSB must know its airborne or surface status and provides two methods to achieve this:

1. An external switch can be wired to the T2000ADSB. This is usually a “Squat Switch” on the

undercarriage or an “Air Switch” on the wings leading edge. The switch must pull the T2000ADSB

input to ground when active but the T2000ADSB can be set for the active state to either be Surface

(NORM) or Airborne (REV). Refer to Program Mode described below.

2. GPS speed can also be used to switch between Airborne and Surface modes. Ground speeds above

35kts will cause the T2000ADSB to switch to Airborne Mode whilst ground speeds below 20kts will

cause the T2000ADSB to switch to Surface Mode.

6.6 External Ident

This line is typically wired to a momentary-ON switch, in a position more easily reached by the pilot /

co-pilot (e.g. control column). When this line is taken to ground briefly, the T2000ADSB will go through

its Ident function.

Most installations to not include an External Ident switch.

IMPORTANT NOTE

If any of the above wiring functions are not required, they can simply be

left unwired.

T2000ADSB Transponder

Installation Manual

T2000ADSB Installation Manual 01R2

Page 12 of 33

24th Mar 2023

7.0 INITIALISATION AND SETUP

On initial power up the T2000ADSB will enter Program Mode to allow the ICAO Code (sometimes call

the Mode S code) to be set. It is important that the Emitter Category and Aircraft ID are also set.

•If the ICAO Code and aircraft Registration were provided to Microair at the time of purchase then

this data may have been preset.

The following procedures provide step by step instructions to program the transponder options.

PROGRAM MODE

VFR CODE

ICAO CODE

EMISSION CATEGORY

AIRCRAFT ID

ENCODER SOURCE

ALTITUDE UNIT (ft/m)

BAROMETER UNIT (Mb/inHg)

AIR GROUND LOGIC

ADSB VERSION

EXIT PROGRAM

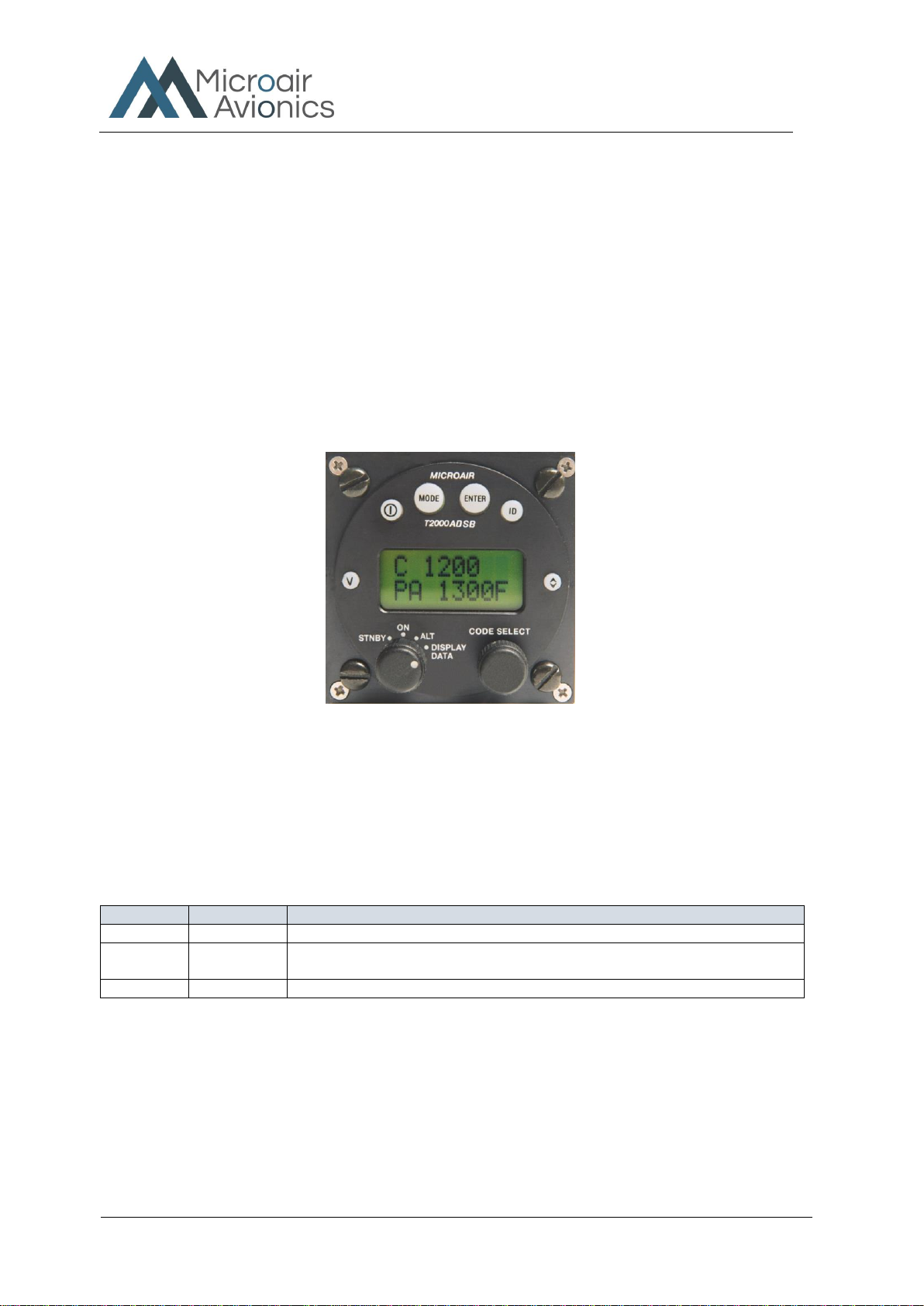

7.1 PROGRAM MODE

To start the T2000ADSB in PROGRAM MODE,

hold down the MODE key whilst powering the

device. Keep the MODE key held down until the

start up self test messsages have been displayed.

Each item can be adjusted to the desired value or

option by scrolling the CODE SELECT knob. The

selected value or option can be saved by pressing the

ENTER key. PROGRAM MODE then moves to

the next menu item.

NOTE: If the ICAO code is not set the T2000ADSB

will always start in PROGRAM MODE as ADSB

cannot operate without a valid code.

7.2 VFR CODE

This item sets the default VFR code which can be hot

key accessed from the V(VFR) key. For most

countries the default general aviation code is 1200.

Press ENTER key

Until VFR CODE message appears

Rotate CODE SELECT knob

Adjust the digit highlighted by the cursor.

Press CODE SELECT knob

Moves the digit to the right

Press ENTER key

The message SAVED appears briefly on the display

The display moves to ICAOCODE menu item

T2000ADSB Transponder

Installation Manual

T2000ADSB Installation Manual 01R2

Page 13 of 33

24th Mar 2023

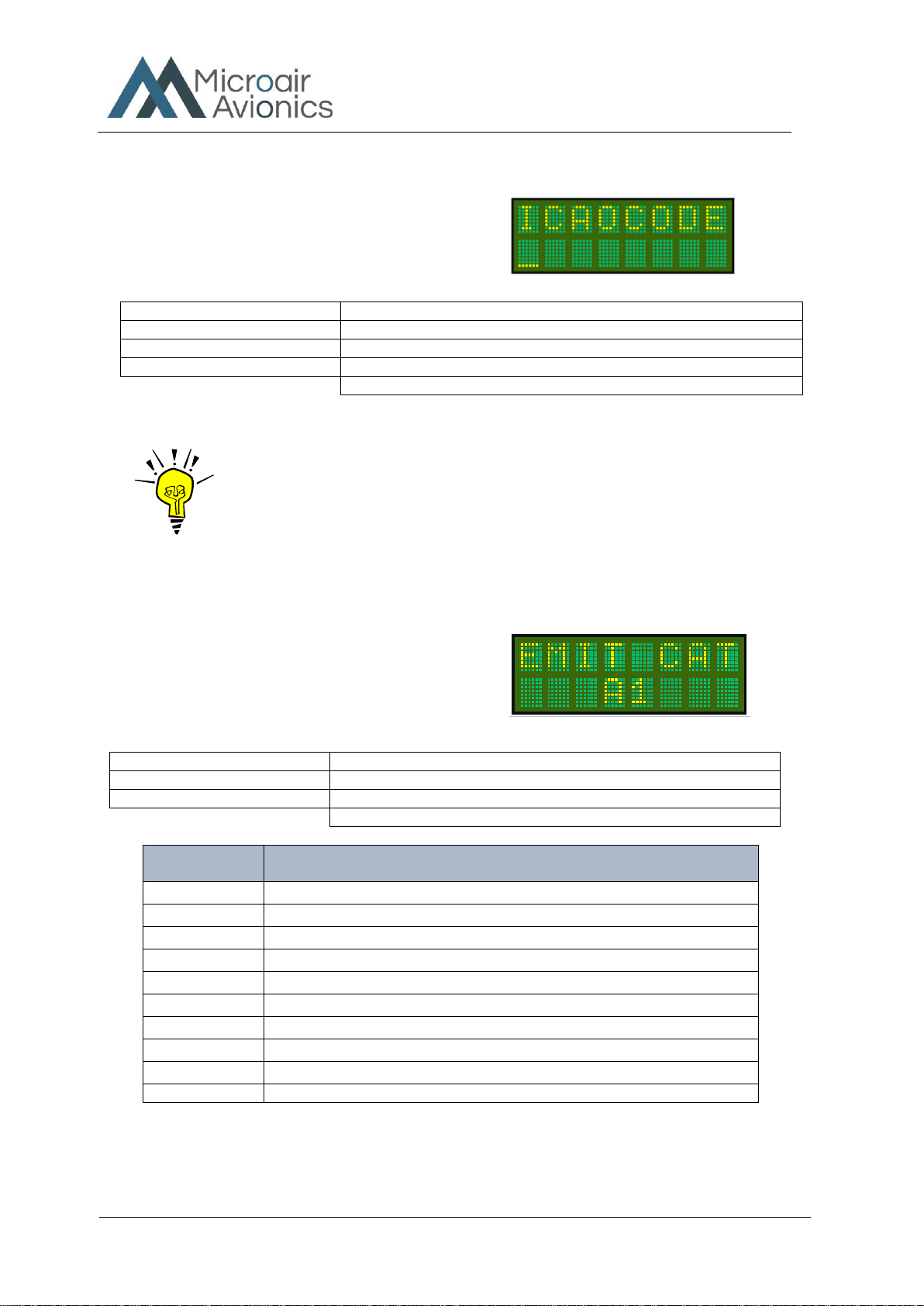

7.3 ICAO CODE

The ICAO code is an essential part of all ADS-B

messages. The operator should check with the Civil

Aviation Authority, to ensure what the correct ICAO

code for their aircraft is.

Press ENTER key

Until ICAOCODE message appears

Rotate CODE SELECT knob

Adjust the digit highlighted by the cursor.

Press CODE SELECT knob

Moves the digit to the right

Press ENTER key

The message SAVED appears briefly on the display

The display moves to EMIS CAT menu item

The ICAOCODE is limited to the hex-decimal character set of numbers 0-9, and letters A-E.

IMPORTANT NOTE

All ADS-B message include the ICAOCODE data. No ADS-B operation

will be possible if the ICAOCODE is not entered. The unit will not

operate until this code is set.

7.4 Emitter Category

The emitter category is an essential piece of ADS-B

data, which is used to describe the aircraft “type”. The

T2000ADSB has restricted the category selections to

those which are required to transmit airborne ADS-B

messages only

Press ENTER key

Until EMIT CAT message appears

Rotate CODE SELECT knob

Scroll to select the desired Emission Category. The default is A0.

Press ENTER key

The message SAVED appears briefly on the display

The display moves to A/C ID menu item

Emission

Category

Description

A1

Light (< 15,500lbs)

A7

Rotorcraft

B1

Glider / Sailplane

B2

Lighter –than –air

B4

Ultralight / hang-glider / paraglider

C1

Surface Vehicle - Emergency Vehicle

C2

Surface Vehicle - Service Vehicle

C3

Point Obstacle

C4

Cluster Obstacle

C5

Line Obstacle

If you are uncertain of which emitter category is applicable to your aircraft, contact your civil aviation

authority for advice. To ensure that ADS-B operation is possible, the emitter category is defaults to A1.

T2000ADSB Transponder

Installation Manual

T2000ADSB Installation Manual 01R2

Page 14 of 33

24th Mar 2023

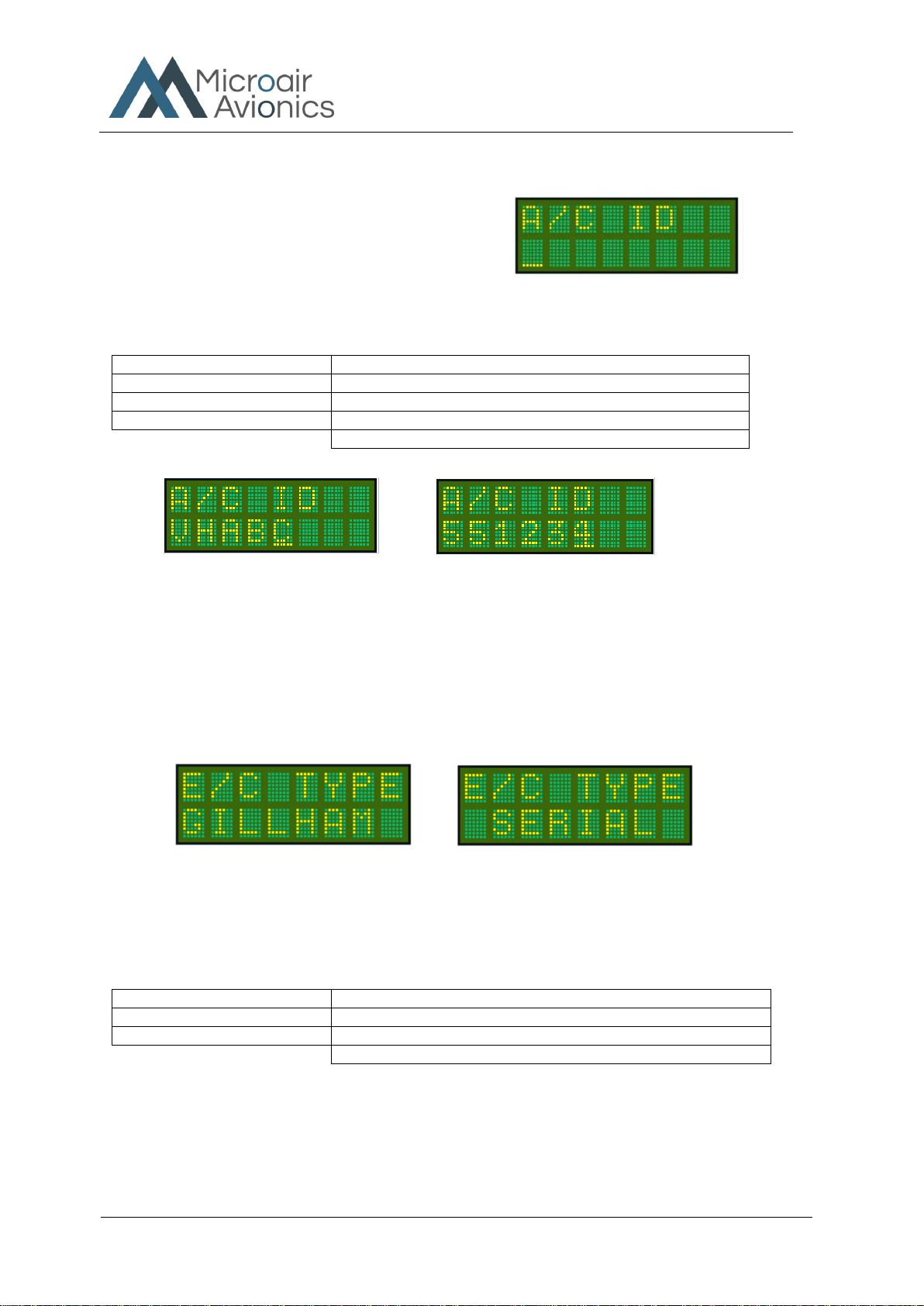

7.5 Aircraft ID

The Aircraft ID data is the default for the Flight ID which

assists ATC to uniquely identify individual aircraft. The

Flight ID is typially the aircraft’s registration, but the

operater should check with the Civil Aviation Authority for

their correct Flight ID format.

The aircraft ID is the default for the flight ID in the MODE MENU. If the Filght ID is not entered the

ADS-B message will transmit “null” in the Aircraft Identification message.

Press ENTER key

Until A/C ID message appears

Rotate CODE SELECT knob

Adjust the digit highlighted by the cursor.

Press CODE SELECT knob

Moves the digit to the right

Press ENTER key

The message SAVED appears briefly on the display

The display moves to next menu item

The Aircraft ID can have a maximum of 8 characters, and can consist of capital letters A-Z and the

numbers 0-9 with spaces in the trailing unused positions (spaces are not allowed in or within the Flight

or Aircraft IDs).

7.6 ENCODER SOURCE

The T2000ADSB is able to use altitude information from either its internal encoder, or serial or parallel

(Gillham) altitude data. If Gillham is selected the T2000ADSB will detect altitude code over the 10 line

Gillham interface. If serial is selected the T2000ADSB will detect altitude data over the RS-232 interface.

Serial data can be in any one of the following protocols.

•Garmin AT

•Magellan

•Northstar / Garmin

•Trimble / Garmin

•Microair Avionics

Press ENTER key

Until ENCODER SOURCE message appears

Rotate CODE SELECT knob

Scroll to select the Altitude Source (Internal, Gillham, Serial).

Press ENTER key

The message SAVED appears briefly on the display

The display moves to EXIT PROGRAM menu item

If the serial data supplies altitude with resolution to 25 foot increments, the T2000ADSB will transmit

ADS-B message with the barometric altitude data resolved to 25 feet. The displayed altitude will also be

resolved to 25 feet. Where the serial data supplies altitude with resolution to 100 foot increments, the

transmitted and display altitudes will be resolved to 100 feet only. When the internal altimeter is selected

the displayed altitude has a resolution of 1ft and the ADSB transmitted resolution will be 25ft.

T2000ADSB Transponder

Installation Manual

T2000ADSB Installation Manual 01R2

Page 15 of 33

24th Mar 2023

7.7 ALTITUDE UNIT

The altitude data can be displayed in feet or

meters. Once the Altitude units are set, all

altitude data is displayed in these units.

Press ENTER key

Until ALTITUDE UNIT message appears

Rotate CODE SELECT knob

Rotate the Code Select to select the unit (Feet or Meters)

Press ENTER key

The message SAVED appears briefly on the display

The display moves to EXIT PROGRAM menu item

7.8 BAROMETER UNIT (Mb or inHg)

The barometric pressure units used by the T2000ADSB

can be either MB = millibars, or HG = inches Mercury.

Press ENTER key

Until BAROMETER UNIT message appears

Rotate CODE SELECT knob

Rotate the Code Select to select the unit (Mb or inHg)

Press ENTER key

The message SAVED appears briefly on the display

The display moves to EXIT PROGRAM menu item

7.9 AIR GROUND LOGIC

For aircraft using the remote air/ground input line (pin 15),

the operation of the switch can be changed by the software

to suit the aircraft.

If the air/ground switch closes to ground when the aircraft

is on the ground then the operation is Norm (normal).

If the air/ground switch closes to ground when the aircraft is in the air then the operation is Rev

(reverse).

If the aircraft doesn’t use an air/ground switch then select GPS which will use aircraft ground speed to

determine air/ground logic for ADSB.

Press ENTER key

Until AIR GROUND LOGIC message appears

Rotate CODE SELECT knob

Rotate the Code Select to select either Norm, Rev or GPS

Press ENTER key

The message SAVED appears briefly on the display

The display moves to EXIT PROGRAM menu item

T2000ADSB Transponder

Installation Manual

T2000ADSB Installation Manual 01R2

Page 16 of 33

24th Mar 2023

7.10 ADSB VERSION

Selects the versions of ADSB messaging which can be Version 2 or Version 3. Default is Version 2.

Press ENTER key

Until ADSB VERSION message appears

Rotate CODE SELECT knob

Rotate the Code Select to select either Version 2 or Version 3

Press ENTER key

The message SAVED appears briefly on the display

The display moves to EXIT PROGRAM menu item

7.11 EXIT PROGRAM

This is the end of the PROGRAM MODE menu.

The user can exit by pressing the ENTER key. The

T2000ADSB will restart in the operational mode.

The user can exit the PROGRAM MODE menu at any time, from any menu item, by pressing the

toggle key. To re-enter the PROGRAM MODE menu the T2000ADSB must be turned off, and

re-started using the ON and MODE keys (refer PROGRAM MODE section).

T2000ADSB Transponder

Installation Manual

T2000ADSB Installation Manual 01R2

Page 17 of 33

24th Mar 2023

8.0 CALIBRATION & TESTING OF INSTALLATION

Please refer to the Civil Aviation rules or regulations for your country to determine what the calibration

requirements are for a transponder installation.

For certified aircraft, most countries will require a test of the installation to be carried out by a qualified

test centre, along with a calibration of the encoder and altimeter in the aircraft. For experimental aircraft,

most regulatory authorities requires that the installer be responsible to ensure that the installation meets

the required functional performance.

This test is typically repeated every two years, to ensure the ongoing accuracy of the system.

IMPORTANT NOTE

It is vital to aircraft safety that all transponder/encoder/altimeter systems,

which will operate within an SSR system or interact with TCAS equipped

aircraft, perform to a minimum civil aviation standard.

For this reason, Microair strongly recommends that all transponder

installations be calibrated at the time of installation, and at periods of not

greater than two years thereafter.

8.1 IFR6000 Test Procedure

Refer to FAA FAR Part 43 appendix E and F for typical transponder/encoder/altimeter equipment

calibration procedures. The diagram below illustrates a standard set up for the testing of the

transponder/encoder/altimeter equipment.

T2000ADSB Transponder

Installation Manual

T2000ADSB Installation Manual 01R2

Page 18 of 33

24th Mar 2023

8.2 ADSB TEST PROCEDURE

Microair recommends the use of an IFR6000 test set for use in the validation of ADS-B installations.

Note, before commencing your test, ensure that the aircraft GPS has a clear view of the sky / GPS

constellation to be able to generate good HPL/NIC. Normally, testing within the confines of a hangar will

not yield acceptable results. Ensure GPS has established a position prior to carrying out these tests (this

can be checked by pressing (I) in the Disp Alt mode and confirming time, LAT, LON etc are present)

Set up the IFR6000 per the manufacturer’s instruction for ADSB monitoring ensuring the following

settings:

1. Ensure that ADSB MON is set to DF18.

2. Ensure the aircrafts Mode S address is entered.

Select ADSB Version 2 on the T2000ADSBs Program menu.

With the aircraft in Surface mode (i.e. Squat switch active, Air switch inactive or GPS speed below

20kts) ensure the following messages are available:

1. SURFACE POS. Confirm the ICAO code, Position (LAT/LON) and NIC/Rc are correct.

2. IDENT & CAT. Confirm the ICAO code, Flight ID and Emitter Category are correct.

3. A/C STATUS ST1. Confirm the ICAO code and Mode A code are correct. Enter code 7500, 7600

or 7700 on the T2000ADSB and ensure the EMERG/PRIOR Code is correct.

Simulate the aircraft being in the air (follow the aircraft maintenance manual or often the easiest way is to

enter Program Mode on the T2000ADSB and change the AIR/GND Logic from Norm to Rev or vice

versa). Ensure the following messages are available:

1. AIRBORNE POS. Confirm the ICAO code, Position (LAT/LON), Altitude and NIC/Rc are

correct.

2. AIRBORNE VAL. Confirm the ICAO code, Velocity (E-W, N-S), vertical rate and NACV are

correct.

3. IDENT & CAT. Must be present but no further testing required is performed for Surface message.

4. A/C STATUS ST1. Must be present but no further testing required is performed for Surface

message.

T2000ADSB Transponder

Installation Manual

T2000ADSB Installation Manual 01R2

Page 19 of 33

24th Mar 2023

8.3 BACKGROUND INFORMATION ON INTEGRITY

8.3.1 Integrity NUC

If the aircraft is transmitting SURFACE squits (eg: squat switch is active), then the type code needs to be

5,6 or 7 in accordance with the table below.

Type code

Rc

NUC

Validity

5

<7.5m

9

Valid

6

<25m

8

Valid

7

<185.2m

7

Valid

8

>185.2m

6

Not useable –indicates no Integrity

If the aircraft is transmitting AIRBORNE extended squiters then the type code needs to be 9-15 in

accordance with the table below.

Type code

Rc

NUC

Usable by

ATC

Observed frequency of type

code (as expected)

9

<7.5m

9

Yes

Rare

10

<25m

8

Common

11

<185.2m

7

Common

12

<0.2 nm

6

Common

13

<0.5 nm

5

Less Common

14

<1.0nm

4

Infrequent

15

<2.0 nm

3

No

Unlikely

16

<10 nm

2

17

<20 nm

1

18

>20 nm

0

Not useable –indicates no Integrity

A “good” installation needs to transmit a NIC of at least 6, 7 or 8. A lower NIC for any period indicates

something is wrong.

The containment radius (Rc or Horizontal Protection Level HPL) is calculated by the GPS receiver based

on which GPS satellites it is receiving and the satellite geometry. It does not depend on actual

measurements of the received satellites. Aircraft in the same position should calculate almost the same

HPL value when exposed to the same satellite constellation.

Aircraft with a clear view of the sky should be generating HPL values below 0.2 nautical miles a very

large percentage of the time. Therefore expect to see NIC=7,8 or 9. Nearly all aircraft output NIC=6 to 9

all the time. A NIC=5 or 4 only occurs very rarely when there is a GPS constellation issue. If NIC=5 or

below then something is probably wrong because real HPLs do not get this low.

T2000ADSB Transponder

Installation Manual

T2000ADSB Installation Manual 01R2

Page 20 of 33

24th Mar 2023

8.3.2 Accuracy NAC

It is important that NAC be non zero. NAC is reported in Type 31 and Type 29 messages. The aircraft

HFOM needs to be 5-11 as per the table below.

HFOM

NAC

Usable by ATC

<3m

11

Yes

<10m

10

<30m

9

<0.05nm

8

<0.1nm

7

<0.3nm

6

<0.5nm

5

<1nm

4

No

<2nm

3

<4nm

2

<10nm

1

<20nm

0

Not useable –indicates no accuracy

8.3.3 Integrity SIL

It is important that SIL be a value of 3. SIL is reported in Type 31 and Type 29 messages.

SIL

Integrity

0

No integrity

1

Inadequate Integrity

2

Acceptable Integrity

3

Other manuals for T2000ADSB

1

Table of contents

Other MicroAir Avionics Marine Radio manuals

Popular Marine Radio manuals by other brands

Uniden

Uniden ATLANTIS 200 Guide d'utilisation

DIGITAL YACHT

DIGITAL YACHT AIT250 Installation & quick start guide

uAvionix

uAvionix tailBeaconX STC Instructions for Continued Airworthiness and Maintenance Manual

Garrecht Avionik

Garrecht Avionik VT-01 installation manual

L3 Communications

L3 Communications ProTec AISA1000-10 Installation and operation manual

vesper marine

vesper marine WatchMate Vision install guide